Professional Documents

Culture Documents

Aoa 737ngx Groundwork Fire Protection English Transcript

Uploaded by

lcesardiasCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aoa 737ngx Groundwork Fire Protection English Transcript

Uploaded by

lcesardiasCopyright:

Available Formats

Nick Collett | 2011

PMDG 737NGX GroundWork FIRE PROTECTION

Fire Protection

Lesson Introduction

This lesson will cover the following topics:

o A brief overview of the fire protection systems on the 737NG,

o Engine overheat detection,

o Engine fire detection and extinguishing,

o APU fire detection and extinguishing,

o Wheel well fire detection,

o Engine/APU/wheel well fire protection systems tests.

o Cargo compartment smoke detection and fire extinguishing,

o The cargo compartment fire protection system test,

o Lesson summary.

Fire Protection Overview

The 737NG has fire detection and extinguishing systems for the:

o Engines,

o APU,

o Cargo compartments

o Lavatories.

The main gear wheel well also has a fire detection system, but no fire extinguishing

capability.

As well as fire detection and extinguishing systems, the engines also have overheat

detection capability.

The various fire detection and extinguishing systems have a clear purpose to combat one

of the most dangerous threats to safety in the air fire.

We will run through these systems one by one, but first lets give a brief overview of the

locations of the controls and indications for the various systems that well be covering in

this lesson.

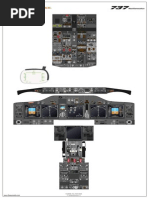

o The Master Fire Warning lights are located on the glareshield.

o Controls and indications for the engine overheat, fire detection and extinguishing

systems are located on the overheat/fire protection panel.

o The APU fire detection and extinguishing system controls and indications are also

located here, as well as the Wheel Well Fire Warning light.

o The Cargo Fire Panel, also located on the aft electronic panel, houses controls and

indications for the cargo fire detection and extinguishing system.

The lavatories have smoke detection and fire extinguishing systems installed.

o The lavatory fire extinguishers trigger automatically when a fire is detected, and the

Page 1

Nick Collett | 2011

flight deck has no indication of extinguisher discharge.

o Some 737s have a LAVATORY SMOKE light on the forward overhead panel.

This is a customer option, and ours does not.

Engine Overheat and Fire Detection/Extinguishing Systems

Engine Overheat Detection

Each engine has two overheat/fire detector loops.

Each engine has eight overheat/fire detectors located in pairs monitoring four different

sections of the engine:

o Upper fan case,

o Lower fan case,

o Left core section,

o Right core section.

Each pair of detectors consists of one detector from loop A, and one detector from loop B.

o Each of these loops provides both fire and overheat detection.

o There are predetermined temperature thresholds for engine OVERHEAT and engine

FIRE conditions.

o When the temperature of a detector reaches the OVERHEAT threshold, it will signal

an OVERHEAT condition.

o If the temperature increases further to the FIRE threshold, the detector will signal a

FIRE condition.

Each detector has a sealed stainless steel sense tube filled with inert gas.

o As the temperature around the tube increases, the gas expands.

o Expansion of the gas increases the pressure in the tube, which is sensed by three

pressure switches.

o Each of the pressure switches trips at different pressure thresholds.

The FAULT pressure switch is normally held closed by gas pressure in the

tube.

If a leak occurs and pressure drops, the switch opens triggering a

FAULT condition.

The OVHT and FIRE pressure switches are calibrated to trip closed at

pressures which correspond to the temperature thresholds we mentioned

earlier.

o If temperatures reduce again and the gas pressure in the tube reduces to normal,

the OVHT and FIRE switches will open again and the overheat or fire conditions will

be reset.

The two separate detector loops in each engine are installed for redundancy.

It is possible to manually select either of the two loops in each engine to be the active

detecting loop.

o This is achieved using the two OVHT DET switches on the Overheat/Fire Protection

Panel.

Page 2

Nick Collett | 2011

o There are two switches, one for each engine.

o Each switch has three positions:

The A and B positions select loops A or B individually to be the sole detecting

loop for that engine.

With the switch in the NORMAL position, BOTH loops must sense an

overheat or fire condition before a warning is activated.

The NORMAL position also provides redundancy if the NORMAL position is

selected and one loop fails, it is automatically deselected and the remaining

loop remains active as the single detector loop.

For this reason, standard procedure is to use the NORMAL position.

o A detector loop failure may be indicated by the illumination of the FAULT light on

the Overheat/Fire Protection Panel.

Whether or not the fault is actually indicated however depends on the

position of the OVHT DET switches.

If the switches are in the NORMAL position and one of the loops on either

engine fails, there will be NO indication of the failure.

If a failed loop is manually selected using either of the OVHT DET switches,

the FAULT light will illuminate indicating failure of that loop.

If the switch is in NORMAL and BOTH loops for an engine fail, the fault light

will illuminate.

To summarize - the FAULT light will only illuminate if a failed loop has been

manually selected using one of the OVHT DET switches, OR if BOTH loops

have failed.

If an overheat condition is detected on the selected loop, or on BOTH loops if the OVHT DET

switch is in the NORMAL position, the corresponding ENG OVERHEAT light will illuminate.

o There are two ENG OVERHEAT lights, one for each engine.

In the event of an overheat condition in either engine, the following will occur:

o The corresponding ENG OVERHEAT light illuminates.

o Both MASTER CAUTION lights illuminate,

o The OVHT/DET system annunciator light illuminates.

Engine Fire Detection

Weve already covered the two detector loops present in each engine.

o When the detectors sense a temperature higher than the overheat threshold, they

trigger an overheat warning.

o If temperatures continue to rise above a further threshold, a fire warning is

triggered.

o Bear in mind that these are the same detector loops covered earlier when talking

about the engine overheat detection.

Everything we said about the OVHT DET switches and the FAULT light still

stands.

In the event of a fire condition in either engine, the following will occur:

Page 3

Nick Collett | 2011

o

o

o

o

The fire warning bell sounds,

Both master FIRE WARN lights on the glareshield illuminate,

The corresponding engine fire switch illuminates,

The relevant ENG OVERHEAT light illuminates.

Engine Fire Extinguishing

The engine fire extinguishing system has two fire bottles, located together in the aft left

corner of the main gear wheel well.

o Each individual bottle is capable of discharging into either of the two engines.

o Each bottle contains Halon 1301 gas that is discharged through three ports in the

engine.

o Once discharged, the Halon dissipates quickly, so bear in mind that this is NOT a fire

suppression system. It is purely for extinguishing an existing fire.

o There are two squibs per fire bottle.

The squibs are small, electrically actuated explosive devices that break the

diaphragm seals on the bottle.

The Halon gas is then expelled from the bottle by pressurized nitrogen at an

initial discharge pressure of 800psi.

The #1 squib on each bottle directs halon to engine 1.

The #2 squib on each bottle directs halon to engine 2.

o It is therefore the squibs which determine which engine the bottle discharges to.

There are two red engine fire switches on the Overheat/Fire Protection Panel. These are

used to discharge the fire bottles.

Before the bottles can be discharged however, the handle must be pulled up.

o There is a locking mechanism that prevents the handle from being pulled up

inadvertently.

o The locking mechanism is automatically released when an overheat or fire condition

is detected.

o It is possible to override it manually by pushing the switch beneath the handle.

Pulling out an engine fire handle does the following for the corresponding engine:

o Trips off the engine Generator,

o Disables thrust Reverser,

o Arms the squib on each fire bottle corresponding to that engine,

o Closes the engine Bleed valve (PRSOV),

o Deactivates the related EDP LOW PRESSURE light,

o Closes Fuel and Hydraulic valves.

o Acronym: GRAB Da Fire Handle.

o Pulling out the fire handle allows it to then be rotated either clockwise or anticlockwise.

The direction of rotation of the handle determines which bottle is discharged into that

engine.

o Turning the handle to the left will discharge the left bottle into the engine.

Page 4

Nick Collett | 2011

o Turning the handle to the right will discharge the right bottle into the engine.

o This is the case for both of the engine fire handles.

o When a bottle is discharged, the bottle pressure reduces.

When pressure drops below 250 psi, the corresponding BOTTLE DISCHARGE

light illuminates.

o The engine fire switch will remain illuminated red until the detector temperature

has dropped below the fire condition threshold.

Its worth noting that the extinguishers are powered by the hot battery bus, meaning that

they can be activated regardless of the position of the BAT switch on the forward overhead

panel.

The detection systems are powered by the battery bus however, so the BAT switch must be

selected ON for the detection systems to function.

APU Fire Detection/Extinguishing Systems

APU Fire Detection

The APU does not announce an overheat condition in the same way as the engines do. This

is a fire detection system only.

APU overtemperature will trigger a protective shutdown and the FAULT light on the

Forward Overhead Panel.

APU fire detection is provided by a single detection loop.

The APU fire detection loop has three detectors:

o Upper APU compartment,

o APU compartment door,

o Tailpipe.

When a detector temperature increases above a predetermined threshold, it senses and

announces a fire condition.

APU Detector loop failure is indicated by the illumination of the APU DET INOP light on the

Overheat/Fire Protection Panel.

The APU fire detectors are of a type similar to those used in the engines.

o As temperature rises, the pressure of the inert gas in the sense tube increases,

tripping a pressure switch which supplies a FIRE signal.

o There is also a FAULT pressure switch which opens when pressure drops below

normal, triggering a FAULT condition.

In the event of a fire condition in the APU, the following will occur:

o The fire warning bell sounds,

o Both master FIRE WARN lights on the glareshield illuminate,

o The APU fire switch illuminates,

o The FAULT light on the APU panel illuminates, triggering a master caution and the

APU system annunciator light.

Additionally, a warning horn in the main gear wheel well sounds, and a collocated warning

light flashes.

Page 5

Nick Collett | 2011

o There is actually a means of discharging the APU fire bottle from down there in the

wheel well, using the APU Ground Control Panel.

The APU is shut down automatically when a fire is detected. Extinguishing the fire still needs

to be commanded manually however.

APU Fire Extinguishing

The APU has its own fire bottle, also containing Halon 1301.

The APU fire bottle is located in the horizontal stabilizer accessory compartment.

It has a single squib that breaks the diaphragm seal on the bottle and discharges the Halon

into the APU compartment.

There is an APU fire switch on the Overheat/Fire Protection Panel that functions similarly to

the two engine fire switches.

It is locked down until the APU fire detector loop senses a fire condition.

Like the engine fire switches the lock can be overridden by pushing the switch beneath the

handle.

Pulling out the APU fire handle does the following:

o Trips off the APU Generator,

o Arms the APU fire bottle squib,

o Closes the APU Bleed valve,

o Closes the APU Fuel shutoff valve,

o Closes the APU air Inlet door.

o Acronym: GABFI.

o Like the engine fire handles, the APU fire handle can then be rotated to discharge

the bottle.

The APU fire switch can be rotated in either direction, but as there is only one bottle with

only one squib, it makes no difference which direction you rotate it.

That said, its best to rotate the switch to the right so that the annunciator lights are still

visible from the first officers perspective.

When the bottle is discharged and pressure reduces below 250 psi, the APU BOTTLE

DISCHARGE light illuminates.

The APU fire switch will remain illuminated red until the detector temperature has dropped

below the fire condition threshold.

Similarly to the engine fire extinguishing system, APU extinguishing is powered by the hot

battery bus.

o The detection system is powered by the battery bus.

Wheel Well Fire Detection System

The main landing gear wheel well has a fire detection system. There is NO fire extinguishing

system.

The nose landing gear wheel well has neither a fire detection system NOR a fire

extinguishing system.

Page 6

Nick Collett | 2011

There is a single overheat sensing element mounted on the ceiling of the main gear wheel

well.

o The element is a thermistor type where resistance varies inversely proportional to

temperature.

o This means that an increase in temperature results in a decrease in resistance.

o This reduction in resistance allows a current to pass through the element, triggering

a fire alert.

o The resistance is low enough to permit passage of current at and above

approximately 205 Celsius, so this is the fire warning threshold for the wheel well.

In the event of a fire condition in the wheel well, the following will occur:

o The fire warning bell sounds,

o Both master FIRE WARN lights illuminate,

o The WHEEL WELL fire warning light illuminates on the Overheat/Fire Protection

Panel.

There is no indication of a wheel well detector loop failure.

Fire detection for the wheel well is powered by AC Transfer Bus 2.

Engine/APU/Wheel Well Fire Protection Systems Tests

FAULT/INOP Test

The FAULT/INOP test is initiated by holding the FAULT/INOP and OVHT/FIRE TEST switch to

the FAULT/INOP position.

o This is a spring loaded switch, so it must be held in position to carry out the test.

This carries out a test of the of the engine and APU fault detection circuits.

Faults are simulated to check the circuits ability to detect a fault.

A successful test of the detection circuitry should flag up the following indications:

o Both MASTER CAUTION lights on the glareshield illuminate,

o The OVHT/DET system annunciator light on the glareshield illuminates,

o The FAULT and APU DET INOP lights on the Overheat/Fire Detection Panel

illuminate.

o That gives 5 yellow lights in total for the FAULT/INOP test.

OVHT/FIRE Test

The OVHT/FIRE test is initiated by holding the FAULT/INOP and OVHT/FIRE TEST switch to

the OVHT/FIRE position.

o This is a spring loaded switch, so you need to hold it in position to carry out the test.

When the switch is released and centered, the test stops and the indications

extinguish.

The OVHT/FIRE test is a test of the overheat and fire detection loops on the engines, the

APU and the wheel well.

A successful test of the fire detection loops should flag up the following indications:

Page 7

Nick Collett | 2011

o The fire warning bell sounds,

o Both master FIRE WARN lights illuminate,

o Both MASTER CAUTION lights illuminate,

o The OVHT/DET system annunciator light illuminates,

o Both engine fire switches illuminate,

o The APU fire switch illuminates,

o Both ENG OVERHEAT lights illuminate,

o The WHEEL WELL fire warning light illuminates,

o That gives 11 lights in total (a combination of red and yellow) and the bell.

Additionally to the indications on the flight deck, the OVHT/FIRE test also activates the APU

fire warning horn and a flashing light in the wheel well.

We mentioned earlier when we were talking about the wheel well fire detection system

that it is powered by AC Transfer Bus 2.

o In contrary, all of the systems tested by the OVHT/FIRE test are powered either by

the Hot Battery Bus or the Battery Bus, so will indicate correctly even without AC

Power.

o The WHEEL WELL light is the exception, so will not illuminate if AC Transfer Bus 2 is

not powered.

Extinguisher Test

The extinguisher test is initiated by holding the EXT TEST switch to the 1 or 2 positions.

For a test of the complete system, both positions should be checked.

o This switch is spring loaded, so needs to be held in position to confirm the results of

the test.

We discussed earlier that fire bottle discharge is achieved by the firing of a squib which

punctures the diaphragm seal on the bottle and frees the contents.

The extinguisher test is a test of the circuit continuity between the engine and APU fire

switches and the squibs on the fire bottles.

Moving the EXT TEST switch to the 1 position tests the #1 squib on each engine fire bottle,

and the squib on the APU fire bottle.

Moving the EXT TEST switch to the 2 position tests the #2 squib on each engine fire bottle,

and the squib on the APU fire bottle.

There is only one APU fire bottle, and that bottle only has one squib, so the switch tests the

same squib in both positions.

Three green lights indicate healthy squib circuitry.

Mid-Lesson Summary

So far in this lesson weve covered:

o Engine overheat detection,

o Engine fire detection,

o Engine fire extinguishing,

Page 8

Nick Collett | 2011

o APU fire detection,

o APU fire extinguishing,

o Wheel well fire detection.

Under system tests we covered:

o FAULT/INOP test,

o OVHT/FIRE test,

o Extinguisher test.

Later in this lesson we will cover:

o Cargo compartment smoke detection,

o Cargo compartment fire extinguishing,

o Cargo compartment fire protection system test,

o Lesson summary.

Cargo Compartment Smoke Detection/Fire Extinguishing Systems

System Overview

The 737 has two cargo compartments forward and aft.

Both holds are sealed and pressurized but have no fresh air circulation or temperature

control.

Some heating is provided by cabin air exhausted around their walls.

Cargo compartment smoke detection and fire extinguishing systems are installed for both

cargo compartments.

o Like the engine and APU fire bottles, the cargo compartment bottles use Halon

1301.

Cargo Compartment Smoke Detection

Cargo compartment fire warnings are triggered by smoke detectors in each compartment.

o The forward cargo compartment has four smoke detectors two in loop A and two

in loop B.

o The aft cargo compartment has six smoke detectors three in loop A and three in

loop B.

It is possible to manually select either of the two loops to be the active detector loop in

each cargo compartment.

o This is achieved using the two DET SELECT switches on the Cargo Fire Panel.

o There are two switches; one each for the FWD and AFT cargo compartments

respectively.

o With either A or B selected, the system acts as a single loop system, and a fire alert

will be activated only when a detector from the selected loop detects smoke.

o With the NORM position selected, a detector from loop A and a detector from loop

B must detect smoke to trigger an alarm.

o The NORM position also provides redundancy if the NORMAL position is selected

Page 9

Nick Collett | 2011

and one loop loses power, it is automatically deselected and the remaining loop

remains active as the single loop.

A detector loop failure may be indicated by the illumination of the DETECTOR FAULT light

on the Cargo Fire Panel.

o Similarly to the engine detector FAULT light, whether or not the light illuminates

depends on which loop is selected by the DET SELECT switches.

o The DETECTOR FAULT light indicates that at least ONE of the SELECTED loops has

failed in either compartment.

o If one loop has failed for instance, but the still functioning loop has been selected

with the DET SELECT switches, the DETECTOR FAULT light would not illuminate.

o With the DET SELECT switches in the NORM position, an illuminated DETECTOR

FAULT light indicates that both loops in either cargo compartment have failed.

The smoke detectors use photoelectric cells to detect smoke.

o They send an alarm signal when smoke is detected or if air temperature rises above

110 Celsius.

In the event of a smoke or overheat condition in either cargo compartment, the following

will occur:

o The fire warning bell sounds,

o Both master FIRE WARN lights illuminate on the glareshield,

o The FWD and/or AFT cargo fire warning light(s) illuminate on the Cargo Fire Panel.

Either of these lights can illuminate individually to indicate a fire in a single

specific cargo compartment.

A smoke or overheat condition in either of the cargo compartments also triggers the cabin

pressure control system to gradually reduce cabin altitude at 750fpm.

o This ensures that during a subsequent emergency descent the cabin is always overpressurized to prevent smoke from entering the cabin.

Cargo Compartment Fire Extinguishing

The cargo compartments on a standard passenger configuration 737 are classified as Class

C.

The installed fire suppression system needs to be capable of providing:

o A minimum initial 5% Halon concentration throughout the compartment after bottle

discharge to suppress any fire to controllable levels,

o A minimum 3% Halon concentration throughout the compartment for 60 minutes

thereafter to prevent re-ignition or spreading of the fire.

Our aircraft is certified to ETOPS-180, so to meet certification requirements a second bottle

is installed giving an additional 120 minutes of protection, for 180 minutes total.

The two cargo compartment fire bottles are installed in the air conditioning mix bay on the

forward wing spar.

Like the engine and APU fire bottles, these contain Halon 1301 which is expelled by

pressurized nitrogen through a diaphragm seal punctured by a squib.

There are two discharge nozzles in the forward cargo compartment, and three discharge

Page 10

Nick Collett | 2011

nozzles in the aft cargo compartment.

The bottles are discharged one by one, and can be discharged into either cargo

compartment.

o The first bottle is discharged in its entirety at a high rate to suppress any fire to

controllable levels and provide that 3% Halon concentration for 60 minutes.

o A timer is then started, and after 60 minutes the second bottle is discharged

automatically.

o The second bottle is discharged at a metered, reduced flow rate to continue the 3%

Halon concentration for a further 120 minutes.

o Discharge of the second bottle can be disabled by disarming the system.

o If the aircraft lands after the first bottle has been discharged, but the second bottle

is still armed for discharge, discharge of the second bottle is inhibited automatically.

o Opening the affected cargo compartments door after landing will cause the Halon

suppressant to disperse, so the fire may erupt again.

The door must therefore not be opened until fire crews are ready to combat

the fire.

There are two Cargo Fire ARM switches on the Cargo Fire Panel which arm the system for

discharge into the forward or aft compartments respectively.

o These switches are used to select the compartment that the bottles will be

discharged into.

Once the desired compartment has been selected, the guarded Cargo Fire Bottle DISCH

switch is used to discharge the bottles into that compartment per the scheduling we just

explained.

o Once discharge has occurred, the DISCH light illuminates on the switch.

Again, this is triggered by a pressure switch once pressure drops below 250

psi.

Cargo compartment smoke and overheat detection is powered by DC Bus 1 and DC Bus 2.

Cargo compartment fire extinguishing is powered by the hot battery bus.

Cargo Compartment Fire Protection System Test

There is a single TEST button on the Cargo Fire Panel.

Pushing this initiates a test of the detector loops and squib circuits.

A successful test of the detector loops and squib circuits should flag up the following

indications:

o The fire warning bell sounds,

o Both master FIRE WARN lights illuminate,

o The FWD and AFT extinguisher test lights illuminate,

o The FWD and AFT cargo fire warning lights illuminate,

o The cargo fire bottle DISCH light illuminates,

If any of the detectors in the selected detector loops have failed, the DECTECTOR FAULT

light will illuminate during the cargo fire test.

o The DETECTOR FAULT light should not illuminate during a successful test.

Page 11

Nick Collett | 2011

The two extinguisher test lights should illuminate green during the cargo fire test to indicate

that the circuits to the bottle squibs are functional.

Lesson Summary

A comfortable and comprehensive understanding of the fire protection systems on your

aircraft is vital.

In the event of a fire of any kind, the onus is on the crew to act decisively and safely

Workload increases dramatically, which is when background knowledge easily recallable to

mind comes into play.

In this lesson, weve covered:

o A brief overview of the fire protection systems on the 737NG,

o Engine overheat detection,

o Engine fire detection and extinguishing,

o APU fire detection and extinguishing,

o Wheel well fire detection,

o Engine/APU/wheel well fire protection systems tests.

o Cargo compartment smoke detection and fire extinguishing,

o The cargo compartment fire protection system test.

Page 12

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Online Brokerage Access AgreementDocument13 pagesOnline Brokerage Access AgreementlcesardiasNo ratings yet

- Aoa 737ngx PMDG Options English TranscriptDocument14 pagesAoa 737ngx PMDG Options English Transcriptvrcatc884No ratings yet

- Transfers LaDocument22 pagesTransfers LalcesardiasNo ratings yet

- Transfers LaDocument22 pagesTransfers LalcesardiasNo ratings yet

- 737 800/900 OVERHEAD PANEL: Does Not Represent Actual Flight Conditions For Simulation Purposes OnlyDocument1 page737 800/900 OVERHEAD PANEL: Does Not Represent Actual Flight Conditions For Simulation Purposes Onlylcesardias100% (1)

- 1LSEC18-100238 CoverageLetterDocument1 page1LSEC18-100238 CoverageLetterlcesardiasNo ratings yet

- Cessna 152 POHDocument135 pagesCessna 152 POHChris GilbertNo ratings yet

- Piper PA44 180 POH PDFDocument354 pagesPiper PA44 180 POH PDFJayson FowlerNo ratings yet

- Learning Statement Reference GuideDocument24 pagesLearning Statement Reference GuideMessala YoveraNo ratings yet

- Ia14 iA14S: Instruction ManualDocument44 pagesIa14 iA14S: Instruction ManuallcesardiasNo ratings yet

- PA44 Manual 1979 1980Document277 pagesPA44 Manual 1979 1980smedleyburlap100% (1)

- HGSDocument1 pageHGSlcesardiasNo ratings yet

- PA44 Manual 1979 1980Document277 pagesPA44 Manual 1979 1980smedleyburlap100% (1)

- Multi-Engine Guide Piper SeminoleDocument94 pagesMulti-Engine Guide Piper SeminoleCelin Concha Araneda100% (2)

- 195 - Using PostgreSQL For Flight Planning PDFDocument58 pages195 - Using PostgreSQL For Flight Planning PDFlcesardiasNo ratings yet

- 737NGX AOA GroundWork Study GuideDocument35 pages737NGX AOA GroundWork Study GuideakifilouNo ratings yet

- Normal Checklist EssentialsDocument3 pagesNormal Checklist Essentialsvrcatc884No ratings yet

- Full CockpitDocument1 pageFull CockpitAndré Pacheco100% (1)

- Center PedestalDocument1 pageCenter PedestallcesardiasNo ratings yet

- 737NGX AOA GroundWork Study GuideDocument35 pages737NGX AOA GroundWork Study GuideakifilouNo ratings yet

- Frequencies: Procedure/Date Flightno/LessonDocument1 pageFrequencies: Procedure/Date Flightno/LessonlcesardiasNo ratings yet

- 737 800/900 Forward Panel: FD FDDocument1 page737 800/900 Forward Panel: FD FDlcesardiasNo ratings yet

- 737NGX AOA GroundWork Study GuideDocument35 pages737NGX AOA GroundWork Study GuideakifilouNo ratings yet

- Aoa 737ngx Groundwork Gear Brakes HandoutDocument15 pagesAoa 737ngx Groundwork Gear Brakes HandoutlcesardiasNo ratings yet

- Aoa 737ngx Groundwork Gear Brakes HandoutDocument15 pagesAoa 737ngx Groundwork Gear Brakes HandoutlcesardiasNo ratings yet

- Aoa 737ngx Linework Flows Approaching RunwayDocument2 pagesAoa 737ngx Linework Flows Approaching RunwaylcesardiasNo ratings yet

- Aoa 737ngx Linework Flows After StartDocument2 pagesAoa 737ngx Linework Flows After StartlcesardiasNo ratings yet

- AOM 1502 017 Rev.04 - Apr 30 10Document2,220 pagesAOM 1502 017 Rev.04 - Apr 30 10AIRBUS320100% (2)

- Radiotelephony Manual 2013Document266 pagesRadiotelephony Manual 2013Hector CarbajalNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Imp 4Document38 pagesImp 4nikhilNo ratings yet

- Upem Ch-22Document9 pagesUpem Ch-22siddharthsrathor04No ratings yet

- Plate Tectonic UnitDocument95 pagesPlate Tectonic Unitapi-227272561No ratings yet

- Structural Design For ArchitectureDocument274 pagesStructural Design For Architecturedamocca100% (13)

- Extraction in Chemical Technology PrincipleDocument24 pagesExtraction in Chemical Technology PrincipleFatima ZaharaNo ratings yet

- William Tell LiteracyDocument29 pagesWilliam Tell LiteracyAndrés Romero SeguraNo ratings yet

- Aits 2223 FT Vi Jeem OfflineDocument15 pagesAits 2223 FT Vi Jeem OfflineSuvrajyoti TaraphdarNo ratings yet

- Sual Power Station: Philippines' Largest Coal-Fired PlantDocument7 pagesSual Power Station: Philippines' Largest Coal-Fired PlantscaffmasterNo ratings yet

- CDI Spark 2530 Datasheet En-PDocument2 pagesCDI Spark 2530 Datasheet En-PKristianto Mathers IIINo ratings yet

- The Study Through Models of Reinforced Concrete Beams Failing in Shear PDFDocument96 pagesThe Study Through Models of Reinforced Concrete Beams Failing in Shear PDFMuhammadWazimAkramNo ratings yet

- Mullion AnalysisDocument4 pagesMullion AnalysisganeshNo ratings yet

- M A I N T e N A N C e M A N U A L F o R La B o R at o R y e Q U I P M e N TDocument77 pagesM A I N T e N A N C e M A N U A L F o R La B o R at o R y e Q U I P M e N TBMTNo ratings yet

- Electric Field and Coulomb's LawDocument19 pagesElectric Field and Coulomb's LawYukiko HachiNo ratings yet

- Brightness Color MeterDocument4 pagesBrightness Color MeterkmacleonNo ratings yet

- 0053 Dynamics of Commodity Forward CurvesDocument25 pages0053 Dynamics of Commodity Forward Curvesamitnp7373No ratings yet

- GS1 AnsDocument3 pagesGS1 AnsGiemhel GeleraNo ratings yet

- Research Paper in MicrowavesDocument10 pagesResearch Paper in MicrowavesManoling PanopioNo ratings yet

- Digital Booklet - Re-AnimatorDocument21 pagesDigital Booklet - Re-AnimatorMoz77No ratings yet

- MM1080 Ie 3Document3 pagesMM1080 Ie 3Paul RuckNo ratings yet

- Water Control Procedures and Chemical TreatmentsDocument16 pagesWater Control Procedures and Chemical TreatmentsDarko DuiloNo ratings yet

- ADS Layout ManualDocument343 pagesADS Layout Manualravi100% (5)

- Caustic Stress Corrosion Cracking of A Graphite Cast Iron ComponentDocument8 pagesCaustic Stress Corrosion Cracking of A Graphite Cast Iron Componentriza9847No ratings yet

- 2A016 Install Rev1972 1965Document40 pages2A016 Install Rev1972 1965Rich McDonaldNo ratings yet

- CLMD4A Science8Document39 pagesCLMD4A Science8GreyNo ratings yet

- Electrostatic ForceDocument3 pagesElectrostatic ForceAlyssa Cole100% (1)

- NB,.NB LHGJK JLHKDocument1 pageNB,.NB LHGJK JLHKPatrícia MouraNo ratings yet

- Bernoulli's PrincipleDocument15 pagesBernoulli's PrincipleDedy KristiantoNo ratings yet

- Part Description AD500-9 TO Order # 3001380: First Sensor APD Data SheetDocument3 pagesPart Description AD500-9 TO Order # 3001380: First Sensor APD Data SheetAnish KumarNo ratings yet

- Ion Exchange ChromatographyDocument3 pagesIon Exchange ChromatographysherfudeenNo ratings yet

- 2nd Mid Assingnment QuestionsDocument3 pages2nd Mid Assingnment QuestionsSatya TejaNo ratings yet