Professional Documents

Culture Documents

Maintenance Facts 0310 Hipot Testing

Uploaded by

Kasiviswanathan ParthipanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Maintenance Facts 0310 Hipot Testing

Uploaded by

Kasiviswanathan ParthipanCopyright:

Available Formats

MAINTENANCE FACTS

Putting Hipot Out to Pasture

As DC high-potential testing starts to show its age,

test methods recommended by IEEE are ready to fill the void

By Wally Vahlstrom, Electro-Test, Inc.

F

or many years, high-voltage

DC testing has been the tra-

ditionally accepted method to

judge the serviceability of

medium-voltage cables. DC

high-potential (hipot) tests

worked well as a withstand and condi-

tion assessment test for paper- and oil-

insulated, lead-covered (PILC) cable.

Even when plastic insulated cables were

first introduced in the ’60s, it was still the

preferred method.

Although applicable industry stan-

dards began to change in 1994, manufac-

turers, testing firms, and standards

groups still agreed that DC hipot test

equipment could be used to perform fac-

tory tests, acceptance tests, and mainte-

nance tests. As far as the installer or main-

tenance electrician was concerned, cables

that withstood the DC hipot test were good

enough to be placed—or placed back— An IEEE study on water trees shows electrical trees will likely progress to failure quickly, so PD

into service. But recent research and field testing is more valuable if performed along with dissipation factor/power factor (DF/PF) testing.

data is calling that practice into question

and raising serious doubts about whether new medium voltage cable doesn’t cause try standards began to change is only just

DC hipot testing might damage or cause any reduction in cable life. now gaining industry-wide acceptance.

extruded cables—especially field aged As noted in IEEE Standard 400-2001, Current versions of some of these stan-

cross-linked polyethylene (XLPE) insu- Guide for Field Testing and Evaluation of dards no longer provide for DC hipot

lated cable—to fail prematurely. Shielded Power Cable Systems, “testing testing of extruded cables as a mainte-

After receiving reports in the early ’90s of cables that have been service aged in a nance test. Of those that still do, all have

that DC hipot testing could be to blame wet environment (specifically, XLPE) reduced the recommended test duration

for latent damage experienced by ex- with DC at the currently recommended from 15 min to only 5 min. None endorses

truded medium-voltage cable insulation, DC voltage levels may cause the cables DC hipot testing as a factory test for ex-

the Electric Power Research Institute to fail after they are returned to service. truded cables, but all continue to provide

(EPRI) funded two studies relating to The failures would not have occurred at for DC hipot testing as an acceptance test

XLPE and ethylene propylene rubber that point in time if the cables had re- on newly installed extruded cable. These

(EPR) cables. These studies, EPRI Reports mained in service and had not been tested industry standards also no longer endorse

TR-101245 and EL-6902, yielded the fol- with DC.” This standard also indicates DC hipot testing as a maintenance test

lowing conclusions regarding XLPE cable: other testing has shown that “even mas- for extruded cables that have been in ser-

• DC hipot testing of field-aged sive insulation defects in extruded dielec- vice for more than five years.

cable reduces its life. tric insulation cannot be detected with

• DC hipot testing of field-aged cable DC at the recommended voltage levels.” Deterioration mechanisms. Partial

generally increases water tree growth. The shift in opinion of hipot testing discharge (PD) and water intrusion are the

• DC hipot testing before energizing that began in 1994 when applicable indus- two age-related deterioration mechanisms

20 EC&M October 2003

of most interest for both laminated PD can occur primarily in voids in can be caused by several things, includ-

(PILC) and extruded (XLPE and EPR) the insulation of cables and cable acces- ing extrusion problems, improper han-

cable designs (Table below). Although the sories. Within a PILC cable, voids may dling during installation, or errors in ter-

source of PD and the process by which result when the insulating oil migrates— mination assembly.

water enters the insulation are different due to elevation differences, cracks in Whether water gets in through a crack

for both cable types, these forms of dete- the lead sheath, or incorrect assembly of in the lead sheath of a PILC cable or per-

rioration have become a primary focus terminations—away from an area within meates through the outer layers of an ex-

for cable manufacturers and owners. the cable. Voids in extruded cable systems truded cable, it can result in deterioration.

Deterioration assessment test methods.

October 2003 EC&M 21

MAINTENANCE FACTS

Moisture decreases the dielectric strength withstand testing and condition assess-

of the insulation and provides a path for ment testing. DC, very low frequency, os-

leakage current or other forms of dete- cillating wave, and power frequency are all

rioration within the insulation. However, types of tests that fall into the first category.

most cable experts are convinced that wet Withstand tests are go/no-go tests,

paper insulation and water trees—named that involve applying an overvoltage and

for their characteristic visual pattern— provide no trend data. A key concept of

in extruded insulation don’t initially pro- withstand tests is that if the overvoltage

duce PD. In their 1997 IEEE paper, doesn’t fail the cable, the insulation

“Mechanism for Impulse Conversion of condition is then considered adequate.

Water Trees to Electrical Trees in XLPE,” To make a crude comparison, these tests

Steven Boggs, John Densley, and Jinbo are analogous to putting a patient on a

Kuang proposed that transient overvolt- treadmill for a predetermined time at a

ages were responsible for converting wa- predetermined speed and pronouncing

ter trees to electrical treeing, or the deg- him healthy if he doesn’t die. Such a test

radation of electrical insulation by the overlooks the possibility of smaller prob-

formation of conductive carbonized lems that don’t seem like a big deal at the

paths, which allows for small electrical time. All withstand tests require the cable

discharges. It’s commonly accepted that to be de-energized, disconnected, and

electrical trees do produce PD. tested with a special voltage source.

On the other hand, condition assess-

Condition assessment methods. ment tests involve the measurement of Online partial discharge testing is one PD test

IEEE Standard 400-2001 establishes characteristics of the insulation. A key that will detect and measure partial discharge

six field tests for shielded power cable that concept of assessment tests is that the data in Pico Coloumbs. It’s beneficial to conduct it

can be broken down into two categories: they compile can be trended over time to in conjunction with DF/PF testing.

help determine whether and to what ex- voltage is applied to insulation that’s in trees in extruded cables. All forms of

tent the insulation has deteriorated. Al- pristine condition, the cable performs available PF and DF test equipment require

though some methods of performing these much like a capacitor: capacitive, or the cable to be de-energized, disconnected,

tests involve applying an overvoltage, it charging, current will flow based prima- and tested with a special voltage source.

isn’t intended as a withstand test that rily on insulation type, cable length, and Now that the industry has soured on

might cause a weak spot to fail. Condi- insulation geometry. Virtually no resis- DC hipot testing, cable installers and

tion assessment tests can be further sub- tive current will flow, resulting in a near- maintenance workers have had to begin

divided into partial discharge and dissi- zero power factor. Power factor (PF) is looking elsewhere to judge the efficacy of

pation factor testing. the ratio of resistive current to total cur- medium-voltage cables. The IEEE stan-

Partial discharge tests. There are sev- rent. Dissipation factor (DF) is the ratio dard for field testing and evaluating

eral methods for detecting and measur- of resistive current to reactive current. For shielded power cable systems presents six

ing PD. Some methods involve de-ener- small values of resistive current, PF and options. Each test has distinct advantages

gizing, disconnecting, and powering the DF are about equal. Any form of deterio- and disadvantages. Of these methods,

cable from a special voltage source, while ration that results in an increase of resis- four are withstand tests. Only two pro-

other methods allow the cable to remain tive current will cause a corresponding vide trendable condition assessment in-

energized at normal line voltage. Both increase in PF and DF. formation: PF/DF and PD. Of these, only

methods will detect and measure partial Since moisture in PILC cable decreases the PD test can be performed while the

discharge in Pico Coulombs (PC). The insulation resistance and allows resistive cable remains energized and in service. For

authors of the IEEE study on water trees leakage current to increase, the result will those applications where it’s impractical to

state that electrical trees will likely be an increase in insulation PF and DF. remove cables from service to perform

progress to failure quickly, so PD testing Similarly, the presence of water trees in maintenance testing, only the online PD

would be more valuable if performed in extruded cable will increase resistive leak- test offers a practical alternative. EC&M

conjunction with dissipation factor/ age current. The manufacturers of DF

power factor (DF/PF) testing. testing equipment claim their products can Vahlstrom is director, technical services for

Dissipation factor tests. When AC detect moisture in PILC cable and water Electro-Test, Inc. in San Ramon, Calif.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

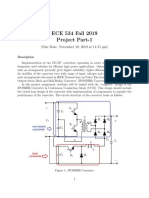

- ECE 534 Project 1 F19Document6 pagesECE 534 Project 1 F19JAY CHHEDANo ratings yet

- A Capacitive Sensor Interface Circuit Based On Phase Differential MethodDocument4 pagesA Capacitive Sensor Interface Circuit Based On Phase Differential MethodPriyanshu_D_An_1642No ratings yet

- Dual Stator Winding Induction Machine - Problems, Progress, and Future Scope PDFDocument12 pagesDual Stator Winding Induction Machine - Problems, Progress, and Future Scope PDFTaiwoNo ratings yet

- 78Xxsr Series: 3.3V/5V/12V Outputs High-Effi Ciency Switching Regulators With Lm78Xx PinoutsDocument6 pages78Xxsr Series: 3.3V/5V/12V Outputs High-Effi Ciency Switching Regulators With Lm78Xx PinoutsDaniel RetcelNo ratings yet

- Light-to-Frequency Conversion (Part 2) : Pulse and Oxygen ContentDocument4 pagesLight-to-Frequency Conversion (Part 2) : Pulse and Oxygen ContentJuan VacaNo ratings yet

- Phys 106: General Physics 2: Chapter IV: InductanceDocument63 pagesPhys 106: General Physics 2: Chapter IV: InductancehwuhwuheNo ratings yet

- Axpert Keb Manual-2Document38 pagesAxpert Keb Manual-2NeerajNo ratings yet

- 1N5062 (Data Sheet)Document3 pages1N5062 (Data Sheet)Dimitris DimitriadisNo ratings yet

- Forma Scientific Freezers ManualDocument38 pagesForma Scientific Freezers ManualEzsilvasilva SilvaNo ratings yet

- TB Chapter28Document28 pagesTB Chapter28eatman96No ratings yet

- Phy 102 Lecture 8 - Electrical Energy and Capacitance (B)Document72 pagesPhy 102 Lecture 8 - Electrical Energy and Capacitance (B)chipango lungoweNo ratings yet

- Ac Ageing Characteristics of Y2O3 Doped ZnO Varistors With High Voltage GradientDocument3 pagesAc Ageing Characteristics of Y2O3 Doped ZnO Varistors With High Voltage GradientJanja TothNo ratings yet

- S-8520/8521 Series: Step-Down, PWM Control or PWM / PFM Switchable Switching Regulator ControllerDocument44 pagesS-8520/8521 Series: Step-Down, PWM Control or PWM / PFM Switchable Switching Regulator ControllerGenilson Dias GomesNo ratings yet

- MCQ Chapter2Document3 pagesMCQ Chapter2Harishankar SNo ratings yet

- Ci 73Document60 pagesCi 73arnoldoplus0% (1)

- CPO N 1 3KR Rack Tower User ManualDocument21 pagesCPO N 1 3KR Rack Tower User ManualmezcalinmezcalinNo ratings yet

- Electro Hydraulic and Electromagnetic FormingDocument3 pagesElectro Hydraulic and Electromagnetic FormingsathiaNo ratings yet

- Mitsubishi FR-Z024 UL Instruction Manual PDFDocument145 pagesMitsubishi FR-Z024 UL Instruction Manual PDFUst TrungNo ratings yet

- A 1 GHZ Cmos RF Front-End Ic For ADocument10 pagesA 1 GHZ Cmos RF Front-End Ic For ASP SpurtinathNo ratings yet

- Toshiba (TV) 46H84 PDFDocument46 pagesToshiba (TV) 46H84 PDFDan PrewittNo ratings yet

- 7UM62 - Rotor Earth Fault ProtectionDocument26 pages7UM62 - Rotor Earth Fault ProtectionfourwheelerNo ratings yet

- Chapter 1-Part 1: Half-Wave RectifiersDocument50 pagesChapter 1-Part 1: Half-Wave RectifiersWeehao SiowNo ratings yet

- ALA5 2-Wire 4-20ma ATEX Load Cell AmplifierDocument26 pagesALA5 2-Wire 4-20ma ATEX Load Cell AmplifierarefNo ratings yet

- LC Ladder Matching NetworksDocument33 pagesLC Ladder Matching NetworksCarriceiros TourNo ratings yet

- An Efficient Procedure For Narrowband Bandpass Filter DesignDocument7 pagesAn Efficient Procedure For Narrowband Bandpass Filter DesignPhilippeaNo ratings yet

- JVC C-13CL3Document2 pagesJVC C-13CL3James ArlanttNo ratings yet

- Value Beyond Measure Eltra Parts CatalogDocument14 pagesValue Beyond Measure Eltra Parts CatalogAliSultanNo ratings yet

- IR Jammer Infrared Remote Control Jammer v1.0.2Document24 pagesIR Jammer Infrared Remote Control Jammer v1.0.2Med50% (2)

- Compu Mate Brochure v2Document11 pagesCompu Mate Brochure v2pabloabelgilsotoNo ratings yet

- 10th January 2019 (First Shift)Document34 pages10th January 2019 (First Shift)hermoine gawarNo ratings yet