Professional Documents

Culture Documents

Winery Winemaking Process

Uploaded by

Anonymous GEyA5Ir0 ratings0% found this document useful (0 votes)

38 views2 pagesWinery Winemaking Process

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentWinery Winemaking Process

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

38 views2 pagesWinery Winemaking Process

Uploaded by

Anonymous GEyA5IrWinery Winemaking Process

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

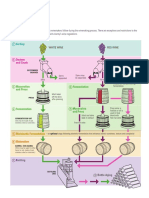

The following is a summary and an measured daily using a Hydrometer.

STEP 4 - PRESSING & SECONDARY

explanation of the wine making process. Residual sugar and alcohol levels are FERMENTATION

Feel free to ask questions along the way so related so the hydrometer helps After the fermentation we will

that you get the best experience possible. determine the progress of the remove the wine from the tub and we

fermentation process. will press the grape skin with the

IT'S ALL ABOUT THE GRAPE We aim for an alcohol level somewhere pressing machine. Thats another step

Shelter Rock Winery purchases the finest between 13% 14.5 % by volume which is that SRW MEMBERS SHOULD NOT

grapes from vineyards in California. There the expected result with the California MISS!

are different varieties of grapes which you grapes we use. The new wine is stored temporarily in

can choose to make the wine that suits your During this process the fermentation tubs stainless steel tanks and other tubs to

palate. Once we know the arrival date of are tightly covered creating an air-lock so allow the sediment to fall to the

the grapes, we contact SRW members to that the gases can escape but nothing can bottom. Thats the first racking. Then

designate the crush/destemming date and contaminate the must. the wine is transferred to barrels where

time. the malolactic fermentation occurs.

STEP 3 PUNCHING MLF is a process in winemaking in

STEP 1 - THE CRUSH During the fermentation process, the which tart-tasting malic acid, naturally

DESTEMMING & CRUSHING grape must will rise and it is very present in grape must, is converted to

Crush date and time, is usually in the first important to release the gases caused by softer-tasting lactic acid.

week of October. the fermentation process. This is called

SRW members will come together at the punching and is performed manually

winery and participate in loading the with a puncher tool. SRW MEMBERS

grapes into the Crusher/Destemmer SHOULD NOT MISS THIS STEP.

machine. The grapes goes through the At SRW we will punch the grape must

crusher/destemmer and fall into the twice per day (once in the morning and

fermentation tub below. The stems and once in the evening.) This process will

leaves are discarded into the waste bin. continue until the sugar level is -0.

STEP 2 PRIMARY FERMENTATION This is where we need the assistance of

The crushed grapes, now called a must are the SRW members. SRW will hold two

kept in the covered fermentation tubs in punching times per day. The first

the main area of SRW. punching will be from 7:30AM10:00AM

A day or so after the crushing, Wine Yeast and the second punching will be from

is added to the must that begins the 5:30PM7:30PM daily.

transformation of sugar to alcohol. As many SRW members as possible

Within 12 24 hours of adding the should plan to stop by SRW throughout

wine yeast, the fermentation activity begins. these two weeks to help in the punching

Throughout the next 2 weeks sugar levels are process. DO NOT MISS IT !

STEP 5 CLEARING & RACKING into the bottle. Then we move to the

After the fermentation has completely Vinyl Capsule & Labeling Stations.

stopped and we have verified this by Vinyl capsules are placed over your

using the hydrometer, we may add a corked bottles and carefully placed in the

small amount of Potassium Bisulfite to heat machine, which shrinks to fit

help preserve the wine flavor and color snuggly on the necks of the bottles. The

while its clearing. next step is to place your preprinted

Wine Label on your bottles. Your bottles

The wine yeast will be finishing up its are then placed into your box, sealed and

activity and the solids will be settling at are ready to take home to enjoy

the bottom. The clearing process can take throughout the year or to give as gifts for

several weeks and months. holidays and special events, or to share

Starting the 4th Monday of January we with your friends and family.

will hold the second racking, running

every day until we finish from 12:00PM Special Note: Since minimal sulfites are

Shelter Rock Winery

to 7:00PM. Be there! SRW members used in the wines we make at Shelter Experience the Wonderful

should assist in this process. Rock Winery, we highly recommend World of Winemaking

storing your personal vintage in an area

STEP 6 - BOTTLING YOUR WINE. that has a consistent temperature of The beginning of October you are going

In JUNE its time to bottle. 55 62 F. to participate in the rewarding

Prior to bottling the wine gets filtered experience of making your own wine!

and transferred to stainless steel tanks Rest assured we will be there every step

and some will be blended by request. Check out our website for special events of the way to guide and educate you in

Bottling starts the first weekend in June throughout the year and for important any way we can.

10AM to 7:00PM. SRW Members will be information and dates for the next

scheduled for specific date and time for winemaking season! As you move through the process, you

their bottling. will want to think of a name for your

Giovanni Petretta wine and decide which label youll want

Bottling your wine is a fairly straight 203-948-8235 to use. Check out the Wine Label Board

forward process. The stainless steel tanks shelterrockwinery@gmail.com to select your label and view the sample

are attached to the wine dispensing 5 Shelter Rock Road labels to get ideas for naming your very

machine and the wine is dispensed into Danbury, Connecticut 06810 own personal vintage!

the bottles. The next station is the www.shelterrockwinery.com

Corking Machine where you place your Be sure to Like Shelter Rock Winery Let the winemaking experience begin!

bottle on the cork press, add the cork and on Facebook and follow us on

press down on the lever, pushing the cork LinkedIn and Twitter! Salute!

You might also like

- 5 Stages of Wine ProcessDocument18 pages5 Stages of Wine ProcessJasmyn AgustinNo ratings yet

- Prathamesh WineDocument36 pagesPrathamesh WinePankaj ThakurNo ratings yet

- Pineapplewine PDFDocument2 pagesPineapplewine PDFAdrian Ellarma RamosNo ratings yet

- Grape Vines - With Chapters on Pot Culture, Propagation and VarietiesFrom EverandGrape Vines - With Chapters on Pot Culture, Propagation and VarietiesNo ratings yet

- Sweet, Reinforced and Fortified Wines: Grape Biochemistry, Technology and VinificationFrom EverandSweet, Reinforced and Fortified Wines: Grape Biochemistry, Technology and VinificationNo ratings yet

- Chemistry of WinemakingDocument12 pagesChemistry of WinemakingbonifacesilveiraNo ratings yet

- Role of Lees in Wine ProductionDocument10 pagesRole of Lees in Wine Productionney_91No ratings yet

- Varieties of GrapesDocument9 pagesVarieties of GrapesBilal ArshadNo ratings yet

- Brassica Vegetables: Growing Practices and Nutritional InformationFrom EverandBrassica Vegetables: Growing Practices and Nutritional InformationNo ratings yet

- White Wines: ChardonnayDocument20 pagesWhite Wines: ChardonnayRaluca Comaneci BarakNo ratings yet

- Part 3 - Fortified Wines of Madeira and The RestDocument11 pagesPart 3 - Fortified Wines of Madeira and The RestPranav JamgaonkarNo ratings yet

- How To Adjust The Level of Acidity in Your WineDocument4 pagesHow To Adjust The Level of Acidity in Your WineScott Young100% (1)

- Example of Fermentation ProcessDocument34 pagesExample of Fermentation ProcessRedzuan Hussin100% (2)

- Jamun and Grape Wines Hyper CMPLTDocument54 pagesJamun and Grape Wines Hyper CMPLTYezdi Solaina50% (2)

- GEA WS Yeast-BrochureDocument24 pagesGEA WS Yeast-Brochuretaufany99No ratings yet

- Wines and Vines June 2013Document100 pagesWines and Vines June 2013Danielle Marlena Cox0% (1)

- Principles of Postharvest Physiology Lecture 8 20 2015bDocument69 pagesPrinciples of Postharvest Physiology Lecture 8 20 2015bJoyce De VeraNo ratings yet

- Grapes Organic ProductionDocument44 pagesGrapes Organic Productionefraim750% (1)

- Prune CanopyDocument58 pagesPrune CanopyGrape Growers PHNo ratings yet

- Cider Production - Sanitation - Fermentation and StabilizationDocument25 pagesCider Production - Sanitation - Fermentation and StabilizationWahyu Arie SuryadiNo ratings yet

- Technology of WineDocument5 pagesTechnology of Winemawamaka90No ratings yet

- The Non-Alcoholic Drink Book (1971)Document104 pagesThe Non-Alcoholic Drink Book (1971)aronfive100% (1)

- Wine Regions of Italy: Italian Appellation SystemDocument4 pagesWine Regions of Italy: Italian Appellation Systemanmol kNo ratings yet

- What Makes A Great WineDocument7 pagesWhat Makes A Great WineAntonio De VitisNo ratings yet

- The New Cider Maker's Handbook Press ReleaseDocument1 pageThe New Cider Maker's Handbook Press ReleaseChelsea Green PublishingNo ratings yet

- Food Chemistry: Krista M. Sumby, Paul R. Grbin, Vladimir JiranekDocument16 pagesFood Chemistry: Krista M. Sumby, Paul R. Grbin, Vladimir Jiranekney_91No ratings yet

- The Physics Behind The Fizz in Champagne and Sparkling WinesDocument88 pagesThe Physics Behind The Fizz in Champagne and Sparkling WinesCromironNo ratings yet

- Grapevine Structure and FunctionDocument15 pagesGrapevine Structure and FunctionRudy Tisnado AlejoNo ratings yet

- Hungarian Wine RegionsDocument36 pagesHungarian Wine RegionsVisitHungary100% (1)

- Cheese MakingDocument19 pagesCheese MakingPoulami DeNo ratings yet

- Kombucha Flavor RecipesDocument1 pageKombucha Flavor RecipesAnonymous g7Tb3IOfNo ratings yet

- Palmento Sicilian Wine OdesseyDocument308 pagesPalmento Sicilian Wine Odesseyaniruddha behalNo ratings yet

- The Book of Shrub Drinks PDFDocument2 pagesThe Book of Shrub Drinks PDFsharmagspNo ratings yet

- The Home Winemakers ManualDocument169 pagesThe Home Winemakers ManualsbombiNo ratings yet

- Laboratory Analyses ManualDocument63 pagesLaboratory Analyses ManualEtienne Paul CowperNo ratings yet

- Cover Crop Species and DescriptionsDocument19 pagesCover Crop Species and Descriptions1ab4cNo ratings yet

- WINESDocument14 pagesWINESsourovbhowmickNo ratings yet

- COOLING AND HEATING IN WINERIES - EditedaDocument10 pagesCOOLING AND HEATING IN WINERIES - Editedaconstantin.iacomi3837No ratings yet

- Final Project of Baker YeastDocument27 pagesFinal Project of Baker YeastTeena Alawad100% (1)

- Absolut VodkaDocument3 pagesAbsolut VodkaazrennNo ratings yet

- Riesling - Alsace and NiederosterreichDocument1 pageRiesling - Alsace and NiederosterreichHawaii Beverage GuideNo ratings yet

- Grape Production Guide 2022 MAY WebDocument94 pagesGrape Production Guide 2022 MAY Webbahman khoshnevisNo ratings yet

- Winegrapes EbookDocument699 pagesWinegrapes EbookDritanRukaNo ratings yet

- ArmagnacDocument7 pagesArmagnacCoffeeJoNo ratings yet

- Alcoholic BeveragesDocument13 pagesAlcoholic BeveragesVikas BansalNo ratings yet

- INSIGHTS #1 - Goblet Vine TrainingDocument5 pagesINSIGHTS #1 - Goblet Vine TrainingGiampiero Nadali100% (1)

- Analysis of Apple JuicesDocument62 pagesAnalysis of Apple JuicesPredrag DjurdjevicNo ratings yet

- The Burgundy Wine Road PDFDocument40 pagesThe Burgundy Wine Road PDFFlavio Martins'e NascimentoNo ratings yet

- Wine MakingDocument42 pagesWine MakingDan Danut100% (1)

- Wine MakingDocument17 pagesWine Makingcarlos17acc100% (3)

- Food Chemistry: A. Roldán, G.C.J. Van Muiswinkel, C. Lasanta, V. Palacios, I. CaroDocument9 pagesFood Chemistry: A. Roldán, G.C.J. Van Muiswinkel, C. Lasanta, V. Palacios, I. CaromyselfzzNo ratings yet

- Grape GuideDocument46 pagesGrape Guidekj4892No ratings yet

- Top 100 Cellar Selections 2015Document9 pagesTop 100 Cellar Selections 2015Luiz ColaNo ratings yet

- OSPF Design Guide: TAC Notice: What'sDocument59 pagesOSPF Design Guide: TAC Notice: What'sAlice James MichaelNo ratings yet

- Cisco HCS-CUCM Architecture PDFDocument49 pagesCisco HCS-CUCM Architecture PDFAnonymous GEyA5IrNo ratings yet

- Evolve Teams Enterprise Voice Implementation ChecklistDocument3 pagesEvolve Teams Enterprise Voice Implementation ChecklistAnonymous GEyA5IrNo ratings yet

- Voice Routing Objects: User Starts TeamsDocument1 pageVoice Routing Objects: User Starts TeamsAnonymous GEyA5Ir100% (1)

- Snapstart Admin GuideDocument26 pagesSnapstart Admin GuideAnonymous GEyA5IrNo ratings yet

- Teams Enterprise Voice Implementation WorkbookDocument40 pagesTeams Enterprise Voice Implementation WorkbookAnonymous GEyA5Ir0% (1)

- SIP To PSTN Cause CodesDocument24 pagesSIP To PSTN Cause CodesusaismgNo ratings yet

- IMS Architecture OverviewDocument45 pagesIMS Architecture OverviewAnonymous GEyA5IrNo ratings yet

- Snapstart Admin GuideDocument26 pagesSnapstart Admin GuideAnonymous GEyA5IrNo ratings yet

- Troubleshooting and Debugging VoIP Call BasicsDocument18 pagesTroubleshooting and Debugging VoIP Call BasicsGabriel DeMarcoNo ratings yet

- 5ESSDocument33 pages5ESSAnonymous GEyA5IrNo ratings yet

- Ven 124 Lab Manual: Linda F. Bisson Department of Viticulture and Enology University of California, DavisDocument71 pagesVen 124 Lab Manual: Linda F. Bisson Department of Viticulture and Enology University of California, Davis1ab4cNo ratings yet

- Signaling Using: NetworkDocument12 pagesSignaling Using: NetworkAnonymous GEyA5IrNo ratings yet

- Dial Peer Features and ConfigurationDocument50 pagesDial Peer Features and ConfigurationAnonymous GEyA5IrNo ratings yet

- Fruit Grape Pruning SystemsDocument27 pagesFruit Grape Pruning SystemsAnonymous GEyA5IrNo ratings yet

- 2018 06 28 Perimeta ClearIP Inbound Scenario Configuration Guide 73b8e3be72Document14 pages2018 06 28 Perimeta ClearIP Inbound Scenario Configuration Guide 73b8e3be72Anonymous GEyA5IrNo ratings yet

- Sigtran OracleDocument108 pagesSigtran OracleAnonymous GEyA5Ir100% (1)

- Wine Spoilage and Defects: Tonight's LectureDocument14 pagesWine Spoilage and Defects: Tonight's LectureAnonymous GEyA5IrNo ratings yet

- Traffic Engineering With MPLSDocument123 pagesTraffic Engineering With MPLSAnonymous GEyA5IrNo ratings yet

- Juniper EX2300 PDFDocument11 pagesJuniper EX2300 PDFAnonymous GEyA5IrNo ratings yet

- Crypto Map Based IPsec VPN FundamentalsDocument11 pagesCrypto Map Based IPsec VPN FundamentalsAnonymous GEyA5IrNo ratings yet

- All-Shotokan Karate Katas PDFDocument25 pagesAll-Shotokan Karate Katas PDFAnonymous GEyA5Ir100% (3)

- Draft Copy of A Practical Guide To Developing A Commercial Wine VineyardDocument178 pagesDraft Copy of A Practical Guide To Developing A Commercial Wine Vineyardzaratustra21No ratings yet

- Juniper EX2300 PDFDocument11 pagesJuniper EX2300 PDFAnonymous GEyA5IrNo ratings yet

- Ccna Ospf Cheat SheetDocument4 pagesCcna Ospf Cheat SheetAnonymous GEyA5IrNo ratings yet

- Basic OSPFv2 inDocument40 pagesBasic OSPFv2 inAnonymous GEyA5IrNo ratings yet

- BGP 2015Document31 pagesBGP 2015Anonymous GEyA5IrNo ratings yet

- Wan Virtualization With Citrix CloudbridgeDocument11 pagesWan Virtualization With Citrix CloudbridgeAnonymous GEyA5IrNo ratings yet

- A Quick Look at CiscoDocument9 pagesA Quick Look at CiscoAnonymous GEyA5IrNo ratings yet

- Mosel Fine Wines No52 Jun 2020Document101 pagesMosel Fine Wines No52 Jun 2020hoh hununNo ratings yet

- Wine Report 2009 Rhône NorteDocument38 pagesWine Report 2009 Rhône NorteLuiz ColaNo ratings yet

- Jacobs Creek Classic Shiraz Cabernet 2011Document2 pagesJacobs Creek Classic Shiraz Cabernet 2011api-248658854No ratings yet

- Wine GuideDocument4 pagesWine GuidepankajkhakareNo ratings yet

- Wine GlossaryDocument41 pagesWine GlossaryMaria Ana Neves FigueiraNo ratings yet

- Piedmont - Wine DictionaryDocument5 pagesPiedmont - Wine Dictionarystefan StefanNo ratings yet

- Caa205 U2 Lecture Notes Foh Day5Document10 pagesCaa205 U2 Lecture Notes Foh Day5api-244949119No ratings yet

- MFW July PortfolioDocument47 pagesMFW July PortfolioJason MalumedNo ratings yet

- The Beer Geek Handbook - Living A Life Ruled by Beer (2016)Document58 pagesThe Beer Geek Handbook - Living A Life Ruled by Beer (2016)zaratustra21No ratings yet

- Module 4 Bar and BeverageDocument32 pagesModule 4 Bar and BeverageROY BULTRON CABARLESNo ratings yet

- Tim Atkin Wine Report Burgundy 2009Document42 pagesTim Atkin Wine Report Burgundy 2009luizcolaNo ratings yet

- Red Winemaking in Cool Climates: Belinda Kemp Karine PedneaultDocument10 pagesRed Winemaking in Cool Climates: Belinda Kemp Karine Pedneaultgjm126No ratings yet

- Brut - French Term Denoting Dry Champagnes or Sparkling WinesDocument3 pagesBrut - French Term Denoting Dry Champagnes or Sparkling WinesSaurabh ChandelNo ratings yet

- Lan-Reserva 2016 enDocument1 pageLan-Reserva 2016 enArda HridaryNo ratings yet

- JP Chenet PresentDocument24 pagesJP Chenet Presentjcrc1972No ratings yet

- Roberson Wine Agency List 2014Document90 pagesRoberson Wine Agency List 2014kkirk74No ratings yet

- Larousse Wine by Librairie Larousse - ExcerptDocument23 pagesLarousse Wine by Librairie Larousse - ExcerptThe Recipe Club33% (6)

- BaroloDocument33 pagesBaroloJonathan MarchatNo ratings yet

- UpdateDocument932 pagesUpdateDarryl FerdinandNo ratings yet

- Metabolic Characterisation of Main Albanian Grape CultivarsDocument1 pageMetabolic Characterisation of Main Albanian Grape CultivarsEndrit KullajNo ratings yet

- EBook - The Art of Wine TastingDocument35 pagesEBook - The Art of Wine TastingLeyre Segura AzcuneNo ratings yet

- D4 Sparkling Wines - An Accompaniment To The WSET Level 4 Diploma in Wines by Wine Spirit Education TrustDocument122 pagesD4 Sparkling Wines - An Accompaniment To The WSET Level 4 Diploma in Wines by Wine Spirit Education TrustMatt Hunt89% (9)

- Wine Additives ListDocument22 pagesWine Additives ListwtdocumentsNo ratings yet

- Glossary of Wine-Tasting Terminology, Matei Alina Mihaela, MTI Anul 1Document30 pagesGlossary of Wine-Tasting Terminology, Matei Alina Mihaela, MTI Anul 1Alina-Mihaela Matei100% (2)

- Complete Wine Tasting Journal - HADM3060 - VinUniDocument6 pagesComplete Wine Tasting Journal - HADM3060 - VinUniNga PhuongNo ratings yet

- Goedhuis Burgundy 2019 EP Brochure IntDocument66 pagesGoedhuis Burgundy 2019 EP Brochure IntAnnieNo ratings yet

- Terre Di San Leonardo Vigneti Delle Dolomiti IGT: Wine DescriptionDocument1 pageTerre Di San Leonardo Vigneti Delle Dolomiti IGT: Wine DescriptionJuan PradoNo ratings yet

- Goedhuis Burgundy - 2016 - EP - BrochureDocument55 pagesGoedhuis Burgundy - 2016 - EP - BrochureJames ChoongNo ratings yet

- Bottle FermentedDocument50 pagesBottle FermentedJonian KokonaNo ratings yet

- PDFDocument72 pagesPDFGCMediaNo ratings yet