Professional Documents

Culture Documents

Us 4037770

Uploaded by

erer0 ratings0% found this document useful (0 votes)

12 views3 pagesj

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentj

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views3 pagesUs 4037770

Uploaded by

ererj

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

United States Patent [19]

[11]

4,037,770

Dorgnon et al.

[45]

July 26, 1977

[54]

TOOL USING CASELESS AMMUNITION

[75]

Inventors Rg" Dm'gmm St- Pemy; Ma"

[73] Assig?eel

3 469 757

9/1969

Kvavle et a1. ....................... .. 227/10

3,558,032

3,973,708

1/1971

8/1976

Oe?nger ................... .. 227/8

Scotoni

227/10

France

3,981,424

9/1976

Maier ................................... .. 227/10

0511 00111018501! New Haven,

Primary Examiner-Granville Y. Custer, Jr.

Attorney, Agent, or Firm-William W. Jones; Paul J.

Conn.

Lerner

0" 69 28

J1me 11, 1976

Foreign Application Priority Data

June 27, 1975

[51]

[52]

France .............................. .. 75.20311

Int. Cl.2 .............................................. .. B25C 1/14

US. Cl. ...................................................... .. 227/9

[58] Field of Search .......................... .. 227/8, 9, l0, l1

Z/

[57]

ABSTRACT

The recess for the ammunition comprises two blind

bores whose width is equal to, or greater than, the

[22] Flledl

[30]

References Cited

U.S. PATENT DOCUMENTS

(3021mm, VaIQIIFe; Jean Luthringe"

Pans; Jean Ollmer, Valence, all of

l N .

[211 App

[56]

thickness of the ammunition and whose depth is similar

to, or greater than, the diameter of the ammunition,

whereby the said blind bores are connected by a groove

issuing over a part of the height thereof which is at least

equal to the diameter of the ammunition

the duct

or ducts issue into the bottom of at least one of the blind

bores

3 Claims, 3 Drawing Figures

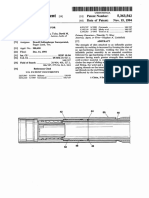

U.S. Patent

July 26, 1977

4,037,770

4,037,770

FIG. 1 is a plan view of part of the breech of a tool

according to one embodiment of the invention;

FIG. 2 is a sectional view along the line 11-11 of FIG.

TOOL USING CASELESS AMMUNITION

The present invention relates to a sealing gun using

caseless ammunition in the form of compacted propel

lant pellets with or without primers.

FIG. 3 is a sectional view along the line III-III of

FIG. 2.

In power-actuated tools of the type disclosed in re

lated United States Application Ser. No. 628,628, ?led

Nov. 4, 1975 the caseless ammunition is placed in a

of the breech is integral with the barrel 1 of the tool in

which is provided the low pressure chamber 21. The

recess 15 for ammunition 36 is linked with the low pres

1;

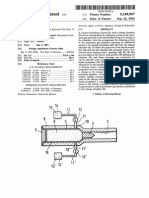

In the embodiment shown the cylindrical portion 13

recess opening into the breech periphery and a duct or

ducts linking this recess with a low pressure chamber

are provided in the breech. The front wall of the recess

serves as an anvil for the percussion striker and must

sure chamber 21 by two ducts 16 and 16' and a passage

17 for a percussion striker (not shown) opens onto the

recess 15 opposite to ducts 16 and 16'.

In the embodiment shown recess 15 comprises two

consequently have a planar portion with an adequate 15 blind bores 40 and 40 terminated by a conical bottom 41

and 41' respectively. The wall separating bores 40 and

- surface area. Moreover, it is desirable that the ammuni

tion does not block the duct or ducts so as to prevent,

40' has partly been milled away to only leave a small

wall portion 42 on which rests ammunition 36 on its

edge. The arrangement is such that ducts 16 and 16

during the combustion of the charge, the carrying of

unburned grains of powder towards the low pressure

issue forth close to the bottom of bores 40 and 40' re

chamber.

The present invention aims at achieving in a simple

manner these two objectives, whilst facilitating the

spectively, partly into the conical portions 41 and 41

respectively of the said bores. FIG. 3 in particular

shows that ammunition 36 only blocks a very small

machining of the breech.

portion

of the intakes to ducts 16 and 16'.

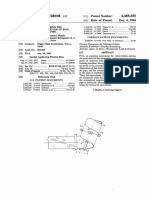

To this end in the tool according to the invention, the

chamber for the ammunition pellet comprises two blind 25 The machining of the recess of the ammunition is

simple and economic because it merely requires a bor

bores each of whose diameter is greater than the thick

ing

operation followed by a milling operation. The

ness of the ammunition pellet and whose depth is similar

milling thickness is selected so that the ammunition 36 is

to, or greater than the diameter of the ammunition pel

maintained between the walls made by the milling tool.

let. The said blind bores are connected by a slot which

is formed with a depth atleast equal to the diameter of

the ammunition. The combustion gas duct or ducts open

into the bottom of at least one of the blind bores.

7 What is claimed is:

1. A power-actuated tool of the type utilizing caseless

ammunition pellets contained in a recess in a cylindrical

breech, said recess for the ammunition comprising two

In the chamber, according to the present invention,

blind bores each of whose diameter is greater than the

the anvil portion has a maximum surface area and the 35 thickness of the ammunition pellet and whose depth is

ammunition rests on that portion of the slot wall be

similar to or greater than the diameter of the ammuni

tween the two blind bores. Moreover, the ducts are not

tion pellet, said blind bores being connected by a slot

blocked by the ammunition which comprises a cylindri

having a depth which is at least equal to the diameter of

cal pellet.

the ammunition pellet and further comprising at least

Preferably the bores have a conical bottom making it

one combustion gas duct opening into the bottom of at

possible to position these ducts closer to the said bottom

least one of the blind bores.

2. The tool of claim 1, wherein said bores have a

substantially without decreasing the strength of the

conical bottom surface.

breech.

3. The tool of claim 1, wherein said breech is integral

The invention will be better understood from reading

the following description with reference to the attached 45 with a barrel member of the tool.

*

drawings in which:

50

55

65

You might also like

- Unlted States Patent (191 1111 3,736,693: Koch 1451 June 5, 1973Document4 pagesUnlted States Patent (191 1111 3,736,693: Koch 1451 June 5, 1973fgrt45No ratings yet

- United States Patent (191: Sullivan Et A1Document21 pagesUnited States Patent (191: Sullivan Et A1fghdfjerNo ratings yet

- Us 3717946Document4 pagesUs 3717946ererNo ratings yet

- April 5, 1966 B. Weiser 3,243,910: Filed Feb. 2, 1965Document4 pagesApril 5, 1966 B. Weiser 3,243,910: Filed Feb. 2, 1965fgrt490No ratings yet

- United States Patent (19) : B JornstadDocument4 pagesUnited States Patent (19) : B JornstadlfilippiniNo ratings yet

- Us 3690255Document5 pagesUs 3690255wewewewNo ratings yet

- 11111111mumnlllgglotgggglgggggnn - : United States Patent (19) (11) Patent Number: 5,613,555Document5 pages11111111mumnlllgglotgggglgggggnn - : United States Patent (19) (11) Patent Number: 5,613,555mohammadreza91No ratings yet

- Us 3823668Document4 pagesUs 3823668wewewewNo ratings yet

- Us 4394836Document4 pagesUs 4394836ererNo ratings yet

- Ester: United States PatentDocument5 pagesEster: United States PatentwewewewNo ratings yet

- Us5361479 PDFDocument5 pagesUs5361479 PDFmohammadreza91No ratings yet

- United States Patent (19) : Wood (45) Date of Patent: Jan. 8, 1985Document5 pagesUnited States Patent (19) : Wood (45) Date of Patent: Jan. 8, 1985mohammadreza91No ratings yet

- Tube Saport PDFDocument4 pagesTube Saport PDFjr110livecomNo ratings yet

- R.T MM MS: ' Filed July 28, 1965Document6 pagesR.T MM MS: ' Filed July 28, 1965Alexcel CorporalNo ratings yet

- Us 5610365Document5 pagesUs 5610365dgfhjsdg hfsdhyjNo ratings yet

- Honing ToolDocument3 pagesHoning ToolKyle YsitNo ratings yet

- Us4587423 PDFDocument12 pagesUs4587423 PDFRamanamurthy PalliNo ratings yet

- United States Patent (19) (11) 4,298,078Document9 pagesUnited States Patent (19) (11) 4,298,078lfilippiniNo ratings yet

- BS 6717 - 1989 (Versi Asli)Document8 pagesBS 6717 - 1989 (Versi Asli)Gita PrestalitaNo ratings yet

- July 3, J 1923. ' 1,461,013: H. D. HodgeDocument4 pagesJuly 3, J 1923. ' 1,461,013: H. D. HodgeerwerNo ratings yet

- Us2996100 PDFDocument8 pagesUs2996100 PDFerzrzretgertfertgeNo ratings yet

- United States Patent: Boulogne-sur-Seine, FranceDocument7 pagesUnited States Patent: Boulogne-sur-Seine, FranceRagini SharmaNo ratings yet

- Byfwf p41 ': March 7, 1961 O. Danyluke 2,973,909Document5 pagesByfwf p41 ': March 7, 1961 O. Danyluke 2,973,909KrozeNo ratings yet

- US2126921Document5 pagesUS2126921Jhonnatan E Avendaño Florez100% (1)

- United States Patent (191 (11) Patent Number: 5 363 542: Sorem Et A1. (45) Date of Patent: Nov. 15, 1994Document6 pagesUnited States Patent (191 (11) Patent Number: 5 363 542: Sorem Et A1. (45) Date of Patent: Nov. 15, 1994mohammadreza91No ratings yet

- Multiple Downcomer Fractional Distillation Tray and ProcessDocument9 pagesMultiple Downcomer Fractional Distillation Tray and Processziz37No ratings yet

- Bassick Mfg. Co. v. R. M. Hollingshead Co. Rogers v. Alemite Corporation, 298 U.S. 415 (1936)Document8 pagesBassick Mfg. Co. v. R. M. Hollingshead Co. Rogers v. Alemite Corporation, 298 U.S. 415 (1936)Scribd Government DocsNo ratings yet

- Us4522105 PDFDocument10 pagesUs4522105 PDFJin SongNo ratings yet

- United States Patent (191 (11) Patent Number: 5,259,288: Vatsvog (45) Date of Patent: Nov. 9, 1993Document13 pagesUnited States Patent (191 (11) Patent Number: 5,259,288: Vatsvog (45) Date of Patent: Nov. 9, 1993fghdfjerNo ratings yet

- Us 6131519Document4 pagesUs 6131519dgfhjsdg hfsdhyjNo ratings yet

- United States Patent (191: SheppardDocument7 pagesUnited States Patent (191: SheppardandreNo ratings yet

- Us 5149907Document7 pagesUs 5149907wewewewNo ratings yet

- Us 5546957Document7 pagesUs 5546957SurgaveryNo ratings yet

- United States Patent (191: (54) Vibrostimulative DeviceDocument5 pagesUnited States Patent (191: (54) Vibrostimulative Devicejalepa_esNo ratings yet

- April 3, 1962 RAE 3,027,711: Securing Isentropic CompressionDocument4 pagesApril 3, 1962 RAE 3,027,711: Securing Isentropic CompressionDinh LeNo ratings yet

- The Combustion Chamber (Options)Document9 pagesThe Combustion Chamber (Options)Đinh Quốc TríNo ratings yet

- Berthier Us1366863Document9 pagesBerthier Us1366863cll1968No ratings yet

- Carlson & Sullivan, Inc. v. Bigelow & Dowse Co., 202 F.2d 654, 1st Cir. (1953)Document5 pagesCarlson & Sullivan, Inc. v. Bigelow & Dowse Co., 202 F.2d 654, 1st Cir. (1953)Scribd Government DocsNo ratings yet

- ZZ? ??/?? ???P?c222/Z: Filed April 20, 1945Document5 pagesZZ? ??/?? ???P?c222/Z: Filed April 20, 1945Edikan AkpanNo ratings yet

- Wellhead Connector H4 TypeDocument9 pagesWellhead Connector H4 Typeste7ieNo ratings yet

- Rechambering ShotgunsDocument6 pagesRechambering ShotgunsZardoz1090No ratings yet

- Us4252504 PDFDocument7 pagesUs4252504 PDFAhmed EltemsahNo ratings yet

- Apl'il 7, 1959 W. Settele ' v2,880,518Document4 pagesApl'il 7, 1959 W. Settele ' v2,880,518राजकुमार यादवNo ratings yet

- United States Patent (191: Cél 296/97 /2/70g Primary Exammer - Margaret A. FocannoDocument7 pagesUnited States Patent (191: Cél 296/97 /2/70g Primary Exammer - Margaret A. FocannoDanister GladwinNo ratings yet

- US2182002Document5 pagesUS2182002Jhonnatan E Avendaño FlorezNo ratings yet

- United States Patent (191: Yamamoto Et Al. (45) Date of Patent: Dec. 4, 1984Document11 pagesUnited States Patent (191: Yamamoto Et Al. (45) Date of Patent: Dec. 4, 1984Anonymous 6HADGUEXDNo ratings yet

- US Pat. 3881777Document6 pagesUS Pat. 3881777GaleriaTechniki.PLNo ratings yet

- United States Patent (191: SeecampDocument4 pagesUnited States Patent (191: Seecamp9aszerfNo ratings yet

- Us 5472145Document4 pagesUs 5472145mhtofighiNo ratings yet

- Connecting Rod CrackerDocument12 pagesConnecting Rod CrackerOkta Pariantoro Budi SetiawanNo ratings yet

- US3841371-metal InsertDocument5 pagesUS3841371-metal InsertgauravNo ratings yet

- Berthier Us1446635Document12 pagesBerthier Us1446635cll19680% (1)

- United States PatentDocument8 pagesUnited States PatentClaudinei MayerNo ratings yet

- US3387560 - Rocket AmmunitionDocument3 pagesUS3387560 - Rocket AmmunitionHosiah BlackfordNo ratings yet

- US2099314Document3 pagesUS2099314Jhonnatan E Avendaño Florez100% (1)

- US1983934Document4 pagesUS1983934Erin GokNo ratings yet

- US3404552Document4 pagesUS3404552Prabal JindalNo ratings yet

- Umted States Patent (19) (11) Patent Number: 5,671,656: Cyphers Et A) - (45) Date of Patent: Sep. 30, 1997Document6 pagesUmted States Patent (19) (11) Patent Number: 5,671,656: Cyphers Et A) - (45) Date of Patent: Sep. 30, 1997zeichsteinNo ratings yet

- The Development of Armor-piercing Shells with Suggestions for their ImprovementFrom EverandThe Development of Armor-piercing Shells with Suggestions for their ImprovementNo ratings yet

- Optimizing AOD Refractory PerformanceDocument10 pagesOptimizing AOD Refractory PerformanceJulio PurezaNo ratings yet

- Index Terms LinksDocument31 pagesIndex Terms Linksdeeptiwagle5649No ratings yet

- Week 1 Lesson 1 2nd QuarterDocument2 pagesWeek 1 Lesson 1 2nd QuarterKristine Jewel MacatiagNo ratings yet

- Wireline Works Tech-BulletinsDocument25 pagesWireline Works Tech-BulletinsRio de Mario100% (1)

- K20 Engine Control Module X3 (Lt4) Document ID# 4739106Document3 pagesK20 Engine Control Module X3 (Lt4) Document ID# 4739106Data TécnicaNo ratings yet

- PistonDocument7 pagesPistongauravarora93100% (1)

- Highway Design ProjectDocument70 pagesHighway Design ProjectmuhammedNo ratings yet

- F3 Chapter 1 (SOALAN) - RespirationDocument2 pagesF3 Chapter 1 (SOALAN) - Respirationleong cheng liyNo ratings yet

- Bates Stamped Edited 0607 w22 QP 61Document6 pagesBates Stamped Edited 0607 w22 QP 61Krishnendu SahaNo ratings yet

- I C Engine LabDocument3 pagesI C Engine LabDevNo ratings yet

- Residual Alkalinity Nomograph by John Palmer PDFDocument1 pageResidual Alkalinity Nomograph by John Palmer PDFcarlos pablo pableteNo ratings yet

- RRB JE CBT-2 Electronics Tech Paper With Key 31-8-2019 1st ShiftDocument55 pagesRRB JE CBT-2 Electronics Tech Paper With Key 31-8-2019 1st ShiftKuldeep SinghNo ratings yet

- Fitting Fundamentals: For SewersDocument21 pagesFitting Fundamentals: For SewersLM_S_S60% (5)

- Pressure Sensor Air PST Datasheet 51 en 2780071435Document3 pagesPressure Sensor Air PST Datasheet 51 en 2780071435Luis GuevaraNo ratings yet

- Stability Analysis of Steel Storage Rack Structures PDFDocument7 pagesStability Analysis of Steel Storage Rack Structures PDFFabian Flemin BahamondeNo ratings yet

- Famous MathematicianDocument116 pagesFamous MathematicianAngelyn MontibolaNo ratings yet

- EXP.2 Enzyme Extraction From BacteriaDocument3 pagesEXP.2 Enzyme Extraction From BacteriaLinhNguyeNo ratings yet

- 5ROS Underslung BSaverTROUGHS25Document1 page5ROS Underslung BSaverTROUGHS25jonodo89No ratings yet

- Body Deassembly 9 Interior TrimDocument7 pagesBody Deassembly 9 Interior TrimCarlos TecnicNo ratings yet

- Table of Trigonometric IdentitiesDocument2 pagesTable of Trigonometric IdentitiesVaios PeritogiannisNo ratings yet

- PDC NitDocument6 pagesPDC NitrpshvjuNo ratings yet

- Data and Specifications: HMR Regulated MotorsDocument21 pagesData and Specifications: HMR Regulated MotorsBeniamin KowollNo ratings yet

- Infinera Ds Isfp Timedivision Multiplexing ModulesDocument3 pagesInfinera Ds Isfp Timedivision Multiplexing ModulesAnonymous bpf0OZSd9No ratings yet

- CFMDocument16 pagesCFMShoaibIqbalNo ratings yet

- Finches Statistics Student-1Document7 pagesFinches Statistics Student-1api-319172404No ratings yet

- SL-19536 - REV2!02!13 User Manual MC CondensersDocument68 pagesSL-19536 - REV2!02!13 User Manual MC CondensersCristian SevillaNo ratings yet

- Genbio 1 NotesDocument1 pageGenbio 1 NoteselishaNo ratings yet

- Data Mining ConceptsDocument175 pagesData Mining ConceptsNikolya SmirnoffNo ratings yet

- 7625-300 Vitamin B12 AccuBind ELISA Rev 6Document2 pages7625-300 Vitamin B12 AccuBind ELISA Rev 6carlosalfredorivasNo ratings yet