Professional Documents

Culture Documents

c235 1tB PDF

Uploaded by

gavallapalliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

c235 1tB PDF

Uploaded by

gavallapalliCopyright:

Available Formats

IS : 12235 (Parts 1 to 11) - 1986

(Reaffirmed 1998)

Edition 1.1

(1999-08)

Indian Standard

METHODS OF TEST FOR UNPLASTICIZED

PVC PIPES FOR POTABLE WATER SUPPLIES

(Incorporating Amendment No. 1)

UDC 621.643.2 [678.743.22] : 628.1 : 620.1

BIS 2003

BUREAU

OF INDIAN

STANDARDS

MANAK BHAVAN , 9 BAHADUR SHAH ZAFAR MARG

NEW DELHI 110002

Price Group 8

IS : 12235 (Parts 1 to 11) - 1986

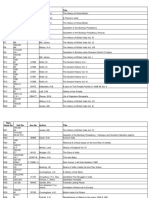

CONTENTS

Page

FOREWORD

IS : 12235 METHODS

WATER SUPPLIES

OF

TEST

FOR

UNPLASTICIZED

PVC

PIPES

FOR

POTABLE

Part 1

Measurement of Outside Diameter

Part 2

Measurement of Wall Thickness

Part 3

Test for Opacity

Part 4

Determining the Detrimental Effect on the Composition of Water

Part 5

Reversion Test

Part 6

Stress Relief Test

10

Part 7

Resistance to Sulphuric Acid

11

Part 8

Internal Hydrostatic Pressure Test

12

Part 9

Impact Strength at 0C

13

Part 10 Method for Determination of Organotin as Tin Aqueous Solution

15

Part 11 Extractability of Cadmium and Mercury Occurring as Impurities

17

As in the Original Standard, this Page is Intentionally Left Blank

IS : 12235 (Parts 1 to 11) - 1986

Indian Standard

METHODS OF TEST FOR UNPLASTICIZED

PVC PIPES FOR POTABLE WATER SUPPLIES

0.

FOREWORD

has been done by basing Part 11 on the

following International publication.

0.1 This Indian Standard (Parts 1 to 11) was

adopted by the Indian Standards Institution on

20 August 1986, after the draft finalized by the

Sanitary Appliances and Water Fittings

Sectional Committee had been approved by the

Civil Engineering Division Council.

ISO/DIS 6992 Unplasticized polyvinyl chloride

(PVC) pipes for drinking water supply

Extractability of cadmium and mercury

occurring as impurities, issued by International

Organization for Standardization.

0.2 This standard has been formulated to

specify methods of test for evaluating physical

and mechanical properties of unplasticized

PVC pipes for potable water supplies. The first

ten parts of this standard were earlier included

in IS : 4985-1988*. For the sake of convenience

as well as for keeping them up to date, these

test methods have been separated from

IS : 4985. Part 11 is newly added method of

test.

0.4 This edition 1.1 incorporates Amendment

No. 1 (August 1999). Side bar indicates

modification of the text as the result of

incorporation of the amendment.

0.5 For the purpose of deciding whether a

particular requirement of this standard is

complied with, the final value, observed or

calculated, expressing the result of a test or

analysis, shall be rounded off in accordance

with IS : 2-1960*. The number of significant

places retained in the rounded off value should

be the same as that of the specified value in

this standard.

0.3 In formulating this standard due weightage

has been given to international co-ordination

among the standards and practices prevailing

in different countries in addition to relating it

to the practices in the field in this country. This

*Specification for unplasticized PVC pipes for potable

water supplies ( second revision ).

*Rules for rounding off numerical values ( revised ).

IS : 12235 (Part 1) - 1986

Indian Standard

METHODS OF TEST FOR UNPLASTICIZED

PVC PIPES FOR POTABLE WATER SUPPLIES

PART 1

MEASUREMENT OF OUTSIDE DIAMETER

2.5 Expression of the Result Round off

the reading or calculate the mean outside

diameter to the next higher 0.1 mm.

1. SCOPE

1.1 This standard (Part 1) covers the method

for measurement of outside diameter of

unplasticized

PVC

pipes

manufactured

according to IS : 4985-1988*.

NOTE The measurement of diameters less than or

equivalent to 40 mm may be obtained from the average

of 4 uniformly distributed measurements of diameters

using vernier calipers. For higher diameters up to

110 mm pitapes or vernier calipers shall be used, taking

the average of two measurements at right angle.

2. MEAN OUTSIDE DIAMETER

2.1 Required Precision The precision

required in each measurement is 0.1 mm.

3. OUTSIDE DIAMETER AT ANY POINT

2.2 Principle The determination of the

circumference of the pipe and division by

3.142 .

3.1 Required Precision The precision

required in each measurement is 0.05 mm.

2.2.1 A Pitape with an accuracy of at least

0.05 mm shall be used for the direct

measurement of the mean outside diameter.

3.2 Principle Determination of the

maximum and minimum outside diameters of

cross-section, several outside diameters being

measured until maximum and minimum values

are found.

2.3 Measuring apparatus shall be an ordinary

flexible tape or flexible tape suitably calibrated

to read diameters directly. This tape shall

comply with the following requirements:

a) It shall be made of stainless steel or some

other suitable material,

b) It shall permit the reading to the nearest

0.05 mm,

c) It shall be graduated in such a way that

neither its own thickness nor the

thickness of the graduation has any

influence

on

the

result

of

the

measurement, and

d) It shall have sufficient flexibility to

conform exactly to the circumference of

the pipe.

3.3 Measuring Apparatus Slide calipers

permitting a reading to the nearest 0.05 mm.

3.4 Procedure Place the fixed jaw of the

slide calipers on one side of the pipe and the

moving jaw on the other side, perpendicular to

the axis of the pipe, and move the calipers

along until both jaws make a clean contact with

the surface of the pipe. Take the reading after

checking that the instrument is in correct

position in relation to the pipe. Take

measurement around the same cross-section,

turning the calipers in the plane of this section

until the maximum and minimum values are

obtained.

3.5 Expression of the Results Round off

the reading to the next higher 0.1 mm and note

the readings of the largest and the smallest

values measured for the same cross-section.

2.4 Procedure Apply the tape on the whole

of the circumference perpendicular to the axis

of the pipe. The reading shall be taken only

under these conditions.

*Specification for unplasticized PVC pipes for potable

water supplies ( second revision ).

IS : 12235 (Part 2) - 1986

Indian Standard

METHODS OF TEST FOR UNPLASTICIZED

PVC PIPES FOR POTABLE WATER SUPPLIES

PART 2

MEASUREMENT OF WALL THICKNESS

d) The surface of the fixed and movable

contact points shall be made of hard steel.

1. SCOPE

1.1 This standard (Part 2) covers the method of

measurement of wall thickness of unplasticised

plastic pipes manufactured in accordance with

IS : 4985-1988*.

2.1.1.3 Procedure After introducing the fixed

contact point inside and perpendicular to the

axis of the pipe and applying it without force on

to the internal surface of the wall, free the

plunger and seek a position for the apparatus

which provides the lowest reading.

2. METHOD OF MEASUREMENT

2.1 The wall thickness shall be measured by

any of the two methods given in 2.1.1 and 2.1.2.

2.1.1 Dial Gauge Method

2.1.1.4 Expression of the result Round off the

lowest reading so obtained to the nearest

0.1 mm.

2.1.1.1 Required precision The precision

required in each measurement of wall

thickness is 0.05 mm.

2.1.2 Micrometer Method

2.1.1.2 Measurement apparatus The wall

thickness shall be measured with a dial gauge

complying with the following measurements:

a) It shall permit a reading up to 0.01 mm,

b) It shall be equipped with a fixed rod

forming a rigid unit with the apparatus,

c) The extremity of the plunger (movable

contact point) shall be hemispherical in

shape with a radius of approximately

1.0 mm, and

2.1.2.1 The precision in each measurement of

wall thickness is 0.05 mm.

2.1.2.2 Measuring apparatus The wall

thickness shall be measured with a ball-ended

micrometer permitting a reading to the

accuracy of 0.01 mm.

2.1.2.3 Expression of the result Round off the

reading obtained to the nearest 0.1 mm.

*Specification for unplasticized PVC pipes for potable

water supplies ( second revision ).

IS : 12235 (Part 3) - 1986

Indian Standard

METHODS OF TEST FOR UNPLASTICIZED

PVC PIPES FOR POTABLE WATER SUPPLIES

PART 3

TEST FOR OPACITY

standard lenses that give an absorption

percentage of about 0.2 percent; and

d) Check the alignment of the installation.

1. SCOPE

1.1 This standard (Part 3) specifies a method

for the determination of the opacity of plastics

pipes and fittings.

2.4.2 Measurement

1.2 It lays down the maximum acceptable limit

for light which may pass through the wall of

the pipe or fitting, if the particular standard

specifies that they be opaque.

2. TEST METHOD 1

2.4.2.1 Adjust the apparatus to obtain a

maximum reading, carefully arranging the

light sensor in such a way that it receives the

maximum light flux and record the maximum

deviation DM.

2.1 Principle Measurement of the light flux

passing through a test piece cut from a pipe of

fitting.

2.4.2.2 Place the test piece on the support and

position the whole ensuring that the test piece

is centred and perpendicular to the light beam.

2.2 Apparatus The

comprise the following.

2.4.2.3 Read the indicated maximum deviation

( D ) produced by the light beam. This deviation

corresponds to the light flux which has passed

through the wall of the test piece.

apparatus

shall

2.2.1 Adjustable power arc or incandescent

lamp, the intensity of light of which is constant

to 1 percent. When an arc lamp is used, a

suitable filter shall be provided to limit the

spectrum to 0.40 to 0.50 mm.

2.5 Calculation and Expression of Results

Calculate the percentage of light which has

passed through the wall of the test piece using

the formula:

2.2.2 Diaphragm and optical lenses; adjusted to

obtain a parallel and symmetrical incident

beams. The diaphragm shall be circular.

D - 100

-------DM

2.2.3 Support, arranged so that it maintains

the surface of the test piece to be examined

perpendicular to the optical axis and at a fixed

distance from the diaphragm of the cell.

where

D = maximum deviation produced by the

light flux from the source which has

passed through the wall of the test

piece, and

2.2.4 Photoelectric cell, used such that the

response of the reading or recording apparatus

is a linear and uniform function of the light

intensity, from a maximum incidence I0 up to

at least 0.01 I0.

DM = maximum deflection produced directly

by the light from the source.

2.3 Test Pieces Take section of convenient

length from the pipe or a sample of suitable

dimensions and the original thickness from the

wall of the fitting.

2.6 Test Report The test report shall

indicate the percentage of light that passed

through the wall of the test piece and whether

or not the result complies with the requirement

specified in 3.

2.4 Procedure

3. SPECIFICATION

2.4.1 Calibration

a) Check that the equipment indicators are

at zero, in the absence of light. Ensure

that the photoelectric cell is protected

from incident daylight;

b) Check that the indicators reach 100

percent, in the light emitted by the

luminous source in the absence of the test

piece;

c) Check the precision of the reading using

3.1 If the particular standard specifies that the

pipe or fittings shall be opaque, the percentage

of light which passes the wall of the pipe or the

fittings, determined according to 2 of this

standard, shall not exceed 0.2 percent.

4. TEST METHOD 2

4.1 Apparatus

4.1.1 The following are the apparatus required:

a) Source of light (Halogen Lamp 1 000 W),

6

IS : 12235 (Part 3) - 1986

4.2.2 Place the test piece on the photo-electric

cell in such a manner that one wall is touching

the photo cell surface between the light source

and the cell (distance between source and from

cell remaining constant).

b) Photo-electric cell (with filter correction to

match eye response), and

c) Digital current meter.

4.2 Procedure

4.2.3 Read on the spot light galvanometer the

maximum deflection produced by the light flux

of the source. The deflection corresponds to the

light flux passing through the wall of the test

piece.

4.2.1 The light source and photo-electric cell

shall be set up at a distance to get maximum

reading in the galvanometer in the absence of

sample and also in the absence of day light.

Connect the galvanometer to the photoelectric

cell and the maximum deflection produced by

the light flux of the source falling on the

photo-electric cell shall be noted.

4.2.4 The second deflection expressed as a

percentage of the first shall give the measure of

visible light transmitted.

IS : 12235 (Part 4) - 1986

Indian Standard

METHODS OF TEST FOR UNPLASTICIZED

PVC PIPES FOR POTABLE WATER SUPPLIES

PART 4

DETERMINING THE DETRIMENTAL EFFECT ON

THE COMPOSITION OF WATER

made solution shall be used for each series of

tests ( see 2.1.6 ).

1. SCOPE

1.1 This standard (Part 4) covers the methods

of test for determining the deterimental effect

on the composition of water flowing through

plastic pipes manufactured according to

IS : 4985-1988*.

2.1.3 Close the other end of each pipe.

2.1.4 Maintain the pipes and contents at room

temperature for 48 hours, then empty the

water into suitable containers and retain for

analysis. This is the sample for lead

determination (first extraction).

2. PROCEDURE

2.1 Three pieces of pipe, as received, each of a

length to contain when stoppered not less than

the quantity of extractant required for

subsequent analysis, are plugged at one end

with a stopper of polyethylene (or some other

non-interfering material), fitted with a glass

cock and clamped to a stand with open end

upwards. Tap water is poured into the pipes

until it overflows slightly. Then the cock shall

be opened just sufficiently for a velocity of

3 m/min to be maintained inside the pipe. The

pipe shall be kept continuously filled with

water. After a period of 6 hours, the

pre-washing is discontinued, the stopper

removed and the interior of the pipe rinsed out

with

a

little

distilled

water

( see

IS : 1070-1977 ) to remove any remnants of

tap water. During pre-washing (but not

subsequently), the pipe sample may be fitted

with a non-interfering core so as to reduce the

quantity of washing water required, provided

the water velocity of 3 m/min is maintained.

2.1.5 Refill the pipes with the standard solution

as in 2.1.2, close and allow to stand as above for

48 hours. Empty and reject the solution. Refill

and repeat for a further 48 hours and retain

this third sample of solution for analysis. This

is the sample for analysis for lead (third

extraction), tin and any other toxic substances.

2.1.6 The water containing the desired quantity

of carbon dioxide may conveniently be prepared

by saturating a large bulk of water with carbon

dioxide, determining the carbon dioxide content

by a standard method such as that given in

IS : 3025-1964* (with suitable adjustment of

quantities) and then mixing with the calculated

quantity of carbon dioxide free water.

2.1.7 The metals present shall now be

determined. Determine the contents of lead and

organotin by the methods described in

IS : 3025-1964* and Part 10/Sec 1 and Sec 2

respectively or by any other suitable method.

The arithmetic average of the triplicate

determinations shall be reported in milligrams

per litre of the standard solution.

2.1.1 After the test pieces have been cleaned as

described above, close one end of each sample

tightly with a material that does not contain

any toxic substances and also does not interfere

with the determination of such constituents in

the aqueous samples.

2.2 Assessment of Results

2.1.2 Fill each pipe with distilled water ( see

IS : 1070-1977 ) containing added carbonic

acid equivalent to 150 mg CO2/litre. A freshly

2.2.1 The specimens, when tested as above,

shall meet the requirements given in 6.3 of

IS : 4985-1988.

*Specification for unplasticized PVC pipes for potable

water supplies ( second revision ).

Specification for water for general laboratory use

( second revision ).

*Methods of sampling and test (physical and chemical)

for water used in industry.

Specification for unplasticized PVC pipes for potable

water supplies ( second revision ).

IS : 12235 (Part 5) - 1986

Indian Standard

METHODS OF TEST FOR UNPLASTICIZED

PVC PIPES FOR POTABLE WATER SUPPLIES

PART 5

REVERSION TEST

c) For pipe of wall thickness greater than

14.1 mm 60 minutes.

1. SCOPE

1.1 This standard (Part 5) covers the method of

test for reversion test performed on

unplasticized

PVC

pipes

manufactured

according to IS : 4985-1988*.

After the specified immersion period, the

specimen shall be removed from the bath, laid

on its side and allowed to cool to room

temperature. The distance between the two

scribed marks shall be measured along the

surface of the pipe and the percentage change

in length calculated.

2. GENERAL

2.1 This test may be carried out either in an air

oven or alternatively in a bath of ethylene

glycol, glycerol or mineral oil free from

aromatic hydrocarbons.

4. OVEN METHOD

2.2 Form of Test Specimen The test

specimen shall consist of a length of pipe

200 20 mm long. Two circumferential marks

shall be scribed on the test specimen 100 mm

apart and in such a way that one of these

marks is approximately 15 mm from one end of

the specimen.

4.1 Apparatus An electrically heated air

oven with circulating fan, the whole interior of

which is maintained automatically at a

temperature of 150 2C.

4.2 Procedure The specimen shall be

placed in the oven and the time measured from

the moment at which the oven regains a

temperature of 150C. The test specimens shall

be kept in the oven for a time determined as

follows:

a) For pipe of wall thickness not greater than

8.6 mm 60 minutes,

b) For pipe of wall thickness greater than

8.6 mm but not greater than 14.1 mm

120 minutes, and

c) For pipe of wall thickness greater than

14.1 mm 140 minutes.

3. IMMERSION METHOD

3.1 Apparatus The apparatus shall consist

of a thermostatically controlled bath in which

heat transfer medium is ethylene glycol,

glycerol or mineral oil free from aromatic

hydrocarbons. The bath is stirred continuously

and maintained automatically at a temperature

of 150 2C.

3.2 Procedure The test specimen shall be

suspended in the heat transfer medium by the

end farther from the scribed marks in such a

way that both scribed marks are completely

immersed. Care shall be taken to ensure that

the specimen does not touch the sides or bottom

of the bath. The test specimen shall be

immersed in the bath for a time determined as

follows:

a) For pipe of wall thickness not greater than

8.6 mm 15 minutes,

b) For pipe of wall thickness greater than

8.6 mm but not greater than 14.1 mm

30 minutes, and

5.1 The specimen, when tested as above, shall

meet the requirements given in 6.4 of IS : 49851988*.

*Specification for unplasticized PVC pipes for potable

water supplies ( second revision ).

*Specification for unplasticized PVC pipes for potable

water supplies ( second revision ).

After the specified period, the specimen shall be

removed from the oven, laid on its side and

allowed to cool to room temperature. The

distance between the two scribed marks shall

be measured along the surface of the pipe and

the percentage change in length calculated.

5. ASSESSMENT OF RESULTS

IS : 12235 (Part 6) - 1986

Indian Standard

METHODS OF TEST FOR UNPLASTICIZED

PVC PIPES FOR POTABLE WATER SUPPLIES

PART 6

STRESS RELIEF TEST

be placed in the oven. The specimen may be

supported, if necessary, by a simple jig that has

been preheated in the oven.

1. SCOPE

1.1 This standard (Part 6) covers the method of

test for stress relief test performed on the

unplasticized

PVC

pipes

manufactured

according to IS : 4985-1988*.

4.2 The specimen shall be kept in the oven for 1

hour. The duration shall be measured from the

time at which the oven regains the temperature

of 150C.

2. TEST SPECIMENS

2.1 The specimen shall consist of full bell end

portion with 100 mm length of plain pipe.

4.3 After 1 hour, the specimen shall be removed

from the oven and allowed to cool naturally in

the air before examination.

3. APPARATUS

3.1 An electrically heated air oven with

circulating fan, the whole interior of which is

maintained automatically at a temperature of

150 2C.

5. ASSESSMENT OF RESULTS

4. PROCEDURE

4.1 The specimen standing on its bell end shall

5.1 The sample shall meet the requirements

specified in 6.5 of IS : 4985-1988*.

*Specification for unplasticized PVC pipes for potable

water supplies ( second revision ).

*Specification for unplasticized PVC pipes for potable

water supplies ( second revision ).

10

IS : 12235 (Part 7) - 1986

Indian Standard

METHODS OF TEST FOR UNPLASTICIZED

PVC PIPES FOR POTABLE WATER SUPPLIES

PART 7

RESISTANCE TO SULPHURIC ACID

dry and weighed, then totally immersed in

93 0.5 percent (m/m) sulphuric acid for 14

days at 55 2C. Care shall be taken to avoid

gradual concentration of the acid during the

test due to evaporation losses, etc. After the

specified time, the specimen shall be removed,

washed in running water for 5 minutes wiped

dry with a clean cloth and reweighed

immediately.

1. SCOPE

1.1 This standard (Part 7) covers the method of

test for resistance to sulphuric acid of

unplasticized

PVC

pipes

manufactured

according to IS : 4985-1988*.

2. FORM OF TEST SPECIMEN

2.1 The test specimen shall be cut from the pipe

and shall have a total surface area of

45 3 cm2.

4. ASSESSMENT OF RESULTS

3. PROCEDURE

3.1 The test specimen shall be cleaned, wiped

4.1 The average change in mass shall not

exceed the value given in 6.6 of IS : 4985-1988*.

*Specification for unplasticized PVC pipes for potable

water supplies ( second revision ).

*Specification for unplasticized PVC pipes for potable

water supplies ( second revision ).

11

IS : 12235 (Part 8) - 1986

Indian Standard

METHODS OF TEST FOR UNPLASTICIZED

PVC PIPES FOR POTABLE WATER SUPPLIES

PART 8

INTERNAL HYDROSTATIC PRESSURE TEST

water at ambient temperature. It shall be then

put in a water-bath at the test temperature

(permissible deviation 1C) and kept in the

bath for 1 hour to adjust the temperature.

1. SCOPE

1.1 This standard (Part 8) covers the method of

test for internal hydrostatic pressure test

carried out on unplasticized PVC pipes

manufactured according to IS : 4985-1988*.

5.3 The pressure in the pipe shall then be

increased to the test pressure ( p ) gradually

and without shock, preferably within 10 to 30

seconds in the bath whose temperature has

been adjusted in accordance with 5.2. The

pressure with a permissible deviation of 2.5

percent shall be maintained for the test period

laid down in Table 4 of IS : 4985-1988*. The

test pressure ( p ) shall be calculated as follows

from the induced stress values in Table 4 and

dimensions given in Table 1 of IS : 4985-1988*:

2. GENERAL

2.1 The test shall be carried out not earlier

than 24 hour after the pipes have been

manufactured.

3. TEST SPECIMENS

3.1 A sample of pipe having free length

between the end fittings equal to ten times the

outside diameter but not less than 250 mm or

greater than 750 mm shall be taken for every

testing from each pipe to be tested.

2 s

p = -----------ds

4. APPARATUS

where

4.1 Equipment which permits the application of

controlled internal hydraulic pressure to the

specimen

which

is

immersed

in

a

thermostatically controlled water-bath.

p = test pressure in MPa,

= induced stress in MPa,

s = minimum wall thickness

nominal and

d = outside diameter in mm.

5. PROCEDURE

5.1 The pipe shall be fitted with the locking

plugs at both ends in such a way that the axial

forces coming from the internal pressure are

transmitted to the pipe. The pipe shall remain

free to move in longitudinal direction.

in

mm,

6. ASSESSMENT OF RESULTS

5.2 Through a closable opening in one of the

locking plugs, the pipe shall be filled with

6.1 The sample shall not rupture during the

prescribed test period. The test showing bursts

within a distance d from the end cap, where d is

the mean outside diameter, shall be

disregarded and the test repeated.

*Specification for unplasticized PVC pipes for potable

water supplies ( second revision ).

*Specification for unplasticized PVC pipes for potable

water supplies ( second revision ).

12

IS : 12235 (Part 9) - 1986

Indian Standard

METHODS OF TEST FOR UNPLASTICIZED

PVC PIPES FOR POTABLE WATER SUPPLIES

PART 9

IMPACT STRENGTH AT 0C

length which is positioned below the

guidelines so that the tip of the impact

striker is not more than 2.5 mm from the

axis of the Vee block.

1. SCOPE

1.1 This standard (Part 9) covers the method of

test of impact strength of unplasticized PVC

pipes at 0C manufactured according to

IS : 4985-1988*.

f) A release mechanism such that a striker

may fall through the height as required in

Table 1 on the top surface of the pipe

specimen.

2. SPECIMEN

2.1 Each specimen 300 mm long shall be a

complete section of pipe. The ends of each

specimen shall be cut clean and square to the

axis of the pipe.

g) Means for maintaining a constant height

of fall by vertical movement of either the

Vee block, the release mechanism or the

main frame in order to accommodate

various diameters of pipe.

3. CONDITIONING OF TEST SPECIMEN

3.1 Each specimen shall be conditioned for at

least 1 hour prior to test at a temperature of

0 1C. Individual specimens shall be tested

within 10 seconds of removal from the

conditioner. For round the clock ( see 5.1.1.2 )

testing, when the test might not be completed

within 10 seconds, the specimen shall be

reconditioned for a further period of at least 10

minutes.

4. APPARATUS

4.1 An impact testing machine (falling weight

machine), a suitable form of which is shown in

Fig. 1, shall be used which shall consist

essentially of the following:

a) A main frame which may be rigidly fixed

in a true vertical position.

b) Guiderails carried from the inside of the

main frame on side bearings which may be

adjusted to keep them parallel and

vertical.

c) A striker which may fall freely within the

guiderails and which is equipped with a

hardened hemispherical striking surface

of 25 1 mm diameter. The striking

surface shall be free from flats and/or

other imperfections.

d) An appropriate set of mass which may be

firmly attached to the striker to enable the

combined mass of striker and mass

attached to be adjusted to the values given

in Table 1.

e) A specimen support comprising a 120

cast steel Vee block at least 250 mm in

FIG. 1 IMPACT TESTING MACHINE

*Specification for unplasticized PVC pipes for potable

water supplies ( second revision ).

13

IS : 12235 (Part 9) - 1986

TABLE 1

5.1.1.1 Each specimen shall be marked with a

longitudinal zero line positioned at random and

from this line, further parallel lines shall be

marked equidistantly at intervals of not less

than 50 mm covering the circumference only

once. The pipes shall be placed on the Vee block

in such a way that one of the marked lines is

uppermost. The striker shall then be allowed to

fail freely on to the marked line on the pipe as

described above.

MASS OF STRIKER AND HEIGHT OF

FREE FALL

[Clauses 4.1 (d), (f) and 5.1]

MEAN OUTSIDE

DIAMETER

mm

TOTAL MASS

OF STRIKER

kg

HEIGHT OF FREE

FALL

mm

Up to and

including 25

0.25

500 10

32 to 50

0.25

1 000 10

63 to 75

0.25

2 000 10

90 to 110

0.50

2 000 10

1.00

2 000 10

125 and above

5.1.1.2 If the specimen does not fail as a result

of cracking or splitting, the specimen shall be

rotated until the next marked line is uppermost

in the Vee block, and a second blow made with

the striker. The process shall then be repeated

until all the marked lines have been tested or

until a failure is recorded. (This procedure of

impact testing a specimen more than once is

known as round the clock testing.)

5. PROCEDURE

5.1 The total mass of the striker and height of

free fall shall be adjusted to the values

appropriate to the diameter of the pipe under

test according to Table 1.

5.1.1 The specimens up to and including 50 mm

mean outside diameter shall be subjected to a

single blow only. For pipes with mean outside

diameter exceeding 50 mm size, the procedure

given in 5.1.1.1 and 5.1.1.2 shall be adopted.

6. ASSESSMENT OF RESULTS

6.1 The sample, when tested as above, shall

meet the requirements given in A-1.7.1 of

IS : 4985-1988*.

*Specification for unplasticized PVC pipes for potable

water supplies ( second revision ).

14

IS : 12235 (Part 10) - 1986

Indian Standard

METHODS OF TEST FOR UNPLASTICIZED

PVC PIPES FOR POTABLE WATER SUPPLIES

PART 10

METHOD FOR DETERMINATION OF ORGANOTIN AS TIN

AQUEOUS SOLUTION

100 ml with water. Filter, if necessary.

This solution should be prepared fresh

daily.

1. SCOPE

1.1 This standard (Part 10) covers the method

for determination of organotin as tin aqueous

solution

of

unplasticized

PVC

pipes

manufactured according to IS : 4985-1988*.

NOTE The life of this solution may be extended to

about one week if it is stored under refrigeration

conditions.

2. PRINCIPLE

g) Standard Tin Solution 0.2 mg Sn/ml.

Dissolve 0.200 g of tin in 100 ml of 50

percent ( v/v ) hydrochloric acid and dilute

with the same acid to 1 000 ml.

h) Standard Tin Solution 0.02 mg Sn/ml.

Prepare by diluting the 0.2 mg Sn/ml

standard solution [reagent (g)] as required

with 25 percent ( v/v ) hydrochloric acid.

j) Standard Tin Solution 0.004 mg Sn/ml.

Prepare by diluting the 0.02 mg Sn/ml

standard solution [reagent (h)] as required

with 25 percent ( v/v ) hydrochloric acid.

2.1 Toluene-3, 4-dithiol (dithiol) forms a

coloured complex with an acid solution of

divalent tin. This colloidally dispersed red

compound is used for the determination of tin

by a spectrophotometric method.

2.2 The lower limit of the determination is

about 2 g of tin.

3. APPARATUS

3.1 Spectrophotometer suitable for use in

the visible region of the spectrum with 1 and

4 cm cells.

5. PROCEDURE

4. REAGENTS

5.1 Preparation of Colour Standards

4.1 The reagents used shall be of. recognized

analytical reagents quality. Water complying

with IS : 1070-1977 shall be used throughout.

a) Concentrated

density 1.42.

Nitric

Acid

a) High Range ( 100-500 m Tin per Test )

Into six 25-ml one-mark volumetric flasks

( see IS : 915-1975* ) transfer volumes of

the 0.004 mg/ml standard tin solution

[reagent (j)] from 0 to 5.0 ml increasing by

stages of 1.0 ml. Treat each in the

following manner:

Dilute with water to about 6 ml, add 2 drops

of thioglycollic acid [reagent (c)] followed by

2 ml of the dilute sulphuric acid [reagent (d)]

and mix thoroughly. Cautiously add 0.4 ml of

the dodecyl sodium sulphate solution

[reagent (e)] with constant swirling; avoid

shaking which creates foam. Continue to

swirl the contents of the flask while adding

0.2 ml of the toluene-3, 4-dithiol solution

[reagent (f)]. Dilute to 25 ml, stopper the

flask and shake thoroughly. Fifteen minutes

after the addition of toluene-3, 4-dithiol

solution, measure the optical density of each

solution in a 1-cm cell at a wavelength of

535 m and with water in the matched

comparison cell. Prepare graph of the optical

density readings against micrograms of tin

present.

relative

b) Perchloric Acid 600 g/litre solution.

c) Thioglycollic Acid approximately 98

percent.

d) Dilute Sulphuric Acid 25 percent (v/v)

solution.

e) Dodecyl Sodium Sulphate 20 g/litre

solution. Dissolve 2 g of dodecyl sodium

sulphate (sodium lauryl sulphate) in

100 ml of warm water. The solution may

lose its clarity on cooling; gentle warming

will restore it.

f) Toluene-3, 4-dithiol 2 g/litre solution.

Dissolve 0.2 g of toluene-3, 4-dithiol

(dithiol) or 0.28 g of zinc toluene-3,

4-dithiol in 5 ml or 5 N sodium hydroxide.

Add 1 ml of thioglycollic acid and dilute to

*Specification for unplasticized PVC pipes for potable

water supplies ( second revision ).

Specification for water for general laboratory use

( second revision ).

*Specification for one-mark volumetric flask ( first

revision ).

15

IS : 12235 (Part 10) - 1986

Dilute with water to about 15 ml, add 2

drops of thioglycollic acid [reagent (c)]

followed by 10 ml of the dilute sulphuric

acid [reagent (d)] and mix thoroughly.

Cautiously add 2.0 ml of dodecyl sodium

sulphate solution [reagent (e)] with

constant swirling; avoid shaking, which

creates foam. Continue to swirl the

contents of the flask while adding

1.0 ml of toluene-3, 4-dithoil solution

[reagent (f)]. Dilute to 25 ml, stopper

the flask and shake thoroughly. Fifteen

minutes after the addition of toluene-3,

4-dithoil solution measure the optical

density of each solution in a 4-cm cell at

a wavelength of 535 m and with water

in the matched comparison cell. Prepare

a graph of the optical density readings

against the micrograms of tin present.

5.2 Determination Evaporate a suitable

volume of the test solution ( see Part 4 ) to

dryness, add 2 ml of the diluted sulphuric acid

[reagent (d)] and evaporate to fumes of sulphur

trioxide. Add concentrated nitric acid [reagent

(a)] dropwise until the oxidation is complete.

Cool, add 1 ml of concentrated nitric acid

[reagent (a)] followed by 0.2 ml of perchloric

acid [reagent (b)] and evaporate to fumes of

sulphur trioxide. Cool, transfer the contents of

the basin quantitatively to 10 ml one-mark

volumetric flask ( see IS : 915-1975* ) and

dilute to about 8 ml with water. Add two drops

of thioglycollic acid [reagent (c)] and, with

constant swirling, 0.4 ml of the dodecyl sodium

sulphate solution [reagent (e)]. Add 0.2 ml of

the toluene-3, 4-dithiol solution [reagent (f)];

dilute to the mark, stopper the flask and shake

thoroughly. Transfer a quantity to a suitable

cell and 15 minutes after the addition of

toluene-3, 4-dithoil solution, measure its optical

density at a wave-length of 535 m, with water

in the matched comparison cell, and read the

amount of tin present from the appropriate

calibration graph ( see 5.1 ).

*Specification for one-mark volumetric flasks ( first

revision ).

*Specification for one-mark volumetric flasks ( first

revision ).

b) Low Range ( Up to 100 m Tin per Test )

Into six 50-ml one-mark volumetric

flasks ( see IS : 915-1975* ) transfer

volumes of the 0.02 mg/ml standard tin

solution [reagent (h)] from 0 to 10.0 ml

increasing by stages of 2.0 ml. Treat each

in the following manner:

16

IS : 12235 (Part 11) - 1986

Indian Standard

METHODS OF TEST FOR UNPLASTICIZED

PVC PIPES FOR POTABLE WATER SUPPLIES

PART 11

EXTRACTABILITY OF CADMIUM AND MERCURY OCCURRING

AS IMPURITIES

2. FIELD OF APPLICATION

2.1 This standard applies to unplasticized

polyvinyl chloride (PVC) pipes intended for the

transport of drinking water. It only relates to

the extractability of:

a) cadmium and its derivatives, and

b) mercury and its derivatives.

6.1.2 Clamp the test pieces vertically with open

end upwards.

6.1.3 Pass tap water of pH 7 to 8 through the

test pieces so that its linear rate of flow is

3 m/min, calculate from the average internal

cross-sectional area of the pipe and the test

pieces are continuously filled with water.

6.1.4 Maintain the water flow for a period of

60 +10 min.

0

6.1.5 At the end of this period, stop the water

flow, remove the stoppers and rinse out the test

pieces with distilled water.

6.2 Extractability Test

3. PRINCIPLE

3.1 Pre-washing of test pieces during a fixed

time. Filling the test pieces with water acidified

with carbon dioxide. Determination of the

quantity of extracted impurity.

6.2.1 Close, with a stopper ( see 4.2 ) one end of

each pre-washed test piece.

6.2.2 Fill each test piece with acidified water

( see 4.2 ), the temperature of which has been

adjusted to approximately 20C.

1. SCOPE

1.1 This standard (Part 11) specifies a method

of test for the determination of the

extractability of cadmium and mercury

occurring as impurities from unplasticized PVC

pipe

manufactured

according

to

IS : 4985-1988*.

NOTE For each series of tests, a freshly prepared

solution of acidified water ( see 4.3 ) shall be used.

NOTE The analytical test methods to be used for the

determination of the quantity of material taken into

solution are not defined. They shall, however, allow the

analysis to be carried out with an accuracy of 0.005 mg/l

for cadmium and of 0.000 6 mg/l for mercury.

6.2.3 Close the other end of each test piece by

means of a stopper ( see 4.2 ) and maintain the

filled test pieces at 20 2C for 48 hours.

6.2.4 First Extraction At the end of 48 hours,

empty the water from the test pieces into

suitable stoppered containers and determine

the quantity of cadmium or mercury.

6.2.5 Second Extract Fill the same test

pieces with the test water ( see 4.3 ) and, having

closed them again, maintain them at 20 2C

for 48 h. At the end of this period, transfer the

test water from the test pieces to suitable

stoppered containers and determine the

quantity of cadmium and mercury in each.

6.2.6 Third Extract Fill the test pieces for a

third time with the test water ( see 4.3 ) and

having closed them again, maintain them at

20 2C for 48 h. At the end of this period,

transfer the test water from the test pieces to

suitable stoppered containers and determine

the quantity of cadmium and mercury in each.

4. APPARATUS

4.1 Glass Tube with Glass Cock

4.2 Stoppers in polyethylene or any other

material which has been shown not to effect the

results.

4.3 Distilled water, acidified to a pH of 4.5 0.1

by bubbling a current carbon dioxide through

it.

5. PREPARATION OF TEST PIECES

5.1 For each test, select three pieces of the pipe

at random, each of which is 300 mm in length

and has an internal volume at least equal to the

volume of the extracting liquid required to

determine with the required precision the

amount of material which has migrated.

6. PROCEDURE

6.1 Pre-washing

6.1.1 Close one end of each test piece with a

stopper ( see 4.2 ) fitted centrally with the

lengths of glass tube ( see 4.1 ) fitted with a

stopcock.

7. EXPRESSION OF RESULTS

7.1 Cadmium

7.1.1 Calculate for the three test pieces the

arithmetic mean of the quantities of cadmium

determined in the extracts for first, second and

third extractions.

*Specification for unplasticized PVC pipes for potable

water supplies ( second revision ).

17

IS : 12235 (Part 11) - 1986

d) Analytical

method

used

for

the

determination of the quantity of mercury

in aqueous solution;

e) Duration of pre-washing;

f) Quantities of extracted cadmium found for

each test piece for first, second and third

extraction;

g) Arithmetic mean of the quantities of

extracted cadmium for the pipe for first,

second and third extraction;

h) Quantities of extracted mercury found for

each test piece for first, second and third

extraction;

j) Arithmetic mean of the quantities of

extracted mercury for the pipe for first,

second and third extraction; and

k) Details of the procedure which have not

been provided for by this test method and

also any accidental circumstance which

might have attached the results.

7.1.2 Express the results in milligrams per litre

with an accuracy of 0.005 mg/l.

7.2 Mercury

7.2.1 Calculate for the three test pieces the

arithmetic mean of the quantities of mercury

determined in the extracts for first, second and

third extractions.

7.2.2 Express the results in milligrams per litre

with an accuracy of 0.000 5 mg/l.

8. TEST REPORT

8.1 The test report shall include the following

information:

a) Complete identification of the pipe tested;

b) Number of test pieces;

c) Analytical

method

used

for

the

determination of the quantity of cadmium

in aqueous solution;

18

Bureau of Indian Standards

BIS is a statutory institution established under the Bureau of Indian Standards Act, 1986 to promote

harmonious development of the activities of standardization, marking and quality certification of goods and

attending to connected matters in the country.

Copyright

BIS has the copyright of all its publications. No part of these publications may be reproduced in any form

without the prior permission in writing of BIS. This does not preclude the free use, in the course of

implementing the standard, of necessary details, such as symbols and sizes, type or grade designations.

Enquiries relating to copyright be addressed to the Director (Publications), BIS.

Review of Indian Standards

Amendments are issued to standards as the need arises on the basis of comments. Standards are also

reviewed periodically; a standard along with amendments is reaffirmed when such review indicates that no

changes are needed; if the review indicates that changes are needed, it is taken up for revision. Users of

Indian Standards should ascertain that they are in possession of the latest amendments or edition by

referring to the latest issue of BIS Catalogue and Standards : Monthly Additions.

This Indian Standard has been developed by Technical Committee : CED 50

Amendments Issued Since Publication

Amend No.

Date of Issue

Amd. No. 1

August 1999

BUREAU OF INDIAN STANDARDS

Headquarters:

Manak Bhavan, 9 Bahadur Shah Zafar Marg, New Delhi 110002.

Telephones: 323 01 31, 323 33 75, 323 94 02

Telegrams: Manaksanstha

(Common to all offices)

Regional Offices:

Central

: Manak Bhavan, 9 Bahadur Shah Zafar Marg

NEW DELHI 110002

Eastern

: 1/14 C. I. T. Scheme VII M, V. I. P. Road, Kankurgachi

KOLKATA 700054

Telephone

323 76 17

323 38 41

337 84 99, 337 85 61

337 86 26, 337 91 20

60

60

Northern : SCO 335-336, Sector 34-A, CHANDIGARH 160022

38 43

20 25

Southern : C. I. T. Campus, IV Cross Road, CHENNAI 600113

235 02 16, 235 04 42

235 15 19, 235 23 15

Western : Manakalaya, E9 MIDC, Marol, Andheri (East)

MUMBAI 400093

832 92 95, 832 78 58

832 78 91, 832 78 92

Branches : A H M E D A B A D . B A N G A L O R E . B H O P A L . B H U B A N E S H W A R . C O I M B A T O R E .

FARIDABAD. GHAZIABAD. GUWAHATI. HYDERABAD. JAIPUR. KANPUR.

LUCKNOW. NAGPUR. NALAGARH. PATNA. PUNE. RAJKOT. THIRUVANANTHAPURAM.

VISHAKHAPATNAM.

You might also like

- Sangraha Chudamani of GovindaDocument554 pagesSangraha Chudamani of GovindaPSGNo ratings yet

- Rare Books PDFDocument49 pagesRare Books PDFgavallapalliNo ratings yet

- Architecture of HindusDocument203 pagesArchitecture of HindusgavallapalliNo ratings yet

- Reaffirmed 1995Document14 pagesReaffirmed 1995gavallapalliNo ratings yet

- 4332 8 PDFDocument15 pages4332 8 PDFgavallapalliNo ratings yet

- Naradiya Darma SastraDocument174 pagesNaradiya Darma SastragavallapalliNo ratings yet

- Dictionarymixed00unkngoog PDFDocument170 pagesDictionarymixed00unkngoog PDFShayan GudipalliNo ratings yet

- 4332 7 PDFDocument12 pages4332 7 PDFgavallapalliNo ratings yet

- Autocad ShortcutsDocument13 pagesAutocad ShortcutsKriscel CaraanNo ratings yet

- 2 IndiaDocument78 pages2 IndiagavallapalliNo ratings yet

- 2720 7 PDFDocument13 pages2720 7 PDFjageshwariNo ratings yet

- Structural Design of Multi-Story Residential BuildingDocument9 pagesStructural Design of Multi-Story Residential Buildingatac101No ratings yet

- Kondamarajupalem Final LPS NumberingDocument1 pageKondamarajupalem Final LPS NumberinggavallapalliNo ratings yet

- 4332 7 PDFDocument12 pages4332 7 PDFgavallapalliNo ratings yet

- 8419 2Document9 pages8419 2gavallapalliNo ratings yet

- Flltration Equipment: I'dian StandardDocument10 pagesFlltration Equipment: I'dian Standardnimm1962No ratings yet

- 4985 PDFDocument26 pages4985 PDFgavallapalliNo ratings yet

- 8419 2 PDFDocument9 pages8419 2 PDFgavallapalliNo ratings yet

- SS Filters DesignDocument2 pagesSS Filters DesigngavallapalliNo ratings yet

- Discusion Forum Nov 2006Document2 pagesDiscusion Forum Nov 2006gavallapalliNo ratings yet

- Code of Practice For Sanitation With Leaching Pits For Rural CommunitiesDocument9 pagesCode of Practice For Sanitation With Leaching Pits For Rural CommunitiesgavallapalliNo ratings yet

- Structural Safety and ServicesDocument6 pagesStructural Safety and ServicesAmit GargNo ratings yet

- Discusion Forum Nov 2006Document2 pagesDiscusion Forum Nov 2006gavallapalliNo ratings yet

- Raft Draw.Document31 pagesRaft Draw.gavallapalliNo ratings yet

- Sup Court Judgment DT 210509 PDFDocument36 pagesSup Court Judgment DT 210509 PDFgavallapalliNo ratings yet

- PNNL (2009) Country Report IndiaDocument24 pagesPNNL (2009) Country Report Indiabcap-oceanNo ratings yet

- Flltration Equipment: I'dian StandardDocument10 pagesFlltration Equipment: I'dian Standardnimm1962No ratings yet

- PDFDocument13 pagesPDFgavallapalliNo ratings yet

- CountryReport IndiaDocument39 pagesCountryReport IndiagavallapalliNo ratings yet

- Code of Practice For Laying of Cast Iron Pipes: Indian StandardDocument15 pagesCode of Practice For Laying of Cast Iron Pipes: Indian StandardgavallapalliNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- B. Optom SyllabusDocument59 pagesB. Optom SyllabusSankalp ZadeNo ratings yet

- The wavelength of the electron is 2.44 x 10-18 m.The wavelength of the 70.0 kg skier traveling at 15.0 m/s is 6.31 x 10-37 mDocument77 pagesThe wavelength of the electron is 2.44 x 10-18 m.The wavelength of the 70.0 kg skier traveling at 15.0 m/s is 6.31 x 10-37 mRoseman TumaliuanNo ratings yet

- Curriculum Map: School of Mount St. MaryDocument11 pagesCurriculum Map: School of Mount St. MaryJayson LabsanNo ratings yet

- Instant Download Test Bank For Options Futures and Other Derivatives 8th Edition by Hull PDF FullDocument32 pagesInstant Download Test Bank For Options Futures and Other Derivatives 8th Edition by Hull PDF Fulloweltyswiller.28sh100% (12)

- HEX To LAB Color ConverterDocument3 pagesHEX To LAB Color ConverterHenry VillegasNo ratings yet

- HiperopiaDocument29 pagesHiperopiaJoice Sari TampubolonNo ratings yet

- Ansi z87.1 PDFDocument15 pagesAnsi z87.1 PDFpercy sandoval acaroNo ratings yet

- Lighting Guides LG 5 Lecture, Teaching and Conference Rooms (Includes Addendum 1, 2003)Document63 pagesLighting Guides LG 5 Lecture, Teaching and Conference Rooms (Includes Addendum 1, 2003)Vinay PallivalppilNo ratings yet

- Activity Sheet in Science Week 4 5Document3 pagesActivity Sheet in Science Week 4 5Ivan Dyem C. San PedroNo ratings yet

- SDH Fibre OpticsDocument228 pagesSDH Fibre OpticsMujNo ratings yet

- RAH Lighting SpecsDocument26 pagesRAH Lighting SpecslcsimalNo ratings yet

- Color Science and Shade SelectionDocument140 pagesColor Science and Shade SelectionToni ArcuriNo ratings yet

- 007 List The Country Portfolio (Short List) : Concern: PhilipsDocument213 pages007 List The Country Portfolio (Short List) : Concern: PhilipsKostas PapadimosNo ratings yet

- MCAT Uhs Past Paper (2008-2016)Document180 pagesMCAT Uhs Past Paper (2008-2016)Abdullah SheikhNo ratings yet

- Technical Requirements for LED Light FixturesDocument66 pagesTechnical Requirements for LED Light FixturesMohammed AnwaruddinNo ratings yet

- A Brief History of Light & Photography: by Rick DobleDocument23 pagesA Brief History of Light & Photography: by Rick Doblesilverfish67No ratings yet

- Electrical OFFICE WAREHOUSE FREEWOOD - PERMIT 2 - Part3Document1 pageElectrical OFFICE WAREHOUSE FREEWOOD - PERMIT 2 - Part3David BarrientosNo ratings yet

- VA Conversion ChartDocument1 pageVA Conversion ChartcurlyfriezNo ratings yet

- Soal RefraksiDocument24 pagesSoal Refraksikautsar abiyogaNo ratings yet

- English Question Paper Class 12Document1 pageEnglish Question Paper Class 12Manish SharmaNo ratings yet

- Bajaj LED Price List Jan 2019Document26 pagesBajaj LED Price List Jan 2019Iam VinitNo ratings yet

- How Colors Affect Perception and MoodDocument57 pagesHow Colors Affect Perception and MoodNARESH GNo ratings yet

- Guide To CMSDocument46 pagesGuide To CMSecdtcenterNo ratings yet

- AQA PHYB1 QP Jun12Document16 pagesAQA PHYB1 QP Jun12dank dankNo ratings yet

- Chemistry in Focus A Molecular View of Our World 6th Edition Tro Test BankDocument14 pagesChemistry in Focus A Molecular View of Our World 6th Edition Tro Test Bankbeyradicantdays100% (32)

- Control 1 - CalificacionesDocument1 pageControl 1 - CalificacionesmximenarrNo ratings yet

- Real Depth in PHYSICS MeasurementDocument6 pagesReal Depth in PHYSICS MeasurementBidisha DeyNo ratings yet

- 5 4 Gizmo Energy ConversionsDocument5 pages5 4 Gizmo Energy Conversionsapi-27357852653% (173)

- Week 24 Questions (FF)Document4 pagesWeek 24 Questions (FF)Solace HusseinNo ratings yet

- Module 4Document49 pagesModule 4asaintjerkNo ratings yet