Professional Documents

Culture Documents

MSS Chemical Process Safety 2013-2014

Uploaded by

Yahyah NahabooCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MSS Chemical Process Safety 2013-2014

Uploaded by

Yahyah NahabooCopyright:

Available Formats

UNIVERSITY OF MAURITIUS

MODULE SPECIFICATION SHEET

1.

GENERAL INFORMATION

Academic Year: 2013/2014

Semester(s): Second

Title

Chemical Process safety

& Loss Prevention

2.

Code

Duration (hrs)

No of credits

Lectures: 45

Practicals:0

CHE 3203 Seminars:

Tutorials:

Others (Specify):

Total: 45

3.0

PRE-REQUISITE(S)/PRE-REQUIREMENT(S) - None

A student will be allowed to follow module y of which module x is a pre-requisite (PR) provided Grade G or Grade E or

above has been achieved in module x.

A student will be allowed to follow module y of which module x is a pre-requirement (PQ) provided s/he has followed

module x and sat for the examinations in module x.

3.

AIMS

This module has been designed to provide an in-depth coverage for best practices

involved in safety and loss prevention in the chemical industry, with specific reference to

industrial safety regulations in Mauritius. Learners will be familiarised with all types of

occupational hazards, their effects as well as the modes of control. Students will be

exposed to a typical chemical plant environment and study therein safety aspects, like

Standard Operating Procedures (SoPs), Process Safety Management (PSM) Tools, PPEs,

management of accidental/incidental chemical release & decontamination procedures.

4.

OUTLINE SYLLABUS

Sources & Evaluation of Exposure to Hazardous Substances; Hazard Control; Hazard and

Operability Study;Hazan; Risk Assessment; Occupational Health & Safety Management;

Health & Safety Audit in workplaces; Types, Effect and Control of Noise; Noise Survey;

Safety in Chemical Process Industry; Occupational Health Hazards (types, health effects

and standards).

5.

LEARNING OUTCOMES

Having studied this module, the students should be able to:

Understand the importance of safety in the chemical industry

Describe health hazards to which workers are exposed.

Evaluate these hazards and to propose control measures.

Have an insight of how accidents cause great loss to the chemical industry.

Demonstrate the usefulness of the legal framework pertaining to safety at the

workplace (with special reference to OSHA 2005).

Understand the different types of noise, their effects and modes of control.

Know all physical, chemical, biological & psyco-social occupational hazards

Understand a safety & health audit in a place of work.

Familiarise with a typical chemical plant and study all safety features of same.

Understand the importance of Standard Operating Procedures (SoP) & know how to

write the SoPs for start-up & shut-down operations of a chemical plant.

Familiarise with the objective, classification & types of PPEs

Understand the major procedures in the management of health & safety in a company

Know some of the Process Safety Management tools.

Understand the safety issues associated with an accidental/incidental release of a

dangerous chemical & the subsequent decontamination procedures.

6.

COOORDINATORS:

Programme Coordinator

Name

Department

Building

Room Number

Phone No.

E-mail address

Consultation Time

Dr V Seebaluck

Chemical & Environmental

Engineering

FoE Phase II

G9

4037766

v.seebaluck@uom.ac.mu

On request

Area Coordinator

(if applicable)

Module Coordinator

Mrs V Dookhun

Chemical & Environmental

Engineering

FoE, Phase II

G7

4037860

v.dookhun@uom.ac.mu

On request

7.

LECTURER(S)

Name

Department

Mr A K Ragen

Chemical & Environmental

Engineering

Building

Room Number

Phone No.

E-mail address

Contact Hours

Consultation Time

FoE, Phase II

G7

4037765

ak.ragen@uom.ac.mu

22.5

Contact Address

(For P/T)

8.

On request

Mrs V Dookhun

Chemical &

Environmental

Engineering

New Eng Tower

4

4037860

v.dookhun@uom.ac.mu

22.5

Thursdays as from 1

pm

VENUE AND HOURS/WEEK

All lectures will normally be held in Room: 2.16 (As indicated in time table)

Hours/week: 3

9.

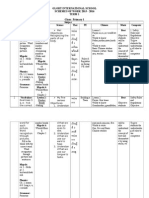

MODULE MAP

Wk(s)

Hr(s)

1.5

Introduction to Chemical process safety and Loss Prevention

1.5

Occupational

Hazards

1.5

1.5

3

4

1.5

1.5

1.5

1.5

Theme(s)

Lecture Title(s)

Intoduction to chemical safety & its

importances with reference to accidents at

work & occupational disease data in the local

context

Occupational health hazards- health effects; Routes of entry;

Dose-response; health standards

Occupational

Physical, chemical, biological & psyco-social

Hazards

hazards, some circumstances, effect & control

Sources and evaluation of exposure to hazardous substances

Occupational

Physical, chemical, biological & psyco-social

Hazards

hazards, some circumstances, effect & control

Hazard control and lone working Control principles & measures

Occupational

Definition, types, health effects & control of

Noise

occupational noise

Assignment 1

Occupational

Noise measurement, decimeter, decibels,

Noise

addition & average of noise; definition of Leq,

noise standards in mauritius

1.5

1.5

1.5

Hazop hazard & operability study; Hazan- brief

description

1.5

Occupational

health & safety

management

1.5

Hazop hazard & operability study; Hazan- brief

description

1.5

Safety Tools

1.5

Hazop hazard & operability study; Hazan- brief

description

1.5

The Chemical

Plant &

associated safety

features

1.5

1.5

Introduction to risk assessment

1.5

1.5

Risk Assessment continued

1.5

Class Test

10

11

The Chemical

Plant &

associated safety

features

The Chemical

Plant &

associated safety

features

Work environment health & safety audit;

occupational health surveillance programme;

organizational procedures; indicators of

progress

Personal Protective Equipments; its aim,

selection, classification, some example of

circumstances when a PPE is needed

Description of a typical chemical plant & its

associated equipment; description of the

process; its PFID

Standard Operating Procedures (SoPs); its

definition, format, scope of application.

Writing SoPs for start-up, shut-down &

maintenance procedures.

Control of Substances Hazardous to Health

(CoSHH); its definition, major requirements,

and the form. Producing a CoSHH form for a

specific maintenance job in the plant.

Lecturer

Initials

VD

L, P, S, V,

T, Test

AKR

VD

AKR

VD

AKR

VD

AKR

VD

AKR

L

L

VD

AKR

VD

AKR

VD

AKR

VD

AKR

L

L

VD

AKR

L

L

VD

12

13

1.5

Process Hazard

Analysis (PHA)

1.5

1.5

Case study

1.5

1.5

Oral presentation

Process Hazard

Analysis (PHA)

Process Hazard

Analysis (PHA)

PHA requirements; PHA tools: What-if, its

objectives, steps, question areas; writing some

what-if questions & answer

PHA tools: Checklist, its objectives; Checklist

questions categories: causes of accidents,

facility functions; drafting checklist questions

PHA tools: What-if/Checklist, its objectives;

Drafting questions in specific areas

14

1.5

Revision

1.5

Class Test & Discussion on Exams

15

1.5

Discussion on exams past papers

1.5

Revision

Abbreviations: L: Lectures, P: Practicals, T: Tutorials, V: Visits, S: Seminars

10.

RECOMMENDED BOOKS/JOURNALS/WEBSITES

11.

ESSAY(S)/ASSIGNMENT(S)/PRACTICAL(S)

AKR

VD

AKR

L

L

VD

AKR

S

L

VD

AKR

VD

AKR

L

L

L

L

RAGEN

1.

Title

Maximum Marks

To produce

MSDS for all chemicals used in the

Department of Chemical &

Environmental labs

10

DOOKHUN

Last

Submission

Date

th

10 week

12.

ASSESSMENT

(i)

Written Examination

Paper Structure

Sections (if any): A: 3 questions

B: 3 questions

Multiple Choice Questions: None

No. of questions to be answered: 4

Exams date: MAY 2014

Paper Duration:2 hours

Compulsory Questions (if any) : None

Weighting (%): 70

Total Marks: 100

(ii)

Pass Marks: 40

Continuous Assessment

Assignment(s): 2

Practical(s): 0

Oral Presentation : 1

Test(s): 2

Mrs V Dookhun

Weighting (15 %)

5

0

5

20

Mr A K Ragen

Weighting (15%)

10

30

60

Total Marks:

30% of the total marks for this module

11.

OTHER INFORMATION

50

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Practitioner Prep Guide 2.1Document90 pagesPractitioner Prep Guide 2.1disha bhaumickNo ratings yet

- AAAE Accreditation Study GuideDocument107 pagesAAAE Accreditation Study GuideandrewpunNo ratings yet

- Norsk ProveDocument6 pagesNorsk Provefaraz45570% (1)

- CO2 Transport Overview - S. Santos IEAGHGDocument29 pagesCO2 Transport Overview - S. Santos IEAGHGYahyah NahabooNo ratings yet

- Energy Balance For Ethanol DistillationDocument17 pagesEnergy Balance For Ethanol DistillationYahyah Nahaboo100% (2)

- 45 Excel FormulasDocument138 pages45 Excel FormulasSeshagiri VempatiNo ratings yet

- Aptitude Test Schlumberger PDFDocument5 pagesAptitude Test Schlumberger PDFRiyan AdiputraNo ratings yet

- Exam Content Guide Life Span Developmental PsychologyDocument32 pagesExam Content Guide Life Span Developmental PsychologyMAPPLE12345667% (3)

- The Above Graph Shows The Hourly Emission of NO2 Gas From Grande Prairie StationDocument2 pagesThe Above Graph Shows The Hourly Emission of NO2 Gas From Grande Prairie StationYahyah NahabooNo ratings yet

- Intro Fluid MechDocument44 pagesIntro Fluid MechAlanbertro OmarNo ratings yet

- 2.2. HydroDocument61 pages2.2. HydroMeron MogesNo ratings yet

- Week 3 NotesDocument28 pagesWeek 3 NotesYahyah NahabooNo ratings yet

- Schulich School of Engineering ENEN 663 - Biological Processes For Wastewater TreatmentDocument1 pageSchulich School of Engineering ENEN 663 - Biological Processes For Wastewater TreatmentYahyah NahabooNo ratings yet

- Final AssignmentDocument2 pagesFinal AssignmentYahyah NahabooNo ratings yet

- Autocad 2008, 1. Level, 2dDocument29 pagesAutocad 2008, 1. Level, 2dSamra DukićNo ratings yet

- Use of Carbon DioxideDocument16 pagesUse of Carbon DioxideYahyah NahabooNo ratings yet

- Harvard System of ReferenceDocument7 pagesHarvard System of Referencejaya1816No ratings yet

- MSS SWMDocument8 pagesMSS SWMYahyah NahabooNo ratings yet

- Qualitative StudyDocument9 pagesQualitative StudyYahyah NahabooNo ratings yet

- BEng (Hons) ChemEngg (Minor - Env) - Level 4Document2 pagesBEng (Hons) ChemEngg (Minor - Env) - Level 4Yahyah NahabooNo ratings yet

- Assessment of CCS Sweden PDFDocument19 pagesAssessment of CCS Sweden PDFYahyah NahabooNo ratings yet

- Alternative To Practicals0002Document1 pageAlternative To Practicals0002Yahyah NahabooNo ratings yet

- Hazards Associated With CCS 1Document10 pagesHazards Associated With CCS 1Yahyah NahabooNo ratings yet

- Industrial Flow Meter PDFDocument6 pagesIndustrial Flow Meter PDFYahyah NahabooNo ratings yet

- AnswerDocument1 pageAnswerYahyah NahabooNo ratings yet

- Milk Powder: Etc., Recombined Milks and Other Liquid BeveragesDocument5 pagesMilk Powder: Etc., Recombined Milks and Other Liquid BeveragesSUTHANNo ratings yet

- Timetable For Academic Year 2017Document2 pagesTimetable For Academic Year 2017Yahyah NahabooNo ratings yet

- University of Mauritius Module Specification SheetDocument5 pagesUniversity of Mauritius Module Specification SheetYahyah NahabooNo ratings yet

- Pid Diagram 2Document1 pagePid Diagram 2Yahyah NahabooNo ratings yet

- SaponifikasiDocument5 pagesSaponifikasiMirza AuliyaNo ratings yet

- Milk Powder Production in New ZealandDocument8 pagesMilk Powder Production in New ZealandYahyah NahabooNo ratings yet

- Problem 11 4 5Document10 pagesProblem 11 4 5Yahyah NahabooNo ratings yet

- Probeml 11 4 3Document16 pagesProbeml 11 4 3Yahyah NahabooNo ratings yet

- Sivarajingam PDFDocument225 pagesSivarajingam PDFanil4u29No ratings yet

- Introduction Cooling TowerDocument2 pagesIntroduction Cooling TowerYahyah Nahaboo100% (1)

- Instruction Booklet: Ts Law Common Entrance Test - 2021Document7 pagesInstruction Booklet: Ts Law Common Entrance Test - 2021Santosh KumarNo ratings yet

- APICS CSCP - Supply Chain Management Certification - ASCM - BrochureDocument6 pagesAPICS CSCP - Supply Chain Management Certification - ASCM - BrochureSintoGNo ratings yet

- Ac7114 Rev H Audit Criteria For Nondestructive Testing (NDT) To Be Used On-After Jan 25, 2015Document25 pagesAc7114 Rev H Audit Criteria For Nondestructive Testing (NDT) To Be Used On-After Jan 25, 2015Nestor Czerwacki100% (1)

- Syllabus in Customers Relation Mgt.Document4 pagesSyllabus in Customers Relation Mgt.Jhoerey D VillegasNo ratings yet

- Plumbing Career - Training Courses BrochureDocument8 pagesPlumbing Career - Training Courses BrochureJulie JonesNo ratings yet

- Test Specification Table Up 1 Examination 2018 Level of Skills Skills Marks L I H Section A Question 1ADocument2 pagesTest Specification Table Up 1 Examination 2018 Level of Skills Skills Marks L I H Section A Question 1ADineswari SelvamNo ratings yet

- Visual Acuity RecordDocument1 pageVisual Acuity Recordivan_vanNo ratings yet

- Ocr A Level Chemistry Year 1 Student BookDocument297 pagesOcr A Level Chemistry Year 1 Student BookHimadri SarkarNo ratings yet

- Sarthi-Pune-Mpsc-Cet-2020b - Guidelines - 0 PDFDocument11 pagesSarthi-Pune-Mpsc-Cet-2020b - Guidelines - 0 PDFamitrocksNo ratings yet

- History, Civics and GeographyDocument4 pagesHistory, Civics and GeographyAdith DeepakNo ratings yet

- Statistical Reasoning - Syllabus AndersonDocument2 pagesStatistical Reasoning - Syllabus Andersonapi-520803720No ratings yet

- ANP 202 Principles of Animal Production PDFDocument207 pagesANP 202 Principles of Animal Production PDFBELKYS100% (1)

- Ultimate Student Guide Science 10Document89 pagesUltimate Student Guide Science 10KiranTShajiNo ratings yet

- TNPSC Group 1 Exam Paper PatternDocument13 pagesTNPSC Group 1 Exam Paper PatternvardhinikumarNo ratings yet

- Hawaii Nurse Aide Testing/Out of State/Reciprocity Application FormDocument4 pagesHawaii Nurse Aide Testing/Out of State/Reciprocity Application FormLovely FinuliarNo ratings yet

- Information Bulletin JEE (Main) - April 2019: Registered OfficeDocument21 pagesInformation Bulletin JEE (Main) - April 2019: Registered OfficeAman OjhaNo ratings yet

- Chapter 033Document25 pagesChapter 033dtheart2821No ratings yet

- Project Report 10Document70 pagesProject Report 10Ayush Desai-DakleNo ratings yet

- Scheme of Work - P1Document9 pagesScheme of Work - P1Glory At ร.ร.กลอรี่100% (1)

- Bank Exam Syllabus 2021 - IBPS, SBI, RBI Exams Syllabus & Exam PatternDocument10 pagesBank Exam Syllabus 2021 - IBPS, SBI, RBI Exams Syllabus & Exam PatternPapan SarkarNo ratings yet

- NMC 355 2009 FinalDocument15 pagesNMC 355 2009 FinalAnonymous Fwe1mgZNo ratings yet

- DNY Syllabus Honors Fall 2010Document4 pagesDNY Syllabus Honors Fall 2010kay_1001No ratings yet

- English As A Foreign Language BrochureDocument15 pagesEnglish As A Foreign Language BrochureKaro López RendónNo ratings yet