Professional Documents

Culture Documents

9714-48581-1-PB PI Conical

Uploaded by

Pandimadevi GanesanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

9714-48581-1-PB PI Conical

Uploaded by

Pandimadevi GanesanCopyright:

Available Formats

Research Paper

Volume : 4 | Issue : 5 | May 2015 ISSN No 2277 - 8179

Engineering

Real Time Implementation of PI Controller

for Conical Tank System

KEYWORDS : Nonlinear system, PI Control-

ler, Direct synthesis method of tuning.

Akash A. Patel

P.G. student, Applied Instrumentation, AITS, Rajkot, 8401115457, India.

Kuldip H. Tarpara

Head & Professor, Department of I.C., AITS, Rajkot, 9824811042, India.

ABSTRACT

This paper deals with control of nonlinear system like conical tank system via interfacing of plant with PC using

Arduino. Control of such nonlinear system is difficult task due to continuous changing of its cross sectional area

with respect to height. In this paper real time conical tank system is controlled by PI controller with the help of Arduino board and Matlab/

Simulink. The conical tank system is represented as a FOPDT model. For each steady state operating point, the FOPDT transfer function is

identified, then controller tuning strategy has been applied using direct synthesis method and model of conical tank system is implemented

in Matlab/Simulink environment. At the end of experiment comparison is done based on time domain specifications between real time result

and simulation result of plant.

INTRODUCTION

In the process industries liquid level is the basic problem as it is

necessary to pump the liquid, store it in tanks and then pump

to the other tanks. If the fluid in the tank undergoes chemical

or mixing treatment, the level control is necessary. The level

and flow plays vital role in industries. Conical tanks are widely

used in industries like food, hydrometallurgical, petrochemical,

wastewater treatment industries, milk industries etc. conical

tank gives better drainage to the solid materials, semi solid materials as well as viscous fluids. The level control in the conical

tank is a challenging problem because of its constantly changing its cross sectional area. For controlling of this type of system PID controller is used. But any conventional controller can

work properly with linear system. So linearity can be obtained

by piecewise linearized method. Many researchers have been

carried out in level control of the conical tank process. S.Anand,

Aswin V. and S. Rakeshkumar [1] explained an adaptive PI controller for conical tank system. Sukanya R. Warier et al., [2] carried out experiment on level control using Model Predictive controller (MPC) based controller. H.Kala et al., [3] have been done

comparative analysis of direct synthesis Pi controller and Model

Predictive Controller. Tuning of Controller for nonlinear process

Fig.1 shows the block diagram of Real time level control of conical Tank system. It consist of Reservoir, plunger pump, level

transmitter, Arduino Mega 2560, I to V converter, V to I converter and PC. PC is connected to the Arduino board using USB cable which can give the supply as well as it can Transmit-Receive

the data to and from plant.

Water is pumped with the help of plunger pump which gives

flow according to input current. The inflow rate of the tank is

adjusted by passing control signal from PC to plunger pump

to manipulate the input current to the pump through Arduino

board and V to I converter. In this system control variable is

height of liquid in conical tank and manipulated variable is inlet

flow of water in process.

has been done based on intelligent controller like Genetic algorithm by D.Mercy et al., [4].

The Arduino Mega 2560 is used for interfacing the personal computer with MATLAB and conical tank system. Level of water in

conical tank is measured with the help of level transmitter (LT)

which is calibrated for 0-60 cm and is converted to an output

current range of 4-20 mA. This output current from LT is passed

through 250 ohm resistor to convert it to 1-5 V range, which is

given to the controller through Arduino board. Controller compare it with set point of height and generate control signal in

form of 1-5 V, which is fed to V to I converter to convert it to

4-20 mA range and then given to the plunger pump.

In this paper PI controller is designed and tuned by direct synthesis method. It is implemented on real time system using Arduino board. The FOPDT model has been derived by piecewise

linearization. Arduino can interface the plant without any programming. It is user friendly and simple to use based on prior

knowledge of Matlab/SIMULINK.

The Arduino Mega 2560 is microcontroller board with ATmega 2560. It has 54 digital I/O pins of which 15 PWM outputs,

16 analog input pins, 4 UART (hardware serial ports), 16 MHz

crystal oscillator. The operating voltage is 5V [12]. The Arduino

board can be operated with console Arduino software and also

with programming software like MATLAB.

EXPERIMENTAL SETUP

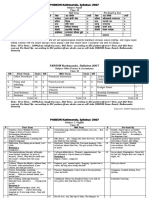

Table 1.

Technical Specifications of Instruments

Components

Process Tank

Level Transmitter

Pump

Fig.1 block diagram of conical tank system

Specifications

Capacity

Height

Diameter

Height

Type

Output

Type

Capacity

Pressure

voltage

Variable Frequency Input

Motor capacity

Drive

Output voltage

87.231 liter

68 cm

70 cm

0-60 cm

Capacitive

4-20 mA

Plunger

0-240 LPH

1 Kg/ cm^2

1 AC 200-230 V

0.75KW

3 AC, 0-230V, 0.8A,

0.3kVA

IJSR - INTERNATIONAL JOURNAL OF SCIENTIFIC RESEARCH

Research Paper

Volume : 4 | Issue : 5 | May 2015 ISSN No 2277 - 8179

MATHEMATICAL MODELING

The Mass-Balance equation is given by

45

X: 225.7

Y: 39.29

40

Rate of accumulation of mass in tank = (rate of mass in) (rate

of mass out)

35

X: 203.9

Y: 32.02

X: 237.6

Y: 43.56

X: 216.5

Y: 36.12

Height (cm)

30

25

X: 153.5

Y: 18.1

20

data

fitted curve

15

X: 108.4

Y: 8.991

10

5

X: 32.08

Y: 0.835

X: 54.18

Y: 2.263

0

0

50

X: 130.2

Y: 13

X: 76.04

Y: 4.427

100

Flow (LPH)

150

200

250

Fig. 2 Open loop response for Steady state point

TABLE 2

Model Parameter of Conical Tank

LINEARIZATION OF MODEL

The nonlinear process model can be linearized around a particular steady state value and with this linearized approximation of

the real model, we can obtain generalized result regarding the

process behavior, but these will only approximate, never completely representing true behavior accurately.

To linearize the equation around steady state operating point

using Taylor series, suppose a nonlinear dynamic model

has been derived from first principles (material, energy or momentum balance).

Region

Inflow (LPH) Height

(cm)

Gain

Time

constant

0-65

3.3

0.366

3.31

65-119

11

0.667

67.16

119-178

24

0.979

469.28

178-238

43.5

1.319

2077.06

Fig. 3 Open Loop Response by step change in flow

4

IJSR - INTERNATIONAL JOURNAL OF SCIENTIFIC RESEARCH

Research Paper

Volume : 4 | Issue : 5 | May 2015 ISSN No 2277 - 8179

CONTROLLER DESIGN

After deriving the transfer function (FOPDT) model the controller must be designed for maintaining the system to the desired

setpoint. Here outlet valve is set to a particular restriction.

Direct Synthesis Method For PI Tuning

Desired setpoint can be achieved by proper tuning of PI parameters likewise kp and ti. For that direct synthesis method is used.

In the direct synthesis method, the controller design is based

on a desired closed-loop transfer function for set-point. The direct synthesis design method has a single design parameter, the

desired closed-loop time constant (). In the direct synthesis

approach, an analytical expression for the feedback controller

is derived from a process model and a desired closed-loop response.

CONCLUSION

This paper proposes a traditional controller for controlling a

nonlinear system by using new method of interfacing the real

time process. The FOPDT model for the conical tank system is

identified for different regions and tuned PI controller is applied

for that in Matlab environment as well as in real time using Arduino board. Here direct synthesis method is used for tuning of

PI controller which takes more time to stable. Other method of

PI tuning can also be applied to obtain better response. From

the comparison of simulation result and real time result of one

operating point real model settle at same time but rise time will

be changed.

25

Height (cm)

20

15

10

Real time Response of PI

Set Point

Simulation Response of PI

500

1000

1500

2000

Time (sec)

2500

3000

3500

4000

Fig. 4 Comparison of Simulation and Real Time PI Implementation

REFERENCE

[1] S.Anand, Aswin V. and S. Rakeshkumar,Simple tuned adaptive PI controller for conical tank process, international conference on recent Advancements in electrical, electronics and control engineering, 2011 IEEE. | [2] Sukanya R. Warier, Sivanandam Venkatesh,Design of controllers

based on MPC for a conical tank system, international conference on Advances in engineering, science and management (ICAESM-2012), March 30, IEEE. | [3] H.Kala, P.Arvind and

M.Valluvan, Comparative analysis of different controller for a nonlinear level control process, proceeding of 2013IEEE conference on information and communication technologies

(ICT 2013). | [4] D.Mercy, S.M.Girirajkumar,Tuning of controller for nonlinear process using intelligent techniques, international journal of advanced reaserch in electrical, electronics and instrumentation engineering, vol. 2, Issue 9, sept. 2013. | [5] R.Valarmathi, P.R.Theerthagiri and S. Rakeshkumar,Design and analysis of Genetic algorithm based controller for nonlinear liquid tank system, international conference on advances in engineering, science and management (ICAESM-2012), March 30, 31, 2012-IEEE. | [6] Seborg, Edgar

and Mellichmp,Process dynamics and Control. | [7] Karl.J. Astrom and Tore Hagglund PID Controllers: Theory, Design and Tuning 2nd Edition. | [8] Babatunde A. Ogunnaike

and W.Harmon Ray,Process dynamics, modelling and Control. | [9] Mohammad Shahrokhi and Alireza Zomorrodi, Comparison of PID Controller Tuning Methods Department of

Chemical & Petroleum Engineering Sharif University of Technology. | [10] LEONID REZNIK, Australia, Fuzzy Controllers, Victoria University of Technology, Melbourne. |

IJSR - INTERNATIONAL JOURNAL OF SCIENTIFIC RESEARCH

You might also like

- Control Basics Chapter - 1Document53 pagesControl Basics Chapter - 1Ahmed SeliemNo ratings yet

- Computer Vision: Spring 2006 15-385,-685 Instructor: S. Narasimhan Wean 5403 T-R 3:00pm - 4:20pmDocument43 pagesComputer Vision: Spring 2006 15-385,-685 Instructor: S. Narasimhan Wean 5403 T-R 3:00pm - 4:20pmPandimadevi GanesanNo ratings yet

- Question Bank - IDocument1 pageQuestion Bank - IPandimadevi GanesanNo ratings yet

- Thermistor Project1 PDFDocument5 pagesThermistor Project1 PDFYan Mg MgNo ratings yet

- Digital Pid Controller - 72S173Document15 pagesDigital Pid Controller - 72S173Pandimadevi GanesanNo ratings yet

- Unit III AnswersDocument9 pagesUnit III AnswersPandimadevi GanesanNo ratings yet

- Hough TransformDocument19 pagesHough TransformSmitha VasNo ratings yet

- Qdoc - Tips Temperature Controlled Fan ReportDocument26 pagesQdoc - Tips Temperature Controlled Fan ReportPandimadevi GanesanNo ratings yet

- Fundamentals of Image Processing: Lecture #7 Edge DetectionDocument65 pagesFundamentals of Image Processing: Lecture #7 Edge DetectionPandimadevi GanesanNo ratings yet

- Computer Vision: Spring 2006 15-385,-685 Instructor: S. Narasimhan Wean 5403 T-R 3:00pm - 4:20pmDocument43 pagesComputer Vision: Spring 2006 15-385,-685 Instructor: S. Narasimhan Wean 5403 T-R 3:00pm - 4:20pmPandimadevi GanesanNo ratings yet

- Question Bank - IDocument1 pageQuestion Bank - IPandimadevi GanesanNo ratings yet

- GiraafeeDocument1 pageGiraafeePandimadevi GanesanNo ratings yet

- 13221037,14121022,14121079,14121074 EeeDocument136 pages13221037,14121022,14121079,14121074 EeeAMISHNo ratings yet

- Effects of Fertilizers, Manure and Polythene on Seed GerminationDocument20 pagesEffects of Fertilizers, Manure and Polythene on Seed GerminationPandimadevi GanesanNo ratings yet

- Direct Digital Control of An Air-HandlerDocument17 pagesDirect Digital Control of An Air-HandlerPandimadevi GanesanNo ratings yet

- Instructions For Installing MATLAB R2014Document1 pageInstructions For Installing MATLAB R2014Pandimadevi GanesanNo ratings yet

- Chap 13-Plant Nutrition LecDocument44 pagesChap 13-Plant Nutrition LecChaiyryl CalagoNo ratings yet

- Aq 378 eDocument368 pagesAq 378 ePandimadevi GanesanNo ratings yet

- Poverty ProjectDocument8 pagesPoverty ProjectPandimadevi GanesanNo ratings yet

- Wireless ChargerDocument14 pagesWireless ChargerPandimadevi GanesanNo ratings yet

- Transmitter Medium ReceiverDocument12 pagesTransmitter Medium ReceiverPandimadevi GanesanNo ratings yet

- Aq 378 eDocument368 pagesAq 378 ePandimadevi GanesanNo ratings yet

- Wireless Energy Transfer: Yue Ma October 22, 2010Document3 pagesWireless Energy Transfer: Yue Ma October 22, 2010Pandimadevi GanesanNo ratings yet

- Realtime Pacer LicenseDocument1 pageRealtime Pacer LicensesunilkumareceNo ratings yet

- Wirelesspowertransferreport2 PDFDocument26 pagesWirelesspowertransferreport2 PDFsuman vvabNo ratings yet

- Applications in The Industrial EnvironmentDocument8 pagesApplications in The Industrial EnvironmentPandimadevi GanesanNo ratings yet

- Smoke Detection Using MQ-2 Gas Sensor - Arduino Project HubDocument37 pagesSmoke Detection Using MQ-2 Gas Sensor - Arduino Project HubPandimadevi GanesanNo ratings yet

- Chapter 4 Controllers ExplainedDocument36 pagesChapter 4 Controllers ExplainedPandimadevi GanesanNo ratings yet

- N3110 3Document44 pagesN3110 3sqkidNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- RECAT Approved List Sent To StudentsDocument4 pagesRECAT Approved List Sent To Studentsdhanya sree nathaniNo ratings yet

- PABSON Kathmandu Syllabus 2067Document14 pagesPABSON Kathmandu Syllabus 2067Tejendra Pachhai0% (1)

- Field Models of Induction Heating For Industrial ApplicationsDocument5 pagesField Models of Induction Heating For Industrial ApplicationsLuckyNo ratings yet

- Proposed Date Sheet Dec, 2019 From 2016 Batch PDFDocument72 pagesProposed Date Sheet Dec, 2019 From 2016 Batch PDFmorning starNo ratings yet

- Capital MarketsDocument10 pagesCapital MarketsAadityaMahanteNo ratings yet

- Term 2 Year 10 Add MathsDocument3 pagesTerm 2 Year 10 Add MathsAONo ratings yet

- Template RPH Form 4Document1 pageTemplate RPH Form 4fienaNo ratings yet

- List of The Best Mathematics BooksDocument10 pagesList of The Best Mathematics BooksFernando J. Correa Delgado100% (3)

- Cambridge International AS & A Level: Further Mathematics 9231/22Document16 pagesCambridge International AS & A Level: Further Mathematics 9231/22M IdkNo ratings yet

- 1.3 Gauss Elimination MethodDocument6 pages1.3 Gauss Elimination Methodshravan mandalNo ratings yet

- ZaraDocument35 pagesZaraRaymytechNo ratings yet

- Spherical Trigonometry: Appendix ADocument42 pagesSpherical Trigonometry: Appendix Aasdffh kjhlbnNo ratings yet

- Laplace Transform for Physical Pendulum MotionDocument4 pagesLaplace Transform for Physical Pendulum MotionAprilia Putri LaurinaNo ratings yet

- Vector Calculus, Linear Algebra, and Differential Forms: A Unified ApproachDocument4 pagesVector Calculus, Linear Algebra, and Differential Forms: A Unified ApproachDhrubajyoti DasNo ratings yet

- Mws Gen Inp TXT SplineDocument12 pagesMws Gen Inp TXT SplineApuu Na Juak EhNo ratings yet

- Singapore Competition Math Training HandbookDocument132 pagesSingapore Competition Math Training HandbookRohmatullah SuniNo ratings yet

- Matematik Modul Topikal K2 SPM 2020Document484 pagesMatematik Modul Topikal K2 SPM 2020mus mustafa67% (3)

- m1 l1.2 - Linear SystemsDocument32 pagesm1 l1.2 - Linear SystemsHera ReinaNo ratings yet

- MCM NKANA SECONDARY SCHOOL GRADE 10 END OF TERM 2 EXAMDocument2 pagesMCM NKANA SECONDARY SCHOOL GRADE 10 END OF TERM 2 EXAMTahpehs Phiri50% (2)

- Pair of Linear Equations in Two VariablesDocument6 pagesPair of Linear Equations in Two VariablesEnglish DemoNo ratings yet

- Mathalino: Design of Steel Reinforcement of Concrete Beams by WSD MethodDocument3 pagesMathalino: Design of Steel Reinforcement of Concrete Beams by WSD MethodDanielle Kiara ZarzosoNo ratings yet

- 2020 Assessment 1 - Alternate Task Ext1 (William's Work) PDFDocument7 pages2020 Assessment 1 - Alternate Task Ext1 (William's Work) PDF黑剑No ratings yet

- Higher Unit 06c Check in Test Quadratic Cubic and Other GraphsDocument7 pagesHigher Unit 06c Check in Test Quadratic Cubic and Other Graphshannah hussainNo ratings yet

- Diffrential EquationsDocument2 pagesDiffrential EquationsHelloNo ratings yet

- Eur J Phys 31 2010Document16 pagesEur J Phys 31 2010Ștefan RăzvanNo ratings yet

- CE 636 Assignment 2Document2 pagesCE 636 Assignment 2Rodrigo RomeroNo ratings yet

- Mathematica SlideDocument16 pagesMathematica Slidesaw roseNo ratings yet

- Nonlinear Functional Analysis - SchwartzDocument242 pagesNonlinear Functional Analysis - SchwartzClayton RibeiroNo ratings yet

- 9709 s14 QP 32Document4 pages9709 s14 QP 32malyksNo ratings yet