Professional Documents

Culture Documents

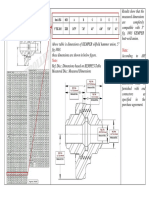

Hytorc Bolt Loads Ref Chart

Uploaded by

TulioLopezJ0 ratings0% found this document useful (0 votes)

1K views1 pageHytorc-BOLT-LOADS-Ref-Chart.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHytorc-BOLT-LOADS-Ref-Chart.pdf

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

1K views1 pageHytorc Bolt Loads Ref Chart

Uploaded by

TulioLopezJHytorc-BOLT-LOADS-Ref-Chart.pdf

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

THESE VALUES ARE ONLY A GUIDE AND MUST NOT BE RELIED UPON IN PLACE OF LOCAL ENGINEERING DATA

TORQUE GUIDE FOR ASTM A193 GRADE B7 AND B16 BOLTS (105,000 P.S.I. MIN. YIELD STRESS)

BOLT TENSION BASED ON 50 PERCENT YIELD

B7 REQUIRED TORQUE (FtLbs)

BOLT HEX STRESS MIN BOLT TS801MOLY MOLYBDE MOLY/LEAD COPPER NICKEL API MACHI DRY CUSTOM

SIZE NUT AREA YIELD TENSION DRY FILM NUM OXIDE/GRA GRAPH. GRAPH. SA2 NE STEEL PLUG IN

DIA. x ACROSS (IN2) STRESS (LBS) SPRAY DISULFIDE PHITE OIL K VALUE

TPI FLATS (PSI) K=.109 K=.100 K=.125 K=.140 K=.150 K=.157 K=.200 K=.300

0.109

3/4 x 10 1-1/4" 0.334 105,000 17,550 120 110 137 154 165 172 219 329 120

7/8 x 9 1-7/16" 0.461 105,000 24,229 193 177 221 247 265 277 353 530 193

1x 8 1-5/8" 0.605 105,000 31,785 289 265 331 371 397 416 530 795 289

1-1/8 x 8 1-13/16" 0.790 105,000 41,478 424 389 486 544 583 611 778 1,167 424

1-1/4 x 8 2" 0.999 105,000 52,458 596 546 683 765 820 858 1,093 1,639 596

1-3/8 x 8 2-3/16" 1.233 105,000 64,726 808 742 927 1,038 1,112 1,164 1,483 2,225 808

1-1/2 x 8 2-3/8" 1.491 105,000 78,282 1,067 979 1,223 1,370 1,468 1,536 1,957 2,936 1,067

1-5/8 x 8 2-9/16" 1.774 105,000 93,126 1,375 1,261 1,576 1,766 1,892 1,980 2,522 3,783 1,375

1-3/4 x 8 2-3/4" 2.081 105,000 109,257 1,737 1,593 1,992 2,231 2,390 2,502 3,187 4,780 1,737

1-7/8 x 8 2-15/16" 2.413 105,000 126,677 2,157 1,979 2,474 2,771 2,969 3,108 3,959 5,938 2,157

2x8 3-1/8" 2.769 105,000 145,385 2,641 2,423 3,029 3,392 3,635 3,804 4,846 7,269 2,641

2-1/8 x 8 3-5/16" 3.150 105,000 165,380 3,192 2,929 3,661 4,100 4,393 4,598 5,857 8,786 3,192

2-1/4 x 8 3-1/2" 3.555 105,000 186,663 3,815 3,500 4,375 4,900 5,250 5,495 7,000 10,500 3,815

2-3/8 x 8 3-11/16" 3.985 105,000 209,234 4,514 4,141 5,176 5,798 6,212 6,502 8,282 12,423 4,514

2-1/2 x 8 3-7/8" 4.440 105,000 233,094 5,293 4,856 6,070 6,799 7,284 7,624 9,712 14,568 5,293

2-3/4 x 8 4-1/4" 5.422 95,000 257,563 6,434 5,902 7,378 8,263 8,854 9,267 11,805 17,707 6,434

3x8 4-5/8" 6.503 95,000 308,894 8,417 7,722 9,653 10,811 11,584 12,124 15,445 23,167 8,417

3-1/4 x 8 5" 7.682 95,000 364,885 10,772 9,882 12,353 13,835 14,823 15,515 19,765 29,647 10,772

3-1/2 x 8 5-3/8" 8.959 95,000 425,537 13,529 12,411 15,514 17,376 18,617 19,486 24,823 37,234 13,529

3-3/4 x 8 5-3/4" 10.334 95,000 490,850 16,720 15,339 19,174 21,475 23,009 24,082 30,678 46,017 16,720

4x8 6-1/8" 11.807 95,000 560,824 20,377 18,694 23,368 26,172 28,041 29,350 37,388 56,082 20,377

4-1/4 x 8 6-1/2" 13.378 75,000 501,678 19,367 17,768 22,210 24,875 26,652 27,895 35,536 53,303 19,367

4-1/2 x 8 6-7/8" 15.047 75,000 564,280 23,065 21,160 26,451 29,625 31,741 33,222 42,321 63,481 23,065

4-3/4 x 8 7-1/4" 16.815 75,000 630,562 27,206 24,960 31,200 34,944 37,440 39,187 49,919 74,879 27,206

5x8 7-5/8" 18.681 75,000 700,523 31,815 29,188 36,486 40,864 43,783 45,826 58,377 87,565 31,815

5-1/4 x 8 8" 20.644 75,000 774,164 36,918 33,870 42,337 47,418 50,805 53,175 67,739 101,609 36,918

5-1/2 x 8 8-3/8" 22.706 75,000 851,485 42,539 39,026 48,783 54,637 58,540 61,271 78,053 117,079 42,539

5-3/4 x 8 8-3/4" 24.866 75,000 932,485 48,703 44,682 55,852 62,554 67,022 70,150 89,363 134,045 48,703

6x8 9-1/8" 27.124 75,000 1,017,165 55,436 50,858 63,573 71,202 76,287 79,847 101,717 152,575 55,436

REV 04.20.05

To use spread sheet click desired tab for B7 or B16 material

Enter the desired percent yield in yellow field at top of form

If 'K' factor is not listed then enter appropriate value under Custom (insert K) , in yellow field only

as always- after entering any value, click outside the field or hit enter to update calculations.

Reduction in minimum yield stress above 2-1/2" diameter is due to stud not hardening uniformly all the way to the center.

You might also like

- Bolt Load-Torque ChartDocument6 pagesBolt Load-Torque ChartIgor ScudellerNo ratings yet

- Astm A193 B7Document2 pagesAstm A193 B7groshan20No ratings yet

- Pipe Flange Torque Summary (Modified by Joan Franco)Document21 pagesPipe Flange Torque Summary (Modified by Joan Franco)Wilmer FigueraNo ratings yet

- Circulating SwagesDocument1 pageCirculating Swageskaveh-bahiraeeNo ratings yet

- Doc-Ser-012 Api 16a 3RD OverviewDocument24 pagesDoc-Ser-012 Api 16a 3RD OverviewDanilo FornaroNo ratings yet

- Triplex Pump Maintenance ManualDocument16 pagesTriplex Pump Maintenance ManualFernandoNo ratings yet

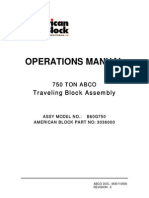

- American Traveling Block PDFDocument1 pageAmerican Traveling Block PDFAnonymous 48jYxR1C100% (2)

- AISI 4130: Incoloy Alloys, Fast QuoteDocument5 pagesAISI 4130: Incoloy Alloys, Fast QuoteSantanu SahaNo ratings yet

- API Flange Slide RuleDocument3 pagesAPI Flange Slide Rulehai minhNo ratings yet

- Type - DH Block: Dimensional ChartDocument1 pageType - DH Block: Dimensional ChartHarzanyi MaldonadoNo ratings yet

- Bolt CapacityDocument2 pagesBolt CapacityMoonzeNo ratings yet

- Catalog - BVMDocument28 pagesCatalog - BVMAlexsandro CordeiroNo ratings yet

- DC Make-Up TorqueDocument5 pagesDC Make-Up TorquepatelsujanNo ratings yet

- Data Sheet of Double Studded Adapter FlangeDocument3 pagesData Sheet of Double Studded Adapter FlangeAGSMotoVlog 06100% (1)

- Mud Pump NOV 8-P80Document1 pageMud Pump NOV 8-P80jonhyto14100% (1)

- Metric Dimensions and Weights of Seamless and Welded Steel Pipe PDFDocument1 pageMetric Dimensions and Weights of Seamless and Welded Steel Pipe PDFAnonymous xcFcOgMiNo ratings yet

- ABS Fire and Safety Features For MODU - Part5Document40 pagesABS Fire and Safety Features For MODU - Part5Eyoma Etim100% (1)

- Api Tubing Casing Id CalculatorDocument45 pagesApi Tubing Casing Id CalculatorRyan LlanetaNo ratings yet

- Access - Air Kelly Spinner Manual PDFDocument9 pagesAccess - Air Kelly Spinner Manual PDFadjoudj100% (1)

- ANSI Flange Bolt & Stud ChartDocument2 pagesANSI Flange Bolt & Stud Chartkh88hmiNo ratings yet

- NPT Thread Dimensions PDFDocument1 pageNPT Thread Dimensions PDFRamnandan MahtoNo ratings yet

- Bolt Shear Strength - MetricDocument1 pageBolt Shear Strength - MetricK.S.MAYILVAGHANANNo ratings yet

- API Drill Pipe Specs-1Document26 pagesAPI Drill Pipe Specs-1SACHIN H. DHAMAPURKARNo ratings yet

- API Revisi Bevel May 2011 Spec 7-2 and Ds-1Document120 pagesAPI Revisi Bevel May 2011 Spec 7-2 and Ds-1Nicolas Roldan100% (1)

- 3 - Casing SlipsDocument2 pages3 - Casing SlipsleoNo ratings yet

- NS Connection For CasingDocument2 pagesNS Connection For Casingrageshmv0% (1)

- Understanding Api 4f StructuresDocument16 pagesUnderstanding Api 4f StructuresGordan KanižajNo ratings yet

- 8-P-80 Mud Pump BrochureDocument2 pages8-P-80 Mud Pump Brochuredavorp1402No ratings yet

- Cameron - DL-Annular BopDocument1 pageCameron - DL-Annular BopAnonymous 48jYxR1C100% (1)

- Flange Weight ChartDocument4 pagesFlange Weight ChartDayo IdowuNo ratings yet

- Pad Eyes PDFDocument1 pagePad Eyes PDFPierluigiBusettoNo ratings yet

- P QUIP Swab and Pony RodDocument5 pagesP QUIP Swab and Pony Rodkrishnsgk0% (1)

- BOP BoltsDocument5 pagesBOP BoltsHadirah DunglahNo ratings yet

- 1 Manual PDFDocument27 pages1 Manual PDFMehdi SoltaniNo ratings yet

- M3036 Block 5861Document21 pagesM3036 Block 5861Gregory StewartNo ratings yet

- TESCO Casing Drive SystemDocument22 pagesTESCO Casing Drive SystemJohnSmith50% (2)

- Iso 11961 Specificacion de Drill Pipe PDFDocument31 pagesIso 11961 Specificacion de Drill Pipe PDFKary SastréNo ratings yet

- Wind Load Calc API 4FDocument4 pagesWind Load Calc API 4FsridharNo ratings yet

- As 3791-1991 Hydraulic HoseDocument7 pagesAs 3791-1991 Hydraulic HoseSAI Global - APAC0% (1)

- Hammer UnionDocument1 pageHammer Unionmahsa100% (1)

- Torque-Tension Relationship For ASTM A193 B7 Bolts and StudsDocument1 pageTorque-Tension Relationship For ASTM A193 B7 Bolts and StudsSiva Krishna ChaudharyNo ratings yet

- Laurus As Built BOP Part Numbers - UnlockedDocument166 pagesLaurus As Built BOP Part Numbers - UnlockedEstuardo OlanNo ratings yet

- Rig Components - Definitions: 1. Gin PoleDocument70 pagesRig Components - Definitions: 1. Gin PoleHarpreetk87No ratings yet

- Drawing Package Crown Block: CB-375-7-50-1 3/8 Serial Number:0058Document5 pagesDrawing Package Crown Block: CB-375-7-50-1 3/8 Serial Number:0058Noureddine AdjNo ratings yet

- Quick Union Identification ChartDocument1 pageQuick Union Identification ChartRefisal BonnetNo ratings yet

- Demco Gate ValveDocument52 pagesDemco Gate Valver_ergin100% (1)

- 8531 S. Freeway Drive - Macedonia, Ohio 44056 (800) 232 - 2659 - Fax: (330) 468-3302Document1 page8531 S. Freeway Drive - Macedonia, Ohio 44056 (800) 232 - 2659 - Fax: (330) 468-3302bcanilkumar007No ratings yet

- LVL & PSL Beam Shear, Flexure and Moment of Inertia TableDocument1 pageLVL & PSL Beam Shear, Flexure and Moment of Inertia Tableodiseo_basquasaNo ratings yet

- FASTORQ-Torque-Estimating-Chart - Barra RoscadaDocument1 pageFASTORQ-Torque-Estimating-Chart - Barra RoscadaLucas RezendeNo ratings yet

- Heavy Hex Nuts Dimensions, Weight Imperial Metric SizesDocument5 pagesHeavy Hex Nuts Dimensions, Weight Imperial Metric SizesEnyNo ratings yet

- LVL & PSL Cap TableDocument1 pageLVL & PSL Cap Tableodiseo_basquasaNo ratings yet

- Area Dimensions, In. Weight Per Foot, LB DC Resistance at 20° C, Microhms Per FT Circular Mils, ThousandsDocument4 pagesArea Dimensions, In. Weight Per Foot, LB DC Resistance at 20° C, Microhms Per FT Circular Mils, Thousandsrafabustamante7651No ratings yet

- WashPipe Data SheetDocument1 pageWashPipe Data SheetAman Aayra Srivastava100% (4)

- Whitworth BSW BSF PDFDocument2 pagesWhitworth BSW BSF PDFsrinuNo ratings yet

- Whitworth BSW BSFDocument2 pagesWhitworth BSW BSFGourav SharmaNo ratings yet

- Whitworth BSW BSF PDFDocument2 pagesWhitworth BSW BSF PDFLaural MarshallNo ratings yet

- Ampacities and Mechanical Properties of Rectangular Copper Busbars: Table 1. Ampacities of Copper No. 110Document4 pagesAmpacities and Mechanical Properties of Rectangular Copper Busbars: Table 1. Ampacities of Copper No. 110Kiran KarthikNo ratings yet

- BWG and SWG Dimensions and Weights PDFDocument1 pageBWG and SWG Dimensions and Weights PDFNicolaSaviliNo ratings yet

- Crosby Shackles Price List - Project Sales Corp - June 19, 2010Document1 pageCrosby Shackles Price List - Project Sales Corp - June 19, 2010Project Sales CorpNo ratings yet

- MT FF Operating Parts PDFDocument6 pagesMT FF Operating Parts PDFTulioLopezJNo ratings yet

- SP STP Fault TreeDocument14 pagesSP STP Fault TreeTulioLopezJNo ratings yet

- SDB 206 2 Small Diameter Beveler DatasheetDocument2 pagesSDB 206 2 Small Diameter Beveler DatasheetTulioLopezJNo ratings yet

- Heavy Duty Split Frame Single Point Cantilevered Tool Slide: User's ManualDocument36 pagesHeavy Duty Split Frame Single Point Cantilevered Tool Slide: User's ManualTulioLopezJNo ratings yet

- 212spflyer PDFDocument2 pages212spflyer PDFTulioLopezJNo ratings yet

- Heavy Duty Split Frame Single Point Cantilevered Tool Slide: User's ManualDocument36 pagesHeavy Duty Split Frame Single Point Cantilevered Tool Slide: User's ManualTulioLopezJNo ratings yet

- HCM-3E4 Hydraulic Power Unit Owner ManualDocument20 pagesHCM-3E4 Hydraulic Power Unit Owner ManualTulioLopezJ100% (1)

- Bearing Self Study PDFDocument73 pagesBearing Self Study PDFcakendriNo ratings yet

- Tabla Conversion ShimDocument1 pageTabla Conversion ShimTulioLopezJNo ratings yet

- 140109-Rt Ccee Leaflet FilmstripDocument4 pages140109-Rt Ccee Leaflet FilmstripTulioLopezJNo ratings yet

- Assembly of Screwed Fastenings: Preloads and Tightening Torque For Fasteners From SteelDocument1 pageAssembly of Screwed Fastenings: Preloads and Tightening Torque For Fasteners From SteelDani Quirante Flaaut EtcNo ratings yet

- hf10b EngDocument6 pageshf10b EngTulioLopezJNo ratings yet

- Wrench CmhartsDocument1 pageWrench Cmhartsmsaqibraza93No ratings yet

- Flange Torque Recommendations GF PDFDocument2 pagesFlange Torque Recommendations GF PDFTulioLopezJNo ratings yet

- Hex Nut Bolt Sizes E411 GBDocument1 pageHex Nut Bolt Sizes E411 GBShahen ShahNo ratings yet

- FASTORQ Standard Stud Heavy Hex Nut SpecsDocument1 pageFASTORQ Standard Stud Heavy Hex Nut SpecsTulioLopezJNo ratings yet

- Torque Values (FT/LBS.) 100% of Yield: Bolt Diam Nut Size Moly Lube Nickel Lube Copper Lube OIL DRYDocument6 pagesTorque Values (FT/LBS.) 100% of Yield: Bolt Diam Nut Size Moly Lube Nickel Lube Copper Lube OIL DRYTulioLopezJNo ratings yet

- Bolt Depot - US To Metric Conversion TableDocument2 pagesBolt Depot - US To Metric Conversion TableTulioLopezJNo ratings yet

- Bolt and Nut Standard Size CatalogDocument154 pagesBolt and Nut Standard Size Catalogiskandarmeran100% (1)

- RT03 Torque ChartDocument2 pagesRT03 Torque ChartTulioLopezJNo ratings yet

- Iso 2768-1: 1989Document7 pagesIso 2768-1: 1989jferreiraNo ratings yet

- Wrench CmhartsDocument1 pageWrench Cmhartsmsaqibraza93No ratings yet

- FLIP p5Document1 pageFLIP p5TulioLopezJNo ratings yet

- 212b Flange Facer Doc 92-0291 Rev 921230Document22 pages212b Flange Facer Doc 92-0291 Rev 921230TulioLopezJNo ratings yet

- 212b Elbow Mandrel Doc 92-0262 Rev 970321Document16 pages212b Elbow Mandrel Doc 92-0262 Rev 970321TulioLopezJNo ratings yet

- RT03 Torque ChartDocument2 pagesRT03 Torque ChartTulioLopezJNo ratings yet

- RT03 Torque ChartDocument2 pagesRT03 Torque ChartTulioLopezJNo ratings yet

- 212b FF Tech SpecDocument3 pages212b FF Tech SpecTulioLopezJNo ratings yet

- 212 SP FlyerDocument2 pages212 SP FlyerTulioLopezJNo ratings yet

- Minutes of Meeting SMPV GCR Review With AnnexDocument22 pagesMinutes of Meeting SMPV GCR Review With AnnexNishant ThakurNo ratings yet

- SWM-A Policy AgendaDocument8 pagesSWM-A Policy AgendaKamran 123No ratings yet

- Building RepairsDocument8 pagesBuilding RepairsRenuka ChalikwarNo ratings yet

- Towards 4.0: The Smelter of The FutureDocument4 pagesTowards 4.0: The Smelter of The FutureShyamal VermaNo ratings yet

- BPVC Ix qw-483 PDFDocument2 pagesBPVC Ix qw-483 PDFazizNo ratings yet

- Design of Aluminum Structure 1Document3 pagesDesign of Aluminum Structure 1Ray Coello100% (2)

- 1:24 Scale Residential Architectural Modeling: What You NeedDocument10 pages1:24 Scale Residential Architectural Modeling: What You NeedNerinel Coronado100% (1)

- Preparation of Methylene Chloride (Greene 1879)Document2 pagesPreparation of Methylene Chloride (Greene 1879)j9cr4zrdxxNo ratings yet

- Aluminum Design Manual-24Document1 pageAluminum Design Manual-24Mohammed AyeshNo ratings yet

- WELD-2008v05 Down To The WireDocument2 pagesWELD-2008v05 Down To The WirepeterNo ratings yet

- Electrical Tools and MaterialsDocument36 pagesElectrical Tools and MaterialsRonaldo Paloma100% (2)

- Material Safety Data Sheet: Global SolutionsDocument5 pagesMaterial Safety Data Sheet: Global Solutionsravikunwar14No ratings yet

- ASTM453Document1 pageASTM453EderNo ratings yet

- DLL - Science 5 - Q1 - W5Document9 pagesDLL - Science 5 - Q1 - W5HEVER TORRESNo ratings yet

- Industrial Brush GuideDocument20 pagesIndustrial Brush Guideiksan_santNo ratings yet

- Impact of Green Supply Chain Management Practices On Firms' Performance: An Empirical Study From The Perspective of PakistanDocument17 pagesImpact of Green Supply Chain Management Practices On Firms' Performance: An Empirical Study From The Perspective of PakistanMaia NovitasariNo ratings yet

- High Velocity Oil FlushDocument2 pagesHigh Velocity Oil FlushNatanael CarpelotiNo ratings yet

- Caracksil Acrylic PasteDocument3 pagesCaracksil Acrylic PasteHaradhon DattaNo ratings yet

- Psych Exercise02 SolutionsDocument9 pagesPsych Exercise02 Solutionsjasson ponce100% (3)

- Group 5 - Sec D - MA - Shun ElectronicsDocument7 pagesGroup 5 - Sec D - MA - Shun ElectronicsYATIN BAJAJNo ratings yet

- Noise and Vibration in PM Motors - Sources and RemediesDocument35 pagesNoise and Vibration in PM Motors - Sources and RemediesVirgilioNo ratings yet

- Fringe EffectsDocument3 pagesFringe EffectsVishnu Vardhan ReddyNo ratings yet

- Bosch Catalog - Edition 2014Document456 pagesBosch Catalog - Edition 2014longtrandang5867No ratings yet

- Low Pressure Steam Curing of Precast UnitsDocument4 pagesLow Pressure Steam Curing of Precast Unitsdash1991No ratings yet

- T Panel PamphletDocument2 pagesT Panel PamphletthermaltechnologiesNo ratings yet

- The Tubular Film Blowing ProcessDocument9 pagesThe Tubular Film Blowing ProcessAlmir MachadoNo ratings yet

- Basf Masterprotect 180 TdsDocument3 pagesBasf Masterprotect 180 TdsHoang An ViNo ratings yet

- Helix Installation Manual Rev 002Document112 pagesHelix Installation Manual Rev 002Edgar Mendoza100% (2)

- Operation & Maintenance of Plug Valves PDFDocument5 pagesOperation & Maintenance of Plug Valves PDFعزت عبد المنعمNo ratings yet

- EC2 DesignDocument62 pagesEC2 Designmihaitimofte100% (1)