Professional Documents

Culture Documents

0 A1000705 Ci3212parra PDF

Uploaded by

uqiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

0 A1000705 Ci3212parra PDF

Uploaded by

uqiCopyright:

Available Formats

Earthquake-Resistant

Coupling Beams

without Diagonal

Reinforcement

Strain-hardening fiber-reinforced concrete provides means to simplify detailing

by Gustavo J. Parra-Montesinos, James K. Wight, and Monthian Setkit

F or some time, there has been an inherent challenge in

the design and construction of coupling beams in

earthquake-resistant coupled wall systems. The failure of

coupling beams with traditional longitudinal and transverse

reinforcement during the 1964 Alaska earthquake indicated

the need for new designs that would allow these beams

to sustain large shear reversals without a substantial

degradation of strength and stiffness. Experimental

research conducted in New Zealand showed that the use

of well-confined diagonal reinforcement cagesdesigned

to resist the total shear demandensures stable

behavior under displacement reversals such as those

induced during a strong earthquake.1 Current design

provisions in the ACI 318-08 Building Code2 are largely

based on this research.

The reliance on diagonal reinforcement to resist the

entire coupling beam shear demand, however, often Fig. 1: Typical diagonally reinforced coupling beam (photo courtesy

of Rmy Lequesne)

translates into the use of large diameter diagonal bars

for example, No. 11 (No. 35) or largerthat require long

development lengths and are difficult to handle on site.

The construction of coupling beams is further complicated In recent years, the use of relatively slender coupling

by the need for column-type transverse reinforcement to beams (that is, beams with span-to-overall-depth ratios

confine each diagonal reinforcement cage or the entire [aspect ratios] on the order of 3) has become popular

beam to maintain the integrity of the concrete and prevent due to limitations in story heights. In these beams,

premature buckling of the diagonal bars. Figure 1 shows however, the effectiveness of diagonal reinforcement to

a typical design of a coupling beam in an earthquake- resist shear significantly decreases because of the

prone region. shallow angle with the beam longitudinal axis (less than

36 december 2010 / Concrete international

20 degrees). For example, approximately twice the Wall face Wall face

6 in.

amount of diagonal reinforcement is needed to resist the (152 mm) No. 6 A No. 4 B 21 in.

(No. 19M) (No. 13M) (533 mm)

same amount of shear when the angle between the

(508 mm)

No. 4

20 in.

diagonal reinforcement and the a)beam axis is reduced (No. 13M)

from 45 to 20 degrees. While the increase in beam aspect

Section A-A No. 6 3 in. 5.75 in. Section B-B

ratio allows flexure to play a more significant role compared (No.19M) A (76 mm) (146 mm) B

to that in shorter coupling beams, results from recent 66 in.

(1676 mm)

research indicate that diagonal reinforcement, combined (a)

with column-type confinement, is still needed in the more

slender coupling beams to ensure stable behavior under

earthquake loading.3 Wall face Wall face

6 in.

Its possible that the addition of randomly oriented (152 mm) No. 6 A

No.4 (No.13M)

B 21 in.

(533 mm)

(No.19M)

steel fibers to the concrete will allow significant No. 5

(No.16M)

(610 mm)

simplifications in the design and construction of slender

24 in.

No. 4

(No.13M)

coupling beams, including theb) complete elimination of No. 5

(No.16M)

diagonal bars and substantial reductions in confinement Section A-A No. 6 3 in. 5.75 in. Section B-B

(No.19M) (146 mm)

reinforcement. This article presents the results from two A (76 mm)

66 in.

B

large-scale tests that support that possibility. (b) (1676 mm)

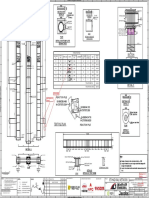

Evaluation of New Design for Slender Fig. 2: Reinforcement details in test coupling beams:

Coupling Beams (a) Specimen 1 had an aspect ratio of 3.3; and (b) Specimen 2

had an aspect ratio of 2.75

In the context of this article, the term slender coupling

beams refers to those with span-to-overall-depth ratios of

about 3. The proposed design builds on previous research

conducted at the University of Michigan on the use of

high-performance fiber-reinforced concrete (HPFRC) in

short coupling beams (with a span-to-overall-depth ratio

< 2).4,5 Contrary to traditional fiber-reinforced concretes,

HPFRC materials exhibit a strain-hardening behavior

under direct tension and a compression behavior that

resembles that of well-confined concrete; thus, they are

able to provide shear resistance with reduced confinement

reinforcement under large displacement reversals.

From previous research, it was concluded that the use

of HPFRC allows a substantial reduction in both diagonal

and confinement reinforcement in short coupling beams.

It was also found that a shear stress of 5fc psi (0.42fc MPa)

represented a lower bound for the contribution of

fiber-reinforced concrete to member shear strength,

where fc is the concrete compressive strength.

Because of the increased role played by flexure, the

use of HPFRC was believed to offer the potential for a

complete elimination of diagonal reinforcement in

slender coupling beams. To evaluate this possibility, two

large-scale coupling beams with aspect ratios of 3.3 and

2.75 were tested under simulated earthquake loading.

The test specimens consisted of a coupling beam

connected to stiff reinforced concrete blocks intended to

represent structural walls. The two test coupling beams

were 66 in. (1676 mm) long and 6 in. (152 mm) wide. The

overall depths of Specimens 1 and 2 were 20 and 24 in.

(508 and 610 mm); their aspect ratios were 3.3 and 2.75,

respectively. The design of the two coupling beams is

shown in Fig. 2. Flexural reinforcement was provided

Concrete international / december 2010 37

such that the shear corresponding to the expected the precast portion. Also, to prevent excessive inelastic

moment capacity being reached at both ends of the deformations at the precast coupling beam-wall interface,

coupling beam would be close to the upper limit in intermediate U-shaped reinforcement was provided,

ACI 318-082 (10fc psi [0.83fc MPa]). The expected beam which extended approximately 8 in. (200 mm) into the

flexural capacity was calculated considering overstrength span (Fig. 2).

and strain-hardening of the steel but neglecting the Figure 3 is a schematic of the test setup. As shown in

contribution of fiber-reinforced concrete in tension. Fig. 3, the beam was rotated 90 degrees for testing

Assuming that the HPFRC provides a shear resistance convenience. The coupling beams were loaded to induce

of 5fc psi (0.42fc MPa), based on previous work,5 double curvature. For this purpose, lateral displacements

transverse reinforcement was designed to resist the were applied to the top block, which was prevented from

remaining shear demand. Because large inelastic rotations rotating by two steel links. These links also provided

were expected at the beam ends, it was decided to provide some axial restraint to the coupling beams to simulate

column-type confinement over a distance of half the the restraint provided by structural walls in an actual

beam depth from the wall faces; this reinforcement was coupled wall system. The specimens were subjected to

greater than that required for shear strength purposes. lateral drift cycles of increasing magnitude until the

The transverse reinforcement outside of the plastic hinge beams exhibited substantial strength degradation.

region consisted of two-legged single stirrups.

We envisioned the use of a precast coupling beam Materials

design. This would allow the use of regular concrete in Based on previous research,5 concrete reinforced

the structural walls and speed up the construction of the with a 1.5% volume fraction of high-strength hooked-

coupled wall system. Interference with wall reinforcement steel fibers was selected for use in the coupling beams.

was prevented by extending the precast portion of the Concrete proportions by weight were as follows: 1.2

beam only into the wall cover. Moment transfer at the (Type III cement): 0.3 (fly ash): 0.6 (water): 1.7 (sand):

connection between the precast coupling beam and the 1.0 (coarse aggregate): 0.01 (high-range water-reducing

cast-in-place walls was to be achieved by extending the admixture): 0.0095 (viscosity-modifying admixture). Coarse

flexural reinforcement a full development length beyond aggregate consisted of crushed limestone with a maximum

size of 1/2 in. (13 mm). Commercially

available hooked-steel fibers were

Table 1: used. These fibers were 1.2 in. (30 mm)

Compressive and flexural strength of fiber-reinforced concrete long and 0.015 in. (0.38 mm) in

diameter, made of a wire with a

Specimen specified tensile strength of 330 ksi

number fc, fp1,* f150, 0.75,* f150, 3.0,* (2300 MPa). The concrete mixture

(aspect ratio) ksi (MPa) psi (MPa) psi (MPa) psi (MPa) was designed such that a highly

1 (3.3) 9.9 (68) 1000 (6.9) 1080 (7.4) 650 (4.5) workable composite with a

compressive strength of about

2 (2.75) 9.8 (68) 1030 (7.1) 1280 (8.8) 980 (6.8) 10,000 psi (70 MPa) would be obtained.

*

Obtained using a four-point bending test per ASTM 1609-06; f p1 is first peak flexural Results from 4 x 8 in. (100 x 200 mm)

strength; f150, 0.75 is equivalent flexural strength at 0.03 in. (0.75 mm) deflection; f 150, 3.0 is cylinder tests, as well as from ASTM

equivalent flexural strength at 0.12 in. (3.0 mm) deflection. 1609-06 four-point bending tests on

beams with a 6 in. (150 mm) square

Table 2: cross section and 18 in. (450 mm)

span, are shown in Table 1.

Properties of reinforcing bars All reinforcing bars were Grade 60

Specimen number Bar size, Yield strength fy, Tensile strength fu, (420) steel. The yield and ultimate

(aspect ratio) No. ksi (MPa) ksi (MPa) strengths for the various reinforcing

bars are shown in Table 2.

1 6 (19) 79 (544) 100 (689)

(3.3) 4 (13) 77 (531) 96 (661) Behavior of HPFRC

Coupling Beams with-

6 (19) 76 (524) 94 (648) out Diagonal Bars

2 Figure 4 shows the average shear

5 (16) 64 (441) 97 (668)

(2.75) stress versus drift response for the

4 (13) 85 (586) 101 (696) two test coupling beams. Drift is

38 december 2010 / Concrete international

Reaction wall 10 0.8

Coupling beam

Actuator

fc' MP a

fc' ps i

5 0.4

Average shear stress,

Average shear stress,

0 0

Link for restricting

end rotation

Load cell

-5 -0.4

Strong floor

(a)

Fig. 3: Schematic of test setup. Each precast HPFRC coupling -10 -0.8

beam was anchored to two stiff concrete blocks. The links -10 -8 -6 -4 -2 0 2 4 6 8 10

maintained the two blocks parallel during loading and simulated (a) Drift, %

the axial restraint provided by coupled walls in an actual system

10 0.8

defined as the applied lateral displacement divided by

the clear beam span. As shown in Fig. 4, both specimens

fc' MP a

fc' ps i

exhibited large drift capacities: Specimen 1 failed during 5 0.4

the cycle at 9% drift and Specimen 2 failed during the cycle

at 8% drift. The behavior of both specimens was governed

Average shear stress,

Average shear stress,

by flexural hinging at both ends with negligible shear-related 0

0

damage, even though the peak shear stress was close to

10fc psi (0.83fc MPa). (b)

As expected, the more slender coupling beam -0.4

-5

(Specimen 1) exhibited slightly wider hysteresis loops,

indicating higher energy dissipation compared with

Specimen 2. The achieved drift capacities under such high -0.8

-10

shear stress demand are a clear indication of the adequacy -10 -8 -6 -4 -2 0 2 4 6 8 10

of the proposed design for use in regions of high seismicity.

(b) Drift, %

In terms of damage tolerance, only minor damage was

observed up to approximately 5% drift because of the Fig. 4: Shear stress versus drift response for coupling beam

tension and compression ductility exhibited by the specimens: (a) Specimen 1 (aspect ratio = 3.3); and (b) Specimen 2

(aspect ratio = 2.75)

HPFRC material (Fig. 5). This indicates that HPFRC

coupling beams are substantially less likely to require

repairs than regular concrete coupling beams after a

major earthquake. Ultimately, failure occurred due to

concrete crushing at the beam ends.

Conclusions

The experimental results support the potential use of

strain-hardening HPFRC as a means to substantially

simplify the reinforcement detailing in coupling beams

with aspect ratios on the order of 3. In particular, the test

results clearly indicate that a complete elimination of

diagonal reinforcement is possible while achieving drift

capacities as large as 8% under shear stresses close to

the upper limit allowed in ACI 318-08. Furthermore, the

results show that column-type confinement reinforcement

is required only at the beam endsthe remainder of

the beam can be reinforced with regular stirrup

reinforcement. The HPFRC provided excellent damage Fig. 5: Specimen 1 at 5% drift

Concrete international / december 2010 39

tolerance with only minor damage observed at drifts as 4. Canbolat, B.A.; Parra-Montesinos, G.; and Wight, J.K.,

large as 5%. The proposed coupling beam design applies Experimental Study on Seismic Behavior of High-Performance Fiber-

to both precast and cast-in-place construction, which Reinforced Cement Composite Coupling Beams, ACI Structural

provides greater flexibility for contractors. Journal, V. 102, No. 1, Jan.-Feb. 2005, pp. 159-166.

5. Lequesne, R.; Parra-Montesinos, G.; and Wight, J.K., Test of a

Acknowledgments Coupled Wall with High-Performance Fiber-Reinforced Concrete

The two coupling beam tests were unfunded. The support of the Coupling Beams, Thomas T.C. Hsu Symposium: Shear and Torsion in

National Science Foundation, under Grants CMS 0001617 and CMMI Concrete Structures, SP-265CD, American Concrete Institute, Farmington

0530383, and the Bekaert Corporation for previous research on Hills, MI, 2009, 18 pp.

HPFRC coupling beams, however, is greatly appreciated.

Note: Additional information on the ASTM standard discussed in

References this article can be found at www.astm.org.

1. Paulay, T., and Binney, J.R., Diagonally Reinforced Coupling

Beams of Shear Walls, Shear in Reinforced Concrete, SP-42, V. 2, Selected for reader interest by the editors.

American Concrete Institute, Farmington Hills, MI, 1974, pp. 579-598.

2. ACI Committee 318, Building Code Requirements for Structural

Concrete (ACI 318-08) and Commentary, American Concrete

Institute, Farmington Hills, MI, 2008, 473 pp.

3. Naish, D.; Wallace, J.W.; Fry, J.A.; and Klemencic, R., Reinforced

Concrete Link Beams: Alternative Details for Improved Construction,

ACI member Gustavo J. Parra-Montesinos is

UCLA-SGEL Report 2009-06, Structural & Geotechnical Engineering

an Associate Professor of civil engineering at

Laboratory, University of California at Los Angeles, Los Angeles, LA,

the University of Michigan, Ann Arbor.

2009, 103 pp.

He is Chair of ACI Committee 335, Composite

and Hybrid Structures; and a member of

ACI Committee 318, Structural Concrete

Building Code; and Joint ACI-ASCE Committee

352, Joints and Connections in Monolithic

Concrete Structures. His research interests

include the behavior and design of reinforced concrete, fiber-

reinforced concrete, and hybrid steel-concrete structures.

James K. Wight, FACI, is a Professor of civil

engineering at the University of Michigan,

Ann Arbor. He is an ACI Vice President, a

member and Past Chair of ACI Committee

Want to connect with thousands 318, Structural Concrete Building Code, and

a member of ACI Subcommittee 318-E,

of other ACI Members? Shear and Torsion; and Joint ACI-ASCE

Committees 352, Joints and Connections in

Join one or both of the ACI Facebook or Monolithic Concrete Structures; and 445,

LinkedIn groups today and start networking Shear and Torsion. His research interests include the earthquake-

with thousands of other concrete professionals, resistant design of reinforced-concrete structures and the use of

receive special ACI announcements, and high-performance fiber-reinforced concrete in critical members or

participate in technical discussions. regions of such structures.

To join, simply visit ACIs Web site at ACI member Monthian Setkit is a PhD

www.concrete.org, and click on the Student at the University of Michigan, Ann

Facebook and LinkedIn links. Arbor. His research interests include the

behavior and design of reinforced concrete

and fiber-reinforced concrete structures.

40 december 2010 / Concrete international

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- RC Rectangular Column DesignDocument6 pagesRC Rectangular Column DesignuqiNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- AsDocument1 pageAsuqiNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Building Has Two Main ComponentsDocument6 pagesThe Building Has Two Main ComponentsuqiNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Construction Management (CM) & Quantity Surveyor (QS)Document1 pageConstruction Management (CM) & Quantity Surveyor (QS)uqiNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Test PageDocument1 pageTest PageTien Thanh DangNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Data TulanganDocument4 pagesData TulanganuqiNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Layer Name Items Di Dalam: Grid Block GridDocument3 pagesLayer Name Items Di Dalam: Grid Block GriduqiNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- NSPTDocument4 pagesNSPTuqiNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Csi Sap2000 v19Document2 pagesCsi Sap2000 v19uqiNo ratings yet

- Waffle Slab2Document19 pagesWaffle Slab2my09No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Img 0020 PDFDocument1 pageImg 0020 PDFuqiNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- ToefelDocument1 pageToefeluqiNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Data Spektra Desain NiccoloDocument2 pagesData Spektra Desain NiccolouqiNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Ample Letter Receptionist Job ApplicationDocument2 pagesAmple Letter Receptionist Job ApplicationuqiNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Img 0020Document1 pageImg 0020uqiNo ratings yet

- Two Options Are Available For Wind AutoDocument7 pagesTwo Options Are Available For Wind AutouqiNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Third Party Legal NoticesDocument1 pageThird Party Legal NoticesvincexianNo ratings yet

- Manual Book Irtdc 2017Document22 pagesManual Book Irtdc 2017uqiNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Two Options Are Available For Wind AutoDocument7 pagesTwo Options Are Available For Wind AutouqiNo ratings yet

- Brosur Waroeng TaugeDocument1 pageBrosur Waroeng TaugeuqiNo ratings yet

- TR189 Kathuria PDFDocument168 pagesTR189 Kathuria PDFuqiNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- XTRACT PreProcess TutorialDocument2 pagesXTRACT PreProcess TutorialuqiNo ratings yet

- Brosur Waroeng TaugeDocument1 pageBrosur Waroeng TaugeuqiNo ratings yet

- Cross-Sectional Properties of Complex Composite Beams: Airil Y. Mohd Yassin, David A. NethercotDocument18 pagesCross-Sectional Properties of Complex Composite Beams: Airil Y. Mohd Yassin, David A. NethercotuqiNo ratings yet

- EN1998 3 Plumier PDFDocument57 pagesEN1998 3 Plumier PDFDana AndonieNo ratings yet

- Sorry, 132399620-5305-Ghoshsupplement3.Pdf Has Already Been Uploaded. Please Upload A New DocumentDocument1 pageSorry, 132399620-5305-Ghoshsupplement3.Pdf Has Already Been Uploaded. Please Upload A New DocumentuqiNo ratings yet

- 5305 GhoshSupplement3Document16 pages5305 GhoshSupplement3Anonymous q0irDXlWAmNo ratings yet

- LAB 10: Support Reactions For A Point-Loaded, Simply Supported BeamDocument8 pagesLAB 10: Support Reactions For A Point-Loaded, Simply Supported BeamDrizzling ADNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- 7.0 Analysis 3: Case Study Concrete Over Pour On Decks Due To Steel Deflection (Structural Breath)Document12 pages7.0 Analysis 3: Case Study Concrete Over Pour On Decks Due To Steel Deflection (Structural Breath)Kiara Ticangan ArgelNo ratings yet

- 8-9. WarpingDocument41 pages8-9. WarpingMd. Towfiq ImrozNo ratings yet

- Chapter Nineteen Base Plate: 19.1 Base Plates For Axially Loaded ColumnsDocument84 pagesChapter Nineteen Base Plate: 19.1 Base Plates For Axially Loaded ColumnsCarl LacanilaoNo ratings yet

- Deep Beam STMDocument98 pagesDeep Beam STMManjula Unnikrishnan N K100% (3)

- Dynamic Analysis of Beams On An Elastic Foundation Subjected To Moving LoadsDocument21 pagesDynamic Analysis of Beams On An Elastic Foundation Subjected To Moving LoadsEugene CommerellNo ratings yet

- Behavior of Cellular Beams With Sinusoidal Openings: S. Durif and A. BouchaïrDocument6 pagesBehavior of Cellular Beams With Sinusoidal Openings: S. Durif and A. BouchaïralbertoxinaNo ratings yet

- Static Analysis of Tall Buildings BasedDocument7 pagesStatic Analysis of Tall Buildings BasedEric S Y KwokNo ratings yet

- Ram Structural SystemDocument234 pagesRam Structural Systemlavy100% (1)

- Structural AnalysisDocument443 pagesStructural AnalysisShuja MehdiNo ratings yet

- Engg (1) .Mechanics Study MatlDocument39 pagesEngg (1) .Mechanics Study Matlmaddy_scribdNo ratings yet

- Computational Exercise 3 BANTAYANDocument78 pagesComputational Exercise 3 BANTAYANAriel LunaNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Idirs BAY-2 PDFDocument50 pagesIdirs BAY-2 PDFBurkan LamaNo ratings yet

- Saudi Aramco Inspection Checklist: Cast-In-Place Concrete Formwork Stripping Inspection SAIC Q-1016 15-Nov-17 MAH-SA-CDocument3 pagesSaudi Aramco Inspection Checklist: Cast-In-Place Concrete Formwork Stripping Inspection SAIC Q-1016 15-Nov-17 MAH-SA-CAbdul HannanNo ratings yet

- Designers Guide To EN1992-2 Eurocode 2Document23 pagesDesigners Guide To EN1992-2 Eurocode 2Cheolung Yoon33% (3)

- Thumb RuleDocument6 pagesThumb RuleVivek ShuklaNo ratings yet

- Design of High-Rise Buildings - Past Present and FutureDocument7 pagesDesign of High-Rise Buildings - Past Present and FutureRoyce MarchaNo ratings yet

- 250 KL ELSR - 25 M StagingDocument125 pages250 KL ELSR - 25 M StagingJAKIR SHAIKNo ratings yet

- P2 Reaction PileDocument1 pageP2 Reaction Pilebejay bermudezNo ratings yet

- Irc JournalDocument72 pagesIrc JournalAbhinav RamprasadNo ratings yet

- FYP Civil Residential BuildingDocument56 pagesFYP Civil Residential BuildingCivilmaze100% (1)

- Simplification of A Force and Couple System: ContinuedDocument19 pagesSimplification of A Force and Couple System: ContinuedTasnim AhmedNo ratings yet

- KSOU Distance M Tech Civil Engineering Sem I SyllabusDocument7 pagesKSOU Distance M Tech Civil Engineering Sem I SyllabusSunil JhaNo ratings yet

- Composite Floors - 1: ©teaching Resource in Design of Steel Structures IIT Madras, SERC Madras, Anna Univ., INSDAGDocument36 pagesComposite Floors - 1: ©teaching Resource in Design of Steel Structures IIT Madras, SERC Madras, Anna Univ., INSDAGCharles AjayiNo ratings yet

- Burj Dubai ReportDocument33 pagesBurj Dubai ReportAhmed Essam67% (3)

- Ib 39Document19 pagesIb 39Rup JoshiNo ratings yet

- Steel Bridges by Metwally Abu-HamdDocument328 pagesSteel Bridges by Metwally Abu-Hamdmabuhamd100% (5)

- Stresses in Beam With ExamplesDocument13 pagesStresses in Beam With ExamplesAnisyahira khalidNo ratings yet

- Buet Question of 2015-2016 (L-2 T-1) - CeDocument18 pagesBuet Question of 2015-2016 (L-2 T-1) - CePicasso Debnath0% (1)

- 63309Document13 pages63309amdevaNo ratings yet

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (138)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNo ratings yet

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsFrom EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNo ratings yet

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetFrom EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetRating: 4.5 out of 5 stars4.5/5 (10)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansRating: 4.5 out of 5 stars4.5/5 (21)

- Geotechnical Engineering Calculations and Rules of ThumbFrom EverandGeotechnical Engineering Calculations and Rules of ThumbRating: 4 out of 5 stars4/5 (17)