Professional Documents

Culture Documents

Date Tehnice Sistem - SingleUp 2015

Uploaded by

Amelia AnorocioaeiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Date Tehnice Sistem - SingleUp 2015

Uploaded by

Amelia AnorocioaeiCopyright:

Available Formats

Page 1

PRODUCT DATA

KLAUS Multiparking GmbH

Hermann-Krum-Strae 2

D-88319 Aitrach

Fon +49 (0 ) 75 65 5 08-0

Fax +49 (0 ) 75 65 5 08-88

info@multiparking.com

www.multiparking.com

Section

Dimensions

Car data

Page 2

Width dim.

Function

Approach

Load plan

2500 kg

Garage without door (basement garage)

Dimensions

Page 3

130

Electrical

installation

Free space

Free space

80

70

Page 4

Delimitation

Cutting through

Standard passenger cars:

Limousine, station wagon, SUV, van

according to clearance and maximal

surface load.

width

weight

190

1 cm

max. 2500 kg

wheel load max. 625 kg

Clearance prole Limousine (L)

530

160

70

see table

40

240

Grounding

15

Before lowering the platform, the vehicle parked on the lower

parking space must be driven off!

13

95

480

105

15

105

105

car height 7 car height

height above (L+S) below (L+S)

150

290 150

car height

car height

height above (L+S) below (L+S)

160

305 150

13

95

170

305

155

290

70

see table

2015-170

2

2015-155

85

240

Version 1: above backward; below forward

20

Clearance prole Station wagon (S)

480

105

Version 2: above and below forward

car height

height

above (L)

305 150

height

320

90

car height

above (L)

150

car height

below (L+S)

160

car height

car height

height above (L+S) below (L+S)

150

320 150

170

335

155

320

170

320

90

car height

below (L+S)

150

2015-170

90

car height

car height

height above (L+S) below (L+S)

160

335 150

2

3

4

5

To follow the minimum nished dimensions, make sure

to consider the tolerances according to VOB, part C

(DIN 18330 and 18331) and the DIN18202.

If a higher ceiling height is available higher cars can

be parked.

If the total length is greater, the max. vehicle length for the

lower parking space increases accordingly.

For dividing walls: cutting through 10 x 10 cm.

Potential equalization from foundation grounding connection

to system (provided by the customer).

7

8

In compliance with DIN EN 14 010, 10 cm wide yellow-black

markings compliant to ISO 3864 must be applied by the

customer with a distance of 90 cm to the edge of the platform

in the access area to mark the danger zone in front of the

supporting surface of the upper platform edge (see Load Plan

Page 2).

L = Limousine / S = Station wagon

Must be at least as high as the greatest car height + 5 cm.

SingleUp 2015 | Code number 583.91.470-009 | Version 05.2013

90

2015-155

2

2015-170

2

2015-155

155

305

Description

Suitable for

90

To be performed by the

customer

Headroom according

to local regulations

Technical

data

45

All space requirements are minimum

nished dimensions.

Tolerances for space requirements + 30 .

Dimensions in cm.

EB (single platform) = 2 vehicles

SingleUp 2015 | Code number 583.91.470-009 | Version 05.2013

Page 1

Section

Page 2 of 4

Width dimensions

Dimensions

Car data

Page 2

Width dim.

Function

Approach

Load plan

Page 3

Electrical

installation

Technical

data

Page 4

To be performed by the

customer

B

usable platform width

210

220

230

Carriageway in

accordance with

local regulations

B

240

250

260

Function

System lifted

System lowered

Description

Before lowering the platform, the vehicle parked

on the lower parking space must be driven off!

Approach

maximum

descending

slope 4 %

maximum

ascending

slope 14 %

The illustrated maximum approach angles must not be exceeded. Incorrect approach angles will cause serious

maneouvring & positioning problems on the parking system for which the local agency of KLAUS Multiparking

accepts no responsibility.

Load plan

380

F3

F3

F4

F2

210

F2

90 12

(105) 35

F4

F1

F1

F1

115

90

F3

F2

F4

10

530

platform load

F1

F2

F3

F4

2500 kg

0,5

+22

11,5

Marking 10

6

6

B

11

Units are dowelled to the oor. Drilling depth: approx. 15 cm.

Floor and walls are to be made of concrete (quality minimum C20/25)!

The dimensions for the points of support are rounded values. If the exact position is required, please contact

KLAUS Multiparking.

9

Dimension B see above

10

Marking compliant to ISO 3864 (colors used in this illustration are not ISO 3864 compliant)

11

All forces in kN

12

Version 1 and 2 see page 1

SingleUp 2015 | Code number 583.91.470-009 | Version 05.2013

Page 1

Section

Dimensions

Page 3 of 4

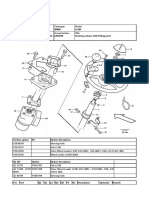

Electrical installation

Installation diagram

Electrical data (to be performed by the customer)

Car data

No. Qunatity

Page 2

Width dim.

Function

Approach

Load plan

Electricity meter

in the supply

line

Main fuse: 3 x fuse 16 A (slow)

or circuit breaker 3 x 16 A

(trigger characteristic K or C)

in the supply

line

1 per unit

Supply line 5 x 2.5 mm2

(3 PH + N + PE) with marked

wire and protective conductor

to main switch

1 per unit

Lockable main switch

defined at the 1 per unit

plan evaluation

12

Page 4

10

To be performed by the

customer

Description

Conduit EN 25

(M25)

height: + 1.70 m

11

180

13

Technical

data

14

6

Frequency

Electrical

installation

Position

Page 3

Description

every

10 m

0.00

to the next

system

Supply line 5 x 2.5 mm

(3 PH + N + PE) with marked wire

and protective conductor

from main

switch to unit

Foundation earth connector

corner pit

floor

Equipotential bonding in accordance

with DIN EN 60204 from foundation

earth connector to the system

1 per unit

1 per

system

Electrical data (included in delivery of KLAUS Multiparking)

No.

Description

Terminal box

Control line 3 x 0.75 mm2 (PH + N + PE)

10

Control line 7 x 1.5 mm2 with marked wire and protective conductor

11

Operating device

12

Control line 5 x 1.5 mm2 with marked wire and protective conductor

13

Hydraulic unit 3.0 kW, three-phase current, 230/400 V / 50 Hz

14

Control line 5 x 1.5 mm2 with marked wire and protective conductor

Technical data

Field of application

By default, the system can only be used for a xed number of

users.

Units

Low-noise power units mounted to rubber-bonded-to metal

mountings are installed. Nevertheless we recommend that

parking systems garage be built separately from the dwelling.

Available documents

wall recess plans

maintenance offer/contract

declaration of conformity

test sheet on airborne and slid-borne sound

Building application documents

According to LBO and GaVo (garage regulations) the Multiparking

systems are subject to approval. We will provide the required

building application documents.

Corrosion protection

See separate sheet regarding corrosion protection.

Care

To avoid damages resulting from corrosion, make sure to follow

our cleaning and care instructions and to provide good ventilation

of your garage.

Railings

If the permissible drop opening is exceeded, railings are to be

mounted on the systems. If there are trafc routes next to or

behind the installations, railings compliant to DIN EN ISO 13857

must be installed by the customer. Railings must also be in place

during construction.

Environmental conditions

Environmental conditions for the area of multiparking systems:

Temperature range 10 to +40 C. Relative humidity 50% at a

maximum outside temperature of +40 C.

If lifting or lowering times are specied, they refer to an

environmental temperature of +10 C and with the system set

up directly next to the hydraulic unit. At lower temperatures or

with longer hydraulic lines, these times increase.

CE Certication

The systems offered correspond to DINEN14010 and the

EC Machinery Directive 2006/42/EG.

Sound insulation

According to DIN 4109 (Sound insulation in buildings), para. 4,

annotation 4, KLAUS Multiparkers are part of the building services

(garage systems).

Normal sound insulation:

DIN 4109, para. 4, Sound insulation against noises from building

services.

Table 4 in para. 4.1 contains the permissible sound level values

emitted from building services for personal living and working

areas. According to line 2 the maximum sound level in personal

living andworking areas must not exceed 30 dB (A).

Noises created by users are not subject to the requirements

(see table 4 , DIN 4109).

The following measures are to be taken to comply with this value:

Sound protection package according to offer/order

(KLAUS Multiparking GmbH)

Minimum sound insulation of building Rw = 57 dB

(to be provided by customer)

Increased sound insulation (special agreement):

Draft DIN 4109-10, Information on planning and execution,

proposals for increased sound insulation.

Agreement: Maximum sound level in personal living and working

areas 25 dB (A). Noises created by users are not subject to the

requirements (see table 4, DIN 4109).

The following measures are to be taken to comply with this value:

Sound protection package according to offer/order

(KLAUS Multiparking GmbH)

Minimum sound insulation of building Rw = 62 dB

(to be provided by customer)

Note: User noises are noises created by individual users in our

Multiparking systems. These can be noises from accessing the

platforms, slamming of vehicle doors, motor and brake noises.

SingleUp 2015 | Code number 583.91.470-009 | Version 05.2013

Page 2

Width dim.

Function

Approach

Load plan

Page 3

Electrical

installation

Technical

data

Page 4

To be performed by the

customer

Description

Safety fences

Any constraints that may be necessary according to DIN EN ISO

13857 in order to provide protection, for pathways directly in front,

next to or behind the unit. This is also valid during construction.

Operating device

Cable conduits and recesses for operating device (for double wing

doors: please contact the local agency of KLAUS Multiparking).

Operating device exposed

Numbering of parking spaces

110 above

carriageway

level

Consecutive numbering of parking spaces.

Building services

= =

Any required lighting, ventilation, re extinguishing and re alarm

systems as well as clarication and compliance with the relevant

regulatory requirements.

Marking

According to DIN EN 14 010, a warning that identies this

danger area must be placed in the entrance area that conforms

to ISO 3864. This must be done according to EN 92/58/EWG

for this systems without a pit 90 cm from the edge of the platform.

Wall cuttings

Any necessary wall cuttings according to page 1.

Electrical supply to the main switch / Foundation earth connector

Suitable electrical supply to the main switch and the control wire

line must be provided by the customer during installation. The

functionality can be monitored on site by our tters together with

the electrician. If this cannot be done during installation for some

reason for which the customer is responsible, the customer must

commission an electrician at their own expense and risk.

In accordance with DIN EN 60204 (Safety of Machinery. Electrical

Equipment), grounding of the steel structure is necessary, provided

by the customer (distance between grounding max. 10 m).

Operating device concealed

120 above

carriageway

level

= =

20

Car data

15

Dimensions

To be performed by the customer

Section

Page 4 of 4

Page 1

Conduit EN 25 (M25)

If the following are not included in the quotation, they will

also have to be provided / paid for by the customer:

Mounting of contactor and terminal box to the wall valve,

complete wiring of all elements in accordance with the circuit

diagram

Costs for nal technical approval by an authorized body

Main switch

Control line from main switch to hydraulic unit

Description Single platform (EB)

General description

Multiparking system providing dependent parking spaces for 2 cars

one on top of the other each. The lower vehicle parks directly on the

oor plate. The vehicle parked on the bottom must be driven out

before lowering the platform.

Dimensions are in accordance with the underlying dimensions of

height and width

The upper vehicle is driven onto and parked on an inclined platform

with a slope of approx. 5 %).

Vehicles are positioned on the upper parking space using wheel

stops on the right side (adjust according to operating instructions).

Operation via operating device with hold-to-run-device, safety

mechanism activated by a master key and push-button.

The operating elements are usually mounted to an extension arm.

Operating instructions are attached to each operator's stand.

For garages with doors at the front of the parking system the special

dimensional requirements have to be taken into account.

Multiparking system consisting of:

2 steel pillars with base plates (mounted on the oor)

2 sliding platforms (mounted to the steel pillars with sliding

bearings)

1 platform

1 telescopic taught rod between platform and base plates,

a mechanic synchronization control system (to ensure

synchronous operation of the sliding platforms while lowering

and lifting the platform)

1 hydraulic cylinder

1 automatic mechanic locking systeme (prevents accidental

lowering of the platform from its upper limit position)

Dowels, screws, connecting elements, bolts, etc.

The platforms and parking spaces are end-to-end accessible

for parking!

Platforms consisting of:

Platform base sections

Adjustable wheel stops

Canted access plates

Side members

Cross members

Screws, nuts, washers, distance tubes, etc.

Hydraulic system consisting of:

Hydraulic cylinder

Solenoid valve

Safety valve

Hydraulic conduits

Screwed joints

High-pressure hoses

Installation material

Electric system consisting of:

Operating device (Emergency Stop, lock, 1master key per

parking space, push-button)

Terminal box at wall valve

Electrical locking device

Hydraulic unit consisting of:

Hydraulic power unit (low-noise, installed onto a console with a

rubber-bonded-to-metal mounting)

Hydraulic oil reservoir

Oil lling

Internal geared wheel pump

Pump holder

Clutch

3-phase-AC-motor

Contactor (with thermal overcurrent relay and control fuse)

Test manometer

Pressure relief valve

Hydraulic hoses (which reduce noise transmission onto the

hydraulic pipe

We reserve the right to change this specication without further notice

KLAUS Multiparking reserves the right in the course of technical progress to use newer or other technologies, systems, processes,

procedures or standards in the fulllment of their obligations other than those originally offered provided the customer derives no

disadvantage from their so doing.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Product Data 2000 KG (4400 LBS) 2600 KG (5730 LBS) : DimensionsDocument9 pagesProduct Data 2000 KG (4400 LBS) 2600 KG (5730 LBS) : DimensionsAmelia AnorocioaeiNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Vanzare Apartament 4 Camere Vitan Mall - Imobiliare Bucuresti - Westmount GroupDocument12 pagesVanzare Apartament 4 Camere Vitan Mall - Imobiliare Bucuresti - Westmount GroupAmelia AnorocioaeiNo ratings yet

- Doc023 Uk Ins Securope HorizontalDocument48 pagesDoc023 Uk Ins Securope HorizontalAmelia Anorocioaei100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Futura Classic - PDFDocument1 pageFutura Classic - PDFAmelia AnorocioaeiNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Lightweight Biaxial Slab: Ubble DeckDocument4 pagesThe Lightweight Biaxial Slab: Ubble DeckAmelia AnorocioaeiNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Building Textures Catalogue3Document54 pagesBuilding Textures Catalogue3Amelia AnorocioaeiNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- RCH-Series, Hollow Plunger Cylinders Versatility in Testing, Maintenance and Tensioning ApplicationsDocument4 pagesRCH-Series, Hollow Plunger Cylinders Versatility in Testing, Maintenance and Tensioning ApplicationsArief sitompulNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Catálogo e Los Cilindros Neumaticos PARKERDocument124 pagesCatálogo e Los Cilindros Neumaticos PARKERmaurozuriNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Sluice GateDocument19 pagesSluice GateAnuradha ChathurangaNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Hydraulic Slip PDFDocument110 pagesHydraulic Slip PDFjaime riañoNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- PLL 1262Document81 pagesPLL 1262DaceDropNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- VOLVO G726B MOTOR GRADER Service Repair Manual PDFDocument17 pagesVOLVO G726B MOTOR GRADER Service Repair Manual PDFsekfsekmddde50% (2)

- Manual Cizalla Durma SB 3006Document100 pagesManual Cizalla Durma SB 3006almas100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Spare Parts For Hydrailic Pump and MotorDocument11 pagesSpare Parts For Hydrailic Pump and MotorqwureyquweryNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Rans S6ES Assembly Manual PDFDocument346 pagesRans S6ES Assembly Manual PDFG.L. ZortmanNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- 06 Steering PDFDocument33 pages06 Steering PDFDaniel NavasNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Back Hoe Loader SOPDocument2 pagesBack Hoe Loader SOPHasnul Wafa100% (1)

- Hydracore 5000 Manportable - 3 Engine - v2018 09 SmallDocument49 pagesHydracore 5000 Manportable - 3 Engine - v2018 09 SmallJulio RamosNo ratings yet

- PN Series ManualDocument23 pagesPN Series ManualgminayasNo ratings yet

- Bomba Caterpillar AplicaçaoDocument4 pagesBomba Caterpillar AplicaçaoIury RezendeNo ratings yet

- Dynapac CC3800Document643 pagesDynapac CC3800Edinson Bolivar100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- GR 550 ExDocument16 pagesGR 550 Exmaziar norooziNo ratings yet

- Ar 307: Building Services-Ii: Assignment IiiDocument21 pagesAr 307: Building Services-Ii: Assignment IiiAakarshit JainNo ratings yet

- Lafarge - TA Grinding VRM v1 (Final)Document62 pagesLafarge - TA Grinding VRM v1 (Final)elwathig bakhiet100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Catalog Ge Oil and GasDocument146 pagesCatalog Ge Oil and GasLászló Lós50% (2)

- Pasadores y Bujes Cilindros DelanterosDocument3 pagesPasadores y Bujes Cilindros DelanterostallerNo ratings yet

- Martillo TB335Document30 pagesMartillo TB335Peter Curi QuiñonesNo ratings yet

- Itr Volvo Repair Parts Complete CatalogDocument155 pagesItr Volvo Repair Parts Complete CatalogHeiki Griffel50% (4)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Scherzinger Flow Dividers and ValvesDocument8 pagesScherzinger Flow Dividers and ValvesAbdNo ratings yet

- Hydraulic Floor Crane 360 Degree - Project ReportDocument34 pagesHydraulic Floor Crane 360 Degree - Project ReportPawan mehta75% (4)

- Escorts EC2420 Parts CatalogDocument202 pagesEscorts EC2420 Parts CatalogPrakash Niroula0% (1)

- Brochure Ec210d t3 en A8 20048851 eDocument24 pagesBrochure Ec210d t3 en A8 20048851 evenki babuNo ratings yet

- Servo-Hydraulic Actuator SHA Fields of Application: RE 08137, Edition: 2018-02, Bosch Rexroth AGDocument12 pagesServo-Hydraulic Actuator SHA Fields of Application: RE 08137, Edition: 2018-02, Bosch Rexroth AGGiovanni TrinidadNo ratings yet

- Medifa 8000 Service ManuelDocument44 pagesMedifa 8000 Service ManuelhoudaNo ratings yet

- Solutions For MiningDocument24 pagesSolutions For MiningChristopher GarciaNo ratings yet

- Mark11 Spare Parts Section - REV3Document72 pagesMark11 Spare Parts Section - REV3Orlando MelipillanNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)