Professional Documents

Culture Documents

RT Mod MS 001

Uploaded by

Kelly BatesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RT Mod MS 001

Uploaded by

Kelly BatesCopyright:

Available Formats

LEVELLING & FENCING OF MOD

LANDS AT RAHIMA

BI/CONTRACT No. 3000624695

METHOD STATEMENT

INSTALLATION OF ARAMCO

STD. FENCE SYSTEM

Doc.No.

ETE/3000624695/MS-001

Rev. A

DATE

05.OCT.2015

METHOD STATEMENT

INSTALLATION OF ARAMCO STANDARD

FENCE SYSTEM

SAUDI ARAMCO APPROVAL

Signature:

Name :

Date :

Rev.

Date

Description of Revision

Prepared

Checked

Approved

05 Oct. 15

Issued For Review & Approval

JCZ

MZ

YKG

This document is the property of EasternTrading & Contracting Company all rights reserved. Violators will be pursued under civil and criminal law.

Page 1 of 10

LEVELLING & FENCING OF MOD

LANDS AT RAHIMA

BI/CONTRACT No. 3000624695

METHOD STATEMENT

INSTALLATION OF ARAMCO

STD. FENCE SYSTEM

Doc.No.

ETE/3000624695/MS-001

Rev. A

DATE

05.OCT.2015

Revision Summary

Approved

Date

Issue Date

Rev.

05 Oct. 15

Section/Page

Revised

All

Description of Revision

Issued for Review and Approval

Page 2 of 10

Approved

By

YKG

LEVELLING & FENCING OF MOD

LANDS AT RAHIMA

BI/CONTRACT No. 3000624695

METHOD STATEMENT

INSTALLATION OF ARAMCO

STD. FENCE SYSTEM

Doc.No.

ETE/3000624695/MS-001

Rev. A

DATE

05.OCT.2015

Table of Contents

A.

PURPOSE .................................................................................................................................................... 4

B.

SCOPE ........................................................................................................................................................ 4

C.

REFERENCE DOCUMENTS .......................................................................................................................... 4

D.

DEFINITIONS .............................................................................................................................................. 5

E.

RESPONSIBILITIES ...................................................................................................................................... 5

F.

RESOURCES ................................................................................................................................................ 5

G.

METHODOLOGY ......................................................................................................................................... 6

H.

QUALITY ASSURANCE AND QUALITY CONTROL ........................................................................................ 8

I.

HEALTH, SAFETY AND ENVIRONMENT ...................................................................................................... 8

J.

RISK ASSESSMENT AND SAFETY MEASURE................................................................................................ 9

K.

RISK ANALYSIS.......................................................................................................................................... 10

Page 3 of 10

LEVELLING & FENCING OF MOD

LANDS AT RAHIMA

BI/CONTRACT No. 3000624695

METHOD STATEMENT

INSTALLATION OF ARAMCO

STD. FENCE SYSTEM

Doc.No.

ETE/3000624695/MS-001

Rev. A

DATE

05.OCT.2015

A. PURPOSE

To define a procedure to provide a proper and efficient sequence of works shall be

performed in safety manner & good working practice in accordance with the Approved

Shop Drawings, Project Specifications, Saudi Aramco and related Industry Codes &

Specifications.

B. SCOPE

This covers the necessary activities associated with the Installation of the Proposed SA

Std. Aramco Type IV Fence & Gate System for the Levelling & Fencing of MOD Lands at

Rahima Project. This shall be read in conjunction with the Approved Shop Drawings,

Project Specifications, Saudi Aramco Engineering Standards and related Industry Codes &

Specifications. In the event of conflict with the others, the most stringent shall govern.

C. REFERENCE DOCUMENTS

Vendor Approved Shop Drawings

Saudi Aramco Engineering Standards

SAES-A-114

Excavation & Backfill

SAES-M-006

Saudi Aramco Security & General Purpose Fencing

SAES-Q-001

Criteria for Design & Construction of Concrete Structures

Saudi Aramco General Instruction

GI-0002.100

Work Permit System

Saudi Aramco Construction Safety Manual

Industry Codes & Standards

American Society for Testing & Materials

ASTM A53

Standard Specification for Pipe, Steel, Black & Hot-Dipped, Zinc

Coated, Welded and Seamless

ASTM A121

Standard Specification for Metallic-Coated CS Barbed Wire

ASTM A123

Standard Specification for Zinc (HDG) Coatings on Iron Steel

ASTM A392

Standard Specification for Zinc-Coated Steel Chain-Link Fence

Fabric

American Concrete Institute

ACI 304R

Guide for Measuring, Mixing, Transporting and Placing Concrete

ACI 305R

Guide for Hot Weather Concreting

ACI 308R

Guide to Curing Concrete

ACI 546

Guide to Concrete Repair

Page 4 of 10

LEVELLING & FENCING OF MOD

LANDS AT RAHIMA

BI/CONTRACT No. 3000624695

METHOD STATEMENT

INSTALLATION OF ARAMCO

STD. FENCE SYSTEM

Doc.No.

ETE/3000624695/MS-001

Rev. A

DATE

05.OCT.2015

D. DEFINITIONS

All terms used in the development of this procedure are defined below:

CLIENT

CONTRACTOR

Saudi Aramco (SA)/ Ministry of Defense (MOD)

Eastern Trading & Contracting Company (ETE)

E. RESPONSIBILITIES

Construction Manager shall ensure that all operations have been risk assessed and

necessary control measures have been implemented to carry out the task in a safely

manner. He shall strictly implement and monitor the methodology of works as per

project specifications & IFC drawings compliance with quality, schedule & safety

requirements.

Civil Supervisor at site to ensure compliance by all labour and equipment operators and

other associated craftsmen to the requirements of this procedure, Project Quality Plan,

relevant IFC drawings, HSE requirements as well as the project specifications. Secure

all necessary Work Permits.

QC-Civil Inspector shall monitor the daily activities and verifies its compliance to project

specifications. Conduct activities in accordance with the Project QA Manual and Quality

Inspection Plan.

Engineering department shall provide technical assistance to construction operation.

Ensure that IFC drawings at site shall be in its most recent revision together with the

relevant shopdrawings shall be provided at site.

HSE officer shall control, supervise and record toolbox meetings. Inspect, approve or reject

engaged resources. Ensure that all HSE requirements are met and implemented while

executing the works. Notify the person in charge on site if any deviation and/or

corrective remedy action to be applied before and while executing the works. Ensure

that recommendation of work place precaution followed up strictly. Stop any/or all works

in case specified recommendation/ observations were not followed up by construction

management team.

F. RESOURCES

The Contractor shall deploy adequate number of resources but not limited to the following

as the Works may requires complying with the approved schedule and resource

histograms:

Equipments/Tools

Auger Drill mounted on JCB/Skid Loader

Transit Mixer

Page 5 of 10

LEVELLING & FENCING OF MOD

LANDS AT RAHIMA

BI/CONTRACT No. 3000624695

METHOD STATEMENT

INSTALLATION OF ARAMCO

STD. FENCE SYSTEM

Doc.No.

ETE/3000624695/MS-001

Rev. A

DATE

05.OCT.2015

Concrete Pump

Water Tanker

Telescopic Crane, SWL 10t MIN.

Flatbed Trailer

Concrete Vibrator

Hand Power Tools

Mason Tools

Concrete Testing Tools

Manpower

Project Engineer

Civil Supervisor

Surveyor

Contractor QC Inspector-Civil

Approved 3rd Party Laboratory Technician

Safety Supervisor

Flagman/ Spotter/ Banksmen

Certified Machinery Operators & Drivers

Foreman

Skilled Workers (Mason, Carpenter, Steel Fixer, etc.)

Labour Crew

Safety Equipment

Fire Extinguishers

Warning Signage

Barricades/Jersey Barriers

G. METHODOLOGY

1. Installation of fencing systems shall be in accordance with the vendor approved

drawings and in conformance to the SA standard drawings.

2. Fence & Brace Post Foundations

2.1 The Contractor shall carry out the erection works directly on-site, i.e. fences steel

posts shall be erected together with the concrete cast directly on-site. Refer to

attach sketch for the erection of fence post.

2.2 With surveyor assistance, established the fence line and mark the line post

foundations. Straining posts shall be provided at: 1) all ends, 2) corners of fences

at change of direction and 3) at intervals not exceeding 90m on straight line.

2.3 Intermediate posts shall be provided at intervals not exceeding 3m.

2.4 With the use of drilling auger machine mounted to JCB or bobcat (skid loader),

carry out the excavation for the line post foundation. Hole for Straining posts

and Gate posts shall not be < 450 while the Intermediate posts shall not be <

350.

Page 6 of 10

LEVELLING & FENCING OF MOD

LANDS AT RAHIMA

BI/CONTRACT No. 3000624695

METHOD STATEMENT

INSTALLATION OF ARAMCO

STD. FENCE SYSTEM

2.5

Doc.No.

ETE/3000624695/MS-001

Rev. A

DATE

05.OCT.2015

Remove any loose soil in the holes then place with PE sheet prior to installation of

the post.

2.6 Ensure the plumbness of posts by providing necessary supports and braces so

that upon the completion of erection it is truly to the line of fence line as specified

in the IFC dwg.

2.7 Carry out the concrete pouring of the foundation using 4000 psi concrete, well

rammed as filling proceeds & consolidated.

3. Install brace posts at 90m c/c (max.) of the fencing runs.

4. The fencing fabric shall be attached to the tension wire by means of tie wires spaced at

intervals not exceeding 300mm. the tension wire shall be attached to the line posts by

tie wire wrapped around the post and secured to the tension wire by 3 complete turns

on each side of the post.

5. The fencing fabric shall be attached to all line posts by means of tie wire spaced at

intervals no exceeding 350mm along each post.

6. The barbed wire shall be held in the extension arm slots by means of lock wire.

7. Secure tension wire to the terminal posts by means of a winding bracket.

8. Each brace assembly shall consist of one top and one intermediate compression

member both of 41mm OD pipe and one adjustable diagonal tension rod of at least

10mm dia. Pipe used for the compression member shall be of one piece without

couplings in the bracing panel.

9. Gate and end posts shall be braced to the nearest line post with one complete brace

assembly.

10. Corner and tension posts shall be braced to the two nearest line posts with one

complete brace assembly to each line post.

11. When fully constructed the barbed wire, tension wire, fabric and truss rods shall be taut

very well.

12. End of procedure.

Page 7 of 10

LEVELLING & FENCING OF MOD

LANDS AT RAHIMA

BI/CONTRACT No. 3000624695

METHOD STATEMENT

INSTALLATION OF ARAMCO

STD. FENCE SYSTEM

Doc.No.

ETE/3000624695/MS-001

Rev. A

DATE

05.OCT.2015

H. QUALITY ASSURANCE AND QUALITY CONTROL

The quality of the works shall be performed in line with the SA Quality Standards. Relevant

Inspections shall be made at stages as per the approved ITPs.

Contractor QA/QC Inspectors shall closely monitor and assure all general materials are

complying with the project specifications. Frequent inspections shall be conducted and all

records shall be maintained as required by project QA/QC Program in accordance with

approved Project Quality Plan & ITPs.

All the tests to be performed shall be in conformance with the project standards. Only

approved third party testing laboratory technician(s) shall be responsible for performing all

related civil tests. Any materials and works not conforming to the project specifications shall

be rejected by the relevant discipline approved QC Inspector(s).

I. HEALTH, SAFETY AND ENVIRONMENT

The health and safety shall perform a splendid role in all construction activities to ensure

that all the works are being carried out in a safe manner and creating a healthy

environment at site. All activities shall be carried out safely in accordance with ETE-HSE

plan approved by Client and related SACSM.

Contractor's site supervisor shall conduct daily toolbox meetings and discuss the

requirements of the project and other special needs to create a safe working environment.

He is responsible for achieving the target and the project milestones.

Appropriate work permits shall be applied in accordance to the requirements of SACSM.

Necessary checklists for the specific job shall be properly completed, approved and be

always made available at the job site.

Safety Inspector (ETE) shall closely monitor and assure that all works are carried out in

highly safe manner, gearing the workers with full strength of safety protective equipment,

preparation of safety barricading and dust control screening wherever applicable in safe

manner, safe workability of equipment to be used and fulfilling any other additional safety

needs as required during work executions. He shall also check and ensure that only

qualified personnel are carrying out the equipment & machinery related works.

ETE/DGC-HSE Manager & personnel shall conduct a safety walk in regular basis, around

the site (e.g. weekly). This shall be reported and submitted to the Client. Any accidents or

incidents that occurred shall be informed immediately to the client and recorded

accordingly.

All works shall be done safely in accordance to the requirements of SACSM, highlighted as

follows:

A safety officer shall be at site during the execution of works.

Daily toolbox meetings shall be conducted as mandatory

Following safety requirements shall be fulfilled

Housekeeping should be done in precast yard on daily basis and waste concrete

and other construction debris shall be disposed off safely as per SA Standards.

Safety barricade shall be provided wherever necessary

Page 8 of 10

LEVELLING & FENCING OF MOD

LANDS AT RAHIMA

BI/CONTRACT No. 3000624695

METHOD STATEMENT

INSTALLATION OF ARAMCO

STD. FENCE SYSTEM

Doc.No.

ETE/3000624695/MS-001

Rev. A

DATE

05.OCT.2015

Necessary safety signboards shall be displayed as required.

All workers shall be provided with job specific PPEs.

Safety flickering lights shall be provided for vehicles working on longtime hours.

The approving authority prior to start of the work shall inspect all equipment.

Working equipment shall be equipped with amber lights, horns, safety guards,

backup alarms etc. as required per safety provisions.

Any incident at site shall be immediately reported to client and recorded.

Weekly safety statistics reports and safety performance reports etc. shall be

prepared and recorded.

Daily safety task assignment to be prepared

Man shelters shall be provided to protect the workers from adverse climatic

condition, i.e. sand storm, high temperature, etc.

Potable water source shall be located within 100m walking distance and in all

designated break/rest areas.

Toilet and eating area shall be provided for adequate number of workers.

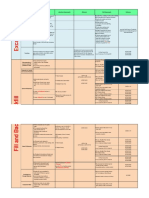

J. RISK ASSESSMENT AND SAFETY MEASURE

Work Activity

Operating equipments

Crane Lifting, inoperation & other H.E.s

Unloading, lifting &

lowering of fencing

materials

Job Hazards

Control Measures

Self-injuries and

property damage

Only skilled worker shall operate the

equipments.

Full PPE must be worn when working.

Calibration of required equipments must

be updated.

Crushing injuries,

hit by equipment

Only licensed operator shall be allowed

to operate the equipments at all times.

Certified lifting tools shall be used.

Assign a back-up man, spotter, flagman

to monitor the equipments blind spot.

Install warning signs in conspicuous

places.

Stay clear against equipment zones.

Pipe slippage or

extrication of lifting

strap

Ensure lifting strap is properly tied and

fasten securely.

Check lifting straps is free damage or

tear prior to use.

Only authorized personnel shall do the

work

Page 9 of 10

LEVELLING & FENCING OF MOD

LANDS AT RAHIMA

BI/CONTRACT No. 3000624695

METHOD STATEMENT

INSTALLATION OF ARAMCO

STD. FENCE SYSTEM

Work Activity

Stacking/ arrangements

of fence materials

Job Hazards

Tip, rolling,

slippage of unit

unto the platform

or pallets

Doc.No.

ETE/3000624695/MS-001

Rev. A

DATE

05.OCT.2015

Control Measures

Ground must be properly leveled.

Ensure the stability of unit before

untying from the crane

K. RISK ANALYSIS

Activities

Hazards

Injury to personnel

Use of Heavy Machine

for Lifting works

Damage to

environment

Lifting works

Injury to personnel

Material damage

Slip, Trips fall

Injury to personnel

Simultaneous operation

Injury to personnel

Material damage

Lack of Knowledge

Injury

Control Steps

Heavy equipment will be checked prior

to the job by safety inspector and every

day by operator. Daily checklist will be

completed in accordance with

procedure.

Only authorized & qualified operator

shall perform the job.

Proper communication will be ensured

between operator & rigger.

All lifting operation will be in accordance

to generic lifting plan.

Barricades will be installed. Good

housekeeping skills will be used to keep

area free of rubbish and debris.

Coordination between other crews

working will be arrange and monitored.

All personnel will be inducted about

procedure in case of emergency.

Page 10 of 10

You might also like

- Installation of Car Parking ShadesDocument6 pagesInstallation of Car Parking ShadesKelly Bates100% (3)

- 016-CIVIL - MS Anchor Bolt Installation PDFDocument14 pages016-CIVIL - MS Anchor Bolt Installation PDFKöksal Patan71% (7)

- Dewatering Construction ProcedureDocument5 pagesDewatering Construction ProcedureKelly BatesNo ratings yet

- Chancadora Secundaria OSBORNDocument12 pagesChancadora Secundaria OSBORNfaviojjglNo ratings yet

- Quality Plan Method StatementDocument10 pagesQuality Plan Method Statementjamie542350% (2)

- JSA For Excavation WorksDocument4 pagesJSA For Excavation WorksKelly Bates100% (12)

- AWS - Design Handbook For Calculating Fillet Weld Sizes 1997 PDFDocument27 pagesAWS - Design Handbook For Calculating Fillet Weld Sizes 1997 PDFMustafaSaylav100% (1)

- ITP-CI-026a-02 (Building Finishing Works)Document4 pagesITP-CI-026a-02 (Building Finishing Works)Delta akathehuskyNo ratings yet

- Method Statement For Installation of Overhead CraneDocument88 pagesMethod Statement For Installation of Overhead CraneJohn100% (3)

- Paint & CoatingDocument43 pagesPaint & CoatingKelly Bates80% (5)

- Temporary Security FenceDocument21 pagesTemporary Security FenceHussam Waleed100% (1)

- Method Statement For Termite Control (AUVA-MS-Civil-MS-023) Rev 01Document9 pagesMethod Statement For Termite Control (AUVA-MS-Civil-MS-023) Rev 01hammad21100% (1)

- Smithsonian Annals of Flight Nr. 10 SAOF-0010 PDFDocument320 pagesSmithsonian Annals of Flight Nr. 10 SAOF-0010 PDFSimon LászlóNo ratings yet

- 3pl & 4plDocument38 pages3pl & 4plsanthosh n prabhuNo ratings yet

- 31 32 13 Cement Stabilization PDFDocument7 pages31 32 13 Cement Stabilization PDFJUAN RULFONo ratings yet

- Asphalt Concrete PavingDocument16 pagesAsphalt Concrete Pavingprobook450_ehsanNo ratings yet

- High-Strength Low-Alloy Columbium-Vanadium Structural Steel: Standard Specification ForDocument4 pagesHigh-Strength Low-Alloy Columbium-Vanadium Structural Steel: Standard Specification ForCarlosNo ratings yet

- GD Earth Works R2Document22 pagesGD Earth Works R2sivaprasad_2k11No ratings yet

- WMS JOB Procedure FOR PIPING WORKDocument9 pagesWMS JOB Procedure FOR PIPING WORKsatyamech1_395565923No ratings yet

- Method of StatmentDocument20 pagesMethod of Statmentrajap2737No ratings yet

- Clouds and Big Data ComputingDocument13 pagesClouds and Big Data ComputingsuryaNo ratings yet

- Screeding WorksDocument1 pageScreeding WorksCindy AmyzaNo ratings yet

- 027 ITP For Pre Cast Concrete PDFDocument27 pages027 ITP For Pre Cast Concrete PDFlinga2014No ratings yet

- Method of Statement - Drainage WorksDocument6 pagesMethod of Statement - Drainage Worksainamin77No ratings yet

- Chain Link FenceDocument3 pagesChain Link Fencekarimakki100% (1)

- Bow Tie TechniqueDocument26 pagesBow Tie Techniquebaaziz2015100% (1)

- ITP For Concrete Paving WorkDocument15 pagesITP For Concrete Paving WorkShewale Pravin100% (1)

- ASTM A352 18aDocument7 pagesASTM A352 18aKelly BatesNo ratings yet

- MS-G-003 - General Method Statement For Horizontal PumpDocument19 pagesMS-G-003 - General Method Statement For Horizontal PumpNGUYEN VINHNo ratings yet

- Railway Engineering DiaryDocument97 pagesRailway Engineering DiaryDev Sharma67% (3)

- Method Statement of ExcavationDocument9 pagesMethod Statement of ExcavationAmit kumar thakurNo ratings yet

- Edoc 001864Document52 pagesEdoc 001864leesger7No ratings yet

- Civil Construction ProcedureDocument6 pagesCivil Construction Procedureคุณพ่อน้อง บิ๊กบอสNo ratings yet

- MS Site and FenceDocument11 pagesMS Site and FenceSahabzada AamirNo ratings yet

- MS - Construction of Duct Bank Under Existing Culvert Rev. 01Document2 pagesMS - Construction of Duct Bank Under Existing Culvert Rev. 01Nazir Hussain100% (3)

- MS - Raft PouringDocument14 pagesMS - Raft PouringAby ThykkodathuNo ratings yet

- Method of Statement For HDPE Pipe InstallationDocument2 pagesMethod of Statement For HDPE Pipe InstallationYe Yint100% (2)

- MS For HVAC Ducting Installation and PipingDocument18 pagesMS For HVAC Ducting Installation and PipingProject enghvacNo ratings yet

- Ms For Demin Water Tank Modification Rev 1 Feb. 28 2011lastDocument9 pagesMs For Demin Water Tank Modification Rev 1 Feb. 28 2011lastsharif339100% (1)

- Method Statement For Stone WorksDocument10 pagesMethod Statement For Stone WorksvisanuNo ratings yet

- Nawaz Khan - Civil InspectorDocument4 pagesNawaz Khan - Civil InspectormlNo ratings yet

- Trench & Shoring Inspection Checklist: Manifa Temporary Office and Camp FacilityDocument2 pagesTrench & Shoring Inspection Checklist: Manifa Temporary Office and Camp FacilityMunawwar KhanNo ratings yet

- 323 1701 190.3.r11.2 Backup Restore TL1 (Local) PDFDocument374 pages323 1701 190.3.r11.2 Backup Restore TL1 (Local) PDFMartin MakenaNo ratings yet

- Method Statement For LPG DismantlingDocument8 pagesMethod Statement For LPG DismantlingHusain abidiNo ratings yet

- Method Statement For Drainange Construction Work: Document/Drawing Number: TNEC-STSB-KLIA-CS-MS-013 Revision: ADocument9 pagesMethod Statement For Drainange Construction Work: Document/Drawing Number: TNEC-STSB-KLIA-CS-MS-013 Revision: AAishah AliasNo ratings yet

- Hydrostatic Testing of Pressure Pipelines PDFDocument3 pagesHydrostatic Testing of Pressure Pipelines PDFEngineerSajidAlam100% (1)

- Aluminium Cladding Method StatementDocument4 pagesAluminium Cladding Method StatementAllan Bryan Sario0% (1)

- Method Statement - Concreting WorkDocument4 pagesMethod Statement - Concreting WorkArnold Roy ManaloNo ratings yet

- Saes A 114Document2 pagesSaes A 114Nino Celso AstilleroNo ratings yet

- MST Installation of UPVC PIPESDocument10 pagesMST Installation of UPVC PIPESShahzaib ShahidNo ratings yet

- P140I Fencing WorksDocument5 pagesP140I Fencing WorkskbldamNo ratings yet

- Method Statement For Installation and Relocation of Isolation FenceDocument13 pagesMethod Statement For Installation and Relocation of Isolation FenceAnantha PadmanabhanNo ratings yet

- R07-HC3C05-FET-MTS-ME-0012 - C1 Method Statement For Installation of DX UnitsDocument46 pagesR07-HC3C05-FET-MTS-ME-0012 - C1 Method Statement For Installation of DX Unitslike saddamNo ratings yet

- Method Statement of Earth WorkDocument13 pagesMethod Statement of Earth WorkSainbayar SBNo ratings yet

- Method Statement For GI Conduit-CDocument4 pagesMethod Statement For GI Conduit-CJaneNo ratings yet

- METHOD STATEMENT FOR System Commissinig and Testing - Rev 0Document5 pagesMETHOD STATEMENT FOR System Commissinig and Testing - Rev 0Osama MZNo ratings yet

- Traffic Signage - Installation - ItpDocument1 pageTraffic Signage - Installation - Itpmoytabura96No ratings yet

- DSR 2013Document472 pagesDSR 2013Anjaneyulu BodhanapuNo ratings yet

- Hose Test Method StatementDocument6 pagesHose Test Method StatementRavi ValiyaNo ratings yet

- Method Statement For Sign Board InstallationDocument45 pagesMethod Statement For Sign Board InstallationEngr Primus ChinonyeNo ratings yet

- BCB Solutions Business ProfileDocument9 pagesBCB Solutions Business ProfileJacaranda FM NewsNo ratings yet

- Earthwork Excavation-Method StatementDocument4 pagesEarthwork Excavation-Method StatementKhaled AbdelbakiNo ratings yet

- Method Statement FOR Embedded Conduits, Boxes and Fittings InstallationDocument6 pagesMethod Statement FOR Embedded Conduits, Boxes and Fittings InstallationWalidNo ratings yet

- 33 05 13 Manholes and Structures 10Document4 pages33 05 13 Manholes and Structures 10salamNo ratings yet

- Duct Bank InformationDocument19 pagesDuct Bank InformationGaneshNo ratings yet

- Process Flow Chart - Method StatementDocument1 pageProcess Flow Chart - Method StatementUbaid Mazhar Abidi SyedNo ratings yet

- ML-KW-MST-001 R1 False Ceiling WorksDocument7 pagesML-KW-MST-001 R1 False Ceiling WorksprithivirajNo ratings yet

- Rev-2 Method Statement For Access Road Construction Works Puma Energy Daulatpur ProjectDocument11 pagesRev-2 Method Statement For Access Road Construction Works Puma Energy Daulatpur ProjectM Waqas HabibNo ratings yet

- MOS For Water Supply Pipe InstallationDocument3 pagesMOS For Water Supply Pipe InstallationDon Roseller Dumaya100% (1)

- Checklist For Precast ConstuctionDocument4 pagesChecklist For Precast ConstuctionSasala Raju100% (1)

- BRT-Peshawer-Package-I-Reach-I - METHOD STATEMENTDocument66 pagesBRT-Peshawer-Package-I-Reach-I - METHOD STATEMENTRizwanNo ratings yet

- Method Statement - Concealed ConduitDocument4 pagesMethod Statement - Concealed Conduitjoo2585No ratings yet

- Corrosion Control InspectionDocument6 pagesCorrosion Control InspectionAutumn SimonNo ratings yet

- Al Ain Stadium & Mixed Use Development Phase 1.1: Inspection & Test Plan For Installation & Termination of Cables & WiresDocument5 pagesAl Ain Stadium & Mixed Use Development Phase 1.1: Inspection & Test Plan For Installation & Termination of Cables & Wiresmidhun muraliNo ratings yet

- Rotating Equipment Installation ProcedureDocument2 pagesRotating Equipment Installation ProcedureathithancapeNo ratings yet

- DIN-En-10056-01 Structural Steel Equal&Unequal Leg AnglesDocument9 pagesDIN-En-10056-01 Structural Steel Equal&Unequal Leg AnglesbacheghoulNo ratings yet

- Normalized High-Strength Low-Alloy Structural Steel Plates: Standard Specification ForDocument3 pagesNormalized High-Strength Low-Alloy Structural Steel Plates: Standard Specification ForKelly BatesNo ratings yet

- DIN-En-10056-01 Structural Steel Equal&Unequal Leg AnglesDocument9 pagesDIN-En-10056-01 Structural Steel Equal&Unequal Leg AnglesbacheghoulNo ratings yet

- Coronavirus and Food HygieneDocument2 pagesCoronavirus and Food HygieneKelly BatesNo ratings yet

- Headache and Neck PainDocument3 pagesHeadache and Neck PainKelly BatesNo ratings yet

- Astm B443.8889Document7 pagesAstm B443.8889Kelly BatesNo ratings yet

- Coronavirus e Influenza. What DifferencesDocument2 pagesCoronavirus e Influenza. What DifferencesKelly BatesNo ratings yet

- Covid-19 How The Virus Has Changed Scientific CommunicationDocument2 pagesCovid-19 How The Virus Has Changed Scientific CommunicationKelly BatesNo ratings yet

- Memory: What Is It, How It WorksDocument2 pagesMemory: What Is It, How It WorksKelly BatesNo ratings yet

- Coronavirus The Risk of SmokingDocument3 pagesCoronavirus The Risk of SmokingKelly BatesNo ratings yet

- Splice Length in ColumnsDocument1 pageSplice Length in ColumnsKelly BatesNo ratings yet

- Coating Data SheetDocument4 pagesCoating Data SheetKelly Bates50% (2)

- Rebar Devt. Length, LDDocument1 pageRebar Devt. Length, LDKelly BatesNo ratings yet

- MS-Exploratory ExcavationDocument6 pagesMS-Exploratory ExcavationKelly BatesNo ratings yet

- MS Exploratory ExcavationDocument6 pagesMS Exploratory ExcavationKelly BatesNo ratings yet

- Autocad Text and ScalingDocument2 pagesAutocad Text and ScalingKelly BatesNo ratings yet

- AISC Shapes TablesDocument64 pagesAISC Shapes TablesJose ManuelNo ratings yet

- AutoCAD Scale FactorDocument2 pagesAutoCAD Scale FactorKelly BatesNo ratings yet

- Autocad Text and ScalingDocument2 pagesAutocad Text and ScalingKelly BatesNo ratings yet

- Issued For Construction: Eastern Trading & Cont. EstDocument1 pageIssued For Construction: Eastern Trading & Cont. EstKelly BatesNo ratings yet

- Beam Rebar DetailDocument1 pageBeam Rebar DetailKelly BatesNo ratings yet

- Concrete BeamDocument1 pageConcrete BeamKelly BatesNo ratings yet

- BBS For BeamDocument1 pageBBS For BeamKelly BatesNo ratings yet

- 67-Lodolo Menta CalzavaraDocument9 pages67-Lodolo Menta Calzavarasandi_oilNo ratings yet

- Industrial Attachment of Shohagpur Textile Mills Ltd.Document88 pagesIndustrial Attachment of Shohagpur Textile Mills Ltd.Anonymous ZH6tcBQNo ratings yet

- UIDMS The ModifierDocument39 pagesUIDMS The ModifierAbhitabh Sinha100% (1)

- 70-534 OdDocument3 pages70-534 OdSanjay SuryadevraNo ratings yet

- People and OrganizationDocument27 pagesPeople and OrganizationClark Ivan TorresNo ratings yet

- Connectors For HELIAX® HJ8-50 Coaxial Cab - 0d - 0a LeDocument4 pagesConnectors For HELIAX® HJ8-50 Coaxial Cab - 0d - 0a LeAnonymous cDWQYsjd9No ratings yet

- Fulfill OrderDocument26 pagesFulfill OrderFafoxifaNo ratings yet

- VarDocument4 pagesVarLoveofyouth ReddyNo ratings yet

- 01Document30 pages01dwimukh360No ratings yet

- PhoenixContact PAR GUERIN B204 EquipmentsDocument23 pagesPhoenixContact PAR GUERIN B204 Equipmentsbennai yougourtaNo ratings yet

- Familia 33 BQ 50Document76 pagesFamilia 33 BQ 50FlakoO0No ratings yet

- Report Industrial Training 20BCE030Document15 pagesReport Industrial Training 20BCE030snowycatt4321No ratings yet

- Internship Report NFDocument55 pagesInternship Report NFmaryamehsanNo ratings yet

- Hall 08Document1 pageHall 08chinsy83No ratings yet

- Process Industry Practices ElectricalDocument10 pagesProcess Industry Practices ElectricaljowarNo ratings yet

- AC 505-005 Issue 01 Aircraft Certification Delegate HandbookDocument46 pagesAC 505-005 Issue 01 Aircraft Certification Delegate Handbookdandylion123No ratings yet

- Checklist For System MonitoringDocument3 pagesChecklist For System MonitoringViSpNo ratings yet

- Hyperlynx High-Speed Serial Interface Analysis: Student WorkbookDocument6 pagesHyperlynx High-Speed Serial Interface Analysis: Student WorkbookPawanNo ratings yet

- The Winning World of Titan: Cover StoryDocument12 pagesThe Winning World of Titan: Cover StoryAnonymous im9mMa5No ratings yet

- EoI RFQ For Development of Visakhapatnam Metro Rail ProjectDocument91 pagesEoI RFQ For Development of Visakhapatnam Metro Rail Projectkmmanoj1968No ratings yet

- Malaysia Inspection Bodies Accreditation Scheme (Mibas)Document11 pagesMalaysia Inspection Bodies Accreditation Scheme (Mibas)Ko NSNo ratings yet

- 9005551Document4 pages9005551Cherie DiazNo ratings yet