Professional Documents

Culture Documents

Operations Analytics MOOC Week 2 Practice Problems Solutions

Uploaded by

Ashfaque FardinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Operations Analytics MOOC Week 2 Practice Problems Solutions

Uploaded by

Ashfaque FardinCopyright:

Available Formats

Operations Analytics MOOC: Solutions to Practice Problems for

Week 2

1. Making Turkish Delight at the Rahat Industries.

Questions and Answers:

(a) Suppose that RI decides to make 250 boxes of Ortaky and 350 boxes of Beyoglu. What is

the weekly profit that it will earn?

Answer:

RI earns a profit of $5 for each box of Ortaky and $5.3 for each box

of Beyoglu. The total profit for this production plan will be

$5*250+$5.3*350 = $1250 + $1855 = $3105.

(b) How many gallons of fruit juice will the production plan NO = 250 and NB = 350 require?

Answer:

Each box of Ortaky and Beyoglu requires 0.03 and 0.02 gallons of

fruit juice, respectively. The total usage of fruit juice for this

production plan is 0.03*250+0.02*350 = 7.5 + 7 = 14.5.

(c) RI is considering setting its production for the next week at the maximum levels that market

will bear - in other words, it is considering a production plan NO = 250 and NB = 400. Is this

plan feasible?

Answer:

We need to check if this production plan satisfies all the resource

constraints. The amount of starch required by this plan is

0.1*250+0.3*400 = 25 + 120 = 145 lbs. This amount is less than the

available amount of 150 lbs. The amount sugar required by this plan

is 0.05*250+0.1*400 = 12.5 + 40 = 52.5 lbs. This amount is also less

than the available amount of 130 lbs. Finally, the amount of fruit

juice required is 0.03*250+0.02*400 = 7.5 + 8 = 15.5 gallons. This

exceeds 15 gallons available. Thus, this production plan is

infeasible.

(d) Write down an algebraic expression for RIs weekly profit, in $, as a function of the decision

variables NO and NB.

Answer:

RI earns a profit of $5 for each box of Ortaky and $5.3 for each

box of Beyoglu. The total profit, in $, for any production plan can

be calculated as 5*NO + 5.3*NB.

Operations Analytics MOOC

Page 1

Operations Analytics MOOC: Solutions to Practice Problems for

Week 2

(e) Using the decision variables NO and NB, write down a linear algebraic expression for the

following constraint: The amount of fruit juice used in the production during the coming week

cannot exceed 15 gallons.

Answer:

Each box of Ortaky and Beyoglu requires 0.03 and 0.02 gallons of

fruit juice, respectively. The total usage of fruit juice for any

production plan can be expressed as 0.03*NO + 0.02*NB. Thus, the

constraint on the amount of the fruit juice used by any production

plan can be written as 0.03*NO + 0.02*NB 15.

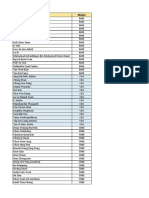

(f) Below is a picture of an excerpt from an Excel file set-up to model the RIs profit maximization

problem, with the number in cell D3 hidden.

The formula in cell E7 is =SUMPRODUCT($C$3:$D$3,C7:D7). What is the value in cell D3?

Answer:

If the value in the cell D3 is X, then the value of

SUMPRODUCT($C$3:$D$3,C7:D7) is 100*0.1+X*0.3. Equating this to 100

and solving for X, we get X=300.

(g) If the formula in cell E7 is copied and pasted into the cell E8, what value will appear in cell

E8?

Answer:

After this copy-and-paste operation, the cell E8 will contain the

formula SUMPRODUCT($C$3:$D$3,C8:D8). Then, the value in E8 will be

100*0.05+300*0.1 = 35.

(h) Use the file Zooter.xlsx as a template to set up and solve an optimization problem RI faces

using Excel and Solver. What are the optimal values of the decision variables? What is the

optimal objective function value?

Operations Analytics MOOC

Page 2

Operations Analytics MOOC: Solutions to Practice Problems for

Week 2

Answer:

For completeness, heres the algebraic formulation of RIs problem.

Objective function to be maximized: 5*NO + 5.3*NB

Constraints:

0.1*NO + 0.3*NB 150

(starch availability)

0.05*NO + 0.1*NB 130 (sugar availability)

0.03*NO + 0.02*NB 15 (fruit juice availability)

NO 250

(maximum number of Ortaky boxes)

NB 400

(maximum number of Beyoglu boxes)

NO, NB = non-negative integers

See Rahat.xlsx for the spreadsheet implementation of the RIs

problem. Below we show the optimized spreadsheet and the Solver

parameters dialog box.

Operations Analytics MOOC

Page 3

Operations Analytics MOOC: Solutions to Practice Problems for

Week 2

The optimal solution is to produce 233 boxes of Ortaky and 400

boxes of Beyoglu. The optimal profit value is $3285.

2. Transporting Fruits at Florida Logistics.

Questions and Answers:

(a) Suppose that FL plans to put the same number of cartons for each fruit on each truck, in other

words, suppose that FL sets A1 = A2 = A3 = 1300 and M1 = M2 = M3 = 1200. Is this a feasible

plan?

Answer:

This plan satisfies the constraints on the numbers of cartons of each

fruit that need to be shipped. In terms of capacity constraints for

each truck, note that each ton of truck capacity corresponds to 2000

lbs, which is equivalent to 100 cartons of 20 lbs each. Thus, truck

capacities expressed in the number of cartons are 2700, 3100, and

2800 for trucks 1, 2, and 3, respectively. This plan requires 2500

cartons to be shipped on each truck, and that requirement is within

the trucks capacities. So, the plan is feasible.

Operations Analytics MOOC

Page 4

Operations Analytics MOOC: Solutions to Practice Problems for

Week 2

(b) Irrespective of whether or not the plan in part a) is feasible, what is the total revenue that FL

would earn under this plan?

Answer:

In order to calculate the revenue associated with this plan, we need

to calculate the revenue contributions for each carton of fruit

shipped on each truck.

For a carton of avocados shipped on truck 1, the revenue contribution

is $20 multiplied by 1-0.05=0.95 (a coefficient reflecting spoiling

losses occurring during travel), or $20*0.95=$19. In a similar way,

the revenue contributions for each carton of avocados shipped on

trucks 2 and 3 are $20*(1-0.04)=$20*0.96=$19.2 and $20*(10.03)=$20*0.97=$19.4, respectively. For a carton of mangos traveling

on trucks 1, 2, and 3, the revenue contributions are $32*(1-0.10) =

$28.8, $32*(1-0.12) = $28.16, and $32*(1-0.11) = $28.48, respectively.

Now, using these revenue contributions, we can calculate the total

revenue, in $, corresponding to this plan: 19*1300 + 19.2*1300 +

19.4*1300 + 28.8*1200 +28.16*1200 + 28.48*1200 = (19+19.2+19.4)*1300

+ (28.8+28.16+28.48)*1200 = 57.6*1300+85.44*1200 = 74880 + 102528 =

177408.

(c) Write down an algebraic expression for the revenue as a function of decision variables A1,

A2, A3, M1, M2, M3.

Answer:

Using the revenue contributions for each carton and the decision

variables, we can express the total revenue, in $, as

19*A1 + 19.2*A2 + 19.4*A3 + 28.8*M1 +28.16*M2 + 28.48*M3.

(d) Using these decision variables, write down an algebraic expression for the constraint the total

number of fruit cartons shipped in truck 1 cannot exceed this trucks capacity.

Answer:

The total number of cartons assigned to truck 1 is the sum of avocado

and mango cartons A1 + M1. The total capacity of truck 1, expressed in

number of cartons, is 2700. Thus, the constraint in case can be

expressed as

A1 + M1 2700.

(e) Use the file Keystone.xlsx as a template to set up and solve the FLs optimization problem.

What is the optimal solution? What is the optimal objective function value?

Operations Analytics MOOC

Page 5

Operations Analytics MOOC: Solutions to Practice Problems for

Week 2

Answer:

Heres the complete algebraic formulation of the FLs problem.

Objective function to be maximized:

19*A1 + 19.2*A2 + 19.4*A3 + 28.8*M1 +28.16*M2 + 28.48*M3

Constraints:

A1 + M1 2700

(truck 1 capacity)

A2 + M2 3100

(truck 2 capacity)

A3 + M3 2800

(truck 3 capacity)

A1 + A2 + A3 = 3900

(total amount of avocado to be shipped)

M1 + M2 + M3 = 3600

(total amount of mango to be shipped)

A1, A2 , A3 , M1, M2 , M3 = non-negative integers

See FL.xlsx for the spreadsheet implementation of this model. Below

we show the optimized spreadsheet and the Solver parameters dialog

box.

Operations Analytics MOOC

Page 6

Operations Analytics MOOC: Solutions to Practice Problems for

Week 2

The optimal solution is to allocate truck 1 to mango cartons (entire

capacity), and truck 2 to avocados (2000 cartons), while splitting

the capacity of truck 3 between mangos (900 cartons) and avocados

(1900 cartons). The optimal total revenue is $178652.

Operations Analytics MOOC

Page 7

You might also like

- MOOC Week 4 Practice Problems PDFDocument2 pagesMOOC Week 4 Practice Problems PDFAshfaque Fardin0% (1)

- Robert Montoya Case LearningsDocument4 pagesRobert Montoya Case Learningsish juneNo ratings yet

- The Dilemma at Day Pro-CaseDocument7 pagesThe Dilemma at Day Pro-CaseTheknower Ofitall50% (2)

- Dec. Analysis ExerciseDocument2 pagesDec. Analysis ExerciseAzman Zalman0% (1)

- Natural Disaster Housing Relief OptimizationDocument21 pagesNatural Disaster Housing Relief OptimizationAhmed Fraz BajwaNo ratings yet

- Vintage Restaurant CaseDocument10 pagesVintage Restaurant Caseanghellow100% (1)

- Mini Case 29Document3 pagesMini Case 29Avon Jade RamosNo ratings yet

- Chap 003Document12 pagesChap 003charlie simoNo ratings yet

- Bond After-Tax Yield CalculatorDocument7 pagesBond After-Tax Yield CalculatorJohnNo ratings yet

- West Jet AirlinesDocument2 pagesWest Jet AirlinesPraeen Kc100% (1)

- Chapter 8 PDFDocument36 pagesChapter 8 PDFRoan CalimdorNo ratings yet

- Financial Planning and ForecastingDocument3 pagesFinancial Planning and ForecastingPrima FacieNo ratings yet

- Risk and Evaluation Quiz AnalysisDocument7 pagesRisk and Evaluation Quiz AnalysisMohammed Abduallah50% (2)

- Ratio Analysis and Forecasting Quiz - CourseraDocument6 pagesRatio Analysis and Forecasting Quiz - CourseraLuisSalvador19874% (28)

- Finance Chapter 17Document30 pagesFinance Chapter 17courtdubs75% (4)

- Case Study Apple Iphone Price CutDocument14 pagesCase Study Apple Iphone Price Cutriteshkumaryadav100% (1)

- Section 5Document2 pagesSection 5Walid Mohamed AnwarNo ratings yet

- Quantative Assignment and ExerciseDocument4 pagesQuantative Assignment and ExerciseHassanNo ratings yet

- Bond ValuationDocument24 pagesBond ValuationFadhlanMuhtadiNo ratings yet

- Caffe Kibbe & Tai Din Fung - 1Document9 pagesCaffe Kibbe & Tai Din Fung - 1Nevan NovaNo ratings yet

- Module 5 - ForecastingDocument5 pagesModule 5 - ForecastingZakiah Abu Kasim100% (1)

- Peachtree SecuritiesDocument55 pagesPeachtree SecuritiesLouredaine MalingNo ratings yet

- Case of Joneja Bright Steels: The Cash Discount DecisionDocument10 pagesCase of Joneja Bright Steels: The Cash Discount DecisionRHEANo ratings yet

- Class Case 5 - The Dilemma at Day-ProDocument13 pagesClass Case 5 - The Dilemma at Day-ProHannahPojaFeria80% (5)

- Exercises-Financial PlanningDocument17 pagesExercises-Financial PlanningNAFEES NASRUDDIN PATEL100% (1)

- Joan Holtz (A) Case Revenue Recognition QuestionsDocument5 pagesJoan Holtz (A) Case Revenue Recognition QuestionsAashima GroverNo ratings yet

- 09 How Low Can It GoDocument3 pages09 How Low Can It GoHéctor Eduardo Moreno Sandoval75% (4)

- AHM13e Chapter 05 Solution To Problems and Key To CasesDocument21 pagesAHM13e Chapter 05 Solution To Problems and Key To CasesGaurav ManiyarNo ratings yet

- Reeby Sports SreeniDocument8 pagesReeby Sports SreeniAtul PandeyNo ratings yet

- Analysis For Reeby SportsDocument4 pagesAnalysis For Reeby SportsMohit SrivastavaNo ratings yet

- Individual Case Writing AssignmentDocument6 pagesIndividual Case Writing Assignmentapi-273010008No ratings yet

- 1 PointDocument10 pages1 PointNatalie NguyenNo ratings yet

- Discussion Problems 1. You Plan To Retire 33 Years From Now. You Expect That You Will Live 27 Years After RetiringDocument10 pagesDiscussion Problems 1. You Plan To Retire 33 Years From Now. You Expect That You Will Live 27 Years After RetiringJape PreciaNo ratings yet

- Quantitative Method Problem Zipper Products, Inc.Document1 pageQuantitative Method Problem Zipper Products, Inc.Aubrey Blancas100% (1)

- RMontoya SolutaDocument21 pagesRMontoya SolutaTy Best CoonNo ratings yet

- Accounting Text & Cases Ed 13th Case 6-3Document1 pageAccounting Text & Cases Ed 13th Case 6-3Ki UmbaraNo ratings yet

- Eco1001 - Tutorial Sheet - 1 - 20.21 - Sem - 1Document3 pagesEco1001 - Tutorial Sheet - 1 - 20.21 - Sem - 1Mikhaela Allen100% (1)

- Group 3 - Property Purchase StrategyDocument7 pagesGroup 3 - Property Purchase Strategychelsea198950% (2)

- Evaluating Starbucks' acquisition of TeavanaDocument4 pagesEvaluating Starbucks' acquisition of Teavanapitcher90100% (1)

- CASE 8 - Norman Corporation (A) (Final)Document3 pagesCASE 8 - Norman Corporation (A) (Final)Katrizia FauniNo ratings yet

- How To Valuation A CompanyDocument42 pagesHow To Valuation A Companyapi-3720563100% (2)

- BF2207 Exercise 6 - Dorchester LimitedDocument2 pagesBF2207 Exercise 6 - Dorchester LimitedEvelyn TeoNo ratings yet

- Joan HoltzDocument10 pagesJoan HoltzKarlo PradoNo ratings yet

- Chapter 14-Ch. 14-Cash Flow Estimation 11-13.El-Bigbee Bottling CompanyDocument1 pageChapter 14-Ch. 14-Cash Flow Estimation 11-13.El-Bigbee Bottling CompanyRajib DahalNo ratings yet

- Testbank - Chapter 18Document3 pagesTestbank - Chapter 18naztig_017100% (1)

- Chapter 8-1 Group Report - NormanDocument6 pagesChapter 8-1 Group Report - Normanvp_zarate100% (1)

- Peachtree Securities Inc. (A) Answers - Irish JuneDocument8 pagesPeachtree Securities Inc. (A) Answers - Irish Juneish juneNo ratings yet

- Quick Lunch CASE 14-1Document2 pagesQuick Lunch CASE 14-1sheeraveal0% (1)

- Lecture 11 Joan Holtz ADocument3 pagesLecture 11 Joan Holtz Avineetk_39100% (1)

- Iridium case study highlights challenges of global satellite communicationsDocument4 pagesIridium case study highlights challenges of global satellite communicationsjonna laysonNo ratings yet

- Example of Investment Analysis Paper PDFDocument24 pagesExample of Investment Analysis Paper PDFYoga Nurrahman AchfahaniNo ratings yet

- Case 2Document5 pagesCase 2Yuan FuFu100% (1)

- Custom Van Maker Expands Midwest OperationsDocument5 pagesCustom Van Maker Expands Midwest OperationsFrancoRodrigoIglesiasRobles100% (1)

- anthonyIM 06Document18 pagesanthonyIM 06Jigar ShahNo ratings yet

- Practice Problems For Week 2Document3 pagesPractice Problems For Week 2daNo ratings yet

- Management Science FinalDocument8 pagesManagement Science FinalAAUMCLNo ratings yet

- Model Test Paper Problem1 (A)Document15 pagesModel Test Paper Problem1 (A)HibibiNo ratings yet

- 02 - Math Prog Formulations LPDocument54 pages02 - Math Prog Formulations LPgeorgemiller47No ratings yet

- 15.053 - Optimization Methods in Management Science (Spring 2007) Problem Set 1Document10 pages15.053 - Optimization Methods in Management Science (Spring 2007) Problem Set 1Ehsan SpencerNo ratings yet

- Management Science 1107 - Midterms AnswersDocument4 pagesManagement Science 1107 - Midterms AnswersHans DelimaNo ratings yet

- Physiotherapy and Prayer (Salah) : Taking Care of Your HealthDocument6 pagesPhysiotherapy and Prayer (Salah) : Taking Care of Your HealthAshfaque FardinNo ratings yet

- Physio Booklet WebDocument28 pagesPhysio Booklet Webআশিকুজ্জামানআশিকNo ratings yet

- Lesson 7: Data Types: Akos Ledeczi and Mike FitzpatrickDocument30 pagesLesson 7: Data Types: Akos Ledeczi and Mike FitzpatrickghghNo ratings yet

- Introduction to MATLAB Programming for BeginnersDocument9 pagesIntroduction to MATLAB Programming for BeginnersZafNo ratings yet

- CS 2 Loops PDFDocument48 pagesCS 2 Loops PDFAshfaque FardinNo ratings yet

- Lesson 7: Data Types: Akos Ledeczi and Mike FitzpatrickDocument30 pagesLesson 7: Data Types: Akos Ledeczi and Mike FitzpatrickghghNo ratings yet

- CS 3 Arrays PDFDocument48 pagesCS 3 Arrays PDFAshfaque FardinNo ratings yet

- Lesson 2Document13 pagesLesson 2GauravKumarNo ratings yet

- Lesson 3: Functions: Akos Ledeczi and Mike FitzpatrickDocument4 pagesLesson 3: Functions: Akos Ledeczi and Mike FitzpatrickAnonymous 0H1z4LT0FNo ratings yet

- Lesson 2Document13 pagesLesson 2GauravKumarNo ratings yet

- Lesson 3: Functions: Akos Ledeczi and Mike FitzpatrickDocument4 pagesLesson 3: Functions: Akos Ledeczi and Mike FitzpatrickAnonymous 0H1z4LT0FNo ratings yet

- Introduction to MATLAB Programming for BeginnersDocument9 pagesIntroduction to MATLAB Programming for BeginnersZafNo ratings yet

- Neurone Abar O Anuranan PDFDocument154 pagesNeurone Abar O Anuranan PDFAshfaque FardinNo ratings yet

- Student List by MajorDocument6 pagesStudent List by MajorAshfaque FardinNo ratings yet

- Practice Problems For Week 2Document3 pagesPractice Problems For Week 2daNo ratings yet

- Operations Analytics MOOC Solutions Week 3 ProblemsDocument3 pagesOperations Analytics MOOC Solutions Week 3 ProblemsAshfaque FardinNo ratings yet

- Practice Problems For Week 3 PDFDocument2 pagesPractice Problems For Week 3 PDFAshfaque FardinNo ratings yet

- MOOC Week 4 Practice Problem Solutions PDFDocument4 pagesMOOC Week 4 Practice Problem Solutions PDFAshfaque FardinNo ratings yet

- DMT MergedDocument206 pagesDMT Mergedskip skipNo ratings yet

- Revised Cape TimetableDocument18 pagesRevised Cape TimetabledijojnayNo ratings yet

- 04 GE 302 DECISION MAKING Quantitative PDFDocument12 pages04 GE 302 DECISION MAKING Quantitative PDFrafaelNo ratings yet

- Mujtaba - Ali - DS - AlmaBetter - Mujtaba AliDocument1 pageMujtaba - Ali - DS - AlmaBetter - Mujtaba AliSandeep DuttaNo ratings yet

- Assignment 3: CSC236H: Introduction To The Theory of ComputationDocument9 pagesAssignment 3: CSC236H: Introduction To The Theory of ComputationKhizar HamzaNo ratings yet

- Chapter-Wise Test-Maths-1Document2 pagesChapter-Wise Test-Maths-1Rayyan HazarikaNo ratings yet

- Decision Tree Induction For Financial Fraud Detection Using Ensemble Learning TechniquesDocument15 pagesDecision Tree Induction For Financial Fraud Detection Using Ensemble Learning Techniquesvijayalakshmi_raoNo ratings yet

- Decision TheoryDocument5 pagesDecision TheoryDevhuti Nandan Sharan MishraNo ratings yet

- Artificial Neural NetworkDocument11 pagesArtificial Neural NetworkLolzNo ratings yet

- RainbowCrack tutorial guide for password crackingDocument5 pagesRainbowCrack tutorial guide for password crackingJunior SanzNo ratings yet

- Introduction To Deep Learning - With Complexe Python and TensorFlow Examples - Jürgen Brauer PDFDocument245 pagesIntroduction To Deep Learning - With Complexe Python and TensorFlow Examples - Jürgen Brauer PDFMecobioNo ratings yet

- Lab ManualDocument69 pagesLab ManualPradeepNo ratings yet

- Tensorflow Neural Network Lab: NotmnistDocument15 pagesTensorflow Neural Network Lab: NotmnistDaniel PetrovNo ratings yet

- Application On Linear Diophantine EquationsDocument8 pagesApplication On Linear Diophantine EquationsHazel Clemente CarreonNo ratings yet

- Go, Rust Cheat SheetDocument99 pagesGo, Rust Cheat SheetDavidNo ratings yet

- Step-by-Step Guide to 25 Classic Codes and CiphersDocument13 pagesStep-by-Step Guide to 25 Classic Codes and CiphersGwyneth NicolasNo ratings yet

- Taint AnalysisDocument93 pagesTaint AnalysisДанило РомановичNo ratings yet

- Local and Stochastic Volatility: Johannes RufDocument62 pagesLocal and Stochastic Volatility: Johannes Rufvenkraj_iitmNo ratings yet

- DA222 KarlukDocument2 pagesDA222 KarlukBurak Cengo tvNo ratings yet

- Delft: Matlab and Simulink For Modeling and ControlDocument12 pagesDelft: Matlab and Simulink For Modeling and Controlawan_krNo ratings yet

- Numerical Analysis ExamDocument11 pagesNumerical Analysis ExamTEHSEEN TARIQNo ratings yet

- Digital Signals Lab #01Document6 pagesDigital Signals Lab #01Zohaib KhanNo ratings yet

- Rcse 002Document2 pagesRcse 002R RNo ratings yet

- AOA Assignment 1 - Aiman Ansari - 272Document19 pagesAOA Assignment 1 - Aiman Ansari - 272Sachin AlamNo ratings yet

- Machine LearningDocument2,520 pagesMachine LearningDip100% (2)

- EditorialDocument7 pagesEditorialPop IuliuNo ratings yet

- Trees and Forests: Machine Learning With Python CookbookDocument5 pagesTrees and Forests: Machine Learning With Python CookbookJayod RajapakshaNo ratings yet

- Adaptive MPC for autonomous lane keeping using online model adaptationDocument7 pagesAdaptive MPC for autonomous lane keeping using online model adaptationEga PramNo ratings yet

- 1.1 Significant Figures (Part 1)Document2 pages1.1 Significant Figures (Part 1)Dhanraj RamNo ratings yet

- Preprints202303 0438 v1Document18 pagesPreprints202303 0438 v1LEGEND OFFICIALNo ratings yet