Professional Documents

Culture Documents

Blustar NMDC Qap R0 14 01 2017

Uploaded by

koushik42000Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Blustar NMDC Qap R0 14 01 2017

Uploaded by

koushik42000Copyright:

Available Formats

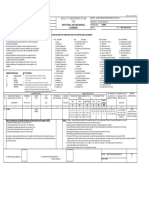

Contractor Blue Star Limited Name of

Project PLC SYSTEM FOR CAS of NMDC

Order No. & Date 2000129199 Dated 06/01/2016 QUALITY ASSURANCE PLAN

Consultant MECON Ltd Spec. No.

Sub-Contractor Schneider Electric India Pvt Ltd Package Name PLC SYSTEM FOR CAS of NMDC

INSTRUCTION FOR FILLING UP CODES FOR EXTENT OF INSPECTION, TESTS, TEST CERTIFICATES & DOCUMENTS

1 QAP shall be submitted for each of the equipment separately with break Code Description Code Description Documents

up of assembly / sub-assembly & part/component or for group of equip- 1. Visual Inspection 14. Impalse Test D1 Approvoved GA Drawings

ment having same specification. 2. Dimensional 15. Partial Discharge Test D2 Approved SLD/Schematics

3. Fitment & Alignment 16. Heat Run Test/Temp. rais Test D3 Catalogs/Approved Datasheets

2 Use numerical codes as indicated for extent of inspection & tests and 4. Physical Test (Sample) 17. Enclosure Protection Test D4 Approved Bill of Material

submission of test certificates & documents. Additional codes & des- 5. Chemical Test (Sample) 18. Calibration D5 Un-priced PO copies

cription for extent of inspection & tests may be added as applicable for 6. Ultrasonic Test 19. Noise & Vibration D6 Calibration Certificates

the plant and equipment. 7. Megnetic Particle Test (MPT) 20. Test certificate for bought of measuring instruments

8. Radiography Test out components

3 Separate identification number with quantity for equipment shall be 9. Dye Penetration Test 21. Tank Presure Test

indicated wherever equipment having same specification belonging to 10. Measurment of IR Value 22. Paint Shade verification

different facilities are grouped together. a) Before HV Test 23. Short time rating

b) After HV Test 24. Operational/Functional Check

4 Weight in tonnes (T) must be indicated under column 5 for each item. 11. High voltage Test/ Dielectric Test 25. Overspeed Test

Estimated weights may be indicated wherever actual weights are not 12. Routine Test as per relevent IS/other standard 26. Flame proof Test

available. 13. Type Tests as per relevent IS/other standard 27. Clearance and creepage distance

ABBRIVIATION USED 28. Acceptance Test as per relevent IS

CONTR CONTRACTOR IW Inspection Waver

MFR MANUFACTURER

Equipment Details Inspection & Tests

Test Certificates & Acceptance

Raw Material and in process stage documents to be Criteria

Quantity Manufacturer Expected Final Inspection/ Test by Remarks

Description (With equipment heading.place of Identificat Inspection submitted to Standards/

SI.No. Name and Schedule of

use and brief specs) ion No MECON Documents

No/ M T Address Final Inspection MFR CONTR MECON MFR CONTR MECON

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

24- Shall be done with

typical software &

Schneider, 1,2,3,4,12,22 1,2,3,4,12,22, 1,2,3,4,12,22,2 D1, D2, D3, D4, D5, D1, D2, D3,

1 PLC Panel 1,2,3 - - hardware as per

Bangalore ,24 24 4 D6,12,13,18,20,22 D4, D5, D6

approved FAT

procedure.

Schneider, 1,2,3,4,12,22 1,2,3,4,12,22, 1,2,3,4,12,22,2 D1, D2, D3, D4, D1, D2, D3,

2 PC Console 1,20 - -

Bangalore ,24 24 4 D6,12,13,18,20,22 D4, D6

Schneider,

3 PLC Software (Unity Pro & Vijeo Citect) 1 - - 1 1 1 D4 D4 LICENSE

Bangalore

Operator Work station, Engineering Work Schneider,

4 1,20 - - 1,20,24 1,20,24 1,20,24 D3,D4 D3, D4

station,Printer Bangalore

FO cable, Ethernet cable, Patch Cords & Schneider,

5 1,2,20 - - 1,2,20 1,2,20 1,2,20 D3,D4 D3,D4

Accessories Bangalore

Schneider,

6 Ethernet Switch 1,2,20 - - 1,2,20 1,2,20 1,2,20 D3,D4 D3,D4

Bangalore

7 -

PROJECT DRAWING NO.:

For MECON ( Stamp & Signature) For CONTRACTOR ( Stamp & Signature) QAP NO.: Rev: 0

Sheet: 1 OF 1

You might also like

- Digital Circuit Testing: A Guide to DFT and Other TechniquesFrom EverandDigital Circuit Testing: A Guide to DFT and Other TechniquesNo ratings yet

- Qap - LR BendDocument1 pageQap - LR BendMecon LtdNo ratings yet

- QAP Plan Elect.Document2 pagesQAP Plan Elect.insap_dineshNo ratings yet

- Qap-Bv, PV, GVDocument10 pagesQap-Bv, PV, GVSachin KumarNo ratings yet

- Qap - Fabrication and Erection EslDocument4 pagesQap - Fabrication and Erection Eslshibaprasad0115No ratings yet

- Annexure - 1 User Manual For IMSDocument221 pagesAnnexure - 1 User Manual For IMSSumantrra ChattopadhyayNo ratings yet

- Qap - LR BendDocument1 pageQap - LR BendSachin KumarNo ratings yet

- Quality Assurance Plan FOR: Refractory MaterialsDocument2 pagesQuality Assurance Plan FOR: Refractory MaterialsPooja TripathiNo ratings yet

- JSW Coke Cob Qap Mech Rev 0Document1 pageJSW Coke Cob Qap Mech Rev 0Md ArshadNo ratings yet

- Qap - TCP-PCP-HPCLDocument2 pagesQap - TCP-PCP-HPCLAashish MoyalNo ratings yet

- Check List For Pre Commissioning of MV SwitchgearDocument2 pagesCheck List For Pre Commissioning of MV Switchgeararuna100% (9)

- 12 - 254624-400-Pl-Int-001 QapDocument2 pages12 - 254624-400-Pl-Int-001 QapNerudaArarNo ratings yet

- Me - Itp - Binh Nguyen Project - Electrical (Final)Document184 pagesMe - Itp - Binh Nguyen Project - Electrical (Final)binhnguyen dmtNo ratings yet

- Test Sample FormatsDocument13 pagesTest Sample FormatsMohamed AshrafNo ratings yet

- Ammeter, Voltmeter Testing Not Applicable For This PanelDocument3 pagesAmmeter, Voltmeter Testing Not Applicable For This Paneleswaran005No ratings yet

- Auxiliary Relay Test Report: Sheet 1 of 1Document1 pageAuxiliary Relay Test Report: Sheet 1 of 1TariqMalikNo ratings yet

- Satr-P-3208 Rev 8 FinalDocument7 pagesSatr-P-3208 Rev 8 FinalMohamed HaleemNo ratings yet

- Section 6.0 SCH of Design Req - ACSUDocument2 pagesSection 6.0 SCH of Design Req - ACSUSHIDIBAHARNo ratings yet

- NDT-SA-SATORP-UT-60, Rev00, Date 15 Aug-2023Document20 pagesNDT-SA-SATORP-UT-60, Rev00, Date 15 Aug-2023Md Abu Hanif RajuNo ratings yet

- Checklist Testing and Inspection With Interconnection To The GridDocument32 pagesChecklist Testing and Inspection With Interconnection To The GridrbewalesNo ratings yet

- QAP IP Format Electrical Instrumentation APEDocument2 pagesQAP IP Format Electrical Instrumentation APEKoushik DeyNo ratings yet

- Ausgrid Utiltiy Cable Test Plan 2017Document31 pagesAusgrid Utiltiy Cable Test Plan 2017Ali NaderianNo ratings yet

- PTS-20WM319 06 Commissioning TestsDocument8 pagesPTS-20WM319 06 Commissioning TestsDurgaprasad RyaliNo ratings yet

- L&T QapDocument2 pagesL&T Qapsriram.5230No ratings yet

- Coupling PDFDocument1 pageCoupling PDFumashankarsinghNo ratings yet

- Saudi Aramco Test Report: Elect-LV Controlgear - ATS / MTS Calibration, Setting, and Functional Testing SATR-P-3824Document6 pagesSaudi Aramco Test Report: Elect-LV Controlgear - ATS / MTS Calibration, Setting, and Functional Testing SATR-P-3824Ma.socorro SaballaNo ratings yet

- Itp-Ofmr - Fat PDFDocument3 pagesItp-Ofmr - Fat PDFPrabhakar SvNo ratings yet

- Checklist Testing and Inspection With Interconnection-Version 1 0 August 2015Document32 pagesChecklist Testing and Inspection With Interconnection-Version 1 0 August 2015jayapalNo ratings yet

- Subcon ItpDocument6 pagesSubcon ItpManu MohanNo ratings yet

- Internal Dispatch Clearance ChecklistDocument54 pagesInternal Dispatch Clearance ChecklistMahesh2101No ratings yet

- LNG-80-100937-RA-6065-00023-0000 HT PipingDocument7 pagesLNG-80-100937-RA-6065-00023-0000 HT PipingMohammad AftabNo ratings yet

- 40-SDMS-02A CT TestingDocument14 pages40-SDMS-02A CT TestingMaktoob M Knif100% (1)

- Inspection and Test Plan: Cement Stucco (Exterior Plastering)Document3 pagesInspection and Test Plan: Cement Stucco (Exterior Plastering)Alvene TagocNo ratings yet

- RESERVOIR GROUP SOW - CORING Tools - QAQC For 12.25" BHA On 30th Nov (Wed)Document1 pageRESERVOIR GROUP SOW - CORING Tools - QAQC For 12.25" BHA On 30th Nov (Wed)EduardNo ratings yet

- 8474L 000 JSD 1510 002 0Document8 pages8474L 000 JSD 1510 002 0danhlakisu1No ratings yet

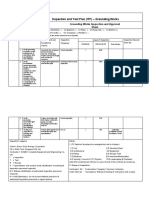

- Inspection and Test Plan (ITP) - Grounding WorksDocument2 pagesInspection and Test Plan (ITP) - Grounding WorksElisco Pher SalmasanNo ratings yet

- Precommissioning Checklist of Pa SystemDocument1 pagePrecommissioning Checklist of Pa SystemTamer EidNo ratings yet

- Check List For Sub Main Distribution Board InstallationDocument2 pagesCheck List For Sub Main Distribution Board InstallationNaing Win TunNo ratings yet

- SATR-P-3825 LV Panelboard - Pre-Energized TestingDocument4 pagesSATR-P-3825 LV Panelboard - Pre-Energized TestingheikelNo ratings yet

- Field Inspection and Test ReportDocument19 pagesField Inspection and Test ReportAe SuwaphanNo ratings yet

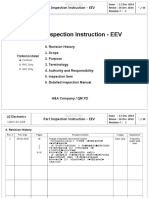

- LG (67) - G3-1028-EEV Eng Rev 1Document10 pagesLG (67) - G3-1028-EEV Eng Rev 1Anonymous Lta32Ta9No ratings yet

- Pre Commissioning Check List For Addressable Fire Alarm Voice Evacuation System Testing CommissioningDocument2 pagesPre Commissioning Check List For Addressable Fire Alarm Voice Evacuation System Testing CommissioningNaing Win TunNo ratings yet

- Manufacturin Quality Plan: Sheet No.: Page 1 of 23Document23 pagesManufacturin Quality Plan: Sheet No.: Page 1 of 23ashiihsaNo ratings yet

- Epic For Upgradation of Ac Ups Units in Ngl3, Mesaieed: Multi Core Cable Test SheetDocument1 pageEpic For Upgradation of Ac Ups Units in Ngl3, Mesaieed: Multi Core Cable Test SheetmeeNo ratings yet

- SOP Name SOP For Indicator Lamp Quality Test (Refrigerator) DATE ISSUED 07.07.2020Document6 pagesSOP Name SOP For Indicator Lamp Quality Test (Refrigerator) DATE ISSUED 07.07.2020swapon kumar shillNo ratings yet

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test ReportMa.socorro SaballaNo ratings yet

- AREVA Relay Test Format ModifDocument97 pagesAREVA Relay Test Format ModifAUHEBEZNo ratings yet

- Sprinkler System Test QCDD FormDocument2 pagesSprinkler System Test QCDD FormMahmoud HassanNo ratings yet

- True Blue Inspection-Test-Plan - Issued For ReviewDocument4 pagesTrue Blue Inspection-Test-Plan - Issued For ReviewJohn HartNo ratings yet

- Sample ChecklistDocument3 pagesSample ChecklistrkssNo ratings yet

- Saudi Aramco Test ReportDocument3 pagesSaudi Aramco Test ReportMa.socorro SaballaNo ratings yet

- ITP - Latticed Steel Tower - Type TestDocument3 pagesITP - Latticed Steel Tower - Type TestPrabhakar SvNo ratings yet

- T & D Circle, JabalpurDocument19 pagesT & D Circle, JabalpurCarlos ClarkNo ratings yet

- Global Power Test Sdn. Bhd. Site Acceptance Test Report: Testing of 415V LV Switchgear PanelDocument10 pagesGlobal Power Test Sdn. Bhd. Site Acceptance Test Report: Testing of 415V LV Switchgear PanelTHULASI RAMNo ratings yet

- Inspection and Test Plan: Fabrication / In-Process InspectionDocument1 pageInspection and Test Plan: Fabrication / In-Process InspectionGLEDSONNo ratings yet

- Et 0000 97 Toc 001bDocument5 pagesEt 0000 97 Toc 001bGLEDSONNo ratings yet

- MV SWGR InspectionDocument10 pagesMV SWGR InspectionTHULASI RAM100% (1)

- Saudi Aramco Test Report: SATR-B-6105 10-Jun-19 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestDocument2 pagesSaudi Aramco Test Report: SATR-B-6105 10-Jun-19 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestSino hydroNo ratings yet

- ITP-Joint Box - FATDocument3 pagesITP-Joint Box - FATPrabhakar SvNo ratings yet

- ITP-Joint Box - FAT PDFDocument3 pagesITP-Joint Box - FAT PDFPrabhakar SvNo ratings yet

- KD Airtel Paymnt 10052017Document1 pageKD Airtel Paymnt 10052017koushik42000No ratings yet

- Appendix - 6 List of Approved Sub-Contractors / VendorsDocument27 pagesAppendix - 6 List of Approved Sub-Contractors / Vendorskoushik42000No ratings yet

- TS Benification Pellet Plant RSP DRGDocument1 pageTS Benification Pellet Plant RSP DRGkoushik42000No ratings yet

- NIT Benification Pellet Plant RSPDocument30 pagesNIT Benification Pellet Plant RSPkoushik42000100% (1)

- Excel PR HM PT TT DryerDocument2 pagesExcel PR HM PT TT Dryerkoushik42000No ratings yet

- EOI For FGD Final ReleaseDocument3 pagesEOI For FGD Final ReleasesiddharathsenNo ratings yet

- Eoi KCCDocument2 pagesEoi KCCkoushik42000No ratings yet

- TND 061380 133458Document3 pagesTND 061380 133458koushik42000No ratings yet

- Inter Plant Standard For Safety in Steel Industry Safety in Contract Works IPSS:1-11-011-01 No Corresponding Indian Standard Exists 0. ForewordDocument22 pagesInter Plant Standard For Safety in Steel Industry Safety in Contract Works IPSS:1-11-011-01 No Corresponding Indian Standard Exists 0. Forewordkoushik42000No ratings yet

- What's Cool - March 2017Document17 pagesWhat's Cool - March 2017koushik42000No ratings yet

- Cas-1 Cable ScheduleDocument10 pagesCas-1 Cable Schedulekoushik42000No ratings yet

- NMDC Cas Letter No-0272Document1 pageNMDC Cas Letter No-0272koushik42000No ratings yet

- HK 2Document1 pageHK 2koushik42000No ratings yet

- HK 1Document1 pageHK 1koushik42000No ratings yet

- SRW2224G4 K9Document1 pageSRW2224G4 K9koushik42000No ratings yet

- EOI For FGD Final ReleaseDocument3 pagesEOI For FGD Final ReleasesiddharathsenNo ratings yet

- Draft Scope Matrix BSL - KCCDocument2 pagesDraft Scope Matrix BSL - KCCkoushik42000No ratings yet

- 1.1 Control Philosophy CAS-1 NMDCDocument36 pages1.1 Control Philosophy CAS-1 NMDCkoushik42000No ratings yet

- Inst & Control - Cable - NMDCDocument4 pagesInst & Control - Cable - NMDCkoushik42000No ratings yet

- 1 Annex - 1 - NCAS Delay Analysis 05 12 16Document1 page1 Annex - 1 - NCAS Delay Analysis 05 12 16koushik42000No ratings yet

- HP Pro 3330mtDocument1 pageHP Pro 3330mtkoushik42000No ratings yet

- 5SL6 MCBDocument3 pages5SL6 MCBkoushik42000No ratings yet

- 1.8 PG Ga PDFDocument1 page1.8 PG Ga PDFkoushik42000No ratings yet

- 1.24 Pressure Switch Catalogue CAS-1Document24 pages1.24 Pressure Switch Catalogue CAS-1koushik42000No ratings yet

- Hmi RSP BVDocument2 pagesHmi RSP BVkoushik42000No ratings yet

- 5SL6 MCBDocument3 pages5SL6 MCBkoushik42000No ratings yet

- Cable Schedule RSP BVDocument17 pagesCable Schedule RSP BVkoushik42000No ratings yet

- Instrument Load ListDocument2 pagesInstrument Load Listkoushik42000No ratings yet

- Hmi RSP BVDocument2 pagesHmi RSP BVkoushik42000No ratings yet

- Liquidation of Comm Punch List of NCAS-DSP As On 17 06 2016Document14 pagesLiquidation of Comm Punch List of NCAS-DSP As On 17 06 2016koushik42000No ratings yet

- Safety Practices Oisd NormsDocument26 pagesSafety Practices Oisd NormsRaju100% (1)

- Sedna Reporting FeaturesDocument13 pagesSedna Reporting Featuressorin1970No ratings yet

- Satuan New (Unit)Document29 pagesSatuan New (Unit)Avininda FitriaNo ratings yet

- Sap On Aws Operations Guide-V1.5Document25 pagesSap On Aws Operations Guide-V1.5ezabalaNo ratings yet

- ECSS-E-HB-32-20 - Part-2A - Structural Materials Handbook - Design Calculation MethodsDocument434 pagesECSS-E-HB-32-20 - Part-2A - Structural Materials Handbook - Design Calculation Methodsdkleeman4444No ratings yet

- SakaiDocument2 pagesSakaiariNo ratings yet

- MSDS PPCPDocument4 pagesMSDS PPCPSivakumar AmbikapathyNo ratings yet

- Datasheet G RelaysDocument10 pagesDatasheet G RelaysthomaswangkoroNo ratings yet

- 5245f en PDFDocument28 pages5245f en PDFdinhvuNo ratings yet

- Process Industry Practices Electrical: Pip Elswc03 600 Volt Power and Control CableDocument7 pagesProcess Industry Practices Electrical: Pip Elswc03 600 Volt Power and Control Cablemariannel perezNo ratings yet

- The ISO27k Standards: Gary HinsonDocument10 pagesThe ISO27k Standards: Gary HinsonKaran DeetNo ratings yet

- En 60730-1 StandardiDocument11 pagesEn 60730-1 StandardiSerdar KaçamerNo ratings yet

- Astm D3950-17Document3 pagesAstm D3950-17Darwin MojicaNo ratings yet

- Eurologistica Hoses Exp Off LemaDocument4 pagesEurologistica Hoses Exp Off LemacarlosjademasterNo ratings yet

- Library ManagementDocument36 pagesLibrary Managementkarthik gunjaNo ratings yet

- Eio0000000734 13Document148 pagesEio0000000734 13Duvan TamayoNo ratings yet

- Ultimate List of ISO Standards For Medical Devices-1Document34 pagesUltimate List of ISO Standards For Medical Devices-1Sridharan PadmanabhanNo ratings yet

- Basic Airframe RepairDocument98 pagesBasic Airframe RepairBookMaggotNo ratings yet

- PMRM-v1.0-cs02 - Privacy by Design - TemplateDocument37 pagesPMRM-v1.0-cs02 - Privacy by Design - TemplateShivesh RanjanNo ratings yet

- BGP On MikrotikDocument35 pagesBGP On MikrotikNaz LunNo ratings yet

- Basic DWDM Components.Document16 pagesBasic DWDM Components.Pradeep Kumar SahuNo ratings yet

- 3500 32m 4-Channel Relay 141533l 0Document6 pages3500 32m 4-Channel Relay 141533l 0Asad SuhailNo ratings yet

- 723 Plus DigitalDocument4 pages723 Plus DigitalproesantNo ratings yet

- Om MP AddsDocument78 pagesOm MP AddsIon Cezar CristianNo ratings yet

- Phase 4Document12 pagesPhase 4Gillian LeeNo ratings yet

- International Standard: ISO 17226-1 Iultcs IUC 19-1Document16 pagesInternational Standard: ISO 17226-1 Iultcs IUC 19-1KatrinaNo ratings yet

- Exercise 14Document2 pagesExercise 14Tuan NguyenNo ratings yet

- KWP2000 ManualDocument20 pagesKWP2000 ManualWolfgang Starkmann50% (2)

- HYD VLV, Fire Hose, HR & Breeching - Export2014Document7 pagesHYD VLV, Fire Hose, HR & Breeching - Export2014Jonathan MartinezNo ratings yet

- LW619DM 22 Groups IP CW1 Assign Brief March 23Document4 pagesLW619DM 22 Groups IP CW1 Assign Brief March 23topintechbooks100% (1)