Professional Documents

Culture Documents

WWTFSP App.F6 Flow Management Alternatives and Recommendations

Uploaded by

Huy NguyenCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WWTFSP App.F6 Flow Management Alternatives and Recommendations

Uploaded by

Huy NguyenCopyright:

Available Formats

Appendix F6: Flow Management Alternatives and

Recommendations

Version 2.0

December 2010

Prepared by:

Carollo Engineers, Inc.

Registration No. F-882

Dallas Water Utilities

Flow Management Alternatives and Recommendations

Table of Contents

TABLE OF CONTENTS

1.0

Executive Summary .................................................................................................3

1.1

1.2

1.3

1.4

2.0

Basis of Alternatives................................................................................................5

2.1

2.2

2.3

2.4

3.0

Introduction.................................................................................................................. 12

Alternative A1: CWWTP 55 Percent / SWWTP 45 Percent....................................... 12

Alternative A2: CWWTP 50 Percent / SWWTP 50 Percent....................................... 15

Alternative A3: CWWTP 45 Percent / SWWTP 55 Percent....................................... 17

Evaluation of Annual Average Flow Alternatives ........................................................ 19

Wet-Weather Flow Management Alternatives......................................................21

4.1

4.2

4.3

4.4

5.0

Introduction.................................................................................................................... 5

Current Flow Management............................................................................................ 5

Projected Flows............................................................................................................. 7

Recycled Water Plans................................................................................................... 9

Average Annual Flow Management Alternatives ................................................12

3.1

3.2

3.3

3.4

3.5

4.0

Objectives...................................................................................................................... 3

Average Annual Flow Recommendation....................................................................... 3

Wet-Weather Recommendation.................................................................................... 3

Estimated Cost .............................................................................................................. 4

Introduction.................................................................................................................. 21

Alternative W1 ............................................................................................................. 23

Alternative W2 ............................................................................................................. 27

Summary of Wet-Weather Alternatives....................................................................... 32

Recommended Alternatives ..................................................................................33

5.1

5.2

5.3

Recommended Average Annual Flow Split ................................................................ 33

Recommended Wet-Weather Alternative ................................................................... 34

Estimated Cost for Peak-Flow Storage and Flow Management ................................. 34

Appendix A

Glossary of Acronyms and Terms............................................................37

Appendix B

References..................................................................................................39

Appendix C

Flow Schematics ........................................................................................40

Appendix D

Peak-Flow Basins.......................................................................................42

Appendix E

Detailed Cost Estimates ............................................................................46

Record of Change ..............................................................................................................62

WWTFSP_App.F6-2.0

December 2010

Page 2 of 62

Dallas Water Utilities

Section 1.0

Flow Management Alternatives and Recommendations

1.0

EXECUTIVE SUMMARY

1.1

Objectives

Executive Summary

The purpose of this technical memorandum is to provide analysis of the various flow alternatives available

to optimize existing process treatment capacity, comply with regulatory requirements, meet recycled flow

commitments, and to minimize cost. The following criteria were used to select recommended flow splits

between Southside Wastewater Treatment Plant (SWWTP) and Central Wastewater Treatment Plant

(CWWTP) for average annual flows (AAF) and wet-weather flows (WWF).

Require at least 69 million gallons per day (mgd) effluent at CWWTP (for Trinity Lakes, reuse, and

other)

Maintain minimum process flows at CWWTP

Dilute the filtrate at SWWTP

Defer expansion at both CWWTP and SWWTP

The Team also took into account biological phosphorus removal improvements needed at both plants

within the planning period. These improvements result in a decreased allowable process flow at

CWWTP.

1.2

Average Annual Flow Recommendation

The recommended AAF split that satisfies the criteria is treatment of approximately 50 percent of the AAF

at CWWTP and 50 percent at SWWTP. This results in a projected 2030 AAF of 99 mgd at CWWTP and

98 mgd at SWWTP.

1.3

Wet-Weather Recommendation

The recommended wet weather peak-flow basin volume at CWWTP is 440 million gallons (MG), and 660

MG at SWWTP. The 2030 total storage volume for a 10-year storage recurrence interval is 1,100 MG.

The total recommended storage volume assumes that Phase IV at SWWTP is not constructed during the

planning period. If Phase IV is constructed during the planning period then the total storage volume

should be reevaluated.

CWWTP improvements include the following:

Rehabilitating basins A, B and C to add a solids settling area

Constructing a new peak-flow basin D

Constructing a 72-inch (in.) diameter peak-flow pipe between the new Influent Pump Station (IPS)

and the peak-flow basins

Constructing Stage 2 IPS improvements

Constructing a new 96-inch interconnect pipe between the White Rock Gate Structure (WRGS) and

the IPS.

Improvements at SWWTP include the following:

Combining basins no. 2 and 3, and converting basin no.1 into a solids settling chamber,

Deepening basins no. 1, 2, and 3 to match the bottom elevation of basin no. 4,

Constructing new peak-flow basins no. 5, 6, and 7, along with

Constructing a new 75 mgd Peak-Flow Pump Station (PFPS).

WWTFSP_App.F6-2.0

December 2010

Page 3 of 62

Dallas Water Utilities

Section 1.0

Flow Management Alternatives and Recommendations

1.4

Executive Summary

Estimated Cost

The estimated construction costs of the combined AAF and WWF split is projected to be $149.8 million in

2010 dollars. This estimate includes improvements at the Sunbeam and Five-Mile diversion structures,

new Peak-Flow Pump Station (PFPS) at SWWTP and peak-flow basin and piping construction at both

CWWTP and SWWTP.

Table 1-1: Estimated Cost of Recommendations

Element

Cost

Peak-Flow Storage

CWWTP 84-Inch Horseshoe Interceptor Rehabilitation

SWWTP Basin No. 5

$13,700,000

$9,500,000

CWWTP Basin D

$23,400,000

CWWTP Existing Basins Rehabilitation

$5,200,000

SWWTP Basins No. 1, 2, and 3 Rehabilitation

$4,500,000

SWWTP Basin No. 6

$18,900,000

SWWTP Peak-Flow Pump Station

$21,600,000

SWWTP Basin No. 7

$24,000,000

CWWTP IPS Interconnect

$7,900,000

CWWTP Stage 2 IPS Improvements

$13,300,000

Flow Management

Sunbeam Junction Structure Replacement

$4,400,000

Five-Mile Diversion Structure Rehabilitation

$3,400,000

Total Construction Cost

WWTFSP_App.F6-2.0

December 2010

$149,800,000

Page 4 of 62

Dallas Water Utilities

Section 2.0

Flow Management Alternatives and Recommendations

2.0

BASIS OF ALTERNATIVES

2.1

Introduction

Basis of Alternatives

This section discusses the various flow alternatives available to optimize existing process treatment

capacity, comply with regulatory requirements, meet recycled flow commitments, and to minimize cost.

The criteria used to select the recommended flow splits include the following:

Require at least 69 mgd effluent at CWWTP (for Trinity Lakes, reuse, and other)

Maintain minimum process flows at CWWTP

Dilute the filtrate at SWWTP

Defer expansion at both CWWTP and SWWTP

Current plans to replace the Sunbeam diversion structure and rehabilitate the Five-Mile diversion

structure were accounted for in each alternative. The Team also took into account biological nutrient

improvements for enhanced biological phosphorus removal (EBPR) needed at both plants within the

planning period. These improvements result in a decreased allowable process flow at CWWTP.

2.2

Current Flow Management

Table 2-1 presents the current and anticipated preferred maximum process flows at each wastewater

treatment plant. Currently, the total preferred maximum process flows at both plants is 260 mgd with a

preferred maximum peak-hourly flow (PHF) process flow of 455 mgd. By 2030 the projected total process

flow capacities will be an AAF of 260 mgd and PHF of 445 mgd. The reduction in interim preferred

maximum process flows, shown in Table 2-1, is a result of biological nutrient improvements for EBPR

occurring before 2030.

Table 2-1: Preferred Maximum Process Flows

Interim (1)

Current

2030 (2)

AAF (3)

(mgd)

PHF (3)

(mgd)

AAF (3)

(mgd)

PHF (3)

(mgd)

AAF (3)

(mgd)

PHF (3)

(mgd)

CWWTP

150

350

120

230

120

230

SWWTP

110

155

110

155

140

215

Total

260

455

230

385

260

445

Notes:

1

EBPR operation in effect. Peak-flow basin sizing based on interim/maximum process flows.

EBPR operation in effect with SWWTP Phase IV in service.

Flows are based on preferred maximum process flows as operated by plant staff with appropriate units

out of service. This is not reflective of the projected AAF. For permitted flows refer to Appendix F9,

Impact of TCEQ217 and Future Permit Considerations.

2.2.1

Average Annual Flow Management

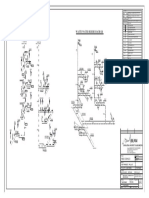

The current AAF management scheme is illustrated in Figure 2-1. Multiple sources contribute to the total

flow reaching each plant. The two primary diversion structures, Sunbeam and Five-Mile can be operated

manually (with some limitations) to control flows reaching each plant. The current AAF flow split is 64

percent to CWWTP and 36 percent to SWWTP.

WWTFSP_App.F6-2.0

December 2010

Page 5 of 62

Dallas Water Utilities

Section 2.0

Flow Management Alternatives and Recommendations

Basis of Alternatives

Figure 2-1: Current AAF Flow Management

2.2.2

Wet-Weather Flow Management

The current WWF split between CWWTP and SWWTP is managed using two diversion structures,

Sunbeam and Five-Mile. These diversion structures can be operated manually (with some limitation) to

control flows reaching each plant. However, during WWF events the ability to accurately shift flows with

the current diversion structures is very challenging. Figure 2-3 illustrates the existing peak-day flow

(PDF)/PHF flows from the sources and the current flow split at the two diversion structures.

WWTFSP_App.F6-2.0

December 2010

Page 6 of 62

Dallas Water Utilities

Section 2.0

Flow Management Alternatives and Recommendations

Basis of Alternatives

Figure 2-2: Current Wet-Weather Flow Management

2.3

Projected Flows

The projected AAF, PDF, and PHF for the year 2030 are used to determine the flow split alternative for an

average annual and wet-weather condition that satisfies the criteria. Projected 2030 flows are based on

the analysis presented in, Appendix F1, Basis of Planning: Wastewater Flow Projections.

Figure 2-3 is a graphical timeline of the historical and projected flows up to 2030. Although recent history

depicts that flows are decreasing, possibly due to successful water conservation efforts, the expected

increases in population and inflow/infiltration (I/I) support the future increase in influent flows to the plant.

The diversion structures at Sunbeam and Five-Mile become crucial to maintaining influent flows at each

plant. Projected PHF require additional peak-flow basins at each WWTP to accommodate a 10-year

storage recurrence interval.

WWTFSP_App.F6-2.0

December 2010

Page 7 of 62

Dallas Water Utilities

Section 2.0

Flow Management Alternatives and Recommendations

Basis of Alternatives

Figure 2-3: DWU Projected Flows

300

250

Annual Average Flow (mgd)

223

200

197

177

150

Historical AAF

Historical DWF

Strategic Plan - Wet Year AAF

Strategic Plan - Projected AAF

Strategic Plan - Dry Year AAF

100

50

0

2000

WWTFSP_App.F6-2.0

2010

2020

December 2010

2030

Page 8 of 62

Dallas Water Utilities

Section 2.0

Flow Management Alternatives and Recommendations

2.4

Basis of Alternatives

Recycled Water Plans

In addition to meeting collection system demands, DWU has also committed to a recycled water (RW)

plan. Part or most of the effluent discharge from each of the WWTPs is committed to various users.

Table 2-2 summarizes the RW commitments for the planning period.

Table 2-2: Recycled Water Flow Commitments

2030 (1)

2010

Flow Commitment (mgd)

Location

Scenario 1

(102 mgd)

Scenario 2

(50 mgd)

Direct Non-Potable Reuse

CWWTP

Indirect Reuse to NTMWD

CWWTP or

SWWTP

35.5

35.5

DWU Indirect Reuse Through Lake

Ray Hubbard

CWWTP or

SWWTP

30.5

30.5

CWWTP

60

60

CWWTP or

SWWTP

102

42

-10 (2)

Total Flow Commitment

111

177

125

Projected DWU Dry-Year AAF

135

177

177

Excess Recycled Flow

24

52

Environmental Flows

Trinity Corridor Lakes

Other Environmental Flows

Notes:

1

Scenario 1 assumes environmental flows equal to 100 mgd.

Scenario 2 assumes environmental flows equal to 50 mgd.

Other environmental flows for Scenario 2 are a negative number because the total

Environmental Flows must equal 50 mgd. The negative number is therefore a surplus.

Due to pending new TCEQ regulation of environmental flows, two possible scenarios emerge as follows:

Scenario 1 assumes that the commitment to environmental flows cannot be less than 102 mgd, which

is the current TCEQ requirement.

Scenario 2 accounts for a pending TCEQ regulation, which once approved requires a 50 mgd

commitment to environmental flows.

Despite the two RW plan scenarios, CWWTP is required to discharge 69 mgd during a dry-year AAF

condition.

Table 2-2 indicates that the row labeled "Total Flow Commitments" is less than or equal to the row

labeled "Projected DWU Dry-Year AAF." This confirms that both RW plan scenarios meet the flow

commitments set by DWU in 2030. However, if all flow commitments are needed before the dry-year AAF

reaches 177 mgd, DWU will not be able to meet all commitments under Scenario 1.

Figure 2-4 and Figure 2-5 illustrate the RW plan for each scenario over the projected timeline to 2030.

The environmental flows are as follows:

Figure 2-4: Scenario 1 environmental flows are 102 mgd.

WWTFSP_App.F6-2.0

December 2010

Page 9 of 62

Dallas Water Utilities

Section 2.0

Flow Management Alternatives and Recommendations

Basis of Alternatives

Figure 2-5: Scenario 2 environmental flows are 50 mgd.

Figure 2-4: Effluent Quantity Availability Scenario 1

WWTFSP_App.F6-2.0

December 2010

Page 10 of 62

Dallas Water Utilities

Section 2.0

Flow Management Alternatives and Recommendations

Basis of Alternatives

Figure 2-5: Effluent Quantity Availability Scenario 2

WWTFSP_App.F6-2.0

December 2010

Page 11 of 62

Dallas Water Utilities

Section 3.0

Flow Management Alternatives and Recommendations

Average Annual Flow Management Alternatives

3.0

AVERAGE ANNUAL FLOW MANAGEMENT ALTERNATIVES

3.1

Introduction

The AAF for a wastewater system is an average of the total flow received from sanitary, groundwater

infiltration, and wet-weather events seen through the course of a year. The dry-weather flow (DWF) for a

wastewater system is an average of the total flow received from sanitary flows and groundwater infiltration

for dry-weather period not including flow resulting from a storm or rain event. For DWU, the DWF and

AAF values are close and for the purposes of this document, they are used interchangeably.

This section discusses the AAF projected flow split for 2030. Three flow split alternatives were developed

to optimize the flow split between CWWTP and SWWTP. See Table 3-1. Each scenario was evaluated

against the following criteria:

TCEQ 75/90 rule

RW plan commitments

Established goals

Table 3-1: Alternatives for AAF Management

2030 Flows (mgd %)

DWF Alternative

CWWTP

SWWTP

A1

108 (55%)

89 (45%)

A2

99 (50%)

98 (50%)

A3

89 (45%)

108 (55%)

Although all source flows remain the same, the three alternatives differ in the flow diverted from the

Sunbeam and Five-Mile Diversion Structures to each plant. The ability to accurately measure and divert

flow at Sunbeam and Five-Mile will be crucial in the implementation of any of the alternatives.

3.1.1

Application of TCEQ 75/90 Rule

The TCEQ has established the 75/90 rule as stated in Chapter 305.126, Additional Standard Permit

Conditions for Waste Discharge Permits (Ref. 58). The rule dictates that if a wastewater treatment plant

has an incoming average daily or AAF approaching 75 percent of the permitted average daily flow for

three consecutive months, then an engineering and financial plan must be initiated for the

expansion/upgrade of the plant.

Once the average daily or AAF approaches 90 percent of the permitted average daily flow for three

consecutive months, then the utility must obtain necessary authorization from TCEQ to commence

construction of expansion/upgrade of the plant.

However, if the AAF approaches the 75/90 requirement and the population served will not cause permit

non-compliance, then the 75/90 requirement may be waived. A 75/90 requirement waiver must be

reviewed by the TCEQ director.

Sections 3.2, 3.3 and 3.4 include figures that illustrate the timeline for each alternative as it relates to the

plant's compliance with the TCEQ 75/90 rule.

3.2

Alternative A1: CWWTP 55 Percent / SWWTP 45 Percent

Alternative A1 assumes that once the Sunbeam and Five-Mile diversion structures are improved, the

incoming flow to each plant will be proportioned to sending 55 percent of the total 2030 AAF to CWWTP

and 45 percent to SWWTP. .Figure 3-1 illustrates the flow schematic for Alternative A1.

WWTFSP_App.F6-2.0

December 2010

Page 12 of 62

Dallas Water Utilities

Section 3.0

Flow Management Alternatives and Recommendations

Average Annual Flow Management Alternatives

Figure 3-1: Flow Schematic for Alternative A1

3.2.1

Trigger Timeline for A1

Figure 3-2 for CWWTP and Figure 3-3 for SWWTP provide a trigger timeline based on the A1 flow split.

Each trigger graph shows the relationship between the preferred maximum AAF and the projected AAF.

Improvements for EBPR are anticipated at both CWWTP and SWWTP sometime between 2015 and

2025; therefore, the preferred maximum AAF timeline at the CWWTP drops from 150 mgd to 120 mgd at

completion. The SWWTP preferred maximum AAF does not change as a result of EBPR implementation.

The projected AAF timeline depends on the improvements timeline of the Sunbeam and Five-Mile

diversion structures. Once replacement and/or rehabilitation are complete, the structures will reliably

divert more flow from CWWTP and to SWWTP.

WWTFSP_App.F6-2.0

December 2010

Page 13 of 62

Dallas Water Utilities

Section 3.0

Flow Management Alternatives and Recommendations

Average Annual Flow Management Alternatives

Figure 3-2: CWWTP Trigger Timeline for Alternative A1

Figure 3-3: SWWTP Trigger Timeline for A1

WWTFSP_App.F6-2.0

December 2010

Page 14 of 62

Dallas Water Utilities

Section 3.0

Flow Management Alternatives and Recommendations

3.3

Average Annual Flow Management Alternatives

Alternative A2: CWWTP 50 Percent / SWWTP 50 Percent

Alternative A2 evenly splits the flows between the two WWTPs. The flow schematic in Figure 3-4 shows

the flow contribution from each source and how much the diversion structures send to each plant.

Figure 3-4: Flow Schematic for Alternative A2

3.3.1

Trigger Timeline for A2

The trigger timeline for Alternative A2 is illustrated in Figure 3-5 for CWWTP and Figure 3-6 for SWWTP.

The AAF for each plant is the same for all AAF alternatives at 2030. The percent of permitted AAF is at

83 percent for CWWTP and at 89 percent for SWWTP.

WWTFSP_App.F6-2.0

December 2010

Page 15 of 62

Dallas Water Utilities

Section 3.0

Flow Management Alternatives and Recommendations

Average Annual Flow Management Alternatives

Figure 3-5: CWWTP Trigger Timeline for A2

Figure 3-6: SWWTP Trigger Timeline for A2

WWTFSP_App.F6-2.0

December 2010

Page 16 of 62

Dallas Water Utilities

Section 3.0

Flow Management Alternatives and Recommendations

3.4

Average Annual Flow Management Alternatives

Alternative A3: CWWTP 45 Percent / SWWTP 55 Percent

Alternative A3 sends more flow to SWWTP than the previous two alternatives. With 45 percent of the

AAF diverted to CWWTP and the remainder to SWWTP, Figure 3-7 is the resulting flow schematic under

this alternative.

Figure 3-7: Flow Schematic for Alternative A3

3.4.1

Trigger Timeline for A3

With the majority of the AAF diverted to SWWTP, the projected AAF approaches the 75/90 requirement

earlier than the other alternatives, which is a disadvantage. SWWTP approaches 75 percent of its

permitted AAF at 2019 and 90 percent at 2025 respectively requiring construction of SWWTP Phase IV.

The advantage of this alternative is that CWWTP will not reach 75 percent of its permitted AAF until after

2030. Figure 3-8 and Figure 3-9 illustrate how CWWTP and SWWTP respectively operate over time

compared to the permitted AAF under alternative A3.

WWTFSP_App.F6-2.0

December 2010

Page 17 of 62

Dallas Water Utilities

Section 3.0

Flow Management Alternatives and Recommendations

Average Annual Flow Management Alternatives

Figure 3-8: CWWTP Trigger Timeline for A3

Figure 3-9: SWWTP Trigger Timeline A3

WWTFSP_App.F6-2.0

December 2010

Page 18 of 62

Dallas Water Utilities

Section 3.0

Flow Management Alternatives and Recommendations

3.5

Average Annual Flow Management Alternatives

Evaluation of Annual Average Flow Alternatives

A summary of all the annual average flow alternatives is shown in Table 3-2 along with projected AAF

designated at each plant for 2030. The goals stated in the beginning of Section 2 are listed under the

criteria column. A next to the item indicates that the criteria are met under the AAF alternative.

Multiple check marks indicate that this alternative meets the criteria and provides additional benefit. A red

X indicates the criteria were not met.

WWTFSP_App.F6-2.0

December 2010

Page 19 of 62

Dallas Water Utilities

Section 3.0

Flow Management Alternatives and Recommendations

Average Annual Flow Management Alternatives

Table 3-2: Evaluation of DWF Management Alternatives

Evaluation Criteria

Alternatives

A1

A2

A3

CWWTP

108

99

89

SWWTP

89

98

108

CWWTP

98

89

79

SWWTP

79

88

98

Meets 2030 Adequate RW

Commitments Scenario 1 (1)

CWWTP

SWWTP

Meets 2030 Adequate RW

Commitments Scenario 2

CWWTP

SWWTP

2010-2020

2020-2030

Minimum Flow at CWWTP to Maintain Process

Dilutes SWWTP Filtrate

2010-2020

2020-2030

2030 AAF (mgd)

2030 During Dry-Year AAF (mgd)

Defers CWWTP Process Expansion

Defers SWWTP Process Expansion Capacity

Note:

1

If all flow commitments are needed before the Dry-year AAF reaches 177 mgd, DWU will not

meet all commitments under Scenario 1.

The costs associated with all three alternatives are nearly identical, since all alternatives include

replacement of the Sunbeam Diversion Structure and rehabilitation of the Five-Mile Structure.

WWTFSP_App.F6-2.0

December 2010

Page 20 of 62

Dallas Water Utilities

Section 4.0

Flow Management Alternatives and Recommendations

Wet-Weather Flow Management Alternatives

4.0

WET-WEATHER FLOW MANAGEMENT ALTERNATIVES

4.1

Introduction

Both the CWWTP and SWWTP require peak-flow basin improvements to handle 2030 projected peak

wet-weather flows. This section identifies the different wet-weather management alternatives for the

planning period.

Historical storm event data collected for the last 70 years was used to generate a peak-flow basin volume

versus storage recurrence interval relationship. A peak-flow storage recurrence interval is different from a

storm recurrence interval, which is used in sizing sewers. A storage recurrence interval is the frequency

of basin usage after a storm event. The WWF management alternatives depend heavily on a chosen wet

weather peak-flow storage recurrence interval. For example a 10-year wet weather peak-flow storage

event is the peak-flow volume generated from particular rain events that, on the average, will fill or

exceed the peak-flow basin volume once every 10 years. It does not mean that the event occurred every

10 years. The probability that an event of a specific magnitude will be equal or exceeded in a given future

year is the inverse of the recurrence interval. Thus, a 10-year peak-flow storage event has a chance of

one in 10 (or 10 percent) chance of occurring in any specified year. The recurrence interval selected for

use in this WWF peak-flow storage analysis is a 10-year recurrence interval. This event would

theoretically generate 1,100 MG of volume based on the Long Term Flow Simulation (Ref. 231). Figure

4-1 illustrates the needed volume at CWWTP and Figure 4-2 illustrates the needed volume at SWWTP

based on the selected 10-year storage recurrence interval.

Figure 4-1: Volume of Basin vs. Recurrence Interval at CWWTP

Volume of Peak Flow Basins (MG)

1,000

900

Planned

Recurrence

Interval and

Storage Volume

800

700

600

500

400

300

200

100

0

0

10

20

30

40

50

60

70

Storage Recurrence Interval (years)

2030 Conditions (future I/I, min interceptor bottlenecks, & 230 mgd process PHF)

2010 Conditions (current I/I, 450 mgd max thru interceptor, & 300 mgd process PHF)

Existing Volume of CWWTP Peak Flow Basins (Design + Emergency Volume = 264 MG)

WWTFSP_App.F6-2.0

December 2010

Page 21 of 62

Dallas Water Utilities

Section 4.0

Flow Management Alternatives and Recommendations

Wet-Weather Flow Management Alternatives

Figure 4-2: Volume of Basin vs. Recurrence Interval at SWWTP

1,600

Volume of Peak Flow Basins (MG)

1,400

Planned

Recurrence

Interval and

Storage Volume

1,200

1,000

800

600

400

200

0

0

10

20

30

40

50

60

70

Storage Recurrence Interval (years)

2030 Conditions (Future I/I, min interceptor bottlenecks, & 155 mgd process PHF)

2010 Conditions (Current I/I, 300 mgd max thru interceptor, & 155 mgd process PHF)

Existing Volume of Peak Flow Basins Size (Design Volume = 158 MG)

The current collection system bottlenecks are slated to be minimized by 2030, allowing better conveyance

of wet-weather flows to the plants. To accommodate these flows, the plant will require within this

planning period, additional peak-flow storage. A reduction in the preferred process maximum PHF (300

mgd to 230 mgd) capacity during the planning period will greatly affect the amount of storage necessary

at CWWTP. SWWTP preferred process maximum PHF will remain at 155 mgd until Phase IV is

constructed at the end of this planning period.

Another consideration for peak-flow basin storage is the influent pumping capacity at each plant. The

maximum rate that a plants influent pumps can pull out of the collection system is the maximum rate at

which the peak-flow basins can be filled. Inadequate influent pumping capacity results in collection

system temporary storage. This section includes the analysis of additional pumping capacity to handle

the larger projected flows and reduce collection system temporary storage.

CWWTP currently has four peak-flow basins A, B1, B2, and C totaling 185 MG when the water surface

elevation (WSE) reaches 402 ft. For additional emergency storage, the WSE can be increased to 407 ft

bringing the emergency storage volume at CWWTP to 264 MG (Ref. 230). SWWTP currently has four

basins no. 1, no. 2, no. 3, and no. 4 with a storage volume of 158 MG (Ref. 228).

The total storage volume (CWWTP and SWWTP) necessary for a 10-year storage recurrence interval in

2030 is 1,100 MG. Two alternatives (W1 and W2) were evaluated to achieve 1,100 MG of storage. A

more detailed analysis during the predesign phase will be necessary to select the most beneficial

alternative.

WWTFSP_App.F6-2.0

December 2010

Page 22 of 62

Dallas Water Utilities

Section 4.0

Flow Management Alternatives and Recommendations

4.2

Alternative W1

4.2.1

CWWTP

Wet-Weather Flow Management Alternatives

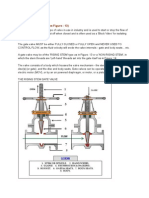

Alternative W1 includes the option to excavate a new basin D. Figure 4-3 and Figure 4-4 illustrate the

proposed layout and profile for Alternative W1. These changes would bring the total storage at CWWTP

to 440 MG.

Basin D is located in CWWTP, adjacent to existing basin A, and includes excavation down to an elevation

that allows drainage by gravity into a new junction structure on the 84-inch Horseshoe Interceptor. Piping

layout, hydraulics, and available land surface dictate the size and depth of a peak-flow basin.

Basins B-2 and C will also have new solids settling chambers installed within the existing basins to allow

large solids to settle out. This will minimize the cleaning area after peak-flow events to a small basin as

opposed to the large basins.

Design includes installation of a new 72-inch diameter peak-flow pipe between the new IPS and basin B.

An additional 96-inch influent pipe between the White Rock Gate Structure and IPS is also planned to

convey flows from the Sunbeam and Five-Mile junction structures directly to the IPS. The pipeline is

planned to be constructed along the east side of the facility as shown in Figure 4-3.

4.2.2

SWWTP

Expansion at SWWTP includes combining basins no. 2 and 3, and converting basin no.1 to a solids

settling chamber. Basins no. 1, no. 2, and no. 3 will also be excavated deeper to match the bottom

elevation of basin no. 4. In addition, basins no. 5, no. 6, and no. 7 will be constructed. These

improvements will provide 660 MG at SWWTP.

Basins no. 5, no. 6, and no. 7 at SWWTP will be sized as shown on the layout in Figure 4-5. The

proposed size and profile of the basins are shown on Figure 4-6. An existing stormwater basin lies in the

proposed area for basin no. 6, which will partially remain to accommodate the large surface area needed

for basins no. 6 and no. 7.

A new SWWTP PFPS with a total capacity of 75 mgd will be proposed to be located upstream of IPSC to

allow direct pumping to multiple peak-flow basins.

WWTFSP_App.F6-2.0

December 2010

Page 23 of 62

Dallas Water Utilities

Section 4.0

Flow Management Alternatives and Recommendations

Wet-Weather Flow Management Alternatives

Figure 4-3: 2030 CWWTP Peak-Flow Basin Layout for W1

WWTFSP_App.F6-2.0

December 2010

Page 24 of 62

Dallas Water Utilities

Section 4.0

Flow Management Alternatives and Recommendations

Wet-Weather Flow Management Alternatives

Figure 4-4: 2030 CWWTP Peak-Flow Basin Profile for W1

WWTFSP_App.F6-2.0

December 2010

Page 25 of 62

Dallas Water Utilities

Section 4.0

Flow Management Alternatives and Recommendations

Wet-Weather Flow Management Alternatives

Figure 4-5: 2030 SWWTP Peak-Flow Basin Layout

WWTFSP_App.F6-2.0

December 2010

Page 26 of 62

Dallas Water Utilities

Section 4.0

Flow Management Alternatives and Recommendations

Wet-Weather Flow Management Alternatives

Figure 4-6: 2030 SWWTP Peak-Flow Basin Profile

4.3

Alternative W2

4.3.1

CWWTP

Alternative W2 includes the option to excavate basin E and basin D. Figure 4-7 and Figure 4-8 illustrate

the proposed layout and profile for Alternative W2. The total volume will be 440 MG.

Basins D and E are located in CWWTP, adjacent to existing basin A, and this option includes excavation

of the basins down to an elevation that allows drainage by gravity into basin A. Piping layout, hydraulics,

and available land surface dictate the size and depth of a peak-flow basin. The lowest possible point for

the bottom of basins D and E is at an elevation of 391 ft.

The proposed location of basin E at CWWTP consists of a rudimentary landfill with inert bio-solids

containing unleachable arsenic (Ref. 231). The arsenic levels are unknown at this time and disposal

methods were not investigated for this technical memorandum. Any future design with this alternative

would have to incorporate a detailed disposal plan for the inert bio-solids. Cost estimates did not include

disposal of contaminants, since level contamination was unknown.

Additional 72-inch diameter peak-flow pipe between the new IPS and Basin B will be constructed. A 96inch influent tunnel between the White Rock Gate structure and IPS is also required to allow an alternate

influent pipe to the 84-inch Horseshoe Interceptor. This new pipe will convey flows from the Sunbeam

and Five-Mile junction structures directly to the IPS. The pipeline will be tunneled along the east side of

the facility as shown in Figure 4-7.

4.3.2

SWWTP

Expansion at SWWTP includes combining basins no. 2 and 3, and converting basin no.1 to a solids

settling chamber. Basins no. 1, no. 2, and no. 3 will also be excavated deeper to match the bottom

WWTFSP_App.F6-2.0

December 2010

Page 27 of 62

Dallas Water Utilities

Section 4.0

Flow Management Alternatives and Recommendations

Wet-Weather Flow Management Alternatives

elevation of basin no. 4. In addition, basins no. 5, no. 6, and no. 7 will be constructed. These

improvements will provide 660 MG at SWWTP.

Basins no. 5, no. 6, and no. 7 at SWWTP will be sized as shown on the layout in Figure 4-5. The

proposed size and profile of the basins are shown on Figure 4-6. An existing stormwater basin lies in the

proposed area for basin no. 6, requiring relocation to accommodate the large surface area needed for

basins no. 6 and no. 7.

A new SWWTP PFPS with a total capacity of 75 mgd will be located upstream of IPSC to allow direct

pumping to multiple peak-flow basins.

WWTFSP_App.F6-2.0

December 2010

Page 28 of 62

Dallas Water Utilities

Section 4.0

Flow Management Alternatives and Recommendations

Wet-Weather Flow Management Alternatives

Figure 4-7: 2030 CWWTP Peak-Flow Basin Profile for W2

Draft WWTFSP_App.F6-1.0

December 2010

Page 29 of 62

Dallas Water Utilities

Section 4.0

Flow Management Alternatives and Recommendations

Wet-Weather Flow Management Alternatives

Figure 4-8: 2030 CWWTP Peak-Flow Basin Profile for W2

WWTFSP_App.F6-2.0

December 2010

Page 30 of 62

Dallas Water Utilities

Section 4.0

Flow Management Alternatives and Recommendations

Wet-Weather Flow Management Alternatives

Figure 4-9: 2030 Wet-Weather Flow Management

WWTFSP_App.F6-2.0

December 2010

Page 31 of 62

Dallas Water Utilities

Section 4.0

Flow Management Alternatives and Recommendations

4.4

Wet-Weather Flow Management Alternatives

Summary of Wet-Weather Alternatives

Table 4-2 is a summary of volumes sent to each plant based on each alternative. Both alternatives meet

the estimated 2030 basin event volume of 1,100 MG. Section 5.0 contains a detailed discussion of the

cost estimates for each alternative.

Table 4-1: Summary of Wet-Weather Alternatives

SWWTP Basin

Volumes

CWWTP Basin

Volumes

Scenario Description

Units

W1

W2

Existing

MG

MG

176

116

MG

N/A

60

Subtotal

MG

440

440

Existing

MG

Additional 1-2-3

MG

22

22

MG

90

90

MG

165

165

MG

225

225

Subtotal

MG

660

660

MG

1,100

1,100

Total Volume

264

158

The existing and required pumping capacities for both plants based on each wet-weather alternative are

summarized on Table 4-2.

Table 4-2: Planned Pumping Capacity

CWWTP

SWWTP

Facility

Flow (mgd)

Facility

Flow (mgd)

IPS (Stage 2) (1)

425

IPSC (1)

348

WRRSPS

(1)

230

DPFPS

(1)

60

SDPFPS (1)

50

PFPS (2)

75

Total Capacity

705

Total Capacity

483

Notes:

1

Existing/Under Design/Construction

Planned/New

WWTFSP_App.F6-2.0

December 2010

Page 32 of 62

Dallas Water Utilities

Section 5.0

Flow Management Alternatives and Recommendations

5.0

Recommended Alternatives

RECOMMENDED ALTERNATIVES

The recommended AAF split is alternative A2 with a 50 percent CWWTP and 50 percent SWWTP flow

split. The recommended wet-weather alternative is A2 which include CWWTP improvements of

excavating basin D, and deepening basins A and D by 5 feet. Improvements at SWWTP include

constructing basins no. 5, no. 6, and no. 7, joining and deepening basins no. 1, no. 2, and no. 3, and

building a new PFPS to accept the additional peak flows.

5.1

Recommended Average Annual Flow Split

After thorough analysis of the three annual average flow split alternatives as presented in Section 3.0, the

recommended alternative that best meets all the goals is alternative A2, as shown in Table 5-1.

Table 5-1: Summary of Average Annual Flow Management Alternatives

Evaluation Criteria

Alternatives

A1

Recommended

Alternative

A3

A2

CWWTP

108

99

89

SWWTP

89

98

108

CWWTP

98

89

79

SWWTP

769

88

98

Meets 2030 Adequate RW

Commitments Scenario 1 (1)

CWWTP

SWWTP

Meets 2030 Adequate RW

Commitments Scenario 2

CWWTP

SWWTP

2010-2020

2020-2030

2010-2020

2020-2030

Minimum Flow at CWWTP to Maintain Process

Dilute SWWTP Filtrate

2030 AAF (mgd)

2030 During Dry-Year AAF (mgd)

Defers CWWTP Process Expansion

Defers SWWTP Process Expansion

Capacity

Note:

1

If all flow commitments are needed before the dry-year AAF reaches 177 mgd, DWU will not

meet all commitments under Scenario 1.

Alternative A2 recommends a 50 percent split of the total 2030 AAF between the two WWTPs.

Alternative A2 also provides for maximum dilution of the filtrate at SWWTP, while delaying improvements

at CWWTP and SWWTP beyond the planning period.

WWTFSP_App.F6-2.0

December 2010

Page 33 of 62

Dallas Water Utilities

Section 5.0

Flow Management Alternatives and Recommendations

5.2

Recommended Alternatives

Recommended Wet-Weather Alternative

Based on the wet-weather peak-flow basin analysis in Section 4.0, alternative W1 is the recommended

alternative. Construction would be in two phases as described below:

Phase 1 (within 5 years)

Construct of basin no. 5 at SWWTP.

Replace Sunbeam Junction Structure.

Improve Five-Mile Diversion Structure.

Rehabilitate existing basins at CWWTP.

Rehabilitate basins no. 1, no. 2, and no. 3 at SWWTP.

Construct new peak-flow basin D at CWWTP.

Construct 96-inch diameter peak-flow piping between IPS and peak-flow basins.

Phase 2 (within 5 - 20 years)

Construct peak-flow basin no. 6 at SWWTP.

Construct SWWTP 75 mgd peak-flow pump station.

Construct peak-flow basin no. 7 at SWWTP.

Construct 96-inch piping between IPS and WRGS.

Table 5-2 shows the risk analysis associated with potential overflow of the peak-flow basins considering

timing of the different alternatives for CWWTP peak-flow storage and when the enhanced biological

phosphorus removal projects go online. This analysis was done for CWWTP because of the particular

challenges it faces. Those challenges are the following:

Land-locked facility

Derated plant capacity

Increased peak flows

Table 5-2 shows both the surplus of peak-flow basins storage in million gallons for four storm events and

also the probability of exceeding basin storage in any given year and decade. The recommended

alternative of having basin D online before EBPR improvements are completed for both Complex A and

Complex B has the lowest risk, with the highest risk associated with the alternative of keeping the existing

storage as is and EBPR at both Complex A and B online, which decreases plant peak-flow capacity.

This analysis can help determine the order and timing of peak-flow basin project based on DWU's

willingness to accept associated risks.

WWTFSP_App.F6-2.0

December 2010

Page 34 of 62

Dallas Water Utilities

Section 5.0

Flow Management Alternatives and Recommendations

Recommended Alternatives

Table 5-2: Peak Flow Storage Risk Analysis

CWWTP

Alternative

Scenario

Complex Complex New PFB

A Online? B Online?

D?

Deepen

PFB A?

Treatment Peak Flow

Capacity

Basin

(mgd)

Capacity (MG)

Existing

No

No

No

No

300

264

Recommended

Yes

Yes

Yes

No

230

440

DWU 1

No

Yes

No

Yes

270

320

DWU 2

Yes

Yes

No

Yes

230

320

DWU 3

Yes

Yes

No

No

230

264

CWWTP

5.3

Storage Parameters

Surplus Peak Flow Basin Storage (MG)

Probability of

Exceeding Basin

Storage

Alternative

5 yr

Event

10 yr

Event

15 yr

Event

20 yr

Event

In any

given

year

In any given

decade

Existing

164

89

39

4.8%

39%

Recommended

265

85

-25

-100

7.1%

52%

DWU 1

180

60

-40

-120

9.1%

61%

DWU 2

145

-35

-145

-220

11.8%

71%

DWU 3

89

-91

-201

-276

14.3%

79%

Estimated Cost for Peak-Flow Storage and Flow Management

Implementation of any AAF or WWF alternative requires replacement of the Sunbeam diversion structure

and rehabilitation of the Five-Mile diversion structure. The Sunbeam diversion structure is recommended

to be replaced since it is nearing the end of its useful life and is not capable of accurately measuring and

diverting flow. The Five-Mile diversion structure is recommended to rehabilitated and modified to

accurately measure and divert flow. None of the AAF alternatives require improvements at the CWWTP

or SWWTP; however, additional peak-flow storage and pumping capacity are included to accommodate

the chosen wet-weather alternative W1. Estimated costs are presented in Table 5-3. Alternative cost

and detailed cost estimates are in Appendix E.

Table 5-3: Estimated Cost for Recommended Alternatives

Element

W1 Cost

Peak-Flow Storage

CWWTP 84-Inch Horseshoe Interceptor Rehabilitation

SWWTP Basin No. 5

$13,700,000

$9,500,000

CWWTP Basin D

$23,400,000

CWWTP Existing Basins Rehabilitation

$5,200,000

SWWTP Basins No. 1, 2, and 3 Rehabilitation

$4,500,000

WWTFSP_App.F6-2.0

December 2010

Page 35 of 62

Dallas Water Utilities

Section 5.0

Flow Management Alternatives and Recommendations

Element

Recommended Alternatives

W1 Cost

SWWTP Basin No. 6

$18,900,000

SWWTP Peak-Flow Pump Station

$21,600,000

SWWTP Basin No. 7

$24,000,000

CWWTP IPS Interconnect

$7,900,000

CWWTP Stage 2 IPS Improvements

$13,300,000

Flow Management

Sunbeam Junction Structure Replacement

$4,400,000

Five-Mile Diversion Structure Rehabilitation

$3,400,000

Total Construction Cost

WWTFSP_App.F6-2.0

December 2010

$149,800,000

Page 36 of 62

Dallas Water Utilities

Appendix A

Flow Management Alternatives and Recommendations

Glossary of Acronyms and Terms

Appendix A Glossary of Acronyms and Terms

Acronym or Term

Definition

AAF

Average Annual Flow

AD

Alternative Disinfection

AGR

Aerated Grit Basins

ASCA

Activated Sludge Complex A

ASCB

Activated Sludge Complex B

ASCC

Activated Sludge Complex C

ASIPS

Activated Sludge Influent Plump Station

BCP1

Basin Complex Phase 1/2

BCP3

Basin Complex Phase 3

CCB

Chlorine Contact Basin

CP

Chemical Polishing Facilities

CWWTP

Central Wastewater Treatment Plant

DIG

Digesters

DPH

Dallas Plant Headworks

DPPC

Dallas Plant Primary Clarifiers

DPSC

Dallas Plant Secondary Clarifiers

DWF

Dewatering Facilities

DWF

Dry-Weather Flow

DWU

Dallas Water Utilities

EBPR

Enhanced Biological Phosphorus Removal

EPS

Effluent Pump Station

EPSA

Effluent Pump Station A

EPSB

Effluent Pump Station B

FC

Filter Complex

FDS

Flow Diversion Structure

FP1

Filter Phase 1/2

FP3

Filter Phase 3

ft

Foot or Feet

IPS

Influent Pump Station

IPSC

Influent Pump Station C

MG

Million Gallons

mg/L

Milligrams per Liter

mgd

Million Gallons per Day

WWTFSP_App.F6-2.0

December 2010

Page 37 of 62

Dallas Water Utilities

Appendix A

Flow Management Alternatives and Recommendations

Acronym or Term

Glossary of Acronyms and Terms

Definition

N/A

Not Applicable

NIPS

New Influent Pump Station

No.

Number

NTMWD

North Texas Municipal Water District

OH&P

Contractor Overhead and Profit

Peak-Daily Flow

PFPS

Peak-Flow Pump Station

PHF

Peak-Hourly Flow

PS

Pump Station

RW

Recycled Water

SDPFPS

South Dallas Peak-Flow Pump Station

SSC

Sidestream Clarifier

SSPR

Sidestream Phosphorous Removal

SWWTP

Southside Wastewater Treatment Plant

TAC

Texas Administrative Code

TCEQ

Texas Commission on Environmental Quality

TM

Technical Memorandum or Technical Memo

VGR

Vortex Grit Removal

WB

West Bank Interceptor

WRGP

White Rock Gate Structure

WRH

White Rock Headworks

WRP

White Rock Plant

WRPC

White Rock Primary Clarifiers

WRPFPS

White Rock Peak-Flow Pump Station

WRRSPS

White Rock Raw Sewage Pump Station

WRSC

White Rock Secondary Clarifiers

WSE

Water Surface Elevation

WWF

Wet-Weather Flow

WWTFSP

Wastewater Treatment Facilities Strategic Plan

WWTP

Wastewater Treatment Plant

WWTFSP_App.F6-2.0

December 2010

Page 38 of 62

Dallas Water Utilities

Appendix B

Flow Management Alternatives and Recommendations

References

Appendix B References

Reference

Number

Reference Information

58

Texas Commission on Environmental Quality. Consolidated Permits, 30 TAC 305, July

2006.

87

Freese & Nichols, Inc. Central Wastewater Treatment Plant Hydraulic and Process

Modeling Project, Technical Memorandum No. 3 Process Alternative Scenarios and

Recommendations. Dallas: Freese and Nichols, July 2006.

135

Carollo Engineers, Inc. Wastewater Treatment Facilities Strategic Plan, Technical

Memorandum, Wastewater Flow Projections. Dallas: Carollo Engineers, Inc., July 2010.

139

Carollo Engineers, Inc. Wastewater Treatment Facilities Strategic Plan, Technical

Memorandum, Condition Assessment White Rock Raw Sewage Pump Station

(WRRSPS). Dallas: Carollo Engineers, Inc., July 2010.

211

Carollo Engineers, Inc. Wastewater Treatment Facilities Strategic Plan, Technical

Memorandum, Impact of TCEQ217 and Future Permit Considerations. Dallas: Carollo

Engineers, Inc., July 2010.

228

Henningson, Durham, and Richardson Inc (HDR). Southside Wastewater Treatment

Plant Peak Flow Basin Expansion Draft Technical Memorandum. Dallas: HDR,

December 2002.

229

Halff Associates Inc. Closure Plan Municipal Sludge Disposal Basin A. Dallas: Halff

Associates Inc.

230

Halff Associates Inc. Predesign Report Wastewater Plant Peak Flow & Process Control

Improvements. Dallas: Halff Associates Inc.

231

Carollo Engineers, Inc. Long Term Flow Simulation. Dallas: January 2009.

WWTFSP_App.F6-2.0

December 2010

Page 39 of 62

Dallas Water Utilities

Appendix C

Flow Management Alternatives and Recommendations

Flow Schematics

Appendix C Flow Schematics

Figure C-1: Flow Schematic Existing Conditions

WWTFSP_App.F6-2.0

December 2010

Page 40 of 62

Dallas Water Utilities

Appendix C

Flow Management Alternatives and Recommendations

Flow Schematics

Figure C-2: Flow Schematic - 2030 Conditions (W1 Alternative)

WWTFSP_App.F6-2.0

December 2010

Page 41 of 62

Dallas Water Utilities

Appendix D

Flow Management Alternatives and Recommendations

Peak-Flow Basins

Appendix D Peak-Flow Basins

Figure D-1: Current Wet-Weather Flow Handling at CWWTP for 10-year Storage Event

Figure D-2: Projected Wet-Weather Flow Handling at CWWTP for 10-year Storage Event

WWTFSP_App.F6-2.0

December 2010

Page 42 of 62

Dallas Water Utilities

Appendix D

Flow Management Alternatives and Recommendations

Peak-Flow Basins

Figure D-3: Current Wet-Weather Flow Handling at SWWTP for 10-Year Storage Event

Figure D-4: Projected Wet-Weather Flow Handling at SWWTP for 10-year Storage Event

WWTFSP_App.F6-2.0

December 2010

Page 43 of 62

Dallas Water Utilities

Appendix D

Flow Management Alternatives and Recommendations

Peak-Flow Basins

Figure D-5: Hydraulic Grade Lines for Future 72 in. and 96 in. Pipes from IPS

WWTFSP_App.F6-2.0

December 2010

Page 44 of 62

Dallas Water Utilities

Appendix D

Flow Management Alternatives and Recommendations

Peak-Flow Basins

Figure D-6: 2030 PF Schematic CWWTP

WWTFSP_App.F6-2.0

December 2010

Page 45 of 62

Dallas Water Utilities

Appendix E

Flow Management Alternatives and Recommendations

Detailed Cost Estimates

Appendix E Detailed Cost Estimates

Table E-1: Estimated Cost for Alternatives

Element

Alternative W1

Alternative W2

Peak-Flow Storage

CWWTP 84-Inch Horseshoe Interceptor Rehabilitation

$13,700,000

$13,700,000

$9,500,000

$9,500,000

$23,400,000

N/A

N/A

$86,600,000

CWWTP Existing Basins Rehabilitation

$5,200,000

N/A

SWWTP Basins No. 1, 2, and 3 Rehabilitation

$4,500,000

$4,500,000

SWWTP Basin No. 6

$18,900,000

$18,900,000

SWWTP Peak-Flow Pump Station

$21,600,000

$21,600,000

SWWTP Basin No. 7

$24,000,000

$24,000,000

$7,900,000

$7,900,000

$13,300,000

$13,300,000

Sunbeam Junction Structure Replacement

$4,400,000

$4,400,000

Five-Mile Diversion Structure Rehabilitation

$3,400,000

$3,400,000

$149,800,000

$213,000,000

SWWTP Basin No. 5

CWWTP Basin D

CWWTP Basin D and E

CWWTP IPS Interconnect

CWWTP Stage 2 IPS Improvements

Flow Management

Total Construction Cost

WWTFSP_App.F6-2.0

December 2010

Page 46 of 62

Dallas Water Utilities

Appendix E

Flow Management Alternatives and Recommendations

Detailed Cost Estimates

Table E-2: 84-Inch Interceptor Rehabilitation Detailed Cost Estimate (W1 & W2)

Description

Quantity

Unit

Unit Cost

Subtotal

Total

84-Inch Horseshoe Interceptor Rehabilitation

Major Site Work

Utility Relocation and/or Flow Diversion

LS

Dewatering

LS

$300,000

$300,000

Site Restoration

LS

$300,000

$300,000

Cleaning Existing Pipe

4,300

LF

$90

$387,000

84-Inch Pipe

4,300

LF

$510 $2,193,000

Slip Lining and Grouting 84-Inch Pipe

4,300

LF

$420 $1,806,000

Sheet Piling

6,400

SF

$29

$185,600

10,667

CY

$14

$149,338

Backfill

$2,000,000 $2,000,000

Subtotal Major Site Work

$7,320,938

Subtotal Structure(s)

$0

Subtotal Major Equipment & Piping

$0

Subtotal All Major Cost

$7,320,938

Other Misc. Yard Piping and Utilities (0%)

$0

Other Site Work (10%)

$732,094

Other Electrical and Instrumentation (0%)

$0

Subtotal Direct Cost

$8,053,000

Total Direct Cost

$8,100,000

Contingencies (30%)

$2,400,000

Structure(s)

None

Major Equipment & Piping

None

Total Direct Cost + Contingencies $10,500,000

General Conditions (15%)

$1,600,000

Contractor OH & P (15%)

$1,600,000

Total Construction Cost $13,700,000

WWTFSP_App.F6-2.0

December 2010

Page 47 of 62

Dallas Water Utilities

Appendix E

Flow Management Alternatives and Recommendations

Detailed Cost Estimates

Table E-3: New Peak Flow Basin No. 5 (W1 & W2)

Description

Quantity

Unit

Unit

Cost

Subtotal

Total

New Peak Flow Basin No. 5

Major Site Work

Clear & Grub

110

AC

Excavation

530,000

CY

$3 $1,590,000

Haul Excess Excavation

430,000

CY

$2

$860,000

LS

$100,000

$100,000

25,000

SF

$5

$125,000

New Perimeter Gravel Road

Bentonite Slurry Trench

$1,400

$154,000

Subtotal Major Site Work

$2,829,000

Structure(s)

6-Inch Concrete Basin Floor

6,667

CY

$295 $1,966,765

6-Inch Concrete Sloped Walls

4,167

CY

$306 $1,275,102

LS

Meter Vault

$100,000

$100,000

Subtotal Structure(s)

$3,341,867

Major Equipment & Piping

48-Inch Pipe

WWTFSP_App.F6-2.0

610

LF

$230

$140,300

Subtotal Major Equipment & Piping

$140,300

Subtotal All Major Cost

$6,311,167

Other Misc. Yard Piping and Utilities (5%)

$315,558

Other Site Work (0%)

$0

Other Electrical and Instrumentation (0%)

$0

Subtotal Direct Cost

$6,627,000

Total Direct Cost

$6,600,000

Contingencies (10%)

$700,000

Total Direct Cost + Contingencies

$7,300,000

General Conditions (15%)

$1,100,000

Contractor OH & P (15%)

$1,100,000

Total Construction Cost

$9,500,000

December 2010

Page 48 of 62

Dallas Water Utilities

Appendix E

Flow Management Alternatives and Recommendations

Detailed Cost Estimates

Table E-4: Existing Peak Flow Basins Rehabilitation

Description

Quantity

Unit

Unit Cost

Subtotal

$8

$900,640

Total

Existing Basin Rehabilitation

Major Site Work

Demolition

Berm Rehabilitation

112,580

SF

LS

$1,000,000 $1,000,000

Subtotal Major Site Work

$1,900,640

Structure(s)

6-Inch Concrete Slab On Grade

2,167

CY

$295

$639,265

6-Inch Sloped Slab On Grade

1,333

CY

$306

$407,898

200

CY

$950

$190,000

2,000

CY

$75

$150,000

10-Inch Wide Concrete Settling Walls

Grouting

Subtotal Structure(s)

$1,387,163

Major Equipment & Piping

None

WWTFSP_App.F6-2.0

$0

Subtotal Major Equipment & Piping

$0

Subtotal All Major Cost

$3,287,803

Other Misc. Yard Piping and Utilities (5%)

$164,390

Other Site Work (5%)

$164,390

Other Electrical and Instrumentation (0%)

$0

Subtotal Direct Cost

$3,617,000

Total Direct Cost

$3,600,000

Contingencies (10%)

$400,000

Total Direct Cost + Contingencies

$4,000,000

General Conditions (15%)

$600,000

Contractor OH & P (15%)

$600,000

Total Construction Cost

$5,200,000

December 2010

Page 49 of 62

Dallas Water Utilities

Appendix E

Flow Management Alternatives and Recommendations

Detailed Cost Estimates

Table E-5: New Peak Flow Basin D

Description

Quantity

Unit

Unit Cost

Subtotal

Total

New Basin D Construction

Major Site Work

Clear & Grub

205

AC

$1,400

$287,000

Bentonite Slurry Trench

147,000

SF

$5

$735,000

Excavation

829,156

CY

$3 $2,487,468

Embankment for Levee

136,889

CY

$3

Haul Excess Excavation

672,711

CY

$2 $1,345,422

LS

$170,000

$170,000

2,685

CY

$150

$402,750

Vertical Shaft

120

LF

$3,000

$360,000

Tunneling and Temporary Support

895

LF

$1,200 $1,074,000

New Perimeter Gravel Road

Cellular Grout for Annular Space

$410,667

Subtotal Major Site Work

$7,272,307

Structure(s)

6-Inch Concrete Slab On Grade

6-Inch Sloped Slab On Grade

Inlet Box Culvert

Outlet Control Structure

13,167

CY

$295 $3,884,265

8,148

CY

$306 $2,493,288

342

LF

$200

$68,400

LS

$190,000

$190,000

Subtotal Structure(s)

$6,635,953

Major Equipment & Piping

66-Inch Pipe

1,765

LF

$320

$564,800

66-Inch Sluice Gate

EA

$20,000

$40,000

Junction Structure

EA

$50,000

$100,000

Existing Junction Structure

LS

$1,000,000 $1,000,000

Subtotal Major Equipment & Piping

$1,704,800

Subtotal All Major Cost $15,613,060

Other Misc. Yard Piping and Utilities (5%)

$780,653

Other Site Work (0%)

$0

Other Electrical and Instrumentation (0%)

$0

Subtotal Direct Cost $16,394,000

Total Direct Cost $16,400,000

Contingencies (10%)

$1,600,000

Total Direct Cost + Contingencies $18,000,000

General Conditions (15%)

$2,700,000

Contractor OH & P (15%)

$2,700,000

Total Construction Cost $23,400,000

WWTFSP_App.F6-2.0

December 2010

Page 50 of 62

Dallas Water Utilities

Appendix E

Flow Management Alternatives and Recommendations

Detailed Cost Estimates

Table E-6: New Peak Flow Basin D and Rehabilitation of Existing Peak Flow Basins (W2)

Description

Quantity

Unit

Unit Cost

Subtotal

Total

New Basin D Construction

Major Site Work

Clear & Grub

180

AC

$1,400

$252,000

Bentonite Slurry Trench

123,000

SF

$5

$615,000

Excavation

438,748

CY

$3

$1,316,244

Embankment for Levee

115,000

CY

$3

$345,000

Haul Excess Excavation

355,891

CY

$2

$711,782

LS

$170,000

$170,000

New Perimeter Gravel Road

Subtotal Major Site Work

$3,410,026

Structure(s)

6-Inch Concrete Slab On Grade

6-Inch Sloped Slab On Grade

Inlet Box Culvert

Outlet Control Structure

13,940

CY

$295

$4,112,300

5,392

CY

$306

$1,649,952

290

LF

$200

$58,000

LS

$190,000

$190,000

Subtotal Structure(s)

$6,010,252

Major Equipment & Piping

66-Inch Sluice Gate

EA

$20,000

$40,000

Subtotal Major Equipment & Piping

$40,000

Subtotal All Major Cost

$9,460,278

Other Misc. Yard Piping and Utilities (5%)

$473,014

Other Site Work (0%)

$0

Other Electrical and Instrumentation (0%)

$0

Subtotal Direct Cost

$9,933,000

New Basin E Construction

Major Site Work

Clear & Grub

Bentonite Slurry Trench

Excavation

Embankment for Levee

Disposal of Waste

New Perimeter Gravel Road

70

AC

$1,400

$98,000

50,000

SF

$5

$250,000

403,000

CY

$3

$1,209,000

46,939

CY

$3

$140,817

403,000

CY

$100

$40,300,000

LS

$170,000

$170,000

Subtotal Major Site Work

$42,167,817

Structure(s)

6-Inch Concrete Slab On Grade

4,490

CY

$295

$1,324,550

6-Inch Sloped Slab On Grade

2,789

CY

$306

$853,434

WWTFSP_App.F6-2.0

December 2010

Page 51 of 62

Dallas Water Utilities

Appendix E

Flow Management Alternatives and Recommendations

Description

Inlet Box Culvert

Outlet Control Structure

Detailed Cost Estimates

Quantity

Unit

Unit Cost

Subtotal

290

LF

$200

$58,000

LS

$190,000

$190,000

Subtotal Structure(s)

Total

$2,425,984

Major Equipment & Piping

66-Inch Sluice Gate

EA

$20,000

$40,000

Subtotal Major Equipment & Piping

$40,000

Subtotal All Major Cost

$44,633,801

Other Misc. Yard Piping and Utilities (5%)

$2,231,690

Other Site Work (0%)

$0

Other Electrical and Instrumentation (0%)

$0

Subtotal Direct Cost

$46,865,000

Existing Basin Rehabilitation

Major Site Work

Berm Rehabilitation

LS

$1,000,000

$1,000,000

Subtotal Major Site Work

$1,000,000

Structure(s)

10-Inch Wide Concrete Settling Walls

Grouting

200

CY

$950

$190,000

2000

CY

$75

$150,000

Subtotal Structure(s)

$340,000

Major Equipment & Piping

Existing Junction Structure

WWTFSP_App.F6-2.0

LS

$2,000,000

$2,000,000

Subtotal Major Equipment & Piping

$2,000,000

Subtotal All Major Cost

$3,340,000

Other Misc. Yard Piping and Utilities (5%)

$167,000

Other Site Work (5%)

$167,000

Other Electrical and Instrumentation (0%)

$0

Subtotal Direct Cost

$3,674,000

Total Direct Cost

$60,500,000

Contingencies (10%)

$6,100,000

Total Direct Cost + Contingencies

$66,600,000

General Conditions (15%)

$10,000,000

Contractor OH & P (15%)

$10,000,000

Total Construction Cost

$86,600,000

December 2010

Page 52 of 62

Dallas Water Utilities

Appendix E

Flow Management Alternatives and Recommendations

Detailed Cost Estimates

Table E-7: Existing Peak Flow Basins No. 1, 2, 3 Rehabilitation/Improvements (W1 & W2)

Description

Quantity

Unit

Unit Cost Subtotal

Total

Existing Peak Flow Basins No. 1, 2, 3 Rehab/Improvements

Major Site Work

Demolition

89,000

SF

$8

$712,000

Excavation

130,000

CY

$3

$390,000

Haul Excess Excavation

106,000

CY

$2

$212,000

Subtotal Major Site Work

$1,314,000

Structure(s)

6-Inch Concrete Slab On Grade

1,667

CY

$295

$491,765

6-Inch Sloped Slab On Grade

267

CY

$306

$81,702

Interior Walls, 24-Inch

667

CY

$600

$400,200

LS

$100,000

$100,000

Meter Vault

Subtotal Structure(s)

$1,073,667

Major Equipment & Piping

48-Inch Pipe

WWTFSP_App.F6-2.0

590

LF

$230

$135,700

Subtotal Major Equipment & Piping

$135,700

Subtotal All Major Cost

$2,523,367

Other Misc. Yard Piping and Utilities (10%)

$252,337

Other Site Work (10%)

$378,505

Other Electrical and Instrumentation (0%)

$0

Subtotal Direct Cost

$3,154,000

Total Direct Cost

$3,200,000

Contingencies (10%)

$300,000

Total Direct Cost + Contingencies

$3,500,000

General Conditions (15%)

$500,000

Contractor OH & P (15%)

$500,000

Total Construction Cost

$4,500,000

December 2010

Page 53 of 62

Dallas Water Utilities

Appendix E

Flow Management Alternatives and Recommendations

Detailed Cost Estimates

Table E-8: New Peak Flow Basin No. 6 (W1 & W2)

Description

Quantity

Unit

Unit Cost

Subtotal

Total

New Basin No. 6 Construction

Major Site Work

Clear & Grub

200

AC

$1,400

$280,000

Dewatering

LS

$80,000

$80,000

Excavation

972,000

CY

$3

$2,916,000

Bentonite Slurry Trench

46,000

SF

$5

$230,000

Haul Excess Excavation

789,000

CY

$2

$1,578,000

LS

$190,000

$190,000

New Perimeter Gravel Road

Subtotal Major Site Work

$5,274,000

Structure(s)

6-Inch Concrete Basin Floor

12,333

CY

$295

$3,638,235

6-Inch Concrete Sloped Walls

7,667

CY

$306

$2,346,102

Solids Settling Chamber Walls

950

CY

$650

$617,500

LS

$100,000

$100,000

Meter Vault

Subtotal Structure(s)

$6,701,837

Subtotal Major Equipment & Piping

$0

Subtotal All Major Cost

$11,975,837

Other Misc. Yard Piping and Utilities (5%)

$598,792

Other Site Work (0%)

$0

Other Electrical and Instrumentation (5%)

$598,792

Subtotal Direct Cost

$13,173,000

Total Direct Cost

$13,200,000

Contingencies (10%)

$1,300,000

Total Direct Cost + Contingencies

$14,500,000

General Conditions (15%)

$2,200,000

Contractor OH & P (15%)

$2,200,000

Total Construction Cost

$18,900,000

Major Equipment & Piping

None

WWTFSP_App.F6-2.0

December 2010

Page 54 of 62

Dallas Water Utilities

Appendix E

Flow Management Alternatives and Recommendations

Detailed Cost Estimates

Table E-9: Peak Flow Pump Station (W1 & W2)

Description

Quantity

Unit

Unit Cost

Subtotal

Total

Peak Flow Pump Station

Major Site Work

Pump Station Structure

LS

$1,490,000

$1,490,000

Subtotal Major Site Work

$1,490,000

Subtotal Structure(s)

$0

Structure(s)

None

Major Equipment & Piping

75 mgd Pump Equipment

LS

$4,630,000

$4,630,000

Coarse Screening Facility

LS

$3,680,000

$3,680,000

Odor Abatement Facility

LS

$1,360,000

$1,360,000

WWTFSP_App.F6-2.0

Subtotal Major Equipment & Piping

$9,670,000

Subtotal All Major Cost

$11,160,000

Other Misc. Yard Piping and Utilities (5%)

$558,000

Other Site Work (5%)

$558,000

Other Electrical and Instrumentation (5%)

$558,000

Subtotal Direct Cost

$12,834,000

Total Direct Cost

$12,800,000

Contingencies (30%)

$3,800,000

Total Direct Cost + Contingencies

$16,600,000

General Conditions (15%)

$2,500,000

Contractor OH & P (15%)

$2,500,000

Total Construction Cost

$21,600,000

December 2010

Page 55 of 62

Dallas Water Utilities

Appendix E

Flow Management Alternatives and Recommendations

Detailed Cost Estimates

Table E-10: New Peak Flow Basin No. 7 (W1 & W2)

Description

Quantity

Unit

Unit Cost

Subtotal

Total

New Peak Flow Basin No. 7

Major Site Work

Clear & Grub

270

AC

$1,400

$378,000

LS

$100,000

$100,000

63,000

SF

$5

$315,000

Excavation

1,325,000

CY

$3

$3,975,000

Haul Excess Excavation

1,075,000

CY

$2

$2,150,000

LS

$100,000

$100,000

Dewatering

Bentonite Slurry Trench

New Perimeter Gravel Road

Subtotal Major Site Work

$7,018,000

Structure(s)

6-Inch Concrete Basin Floor

16,667

CY

$295

$4,916,765

6-Inch Concrete Sloped Walls

10,500

CY

$306

$3,213,000

Subtotal Structure(s)

$8,129,765

Major Equipment & Piping

48-Inch Sluice Gate

WWTFSP_App.F6-2.0

EA

$15,000

$30,000

Subtotal Major Equipment & Piping

$30,000

Subtotal All Major Cost

$15,177,765

Other Misc. Yard Piping and Utilities (5%)

$758,888

Other Site Work (5%)

$758,888

Other Electrical and Instrumentation (5%)

$0

Subtotal Direct Cost

$16,696,000

Total Direct Cost

$16,700,000

Contingencies (10%)

$1,700,000

Total Direct Cost + Contingencies

$18,400,000

General Conditions (15%)

$2,800,000

Contractor OH & P (15%)

$2,800,000

Total Construction Cost

$24,000,000

December 2010

Page 56 of 62

Dallas Water Utilities

Appendix E

Flow Management Alternatives and Recommendations

Detailed Cost Estimates

Table E-11: IPS Interconnect (W1 & W2)

Description

Quantity

Unit

Unit Cost

Subtotal

Total

IPS Interconnect

Major Site Work

Dewatering

2800

LF

$150

$420,000

Temporary Trench Support

2800

LF

$240

$672,000

Trenching and Backfill

2800

LF

$480

$1,344,000

Subtotal Major Site Work

$2,436,000

Structure(s)

Junction Structure

LS

$200,000

$200,000

Subtotal Structure(s)

$200,000

Major Equipment & Piping

96-Inch Pipe

96-Inch Sluice Gate

WWTFSP_App.F6-2.0

2800

LF

$460

$1,288,000

EA

$30,000

$30,000

Subtotal Major Equipment & Piping

$1,318,000

Subtotal All Major Cost

$3,954,000

Other Misc. Yard Piping and Utilities (10%)

$395,400

Other Site Work (10%)

$395,400

Other Electrical and Instrumentation (0%)

$0

Subtotal Direct Cost

$4,745,000

Total Direct Cost

$4,700,000

Contingencies (30%)

$1,400,000

Total Direct Cost + Contingencies

$6,100,000

General Conditions (15%)

$900,000

Contractor OH & P (15%)

$900,000

Total Construction Cost

$7,900,000

December 2010

Page 57 of 62

Dallas Water Utilities

Appendix E

Flow Management Alternatives and Recommendations

Detailed Cost Estimates

Table E-12: Stage 2 IPS Improvements (W1 & W2)

Description

Quantity

Unit

Unit Cost

Subtotal

Total

Stage 2 IPS Improvements

Major Site Work

Dewatering

3,700

LF

$75

$277,500

Temporary Trench Support

3,700

LF

$120

$444,000

Trenching and Backfill

3,700

LF

$240

$888,000

Subtotal Major Site Work

$1,609,500

Structure(s)

Junction Structures

EA

$250,000

$750,000

Subtotal Structure(s)

$750,000

Major Equipment & Piping

72-Inch Pipe

3,700

LF

$345

$1,276,500

72-Inch Sluice Gate

EA

$23,000

$23,000

VTSH Pumps (50 mgd)

EA

$1,300,000

$2,600,000

Screen (150 mgd)

EA

$630,000

$630,000

WWTFSP_App.F6-2.0

Subtotal Major Equipment & Piping

$4,529,500

Subtotal All Major Cost