Professional Documents

Culture Documents

Itp For Hvac (Heating Ventilation and Air Conditioning) System Installation

Uploaded by

Ahmed HassanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Itp For Hvac (Heating Ventilation and Air Conditioning) System Installation

Uploaded by

Ahmed HassanCopyright:

Available Formats

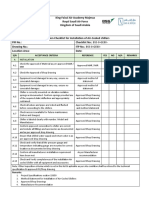

CUSTOMER

ISO 9001 :

2008

POWER AND WATER UTILITY COMPANY FOR JUBAIL & YANBU (MARAFIQ)

Yanbu Industrial City, KSA

PLANT LOCATION

PROJECT CONTRACT

NUMBER/TITLE

CONTRACT

NO. 7200 012

306 -(IWTP-II)

INSTALLATION

OF 48,000m3/day

TREATMENT

PLANT

AT MARAFIQ

- YANBU WASTE

Rev No: A

ITP FOR HVAC(HEATING VENTILATION AND AIR CONDITIONING) SYSTEM INSTALLATION

DATE: 20-02-

DOC.NO: 12306-ME-A4-2702

2012

ITEM

No.

Inspection & Testing Description

Acceptance Criteria

Reference Document

AKWAN

M.E

MFQ

QCF-001

QCF - 113

QCF - 115

QCF - 116

QC

Checklist

Remarks

MATERIAL INSPECTION

Equipment/Material Receiving inspection for HVAC

1

RC Standard

15820/15670,Material

Approval

Drawing,Manufacturer

Instruction, Approved

Material

equipment,duct & accessories,hanger/supports,

Insullation, air terminal devices,Flexible Connection, submittal,Drawing,Relav Submittal,Purchase

volume/fire dampers,Electrical Instument Materials.

Storage,handling & Preservation of Above

material/Equipment for HVAC System.

ant applicable Industrial Order,Project

Codes/standars.

Specification, QCP/M.S

Project Specification,

Project

RC Standard

15820/15670,Manufactu Specification,,Manufactu

rer Recommendation.

rer instruction.

DUCT SYSTEM INSTALLATION

3.1).Duct Material conforming to specification.

3.2).Duct Layout and Elevation.

3.3).Duct Installation as per approved drawings.

3.4)Hangers and support installation support

spacing,ducting route,reinforcement & hangers.

3.5)Check joints & Application of duct Sealant.

3.6). Visual check of connection tightness.

gaskets

& seals.

3.7)Visual Inspection of duct & its accessories

conforming to the project.

3.8).Check accessories & duct free from damage.

3.9).Duct Insulation material are conforming to

the project specification.

3.10).Duct insulation installation as per drawing,

check the insulation band spacing as per drawing.

RC Standard

15810/15820,QCP

Project

specification,Relavant

applicable Industrial

codes/standards

Manufacturer

Installation manual.

Manufacturer

recommendation,HVAC

Duct construction

standards,SMACNA,

Project specification,

Drawing.

Page 1 of 5

Rev No: A

ITP FOR HVAC(HEATING VENTILATION AND AIR CONDITIONING) SYSTEM INSTALLATION

DOC.NO: 12306-ME-A4-2702

DATE: 20-022012

ITEM

No.

Inspection & Testing Description

Duct accessories, duct heater, Volume

Damper,sound alternator,Flow grid inspection,fire

damper.

Installation of air terminal device, Flexible

connections.

Functional test of Fire Damper.

Acceptance Criteria

RC Standard

15820/15670,SMACNA

Standards,Project

specification,

drawing,QCP Relavant

applicable industrial

code & standards,

Manufacturer

installation manual.

RC Standard

15840,SMACNA

Standards,Project

specification,

drawing,QCP Relavant

applicable industrial

code & standards,

Manufacturer

installation manual.

Project Specification,

RC Standard 15820,

Codes/relavant

applicable Industrial

codes & standards,

Manufacturer manual.

Reference Document

Approved

Drawing,SMACNA

Standard QCP

Approved

Drawing,SMACNA

Standard QCP

IFC Drawing,Manu

Instru,RC Standars

15820,Project

Specification.

QC

Checklist

AKWAN

M.E

MFQ

QCF - 117

QCF - 118

AS PER

VENDOR

FORM

Remarks

HVAC Electrical & Instrumentation Material

Receving Visual Inspections

Project Specification

Specification

RC

AS PER

ELECTRICAL

ITP

Page 2 of 5

Rev No: A

ITP FOR HVAC(HEATING VENTILATION AND AIR CONDITIONING) SYSTEM

INSTALLATION DOC.NO: 12306-ME-A4-2702

DATE: 20-022012

ITEM

No.

Inspection & Testing Description

Acceptance

Criteria

Reference Document

QC Checklist

AKWAN

M.E

MFQ

QCF-120

D UCT INSULATION / CLADDING

8.1) Material Thickenss, Approved Insulations /

Cladding Sheet.

8.2) Material Delivered at Site is free from Defects &

RC Standard

as per specifications.

15820/15670,Project

8.3) Check duct Surface for Clean & dry prior to

specification,

Insulations.

drawing,QCP Relavant

8.4) Size of fastening

applicable code &

Screws. 8.5) workmanship.

sMt anduafarcdtsu,rer

8.6) Check sealant.

8.7) Correct flow direction.

instructions manual.

8.8) Check all the joints are sealed properly.

8.9) Visual Inspection of conditions of air cutlets &

inlets & dirction of grills.

SMACNA HVAC Duct

construction

Standard,Purchase

Order,Manufacturer

Recommendation.

LEAK TEST INSPECTION

Check for Leak Test for Duct Installation, by

conducting light test Method

RC Standard 15820 /

15670,QCP ,Project

specification,Relavant

applicable

codes/standards

Vendor

recommendation,SMAC

QCF-119

Manufacturer Instruction NA Standards, RC

Standard.

manual.

EQUIPMENT INSTALLATION

Equipment Foundation Location Check as per

Approved Drawing.

RC Standard

15820/15730,QCP

10.1) Verify unit Installation is as per approved Project

specification,Relavant

Drawing, Check Vibration pad Place Beneath

Approved Drawing.

10

the Package Equipment installation.

applicable Industrial

10.2) Check Orientation & Level is per IFC

codes/standards

Drawing. C) Check Condensate Drain System Manufacturer

is as per approved drawing.

Installation manual.

Page 3 of 5

QCF - 11 4

Remarks

You might also like

- Yanbu Industrial City, KSA: Itp For Hvac (Heating Ventilation and Air Conditioning) System InstallationDocument5 pagesYanbu Industrial City, KSA: Itp For Hvac (Heating Ventilation and Air Conditioning) System InstallationHARSHAL100% (2)

- Itp - HvacDocument3 pagesItp - HvacAbdulah Asagi100% (1)

- Inspection Amp Test Plan Itp Hvac Installation New Pump Station Ps 56a and Force Main To SWTP 9 Jubail PDF FreeDocument28 pagesInspection Amp Test Plan Itp Hvac Installation New Pump Station Ps 56a and Force Main To SWTP 9 Jubail PDF Freeأبو محمدNo ratings yet

- Yanbu Industrial City, KSA: Itp For Hvac (Heating Ventilation and Air Conditioning) System InstallationDocument5 pagesYanbu Industrial City, KSA: Itp For Hvac (Heating Ventilation and Air Conditioning) System InstallationAmair Cool88% (8)

- Itp - HvacDocument3 pagesItp - HvacAbdulah Asagi100% (2)

- Itp HvacDocument9 pagesItp HvacYada Giri100% (6)

- Inspection & Test Plan for Chilled Water Expansion TanksDocument1 pageInspection & Test Plan for Chilled Water Expansion TanksvictorNo ratings yet

- 02 Inpection and Test Plan - Installation of Air-Cooled ChillersDocument3 pages02 Inpection and Test Plan - Installation of Air-Cooled ChillersBabar Shehzad100% (1)

- DSM-xxx-0xxx-xx, Checklist For HDPE Piping InstallationDocument1 pageDSM-xxx-0xxx-xx, Checklist For HDPE Piping Installationkadir tanzania100% (4)

- Itp - Ahu, Fcu and FansDocument3 pagesItp - Ahu, Fcu and FansUmair Liaqat100% (1)

- ITP Check List HVAC Piping WorksDocument5 pagesITP Check List HVAC Piping WorksResearcherNo ratings yet

- 048-Itp For Installation of Hvac Unit PDFDocument8 pages048-Itp For Installation of Hvac Unit PDFKöksal Patan100% (4)

- ITP For Sprinkler and Spary SystemDocument6 pagesITP For Sprinkler and Spary System梁奇龙100% (2)

- Itp For InsulationDocument14 pagesItp For InsulationHytham El-NoubyNo ratings yet

- Inspection & Test Plan for HVAC Duct InstallationDocument1 pageInspection & Test Plan for HVAC Duct InstallationDong VanraNo ratings yet

- Copper Piping Checklist VRVDocument1 pageCopper Piping Checklist VRVSkill IndiaNo ratings yet

- Mep Inspection and Test PlanDocument2 pagesMep Inspection and Test PlanIm Chinith100% (5)

- Checklist For Installation of Pressurization UnitDocument1 pageChecklist For Installation of Pressurization Unitvictor100% (3)

- CHECKLIST For Installation & Testing of Fire Fighting Pipe WorkDocument1 pageCHECKLIST For Installation & Testing of Fire Fighting Pipe WorkTHEOPHILUS ATO FLETCHER50% (2)

- Mech Inspection Checklist PDFDocument11 pagesMech Inspection Checklist PDFDesigner Forever100% (1)

- Saudi Aramco inspection plan for medium voltage cablesDocument3 pagesSaudi Aramco inspection plan for medium voltage cablesHatemS.MashaGbehNo ratings yet

- Itp Installation of FcuDocument4 pagesItp Installation of FcuAkmaldeen AhamedNo ratings yet

- Test Pack Format: Contents of Hydrostatic Test PackagesDocument2 pagesTest Pack Format: Contents of Hydrostatic Test PackagesmiteshNo ratings yet

- Inspection and Test Plan - Fire Protection Works (Qcitp) : Material InspectionsDocument29 pagesInspection and Test Plan - Fire Protection Works (Qcitp) : Material InspectionsJay Chris L. Beron50% (2)

- 00 ITP For Installation & Testing of HVAC Ductwork SystemDocument3 pages00 ITP For Installation & Testing of HVAC Ductwork SystemBabar Shehzad100% (1)

- Duct Works ChecklistDocument1 pageDuct Works Checklistmd azmathNo ratings yet

- Checklist Mechanical Block-Outs and Pipe SleevesDocument2 pagesChecklist Mechanical Block-Outs and Pipe SleevesImho Tep100% (1)

- HVAC Duct Installation ITPDocument9 pagesHVAC Duct Installation ITPLouis Clark100% (1)

- Plumbing Works (Plumbing & Sanitary Works) : Inspection and Test PlanDocument3 pagesPlumbing Works (Plumbing & Sanitary Works) : Inspection and Test PlanAyi67% (3)

- Masinloc Power Plant Ducting Project Inspection PlanDocument9 pagesMasinloc Power Plant Ducting Project Inspection PlanResearcher100% (2)

- 0734 Refrigerant Installation ChecklistDocument1 page0734 Refrigerant Installation ChecklistMubashir KhanNo ratings yet

- Piping Field Inspection Checklist DikonversiDocument3 pagesPiping Field Inspection Checklist DikonversiJo Francesc100% (2)

- CHECKLIST For Installation of Above Ground Drainage Pipe WorkDocument1 pageCHECKLIST For Installation of Above Ground Drainage Pipe WorkTHEOPHILUS ATO FLETCHERNo ratings yet

- Inspection and Test Plan: Installation of Fire Alarm SystemDocument3 pagesInspection and Test Plan: Installation of Fire Alarm SystemBinu Sulochanan100% (2)

- Ma'aden Non-Process Buildings Project Method StatementDocument11 pagesMa'aden Non-Process Buildings Project Method StatementAbdul raheem syed100% (1)

- ITP-Duct InsulationDocument2 pagesITP-Duct Insulationdicky100% (1)

- Check List For DI Pipe InstallationDocument1 pageCheck List For DI Pipe InstallationSaifur Rahman0% (1)

- 04 Inspection Checklist - Installation of Air-Cooled ChillersDocument2 pages04 Inspection Checklist - Installation of Air-Cooled ChillersBabar Shehzad100% (3)

- Method Statement For Firefighting Piping Equipment and Accessories InstallationDocument12 pagesMethod Statement For Firefighting Piping Equipment and Accessories InstallationMohamedNo ratings yet

- Marriot Grand Ballroom Project Inspection and Test PlanDocument3 pagesMarriot Grand Ballroom Project Inspection and Test PlanImho Tep75% (4)

- Checklist For Testing & Commissioning of Sprinkler SystemDocument2 pagesChecklist For Testing & Commissioning of Sprinkler Systembeho2000100% (6)

- PRECOMMISSIONING and COMMISSIONING METHOD STATEMENT FOR FIRE HOSE RACKS and FIRE HOSE REELDocument2 pagesPRECOMMISSIONING and COMMISSIONING METHOD STATEMENT FOR FIRE HOSE RACKS and FIRE HOSE REELHumaid ShaikhNo ratings yet

- Inspection Report For Installation of JB, Juncation BoxDocument1 pageInspection Report For Installation of JB, Juncation BoxnayumNo ratings yet

- Inspection Checklist For Installation of Duct Hangers and Supports For HVAC Ductwork SystemDocument2 pagesInspection Checklist For Installation of Duct Hangers and Supports For HVAC Ductwork SystemBabar ShehzadNo ratings yet

- King Salman Airbase Project DirabDocument5 pagesKing Salman Airbase Project DirabArif Mohammed100% (1)

- Itp Package UnitDocument2 pagesItp Package UnitWasim AhmedNo ratings yet

- Fireproofing Check List Quality Control and Inspection Report FormDocument1 pageFireproofing Check List Quality Control and Inspection Report FormAnonymous 4e7GNjzGWNo ratings yet

- Low Voltage Cable - Itr ADocument2 pagesLow Voltage Cable - Itr AHaider HassanNo ratings yet

- 006 ChecklistDocument1 page006 ChecklistAbdul HakkimNo ratings yet

- Inspection and Test Plan - Mechanical Works (Qcitp) : Document ReviewDocument28 pagesInspection and Test Plan - Mechanical Works (Qcitp) : Document ReviewJay Chris L. Beron100% (4)

- GASOLINE STORAGE TANK INSPECTION AND TEST PLANDocument1 pageGASOLINE STORAGE TANK INSPECTION AND TEST PLANAmer Y KNo ratings yet

- Method Statement For Air Leak Test For HVAC Duct System Light TestDocument18 pagesMethod Statement For Air Leak Test For HVAC Duct System Light TestAhmed Omar100% (2)

- Method Statement For Installation of Grills Diffusers Disc Valves and LouversDocument9 pagesMethod Statement For Installation of Grills Diffusers Disc Valves and LouversHelder FigueiredoNo ratings yet

- Check List For Installation of External Fire Hydrant PDFDocument1 pageCheck List For Installation of External Fire Hydrant PDFvishalkadam57No ratings yet

- FF Water Sprinkler Test ProcedureDocument2 pagesFF Water Sprinkler Test ProcedureSalim Bakhsh100% (1)

- ITP For Plumbing & Drainage SystemDocument97 pagesITP For Plumbing & Drainage Systemmagdi badran100% (7)

- Itp For SSDP Project Rev CDocument9 pagesItp For SSDP Project Rev CRachel FloresNo ratings yet

- 3.itp ElectricalDocument28 pages3.itp ElectricalJoel Alcantara75% (4)

- FQPDocument9 pagesFQPtushar647No ratings yet

- 038-Pro Welding Consumable Control Procedure PDFDocument20 pages038-Pro Welding Consumable Control Procedure PDFKöksal Patan100% (7)

- Power Systems LTD, BangloreDocument2 pagesPower Systems LTD, BangloreAhmed HassanNo ratings yet

- NBL 0332512Document1 pageNBL 0332512Ahmed HassanNo ratings yet

- Mentioned in ContraDocument2 pagesMentioned in ContraAhmed HassanNo ratings yet

- Coating For InvoicingDocument16 pagesCoating For InvoicingAhmed HassanNo ratings yet

- Temperature Inspection ReportDocument2 pagesTemperature Inspection ReportAhmed HassanNo ratings yet

- CKpo L 0310Document2 pagesCKpo L 0310Ahmed HassanNo ratings yet

- Manufacturing and SupDocument1 pageManufacturing and SupAhmed HassanNo ratings yet

- MR 381 - Replacement Jackscrews For Y050ADocument1 pageMR 381 - Replacement Jackscrews For Y050AAhmed HassanNo ratings yet

- Carrier psychrometric chart analysisDocument1 pageCarrier psychrometric chart analysisonspsnons100% (3)

- Piping Test Packages Reinstatement StatusDocument6 pagesPiping Test Packages Reinstatement StatusAhmed HassanNo ratings yet

- Baseline - 26.06.2021Document1 pageBaseline - 26.06.2021Ahmed HassanNo ratings yet

- Email For QuotationDocument1 pageEmail For QuotationAhmed HassanNo ratings yet

- Insulating GasketsDocument1 pageInsulating GasketsAhmed HassanNo ratings yet

- Material Request Form: Project Koc Feed Pipe Line For NRP Client Saipem MR Number MR-PIP-R0-ALG-378 Raised On: 22-Jan-22Document1 pageMaterial Request Form: Project Koc Feed Pipe Line For NRP Client Saipem MR Number MR-PIP-R0-ALG-378 Raised On: 22-Jan-22Ahmed HassanNo ratings yet

- 29-Dec-21 PSV and Pse Installation Status Main Line Location PSV PSE RemarksDocument1 page29-Dec-21 PSV and Pse Installation Status Main Line Location PSV PSE RemarksAhmed HassanNo ratings yet

- Hydraulic Calculation For FFDocument2 pagesHydraulic Calculation For FFAhmed Hassan100% (2)

- Production of Toilet SoapDocument60 pagesProduction of Toilet Soapiko856100% (2)

- Resd Load CalcDocument5 pagesResd Load CalcOre Ulil DesuNo ratings yet

- 1 Duct 1Document16 pages1 Duct 1Ahmed HassanNo ratings yet

- Fire Sprinklers Hydraulic CalculationsDocument38 pagesFire Sprinklers Hydraulic CalculationsVerlin Ann LacastesantosNo ratings yet

- Hazen Williams EquationDocument1 pageHazen Williams EquationEnsan MasryNo ratings yet

- Ahmed Mi................Document1 pageAhmed Mi................Ahmed HassanNo ratings yet

- Incoming Transmittal Log Ag4Document5 pagesIncoming Transmittal Log Ag4Ahmed HassanNo ratings yet

- Elite Hydraulic Calculation SampleDocument12 pagesElite Hydraulic Calculation SampleSam Choi100% (1)

- Hydraulic Calculation For FFDocument2 pagesHydraulic Calculation For FFAhmed HassanNo ratings yet

- CO2 System CalculationsDocument1 pageCO2 System CalculationsAhmed HassanNo ratings yet

- 3 HVAC Duct 3Document14 pages3 HVAC Duct 3Ahmed HassanNo ratings yet

- A) Paw Rules For Construction of Pressdivision 3: 1-Max. - P91: 205C 2-Monel: 10C MaxDocument1 pageA) Paw Rules For Construction of Pressdivision 3: 1-Max. - P91: 205C 2-Monel: 10C MaxAhmed HassanNo ratings yet

- YoutubeDocument1 pageYoutubeAhmed HassanNo ratings yet

- A) Paw 1-What Are The Asme Sectiosection Viii: Rules For Loy: LJKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKDocument1 pageA) Paw 1-What Are The Asme Sectiosection Viii: Rules For Loy: LJKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKAhmed HassanNo ratings yet

- Amos Module 4 Part2Document11 pagesAmos Module 4 Part2bokax95577No ratings yet

- Pressure Vessel RT TestDocument3 pagesPressure Vessel RT TestAriq FauzanNo ratings yet

- Process Control FundamentalsDocument151 pagesProcess Control FundamentalsKzenette Anne RoblesNo ratings yet

- Fluid Machinery Syllabus PDFDocument3 pagesFluid Machinery Syllabus PDFBajajNo ratings yet

- Week 2 - Physical Science Q2Document2 pagesWeek 2 - Physical Science Q2Gemma Quiocho-CardenasNo ratings yet

- SENR5672Document2 pagesSENR5672Gilvan JuniorNo ratings yet

- M0066206-02 (En-Us) - 00-ALLCD - 001Document1,039 pagesM0066206-02 (En-Us) - 00-ALLCD - 001Edilberto zegarra camposNo ratings yet

- Solved Problems in PsychrometryDocument86 pagesSolved Problems in Psychrometrylakshminarayanan67% (9)

- Elster Rotary Gas Meter: I Connected IndustrialDocument6 pagesElster Rotary Gas Meter: I Connected IndustrialAlvaro Joel Quinteros RochaNo ratings yet

- Product Data Sheet OK 74.78: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenDocument2 pagesProduct Data Sheet OK 74.78: E 'Manual Metal-Arc Welding' ESAB Perstorp AB Swedentungau87No ratings yet

- Standard Practice For Direct Design of Buried Precast Concrete Pipe Using Standard InstallDocument51 pagesStandard Practice For Direct Design of Buried Precast Concrete Pipe Using Standard Installsandeep100% (2)

- Canadian Seismic Design of Steel Structures OverviewDocument25 pagesCanadian Seismic Design of Steel Structures OverviewJamal Muhammad BahajajNo ratings yet

- Cantilivered Column SystemDocument11 pagesCantilivered Column SystemRichard SarominesNo ratings yet

- Calculation Salim 1Document9 pagesCalculation Salim 1Abdullahi AwwalNo ratings yet

- TCC82 Pilecap DesignDocument99 pagesTCC82 Pilecap DesignFatima Marah100% (2)

- Ej Vol Control Pelu oDocument8 pagesEj Vol Control Pelu oPablo Martínez CavieresNo ratings yet

- Sample 35313Document16 pagesSample 35313Francis CometaNo ratings yet

- Kesetimbangan KimiaDocument19 pagesKesetimbangan KimiaAmel RahmaNo ratings yet

- BPT 13 Balanced Pressure Thermostatic Steam TrapDocument2 pagesBPT 13 Balanced Pressure Thermostatic Steam Trapmember1000No ratings yet

- Hydraulic Thrust DeviceDocument2 pagesHydraulic Thrust DeviceGuilherme Augusto100% (1)

- Welding Consumable Storage and Handling ProceduresDocument27 pagesWelding Consumable Storage and Handling ProceduresKannan MurugesanNo ratings yet

- Nitric Acid Alarm and Safety SystemDocument5 pagesNitric Acid Alarm and Safety Systemlaoy aolNo ratings yet

- Operating Instructions: Oil Sealed Rotary Vacuum PumpDocument11 pagesOperating Instructions: Oil Sealed Rotary Vacuum PumpAlejandro PalominoNo ratings yet

- Boom Hydraulic System CAT 330Document17 pagesBoom Hydraulic System CAT 330hector100% (1)

- Basics of Seismic Wave TheoryDocument154 pagesBasics of Seismic Wave TheoryYinfeng Dong0% (1)

- Testing ReportDocument1 pageTesting ReportfaizNo ratings yet

- PHYS 211 6.STATIC 1ST CONDITION MergedDocument36 pagesPHYS 211 6.STATIC 1ST CONDITION MergedLEENo ratings yet

- Sumitomo HSMDocument68 pagesSumitomo HSMEdisson Yanqui VivancoNo ratings yet

- F.sq-p-009 Rev. 0 Procedure For Inspection of Rotating EquipmentDocument13 pagesF.sq-p-009 Rev. 0 Procedure For Inspection of Rotating EquipmentIksan Adityo Mulyo100% (1)

- Town and Contry 4.0 2008Document4 pagesTown and Contry 4.0 2008Jessica BustillosNo ratings yet