Professional Documents

Culture Documents

Thermal Values Within Tensile Fabric Structures

Uploaded by

Collin NguCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thermal Values Within Tensile Fabric Structures

Uploaded by

Collin NguCopyright:

Available Formats

Thermal Values within Tensile Fabric Structures

Products

News

Services

FAQ

Contact Us

Jobs

Blog

FEBRUARY 11, 2015

Thermal Values within Tensile Fabric

Structures

Thermal values within Tensile Fabric Structures have not

historically caused architects or tensile engineers too many

problems. However, with tensile fabric buildings becoming more

and more popular due to their cost savings and the design

freedom which they offer, such fabric structures are increasingly

being used within architecture where Thermal Values are proving

to be problematic.

UK (Group

Head office)

USA (North

America)

more stories

New Interior Tensile

Tweets

by @AirsculptLimite

Membrane

Project

Coordinator

Thermal Values, also known as U-Values, covered

by Part L of

Airsculpt

the Design and Build Regulation had a massive upgrade in 2013;

C/O Sattler

however, tweaks and upgrades are continuingly coming

North

throughespecially within commercial buildings

whereAmerica

Tensile Fabric Structures are predominantly being used.

Airsculpt Ltd

Suite 20,

Bowman

Corp

With commercial

buildings roof U-Values currently

being

aimed880at

+1

(844)

Court,

0.2W/m2k, traditional Tensile Fabric Buildings are struggling to

9900

meet suchWhitehill

ecological thermal values. A single membrane layer of

1200gm

info@airsculpt.com

PVC orPTFE/glass weighing in at around

per meter

Lane,

Royal

square has a U-Value of approximately 4.4W/m2k. With this in

mind we can quickly see that such a PVC or PTFE fabric

Wootton

membrane building offers a similar U-Value

to that of glass. If we

Germany

then add aBassett

second internal membrane layer, also known as a

Airsculpt

double skin and, create an air gap of 200mm, it will

reduce the Ltd

U

Wiltshire

Value down

to around 2.6W/m2k, without reducing

C/O

the fabrics

CENO-Tec

translucency benefits. But this still doesnt

achieve

help us+49

(0)a 2571

SN4

7DB

thermal value or U-Value which Part L of the Design and Building

9690

Regulations can and does ask for on certain commercial

01249

mail@sattlerbuildings.

http://www.airsculpt.com/latest-news/thermal-values-within-tensile-fabric-structures/[1/6/2016 5:18:23 PM]

Interactive Stadium

Facades

Frank Molter Joins the

Ranks of Airsculpt

Thermal Values within Tensile Fabric Structures

848649

0844 8111382

With more and more architects wishing to push the boundaries of

form

info@airsculpt.com

design,

and function within their craft, Tensile Fabric

global.com

Use of Tensile Fabric Construction within Modern

Architecture

Architecture is increasingly being used to help realise the

architects vision. And why shouldnt it, after all membrane

structures can last upwards of 30-years Just as long as most

traditional forms of roofing structure. Additionally, with

Copyright AirSculpt 2014 - All Rights Reserved | Web Design by Imagine

advancements in fabric technology this longevity is set to

increase significantly. Add this to the free flowing clear span

design function which only tensile engineering can offer and you

soon see why Fabric Architecture is helping architects design

the future.

A current and emerging trend we are seeing at Airsculpt is the

amalgamation of traditional construction and tensile construction.

This is allowing architects to develop some truly amazing,

practical and cost efficient design solutions. However, this trend

in design is highlighting the potential conflict with Fabric

Architecture whilst achieving the ever lowering Thermal Values.

What Affects Thermal Values within Tensile Fabric

Buildings?

We could write an entire book trying to answer this, what seems to

be a relatively simple question; however, the best way of

answering this is with another question..what is the

building to be used for?

For instance, if you want to have a tensile fabric structure to cover

and protect goods or property, such as a Temporary Fabric

Warehouse, U-Values dont really come into it, unless you need

to keep the goods at a certain temperature that is. However, if

you add an office area or toilets within the tensile fabric building,

it dramatically changes not only the Thermal Value / U-Value

regulation requirements but also the planning regulations. A good

example to demonstrate this on would be a fabric building such

as a Tensile Fabric Sports Hall. If the Fabric Sports Hall

contained nothing but Tennis, Badminton or Basketball courts

etc., all you need to think about how to keep the temperature

even throughout the year. Add ventilation together with a form of

heating matrix and youve practically sorted this out with M&E

(Mechanical and Electrical). However, add changing room

facilities with showers and toilets and suddenly the structure is

then deemed as a permanent building. In such instances your UValue requirements would drop to that of around 0.2W/m2k which

falls in line with the same U-Values / thermal values which are

found with traditional permanent steel and brick forms of

commercial buildings.

http://www.airsculpt.com/latest-news/thermal-values-within-tensile-fabric-structures/[1/6/2016 5:18:23 PM]

Thermal Values within Tensile Fabric Structures

How to Lower U-Values within Tensile Structures

One way is by suspending a quilted insulation layer such as

Rockwool between the air gaps which have been created by

adding an internal membrane. With such an approach you could

potentially get U-Values down to meet practically any building

regulation requirements. However, with this approach you would

need to use an extremely dense insulation layer, resulting in the

loss of natural lighting benefits which translucent tensile fabric

buildings offer. Quilted insulation layers therefore only offer part

of the solution to meet the ever lowering U-Values within modern

Building Regulations.

At Airsculpt we have seen the need for Tensile Fabric Designs

and engineering to evolve and meet this U-Value challenge head

on. This is why we have been working on developing workable

solutions to help our fabric buildings achieve and surpass the

latest U-Value requirements.

A particular design and build project which we at Airsculpt have

been working on, with such U-Value stipulations, is a sports hall

in Lowestoft. Once built this project is set to see Airsculpt

delivering the first Tensile Fabric Building in the UK to surpass

0.2W/m2k U-values for a roof. Although, we cannot provide

specific details on how we have achieved this U-Value

breakthrough, as it would provide our competition with our

intellectual property, we can say that we have achieved this by

utilising a thermal dynamic air flow and layer system, unique to us

and us alone. Such advancements with U-Values within Tensile

Architecture will soon see membrane buildings becoming one the

most environmentally sound, and, economical forms of

commercial building constructions around.

To find out more about U-Value changes and the challenges they

pose within Tensile Buildings, please feel free to contact us on

+44(0) 1249 848649 or email us at info@airsculpt.com

http://www.airsculpt.com/latest-news/thermal-values-within-tensile-fabric-structures/[1/6/2016 5:18:23 PM]

Thermal Values within Tensile Fabric Structures

Share this:

TO THE

TOP

http://www.airsculpt.com/latest-news/thermal-values-within-tensile-fabric-structures/[1/6/2016 5:18:23 PM]

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- STRUCTURAL GLASS DESIGN REPORTDocument1 pageSTRUCTURAL GLASS DESIGN REPORTsamgivp2869100% (4)

- Perkins 2800 Series WorkshopmanualDocument10 pagesPerkins 2800 Series Workshopmanualmarylee100% (41)

- ForexDocument1 pageForexCollin NguNo ratings yet

- CriteriaDocument5 pagesCriteriaCollin NguNo ratings yet

- AxiTrader Setup GuideDocument10 pagesAxiTrader Setup GuideCollin NguNo ratings yet

- AxiTrader Setup GuideDocument10 pagesAxiTrader Setup GuideCollin NguNo ratings yet

- BS5950 BOLT AND WELD CAPACITIESDocument1 pageBS5950 BOLT AND WELD CAPACITIESHelena DomičićNo ratings yet

- tb0006 PDFDocument12 pagestb0006 PDFCollin NguNo ratings yet

- NewDocument1 pageNewCollin NguNo ratings yet

- F2150RA xhe-dynamic Crane SpecsDocument16 pagesF2150RA xhe-dynamic Crane SpecsCollin NguNo ratings yet

- ColumnDocument1 pageColumnCollin NguNo ratings yet

- 2018 Android N Models User Manual AUDocument22 pages2018 Android N Models User Manual AUCollin NguNo ratings yet

- ManuelDocument1 pageManuelCollin NguNo ratings yet

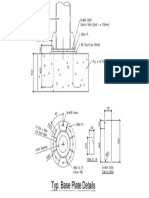

- Base PlateDocument1 pageBase PlateCollin NguNo ratings yet

- NewDocument1 pageNewCollin NguNo ratings yet

- Koei JIS PDFDocument49 pagesKoei JIS PDFTimoNo ratings yet

- Authorisation Letter v2Document1 pageAuthorisation Letter v2Collin NguNo ratings yet

- Bca 3Document5 pagesBca 3Collin NguNo ratings yet

- 1 Input Data: Profis Anchor 2.6.6Document6 pages1 Input Data: Profis Anchor 2.6.6Collin NguNo ratings yet

- Roof Drainage Calculator - FloPlastDocument2 pagesRoof Drainage Calculator - FloPlastCollin NguNo ratings yet

- m26 Specification For Lighting ColumnsDocument24 pagesm26 Specification For Lighting ColumnsCollin NguNo ratings yet

- Guttermaster Print PageDocument1 pageGuttermaster Print PageCollin NguNo ratings yet

- Plane Sections Remain Plane. Y: CompressionDocument5 pagesPlane Sections Remain Plane. Y: CompressionakanyilmazNo ratings yet

- Energy Use and Lighting - Birdair, IncDocument3 pagesEnergy Use and Lighting - Birdair, IncCollin NguNo ratings yet

- CriteriaDocument5 pagesCriteriaCollin NguNo ratings yet

- 官人Document21 pages官人Collin NguNo ratings yet

- Structural Analysis HandoutDocument2 pagesStructural Analysis HandouthgorNo ratings yet

- Example1 Timber DesignDocument3 pagesExample1 Timber DesignCollin NguNo ratings yet

- Canopy Height Size Uplift Downwards Moment Shear No + 1.2M Sq. M KN KN KNM KNDocument1 pageCanopy Height Size Uplift Downwards Moment Shear No + 1.2M Sq. M KN KN KNM KNCollin NguNo ratings yet

- Exercise 8.4Document13 pagesExercise 8.4Socio JiwapatriaNo ratings yet

- Exer 2 - PH and BuffersDocument4 pagesExer 2 - PH and BuffersAsi JenNo ratings yet

- Section 8 - Synchronism-Check Protection (25) : SEL-751A Feeder Protection Relay - APP 751ADocument19 pagesSection 8 - Synchronism-Check Protection (25) : SEL-751A Feeder Protection Relay - APP 751ABouazzaNo ratings yet

- Electric Vehicle ChargingDocument60 pagesElectric Vehicle Chargingvinod 7100% (1)

- Cole Tarango - Research Paper 2018-2019Document5 pagesCole Tarango - Research Paper 2018-2019api-447838694No ratings yet

- Accident Radio Logic GOIANIADocument157 pagesAccident Radio Logic GOIANIACatalin CuraliucNo ratings yet

- SERIES AC CIRCUIT PROBLEMSDocument4 pagesSERIES AC CIRCUIT PROBLEMSHubert Semeniano100% (1)

- Brine ZLD Process-GEDocument7 pagesBrine ZLD Process-GEvijayendra100% (1)

- Utilization of Lignocellulosic Biomass by Oleaginous Yeast and Bacteria For Production of Biodiesel and Renewable DieselDocument18 pagesUtilization of Lignocellulosic Biomass by Oleaginous Yeast and Bacteria For Production of Biodiesel and Renewable DieselIkrar AdiNo ratings yet

- Makalah Tentang AnnouncementDocument10 pagesMakalah Tentang AnnouncementBayu Grafika 2No ratings yet

- Airframe Fuel SystemDocument30 pagesAirframe Fuel SystemLuis GarciaNo ratings yet

- HVAC Control Panel ArrangementDocument82 pagesHVAC Control Panel ArrangementMohamed Ali JNo ratings yet

- Wattstopper Sensor The Most Advanced Energy Saving TechnologyDocument7 pagesWattstopper Sensor The Most Advanced Energy Saving TechnologyDemo Only100% (1)

- Wipro CSR BBDocument35 pagesWipro CSR BBYogesh GomsaleNo ratings yet

- Wuhuan - MR Pi JinlinDocument34 pagesWuhuan - MR Pi JinlinAmanNo ratings yet

- Screw Compressors: Models: VEDocument42 pagesScrew Compressors: Models: VEVoştinar IoanNo ratings yet

- PRAI-M0-YT01-LA-7500 - As-Built - Data Sheet For Feed Water PumpDocument3 pagesPRAI-M0-YT01-LA-7500 - As-Built - Data Sheet For Feed Water PumpSuman GhoshNo ratings yet

- Single Split PAC R410A Non-Inverter CatalogDocument12 pagesSingle Split PAC R410A Non-Inverter CataloghuntsecondlifeNo ratings yet

- Igcse: Definitions & Concepts of ElectricityDocument4 pagesIgcse: Definitions & Concepts of ElectricityMusdq ChowdhuryNo ratings yet

- Monbat 12V200AhDocument1 pageMonbat 12V200AhMaria MuresanNo ratings yet

- Coupling and ApplicationDocument4 pagesCoupling and Applicationekobudi94No ratings yet

- Compresores DaewooDocument30 pagesCompresores DaewooJader Leon55% (20)

- DXXXX-QSOP - Well Control Procedure For Non - Routine OperationsDocument6 pagesDXXXX-QSOP - Well Control Procedure For Non - Routine Operationsharry mulyafitNo ratings yet

- Flow of Lubricating Greases in Centralized Lubricating SystemsDocument8 pagesFlow of Lubricating Greases in Centralized Lubricating SystemsFelipe LeiteNo ratings yet

- Plumbing Systems For BuildingsDocument62 pagesPlumbing Systems For BuildingsDileep Kumar100% (1)

- Electrocardiograf Ym412i Service ManualDocument14 pagesElectrocardiograf Ym412i Service ManualramarservmedNo ratings yet

- 7.5 01 02 01Document19 pages7.5 01 02 01Feri SaputraNo ratings yet

- BOMAG - Brochure - BF600-700-800-3 - PRE107416 - 2103Document32 pagesBOMAG - Brochure - BF600-700-800-3 - PRE107416 - 2103Jason TanNo ratings yet

- L7 Voltage Regulator, Half Wave Rectifier S2 1617Document20 pagesL7 Voltage Regulator, Half Wave Rectifier S2 1617Bhagyalaxmi patilNo ratings yet