Professional Documents

Culture Documents

Enclosures 17 - 1

Uploaded by

Rajesh BarkurOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Enclosures 17 - 1

Uploaded by

Rajesh BarkurCopyright:

Available Formats

Enclosures

17 - 1

ENCLOSURES

He that is too secure is not safe

- Proverb

Course 9050 - October 1996

Principles of Instrumentation and Control

17 - 2

Enclosures

Synopsis

The two major Ingress Protection standards are reviewed.

- IEC

- NEMA

Degrees of protection are associated with varying codes.

Principles of Instrumentation and Control

Course 9050 - October 1996

Enclosures

17 - 3

The two standards commonly associated with Ingress Protection of Enclosures are:

1.

IEC

2.

NEMA

IEC Standard

IEC stands for International Electrotechnical Commission.

Table 17.1

NOTES:

1.

To be used in place of a first characteristic numeral where it is categorically claimed that a

degree of protection does not apply.

Course 9050 - October 1996

Principles of Instrumentation and Control

17 - 4

Enclosures

Table 17.2

NOTE

1.

To be used in place of a second characteristic numeral where it is categorically claimed that a

degree of protection does not apply.

Principles of Instrumentation and Control

Course 9050 - October 1996

Enclosures

17 - 5

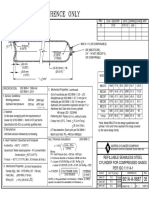

Table 17.3

IEC Standard Test Finger

The standard test finger shall be so designed that each of the jointed sections can be turned through

an angle of 90 degrees with respect to the axis of the finger in the same direction only.

The tip of the finger shall be made of copper alloy, the handle shall be made of insulating material.

The finger shall be provided with two joints operating in the same plane and so constructed that

they will remain in any desired position.

A terminal or other equivalent means shall be provided to permit attachment of a flexible wire lead

to the finger.

Course 9050 - October 1996

Principles of Instrumentation and Control

17 - 6

Enclosures

Fig. 17.1

NEMA Standards

The National Electrical Manufacturers Association has developed standards for various types of

enclosures for electrical equipment. The enclosures are classified by type number in accordance

with NEMA Standard ICS-6-110 to indicate the external conditions for which the enclosure is

suitable.

NEMA 1 GENERAL PURPOSE ENCLOSURE

These have sheet metal enclosures and serve as protection against dirt and against light indirect

splashing. They are not dust tight or splash proof.

NEMA 2 DRIP TIGHT ENCLOSURE

Severe condensation, cooling rooms, laundries, tunnels.

NEMA 3 WEATHER RESISTANT (WEATHER PROOF)

Used outdoors for splashing rain, snow, sleet. Ship docks, subways, tunnels.

NEMA 4 WATER TIGHT

Used in dairies, breweries, etc. Must pass hose test, using one inch nozzle, delivering 65 gpm

10 foot distance for 5 minutes.

NEMA 5 DUST TIGHT

Gasketed enclosure to exclude non-hazardous dust in cement mills, steel mills etc. Do not

use for grain or coal dust atmosphere.

NEMA 6 SUBMERSIBLE

Used in quarries, mines and manholes. To operate while submerged in water under conditions

of pressure and time.

Principles of Instrumentation and Control

Course 9050 - October 1996

Enclosures

17 - 7

NEMA 7 HAZARDOUS LOCATIONS (CLASS I GROUP C & D)

Explosion proof. Atmospheres of ethylether, ethylene, cyclo propane, gasoline, petroleum,

naptha, benzene, propane, alcohol, acetone, benzol, lacquer solvent vapour, natural gas.

NEMA 8 HAZARDOUS LOCATIONS (CLASS I OIL IMMERSED)

Oil circuit breakers.

NEMA 9 HAZARDOUS LOCATIONS (CLASS II GROUP E,F,G)

Combustible dust such as metal dust, carbon black, coal dust, coke dust, grain dust.

NEMA 10 BUREAU OF MINES 0 (EXPLOSION PROOF)

Used in gassy coal mines.

NEMA 11 ACID & FUME RESISTANT - OIL EMMERSED- USED INDOORS

Equipment submerged in oil when subjected to acid or other corrosive fuels, as in chemical

plants, plating rooms, sewage plants, etc.

NEMA 12 INDUSTRIAL USE

To exclude dust lint, flyings, oil seepage.

NEMA 13 DUST PROOF

Special design required for each application.

ENCLOSURES FOR NONHAZARDOUS LOCATIONS

LEGEND:

I = Enclosures intended for indoor nonhazardous locations

X = Enclosures intended for indoor and outdoor nonhazardous locations

In or X n = Same as above: however, recognized by NEMA enclosure type ratings only

Ic or Xc = Same as above; however, recognized by CSA enclosure type ratings only

Table 17.4

Course 9050 - October 1996

Principles of Instrumentation and Control

17 - 8

Enclosures

Enclosure Classification Designations Comparison

The North American ingress protection designations are easily comparted with the IEC enclosure

classifications for compatibility. Both classification designations are similar; however, they are not

identical in all respects. The following table displays the ingress protection comparison:

Table 17.5

Summary

The International Electrotechnical Commission (IEC) use a code of the form IP [1] [2] where [1]

is the level of protection from ingress of solids and [2] is the level of protection from ingress of

water.

The National Electrical Manufacturers Association (NEMA) lists protection using numbers from

1-13. These cover liquid, solid and hazardous area requirements.

Activity

1.

2.

3.

Which codes (IEC, NEMA) apply to protection from dusts? high pressure water?

Convert these to their IEC equivalent(s):

i. Nema 6

ii. Nema 9

Convert these to their NEMA equivalent(s);

i. IP10

ii. IPX5

Discussion

Where are special enclosures used in your plant environment? Why?

Third Printing: October 1996

Second Printing: December 1993

First Printed: Otober 1991

Principles of Instrumentation and Control

Course 9050 - October 1996

You might also like

- Understanding NEMA and IEC Enclosure RatingsDocument3 pagesUnderstanding NEMA and IEC Enclosure RatingsTodd WhiteNo ratings yet

- Nema-Iec Enclosure RatingsDocument6 pagesNema-Iec Enclosure Ratingsamr saadNo ratings yet

- Informative Annex 10A IP Vs NEMA EnclosuresDocument6 pagesInformative Annex 10A IP Vs NEMA EnclosureshernicoNo ratings yet

- NEMA FAQ-EnclosuresDocument22 pagesNEMA FAQ-EnclosureslataNo ratings yet

- Guide to NEMA and IEC Enclosure RatingsDocument3 pagesGuide to NEMA and IEC Enclosure Ratingschootymalli9760No ratings yet

- Crouse HindsDocument7 pagesCrouse HindsNoman KhanNo ratings yet

- Area Classification Guide for Flammable AtmospheresDocument1 pageArea Classification Guide for Flammable Atmosphereswado11No ratings yet

- Intertek - IEC 60079-1 and UL1203, Explosionproof Vs Flameproof White paper-ITDocument10 pagesIntertek - IEC 60079-1 and UL1203, Explosionproof Vs Flameproof White paper-ITPierdavide Boni LauriNo ratings yet

- MCC 4Document34 pagesMCC 4Makarand KhareNo ratings yet

- Nema Neca NetaDocument47 pagesNema Neca NetaKent GaramayNo ratings yet

- Intertek Explosionproof Vs Flameproof IEC 60079 1 and UL 1203 PDFDocument10 pagesIntertek Explosionproof Vs Flameproof IEC 60079 1 and UL 1203 PDFchertanNo ratings yet

- Technical Paper-French Standard NFC 17-102 (2011)Document10 pagesTechnical Paper-French Standard NFC 17-102 (2011)Mohamad HishamNo ratings yet

- GBDocument11 pagesGBdungtran77No ratings yet

- Ilinox Atex LineDocument13 pagesIlinox Atex LineDidit AndiatmokoNo ratings yet

- Blitzsch enDocument36 pagesBlitzsch enNeranjan LihinikumaraNo ratings yet

- ECP Electrical Enclosure Specification GuideDocument3 pagesECP Electrical Enclosure Specification GuideClaudia MondragónNo ratings yet

- ExtronicsWallchart 160708Document1 pageExtronicsWallchart 160708Shyam VarunNo ratings yet

- NEMA Rating Guide for Instrument EnclosuresDocument17 pagesNEMA Rating Guide for Instrument EnclosuresJulius ChavezNo ratings yet

- Catalog of Flexicon Flexible Conduit Solutions For Hazardous AreasDocument17 pagesCatalog of Flexicon Flexible Conduit Solutions For Hazardous AreasIBJSC.comNo ratings yet

- CMP Triton Deluge Proof Cable GlandsDocument6 pagesCMP Triton Deluge Proof Cable GlandsrocketvtNo ratings yet

- Lightning Protection SystemDocument10 pagesLightning Protection SystemJuan Araque100% (1)

- Cast Resin Planning Guidelines GEAFOL PDFDocument24 pagesCast Resin Planning Guidelines GEAFOL PDFtenk_man100% (1)

- Hazardous Area Classification: Codes of Practice and StandardsDocument13 pagesHazardous Area Classification: Codes of Practice and StandardsborrowmanaNo ratings yet

- IP degrees of protection guideDocument109 pagesIP degrees of protection guideDino PedutoNo ratings yet

- Comparing IP and NEMA Standards for Electrical Equipment ProtectionDocument9 pagesComparing IP and NEMA Standards for Electrical Equipment ProtectionEng TrNo ratings yet

- IEC NEC ComparationDocument18 pagesIEC NEC ComparationDen Andri NchuNo ratings yet

- 900 Series Product Training ModuleDocument13 pages900 Series Product Training Modulemcr16986No ratings yet

- V International Symposium On Lightning Protection: Experience in The Design of Protection Systems Against Ligh1.) NingDocument6 pagesV International Symposium On Lightning Protection: Experience in The Design of Protection Systems Against Ligh1.) NingCarlos CastilloNo ratings yet

- IP Protection Number SummaryDocument4 pagesIP Protection Number SummaryDina DineshNo ratings yet

- 21st Electrical Engineering Safety Seminar Presentation on Cable Glands and Explosion ProtectionDocument38 pages21st Electrical Engineering Safety Seminar Presentation on Cable Glands and Explosion ProtectionRajmohanNo ratings yet

- ABB Motors for Hazardous AreasDocument65 pagesABB Motors for Hazardous Areaslaem269No ratings yet

- Understanding IP RatingsDocument4 pagesUnderstanding IP Ratingsvictor.ciprianiNo ratings yet

- NEMA and IEC Classifications: EnclosuresDocument1 pageNEMA and IEC Classifications: EnclosuresUrsap BuddyNo ratings yet

- CobramaticDocument40 pagesCobramaticHiram MartinezNo ratings yet

- Iec 60079Document7 pagesIec 60079Shirish33% (3)

- Explosion Protection Wall Chart BASEEFADocument1 pageExplosion Protection Wall Chart BASEEFAweby98No ratings yet

- SECTION 08 33 13 Coiling Counter DoorsDocument10 pagesSECTION 08 33 13 Coiling Counter DoorsJuanPaoloYbañezNo ratings yet

- Tica SpecDocument29 pagesTica SpecCong ThanhNo ratings yet

- The Risk Assessment of Fire Damper InstallationsDocument43 pagesThe Risk Assessment of Fire Damper Installationsalan.edwards7282100% (1)

- Instrucciones de OperaciónDocument24 pagesInstrucciones de OperaciónAníbal LópezNo ratings yet

- NormeDocument33 pagesNormeAndreea Anca BordeaNo ratings yet

- Commissioning Low Voltage Distribution PanelboardsDocument38 pagesCommissioning Low Voltage Distribution Panelboardsbookbum100% (4)

- R18!01!03 - QSil 250 Post - Prototype Test ReportDocument22 pagesR18!01!03 - QSil 250 Post - Prototype Test ReportGlenys MuñozNo ratings yet

- Abb ArrestersDocument132 pagesAbb ArrestersCesar Becerra P.No ratings yet

- ATEX PosterDocument1 pageATEX PosterJuan Ramon RodriguezNo ratings yet

- Technical Specifications - Lightning Protection SystemDocument5 pagesTechnical Specifications - Lightning Protection SystemMarcons Jon Maturan CasabaNo ratings yet

- Jim 1 IP RatingsDocument2 pagesJim 1 IP RatingsAamir HussainNo ratings yet

- NEMA 2 Enclosure Guide - FAQs on Uses, Benefits & MaterialsDocument5 pagesNEMA 2 Enclosure Guide - FAQs on Uses, Benefits & MaterialsKriezel Anne SivaNo ratings yet

- Ex Cable GlandsDocument18 pagesEx Cable GlandsAntonis BafatakisNo ratings yet

- Equipment Certification Guide For Hazardous Areas: North America Atex and Iec Ex ComparisonDocument1 pageEquipment Certification Guide For Hazardous Areas: North America Atex and Iec Ex ComparisonBalan PalaniappanNo ratings yet

- DF PDFDocument8 pagesDF PDFAtif JaveadNo ratings yet

- ATEXDocument15 pagesATEXsagar_ovhalNo ratings yet

- Chalmit Lighting 2010Document172 pagesChalmit Lighting 2010charlnnmd0% (2)

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Cryogenics Safety Manual: A Guide to Good PracticeFrom EverandCryogenics Safety Manual: A Guide to Good PracticeNo ratings yet

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Healthify Diet Plan PDFDocument4 pagesHealthify Diet Plan PDFRajesh BarkurNo ratings yet

- ABSL Business Cycle Fund - PresentationDocument37 pagesABSL Business Cycle Fund - PresentationRajesh BarkurNo ratings yet

- NJ India Safety and Quality: Teemu TeittoDocument8 pagesNJ India Safety and Quality: Teemu TeittoRajesh BarkurNo ratings yet

- CopDocument8 pagesCopRajesh BarkurNo ratings yet

- Block 31 - Suriname - Suriname, South America PDFDocument4 pagesBlock 31 - Suriname - Suriname, South America PDFRajesh BarkurNo ratings yet

- Integrated Field Plan Execution Services In Satellite Fields In RJ-ON 90/1 Block Instrumentation & Control Design BasisDocument40 pagesIntegrated Field Plan Execution Services In Satellite Fields In RJ-ON 90/1 Block Instrumentation & Control Design BasisRajesh Barkur100% (2)

- Sample DESIGN BASISDocument34 pagesSample DESIGN BASISRajesh BarkurNo ratings yet

- STN ESL SymbolsDocument71 pagesSTN ESL SymbolsRajesh BarkurNo ratings yet

- When You See A HazardDocument17 pagesWhen You See A HazardfawnNo ratings yet

- Differential Pressure Transmitters: Date Revision Sheet Inquiry Area CodeDocument4 pagesDifferential Pressure Transmitters: Date Revision Sheet Inquiry Area CodeRajesh BarkurNo ratings yet

- Zora Gas Field - United Arab Emirates, Middle-EastDocument4 pagesZora Gas Field - United Arab Emirates, Middle-EastRajesh BarkurNo ratings yet

- Titicaca Basin - Block 105 - Peru, South AmericaDocument4 pagesTiticaca Basin - Block 105 - Peru, South AmericaRajesh BarkurNo ratings yet

- Instrument IndexDocument1 pageInstrument IndexRajesh BarkurNo ratings yet

- Design BasisDocument34 pagesDesign BasisRajesh BarkurNo ratings yet

- Integrated Field Plan Execution Services In Satellite Fields In RJ-ON 90/1 Block Instrumentation & Control Design BasisDocument40 pagesIntegrated Field Plan Execution Services In Satellite Fields In RJ-ON 90/1 Block Instrumentation & Control Design BasisRajesh Barkur100% (2)

- Successful Instrument and Control System DesignDocument16 pagesSuccessful Instrument and Control System DesignChen WsNo ratings yet

- Control Valve Datashee T PDFDocument4 pagesControl Valve Datashee T PDFRajesh BarkurNo ratings yet

- Hummer Prospect - United States of America, North AmericaDocument4 pagesHummer Prospect - United States of America, North AmericaRajesh BarkurNo ratings yet

- 6 Electricity FundamentalsDocument80 pages6 Electricity FundamentalsOgunranti RasaqNo ratings yet

- Hibernia Southern Extension Project - Canada, North AmericaDocument4 pagesHibernia Southern Extension Project - Canada, North AmericaRajesh BarkurNo ratings yet

- CNTRL Valve Demo Datasheet222Document9 pagesCNTRL Valve Demo Datasheet222Rajesh BarkurNo ratings yet

- BKDD00-ME-4M-87-001 Rev.d - Code 2 Data Sheet For Control ValvesDocument25 pagesBKDD00-ME-4M-87-001 Rev.d - Code 2 Data Sheet For Control ValvesnileshanaNo ratings yet

- Guyana Maritime PermitDocument7 pagesGuyana Maritime PermitRajesh BarkurNo ratings yet

- DotcomDocument325 pagesDotcomDerence VooNo ratings yet

- CPO-5 Block - Llanos Basin - Colombia, South AmericaDocument4 pagesCPO-5 Block - Llanos Basin - Colombia, South AmericaRajesh BarkurNo ratings yet

- LLA-47 Block - Llanos Basin - Colombia, South AmericaDocument4 pagesLLA-47 Block - Llanos Basin - Colombia, South AmericaRajesh BarkurNo ratings yet

- Quifa Block - Prospects I and E - Rubiales Field - Colombia, South AmericaDocument4 pagesQuifa Block - Prospects I and E - Rubiales Field - Colombia, South AmericaRajesh BarkurNo ratings yet

- (Instreng - Com) Instrument QuestionsDocument34 pages(Instreng - Com) Instrument QuestionsRajesh BarkurNo ratings yet

- Dolphin Gas Field - Qatar ContractsDocument4 pagesDolphin Gas Field - Qatar ContractsRajesh BarkurNo ratings yet

- Coiron Amargo Block - Argentina, South AmericaDocument4 pagesCoiron Amargo Block - Argentina, South AmericaRajesh BarkurNo ratings yet

- Fauji Fertilizer Bin Qasim Limited: Nust-PnecDocument27 pagesFauji Fertilizer Bin Qasim Limited: Nust-PnecAhmed MustafaNo ratings yet

- 4000 Series: 4012-46TAG2ADocument5 pages4000 Series: 4012-46TAG2Aherry tristantoNo ratings yet

- 9701 w10 QP 23Document12 pages9701 w10 QP 23panshanrenNo ratings yet

- Cat 434e Schematic Hydraylic SystemDocument2 pagesCat 434e Schematic Hydraylic SystemJuan Pablo Barron Marin100% (1)

- Student Trainee Learns Electrical Skills During PracticumDocument3 pagesStudent Trainee Learns Electrical Skills During PracticumGacutan Jn100% (1)

- Alcorcon Engineering Review Center: Ppe - Problem Set # 3Document3 pagesAlcorcon Engineering Review Center: Ppe - Problem Set # 3Juan T Amad100% (1)

- Book3 Surface TestingDocument117 pagesBook3 Surface Testingamine50% (2)

- Refillable Seamless Steel Cylinder For Compressed Gases PER ISO 11114-1Document1 pageRefillable Seamless Steel Cylinder For Compressed Gases PER ISO 11114-1bkprodhNo ratings yet

- HITACHI ZAXIS 135US EXCAVATOR Service Repair Manual PDFDocument62 pagesHITACHI ZAXIS 135US EXCAVATOR Service Repair Manual PDFhfjskemmdm67% (3)

- Spe 128712 MS PDocument8 pagesSpe 128712 MS Pb4rfNo ratings yet

- Food Grade Lube From Each BrandDocument6 pagesFood Grade Lube From Each BrandCindy OrangeNo ratings yet

- EcoBurn Manual TextDocument31 pagesEcoBurn Manual TextIoa SeuleanNo ratings yet

- Self Inspection CH KLT SurveyDocument4 pagesSelf Inspection CH KLT SurveyRecel Joy ArcedeNo ratings yet

- Fire and Explosion HazardsDocument10 pagesFire and Explosion Hazardsاحمد الجزار2007No ratings yet

- Tehnologija Čistog UgljaDocument34 pagesTehnologija Čistog Ugljapraicevic74No ratings yet

- R22 Starting Engine and Run UpDocument4 pagesR22 Starting Engine and Run UpBlueSkyMasterNo ratings yet

- MG ROEWE 350 2010 Service ManualDocument749 pagesMG ROEWE 350 2010 Service ManualÁlvaro Araúz100% (1)

- MB LalDocument13 pagesMB Lalshona2rockNo ratings yet

- Ic Engine MCQDocument48 pagesIc Engine MCQVokNo ratings yet

- A Review of Liquefied Natural Gas Refueling Station DesignsDocument11 pagesA Review of Liquefied Natural Gas Refueling Station DesignsShayne229No ratings yet

- Different Types of VVT VTECDocument12 pagesDifferent Types of VVT VTECshahrizalNo ratings yet

- Spec Est2dDocument4 pagesSpec Est2dJuan David Rondinel BulejeNo ratings yet

- Propylene ProductionDocument24 pagesPropylene ProductionFadlan BaharNo ratings yet

- Determination of Corrosion Rate and Remaining Life of Pressure Vessel Using Ultrasonic Thickness Testing TechniqueDocument8 pagesDetermination of Corrosion Rate and Remaining Life of Pressure Vessel Using Ultrasonic Thickness Testing TechniqueEdwinMauricioMacabeoNo ratings yet

- Pump GDDocument2 pagesPump GDdelcololalunaNo ratings yet

- SL96-341 B&W Service LetterDocument4 pagesSL96-341 B&W Service LetterkamalNo ratings yet

- Refinery OverviewDocument79 pagesRefinery Overviewchikukotwal100% (1)

- Start Sugarcane BusinessDocument3 pagesStart Sugarcane BusinessAMINNo ratings yet

- Reactors Can Be Selected Depending Upon Following FactorsDocument5 pagesReactors Can Be Selected Depending Upon Following FactorsGulfam RazaNo ratings yet