Professional Documents

Culture Documents

The Effects of Recycled Aggregates On Compressive Strength of Concrete

Uploaded by

IJAERS JOURNALOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Effects of Recycled Aggregates On Compressive Strength of Concrete

Uploaded by

IJAERS JOURNALCopyright:

Available Formats

International Journal of Advanced Engineering Research and Science (IJAERS) [Vol-4, Issue-1, Jan- 2017]

https://dx.doi.org/10.22161/ijaers.4.1.41 ISSN: 2349-6495(P) | 2456-1908(O)

The Effects of Recycled Aggregates on

Compressive Strength of Concrete

Idagu Francis Ogar

Department of Civil Engineering, Cross River University of Technology, PMB 1123, Calabar, Nigeria

Abstract Demolished concrete can be used as recycled The use of RCA in construction work started after the

concrete aggregate (RCA) for construction purposes. In Second World War, when many structures were

the research, the compressive strength of concrete made demolished by bombing. During rebuilding, the

from 100% recycled coarse aggregates and 100% natural demolished concrete was used as aggregate in

coarse aggregates was compared. The values of construction. Today, RCA is used successfully in many

compressive strength of the natural aggregates concrete countries, in many fields such as road construction,

(NAC) served as a control. 24 concrete cubes (150 x 150 protection against erosion, parking areas as well as

x 150mm) each for the NAC and RCA were casted making structural concrete. A number of structures in Germany,

a total of 48 concrete cubes. Three cubes for each Norway, United Kingdom, Finland and Netherlands have

category was cured for 3 days, 7 days, 21 days and 28 been built with RCA as partial or full replacement of

days respectively. Concrete mix ratios of 1:2:4 and natural aggregate.

1:1.5:3 were used in both cases. The results show clearly Coarse aggregate is usually greater than 4.75mm (retained

shown that the compressive strength of RAC was higher on no. 4 sieve), while fine aggregate is less than 4.75mm

than those of NAC at the early ages before day 12. It can (passing the no.4 sieve). The compressive strength is an

be deduced from the graph that the compressive strength important factor in the selection of aggregate.

of RAC was higher than that of NAC at early ages while Other physical and mineralogical properties of aggregate

the compressive strength of NAC was higher than that of must be known before mixing concrete to obtain a

RAC at later ages. This means that RAC will have better desirable mixture. These properties include shape, texture,

usage in quick set concrete where early strength is size gradation, moisture content, specific gravity,

desired. reactivity, soundness and bulk unit weight. These

Keywords Strength of Concrete, RCA, NAC, C &DW. properties along with the water/cement ratio determine

the strength, workability and durability of concrete.

I. INTRODUCTION The shape and texture of aggregate affect the properties of

Concrete is a mixture of binder materials usually cement, fresh concrete more than hardened concrete. Concrete is

aggregates and water. Aggregate is commonly considered more workable when smooth and rounded aggregate is

inert filler as they do not get involved in any serious used instead of rough angular or elongated aggregate.

chemical reaction in the process, which accounts for 60 to Most natural sands and gravel from riverbeds or seashores

80 percent of the volume and 70 to 85 percent of the are smooth and rounded and are excellent aggregate.

weight of concrete. Although, aggregate is considered Crushed stone produces much more angular and

inert fillers, it is a necessary component that defines the elongated aggregates, which have a higher surface-to-

concretes thermal and elastic properties and dimensional volume ratio, better bond characteristics but requires

stability. Aggregate is classified as two different types, more cement paste to produce a workable mixture. A

coarse and fine aggregate. smooth surface can improve workability, yet a rougher

Concrete, one of the dominant construction materials due surface generates a stronger bond between the paste and

to its availability, relatively lower cost and the possibility the aggregate creating a higher strength.

to be cast into desired shapes, has contributed strongly The advantages of using recycled concrete product as

internationally in terms of infrastructure development. road base aggregates includes:

The successes are however accompanied by large Recycled concrete is non-expansive and will not

volumes of construction and demolition waste (C &DW). grow or expand with moisture.

Recycling of concrete by crushing C &DW and using it as Recycled concrete has optimum moisture of

aggregate in structural concrete, has become possible in approximately 13 percent about twice that of

several countries, where national standards provide for natural road base, due to its particles size

appropriate use of recycled concrete aggregate(RCA).

www.ijaers.com Page | 250

International Journal of Advanced Engineering Research and Science (IJAERS) [Vol-4, Issue-1, Jan- 2017]

https://dx.doi.org/10.22161/ijaers.4.1.41 ISSN: 2349-6495(P) | 2456-1908(O)

distribution, it may absorb twice the water before other factors are essentially equal. Therefore, dependence

becoming saturated. exists with respect to the old w/c ratio. Bairagi et al.

Recycled concrete is 10-15 percent lighter in (1993) concluded that the average relative compressive

weight, resulting in reduced transportation cost. strength varies from 98 to 94% when the replacement

Recycled concrete compact faster-up to two to ratio is varied from 0.25 to 0.50. For the replacement ratio

three times as fast as non-stabilized natural road 1.0 the average relative compressive strength was 86%.

base. Salem et al. (1998) concluded that the compressive

strength of concrete made with 100% of recycled

II. LITERATURE REVIEW aggregate increases by 2% from 7 to 28 days with respect

The particle shape analysis of recycled aggregate to the 16% increase by conventional concrete. This could

indicates similar particle shape of natural aggregate be due to either the absorption capacity of the recycled

obtained from crushed rock. aggregate or the bad adherence of the aggregate with the

The recycled aggregates which originated from a low Cementpaste. In particular, the strength of the concrete

strength concrete had less adhered mortar and the high with HPC recycled aggregates reached the level of the

strength concrete had more adhered mortar, when the concrete prepared with the crushed natural granite

crushed concrete was grinded with the same type of the aggregates after 90 days of curing. The difference in the

machine and the same energy applied.Prasad et al. (2007) strength development between the concretes with high-

noted that the specific gravity of demolished concrete performance concrete and normal-strength concrete

aggregates is lower than that of natural aggregate. The recycled aggregates was due to the differences in both the

average specific gravity of aggregate usually varies from strength of the coarse aggregates and the microstructural

2.6 to 2.8.Bairagi et al. (1993) concluded that very rapid properties of the interfacial transition zones.

rates of absorption are observed for recycle aggregate.

Nearly 75% of the 24hour absorption capacity was III. MATERIALS AND METHOD

attained in the first 30 minutes of the soaking period. In Laboratory tests was carried out to obtain the relevant

accordance with Hansen et al. (1983), recycled aggregate data and information needed to aid this project such as

concrete made with recycled coarse aggregates and sieve analysis determination, specific gravity

natural sand needs 5% more water than conventional determination, bulk density determination and

concrete in order to obtain the same workability. If the compressive strength test.

sand was also recycled, 15% more amount of water was 3.1 Sourcing of Aggregate

necessary to obtain the same workability.Tavakoli et al. The recycled aggregate for this project was sourced from

(1996) demonstrated that concrete made with 100% demolished culverts concrete and crushed concrete cubes

recycled aggregate with lower W/C ratio than the from CRUTECH laboratory in Calabar. The recycled

conventional concrete can have a larger compressive aggregate was afterwards manually crushed in the

strength. When the W/C ratio is the same, the laboratory, filtered and graded in accordance with British

compressive strength of concrete made with 100% Standards (812, 1974, 1990).

recycled aggregate was lower. The natural coarse aggregate and fine aggregates was

Though researchers have reported a reduction in strength sourced from heaps of commercial supply of crushed

in recycled aggregate, it should be noted that the extent of quarried natural aggregates within Calabar.

reduction is related to the parameters such as the type of 3.2 Experimental Work

concrete used for making the recycle aggregate (high, The experimental works were directed towards achieving

medium or low strength), replacement ratio, water/cement the aim of this research. Comparison of two grades of

ratio and the moisture condition of the recycled aggregate concrete using basic properties of recycled aggregate and

(Crentsil et al., 2001). At a high w/c ratio (between 0.6 natural aggregate was made. The compressive strength

and 0.75), the strength of recycled aggregate is was the main criteria used in the comparison. Two

comparable to that of reference concrete even at a concrete types were tested within the research project.

replacement level of 75%(Katz, 2003). Hansen et al. Mix proportions of the concrete types were tested in

(1983) concluded that, not only the w/c ratio influences accordance with the following conditions:

the compressive strength of concrete made with 100% of Same cement content

recycled aggregate, but the compressive strength of the Same workability

recycled aggregate concrete also depends on the strength Same maximum grain size (25mm)

of the original concrete. The compressive strength of Same grain size distribution of aggregate

recycled aggregate concrete is strongly controlled by the mixture

combination of w/c ratio of the original concrete, when Same type and quantity of fine aggregate.

www.ijaers.com Page | 251

International Journal of Advanced Engineering Research and Science (IJAERS) [Vol-4, Issue-1, Jan- 2017]

https://dx.doi.org/10.22161/ijaers.4.1.41 ISSN: 2349-6495(P) | 2456-1908(O)

The type and quantity of coarse aggregate varied in the IV. RESULTS AND ANALYSIS

following ways: The data used for this project were results obtained from

The first concrete mix had 100% natural coarse laboratory test conducted on Natural Aggregate Concrete

aggregate (NCA). (NAC) and Recycled Aggregate Concrete (RAC)

The second concrete mix had 100% recycled specimens at the Material Testing Laboratory, Cross

coarse aggregate. River University of Technology, CRUTECH, Calabar.

3.3Casting Of Concrete Samples

Casting was done for concrete cubes to test for the Table.4.1: Compressive Strength Test Result on Natural

compressive strength. The mould used for the research Aggregate Concrete NAC, Mix Ratio 1:2:4

work was a steel mould of size 150x150x150mm, it was Age of Cubes Compressive strength in

oiled to avoid friction during moulding and de-moulding (Days) N/mm2

of concrete cubes. Mix ratios of 1:2:4 and 1:1.5:3 were 3 11.5

used. 7 14.0

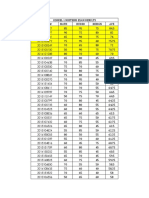

Table.3.1: Schedule of Samples Per mix Ratio 14 17.6

3 7 14 21 28

21 19.7

Days Days Days Days Days

28 21.1

Number of cubes RAC 3 3 3 3

(150x150x150mm) NAC 3 3 3 3

Figure 4.1 below shows the average compressive strength of

natural aggregate concrete (NAC) versus age. As the age

increases, the compressive strength also increased.

NAC MIX RATIO 1:2:4

25

Average Cimpressive Strength of NAC (N/mm2)

20

15

NAC

10

0

3 7 14 21 28

Age (Days)

Fig.4.1: Graph of compressive strength versus age for NAC with mix ratio 1:2:4

www.ijaers.com Page | 252

International Journal of Advanced Engineering Research and Science (IJAERS) [Vol-4, Issue-1, Jan- 2017]

https://dx.doi.org/10.22161/ijaers.4.1.41 ISSN: 2349-6495(P) | 2456-1908(O)

Table.4.2: Compressive Strength Test Results Of Recycled Aggregate Concrete RAC for Mix Ratio 1:2:4

Age of Cubes (Days) Compressive strength in

N/mm2

3 13.0

7 15.3

14 17.2

21 18.9

28 20.5

Figure 4.2 shows the average compressive strength of recycled aggregate concrete (RAC) versus age for mix ratio 1:2:4. As

the age increases, the average compressive strength increased.

MIX RATIO 1:2:4 RAC

25

Average Compressive Strength RAC (N/mm2)

20

15

RAC

10

0

3 7 14 21 28

Age(Days)

Fig.4.2: Graph of compressive strength versus age for RAC with mix ratio 1:2:4

Table.4.3: Comparison Of NAC And RAC With Mix Ratio 1:2:4

Age of Cubes Compressive strength Compressive

(Days) in N/mm2 for NAC strength in N/mm2

for RAC

3 11.5 13.0

7 14.0 15.3

14 17.6 17.2

21 19.7 18.9

28 21.1 20.5

www.ijaers.com Page | 253

International Journal of Advanced Engineering Research and Science (IJAERS) [Vol-4, Issue-1, Jan- 2017]

https://dx.doi.org/10.22161/ijaers.4.1.41 ISSN: 2349-6495(P) | 2456-1908(O)

Figure 4.3 shows the comparison for mix ratio 1:2:4 for NAC and RAC. In the graph, it is clearly shown that the

compressive strength of RAC was higher than those of NAC at the early ages before day 12. At age of 12days, there was an

intersection point between RAC and NAC and there was an equal and average compressive strength of about 16.8N/mm2.

After this age of 12 days, it was observed that the average compressive strength of NAC started rising above that of RAC. It

can be deduced from the graph that the compressive strength of RAC was higher than that of NAC at early ages while the

compressive strength of NAC was higher than that of RAC at later ages. This means that RAC will have better usage in quick

set concrete where early strength is desired.

Comparison for mix ratio 1:2:4 for NAC & RAC

25

20

Average Compressive Strength (N/mm2)

15

NAC

RAC

10

0

3 7 14 21 28

Age (Days)

Fig.4.3: Graph of compressive strength versus age for RAC and NAC versus age for mix ratio 1:2:4

Table.4.4: Compressive Strength Test Results of NAC With Mix Ratio 1:1.5:3

Age of Cubes Natural Aggregate Concrete

(Days) (NAC)

3 14.8

7 18.3

14 20.5

21 24.9

28 29.8

Figure 4.4 below shows the average compressive strength of natural aggregate concrete (NAC) versus age for mix ratio

1:1.5:3. As the age increases, the average compressive strength increased.

www.ijaers.com Page | 254

International Journal of Advanced Engineering Research and Science (IJAERS) [Vol-4, Issue-1, Jan- 2017]

https://dx.doi.org/10.22161/ijaers.4.1.41 ISSN: 2349-6495(P) | 2456-1908(O)

NAC MIX RATIO 1:1.5:3

35

30

25

Average Compressive Strength (N/mm2)

20

NAC

15

10

0

3 7 14 21 28

Age(Days)

Fig.4.4: Graph of Average Compressive Strength versus Age (Days) for NAC with mix ratio 1:1.5:3

Table.4.5: Compressive Strength Test Result OfRAC With Mix Ratio 1:1.5:3

Age of Cubes (Days) Recycled Aggregate Concrete

(RAC)

3 14.5

7 19.5

14 21.0

21 24.5

28 30.2

www.ijaers.com Page | 255

International Journal of Advanced Engineering Research and Science (IJAERS) [Vol-4, Issue-1, Jan- 2017]

https://dx.doi.org/10.22161/ijaers.4.1.41 ISSN: 2349-6495(P) | 2456-1908(O)

RAC MIX RATIO 1:1.5:3

35

30

Average Compressive Strength of RAC(N/mm2)

25

20

15

10

0

3 7 14 21 28

Age(days)

RAC

Fig.4.5: Average Compressive Strength versus Age (Days) for Recycled Aggregate Concrete (RAC) for mix ratio 1:1.5:3

Table.4.7: Comparison Of Compressive Strength Test Result For RAC and NAC, Mix Ratio 1:1.5:3

Age of Cubes (Days) Natural Aggregate Recycled

Concrete (NAC) Aggregate

Concrete (RAC)

3 14.8 14.5

7 18.3 19.5

14 20.5 21.0

21 24.9 24.5

28 29.8 30.2

At the early stage, compressive strength for RAC was higher than NAC. In figure 4.6, at age of 12 days, there was an

intersection between RAC and NAC at an average compressive strength of about 16.8N/mm 2 and at that point. It can be

deduced from the graph that the compressive strength of RAC was higher than that of NAC at early ages while the

compressive strength of NAC was higher than that of RAC at later ages. This means that RAC will have better usage in quick

set concrete where early strength is desired.

www.ijaers.com Page | 256

International Journal of Advanced Engineering Research and Science (IJAERS) [Vol-4, Issue-1, Jan- 2017]

https://dx.doi.org/10.22161/ijaers.4.1.41 ISSN: 2349-6495(P) | 2456-1908(O)

COMPARISON OF NAC AND RAC WITH MIX

RATIO 1:1.5:3

25

20

Average Compressive Strength(N.mm2)

15

NAC

10 RAC

0

3 7 14 21 28

Age(Days)

Fig.4.6: Comparison Of Average Compressive Strength versus Age (Days) for RAC and NAC with mix ratio 1:1.5:3

V. CONCLUSION AND RECOMMENDATION 5.2 Recommendation

5.1Conclusion The following recommendations can be made from the

The following conclusions can be drawn from the results research:

of experimental study to compare the compressive Concretes made with RCA have equivalent

strength of concrete made with recycled aggregate and compressive strength with those made from

natural aggregate: NCA provided the mix ratio and water cement

With constant water cement ratio and mix design, the ratio are not varied.

early compressive strength of RCA concrete is higher Concretes made from RCA have higher early

than that of NCA concrete. However, at later ages, the compressive strength compared to those made

compressive strength of NCA concretes were slightly from NCA

greater than those of RCA by a little margin of about The use of RCA in concrete should be

10%. It was observed that the performance of concrete encouraged by legislation to solve environmental

with RCA was slightly lower than NCA. problems of disposal and depletion of natural

It was also observed that the concrete manufactured with aggregates.

RCA provided less compressive strength as compared to The process of preparation of recycled aggregate

NCA. However, this reduction is considerably small, as plays a significant role in determination of the

such; RCA can be used comfortably in concrete structures strength of the recycled aggregate concrete. If

with modifications to meet specific and desired purpose. not properly crushed and washed to remove the

adhered mortar, the concrete density will be low

thus reduction in strength.

www.ijaers.com Page | 257

International Journal of Advanced Engineering Research and Science (IJAERS) [Vol-4, Issue-1, Jan- 2017]

https://dx.doi.org/10.22161/ijaers.4.1.41 ISSN: 2349-6495(P) | 2456-1908(O)

REFERENCES

[1] Bairagi, N.K., Vidyadhare, H.S. &Ravande, K.:Mix

Design Procedure for Recycled Aggregate Concrete.

Construction & Building Material 4(1990) 4.

[2] Buck, A.D.:Recycled Concrete as a Source of

Aggregate. ACI Journal Proceedings 74 (1977) 212-

219.

[3] Chesner, W.H., (1999):Technical Conference on the

Beneficial Use of By-Product Materials in

Construction Applications. Albany, New York.

[4] HansenT.C., (1983):Recycling of demolished

concrete and masonry, RILEM Report, No 6, E&FN

Spon, London, UK.

[5] HansenT.C., NarudH.,:Strength of recycled concrete

made from crushed concrete coarse aggregate, ACI.

Concrete International. 5 (1983)79-83

[6] Katz, A.:Properties of concrete made with recycled

aggregate from partially hydrated old concrete.

Cement and Concrete Resources, 33 (2003) 703-

711.

[7] Levy, S.M.; Helene, P.:Durability of recycled

aggregates concrete: A safe way to sustainable

development. Cement and Concrete Resources, 34

(2004) 1975-1980.

[8] Salem, R.M., Burdette, E.G., Jackson, N.M.

(2003):Resistance to freezing and thawing of

recycled aggregate concrete. ACI Material, 100,

216-221.

[9] Sanchez de Juan, M., Gutierrez, P.A.

(2004) :Influence of recycled aggregate quality on

concrete properties. In Proceeding of the

International RILEM Conference: The Use of

Recycled Materials in Building and Structures,

Barcelona. 545-553.

[10] Tavakoli, M. &Soroushian, P.:Strength of Recycled

Aggregate Concrete Made Using Field-Demolished

Concrete as Aggregate. ACI Materials Journal 93

(1996) 182-190.

[11] Xiao, J.; Li, J.; Zhang, C.:Mechanical properties of

recycled aggregate concrete under uniaxial loading.

Cement and Concrete Resources. 35 (2005) 1187-

1194.

www.ijaers.com Page | 258

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- WR424GB00DDocument16 pagesWR424GB00DIgor San Martín PeñalozaNo ratings yet

- Cec 103. - Workshop Technology 1Document128 pagesCec 103. - Workshop Technology 1VietHungCao92% (13)

- Bellin, E. H. (1984) - The Psychoanalytic Narrative On The Transformational Axis Between Writing and SpeechDocument15 pagesBellin, E. H. (1984) - The Psychoanalytic Narrative On The Transformational Axis Between Writing and SpeechofanimenochNo ratings yet

- Methods For Assessing The Stability of Slopes During Earthquakes-A Retrospective 1Document3 pagesMethods For Assessing The Stability of Slopes During Earthquakes-A Retrospective 1ilijarskNo ratings yet

- WPS Office 2016Document22 pagesWPS Office 2016Muhammad Aliff SyukriNo ratings yet

- Operational Guidelines For VlsfoDocument2 pagesOperational Guidelines For VlsfoИгорьNo ratings yet

- Climatic Rhythms and Prevalence of Malaria in The Municipality of Sinende in Northern BeninDocument8 pagesClimatic Rhythms and Prevalence of Malaria in The Municipality of Sinende in Northern BeninIJAERS JOURNALNo ratings yet

- Water Quality Assessment Using GIS Based Multi-Criteria Evaluation (MCE) and Analytical Hierarchy Process (AHP) Methods in Yenagoa Bayelsa State, NigeriaDocument11 pagesWater Quality Assessment Using GIS Based Multi-Criteria Evaluation (MCE) and Analytical Hierarchy Process (AHP) Methods in Yenagoa Bayelsa State, NigeriaIJAERS JOURNALNo ratings yet

- Beef Cattle Farmers' Economic Behavior in The Minahasa Tenggara Regency, IndonesiaDocument7 pagesBeef Cattle Farmers' Economic Behavior in The Minahasa Tenggara Regency, IndonesiaIJAERS JOURNALNo ratings yet

- Facing Dengue and Malaria As A Public Health Challenge in BrazilDocument6 pagesFacing Dengue and Malaria As A Public Health Challenge in BrazilIJAERS JOURNALNo ratings yet

- Design and Building of Servo Motor Portable Coconut Peller MachineDocument5 pagesDesign and Building of Servo Motor Portable Coconut Peller MachineIJAERS JOURNALNo ratings yet

- Breastfeeding and Factors Associated With The Prevention of Childhood Obesity: An Integrative Literature ReviewDocument16 pagesBreastfeeding and Factors Associated With The Prevention of Childhood Obesity: An Integrative Literature ReviewIJAERS JOURNALNo ratings yet

- Business Logistics and The Relationship With Organizational SuccessDocument4 pagesBusiness Logistics and The Relationship With Organizational SuccessIJAERS JOURNALNo ratings yet

- Enhancing Cybersecurity: The Power of Artificial Intelligence in Threat Detection and PreventionDocument6 pagesEnhancing Cybersecurity: The Power of Artificial Intelligence in Threat Detection and PreventionIJAERS JOURNALNo ratings yet

- Impacts On The Mental Health of Professionals in A Prisonal System in Alagoas During The Covid-19 PandemicDocument7 pagesImpacts On The Mental Health of Professionals in A Prisonal System in Alagoas During The Covid-19 PandemicIJAERS JOURNALNo ratings yet

- Study of The Extraction Process of The Pleurotus Citrinopileatus Mushroom and Evaluation of The Biological Activity of The ExtractDocument8 pagesStudy of The Extraction Process of The Pleurotus Citrinopileatus Mushroom and Evaluation of The Biological Activity of The ExtractIJAERS JOURNALNo ratings yet

- The Economic Impact of Coronavirus Disease (COVID-19) : A Study On Tourism Indicators in The Kingdom of Saudi ArabiaDocument4 pagesThe Economic Impact of Coronavirus Disease (COVID-19) : A Study On Tourism Indicators in The Kingdom of Saudi ArabiaIJAERS JOURNALNo ratings yet

- VCO Rancidity Analysis Refers To Fermentation Time That Produced by Gradual Heating MethodDocument6 pagesVCO Rancidity Analysis Refers To Fermentation Time That Produced by Gradual Heating MethodIJAERS JOURNAL100% (1)

- The Economic Impact of Coronavirus Disease (COVID-19) : A Study On Tourism Indicators in The Kingdom of Saudi ArabiaDocument4 pagesThe Economic Impact of Coronavirus Disease (COVID-19) : A Study On Tourism Indicators in The Kingdom of Saudi ArabiaIJAERS JOURNALNo ratings yet

- Analysis of The Thermal Behavior of Masonry Concrete Block With Internal Natural Element CoatingDocument11 pagesAnalysis of The Thermal Behavior of Masonry Concrete Block With Internal Natural Element CoatingIJAERS JOURNALNo ratings yet

- Constructed Wetlands: Technology For Removing Drug Concentration From WaterDocument12 pagesConstructed Wetlands: Technology For Removing Drug Concentration From WaterIJAERS JOURNALNo ratings yet

- Associativism As Strategy of Reaching Territorial Rights, Programs, Projects and Public Policies of Rural Development: The Case of The São Francisco Do Mainã Community, Manaus, AMDocument9 pagesAssociativism As Strategy of Reaching Territorial Rights, Programs, Projects and Public Policies of Rural Development: The Case of The São Francisco Do Mainã Community, Manaus, AMIJAERS JOURNALNo ratings yet

- Process Sequence Optimization and Structural Analysis of Nanoscale Heterostructure Using Compound Semiconductors AlAsSb/In0.59Ga0.41As/GaAs0.53Sb0.47Document5 pagesProcess Sequence Optimization and Structural Analysis of Nanoscale Heterostructure Using Compound Semiconductors AlAsSb/In0.59Ga0.41As/GaAs0.53Sb0.47IJAERS JOURNALNo ratings yet

- Childhood/ Pediatric Cancer: Nursing Care in Oncopediatrics With A Central Focus On HumanizationDocument12 pagesChildhood/ Pediatric Cancer: Nursing Care in Oncopediatrics With A Central Focus On HumanizationIJAERS JOURNALNo ratings yet

- Association of Bacterial Vaginosis To Atypia in Squamous Cells of The CervixDocument15 pagesAssociation of Bacterial Vaginosis To Atypia in Squamous Cells of The CervixIJAERS JOURNALNo ratings yet

- Multiprofessional Care For A Patient With Gestational DiabetesDocument12 pagesMultiprofessional Care For A Patient With Gestational DiabetesIJAERS JOURNALNo ratings yet

- Morphometric Analysis of The Ekole River As A Consequence of Climate Change: A Case Study in Yenagoa, Bayelsa State, NigeriaDocument9 pagesMorphometric Analysis of The Ekole River As A Consequence of Climate Change: A Case Study in Yenagoa, Bayelsa State, NigeriaIJAERS JOURNALNo ratings yet

- Komla Uwolowudu Amegna: International Journal of Advanced Engineering Research and Science (IJAERS)Document9 pagesKomla Uwolowudu Amegna: International Journal of Advanced Engineering Research and Science (IJAERS)IJAERS JOURNALNo ratings yet

- Morphometric Analysis of The Ekole River As A Consequence of Climate Change: A Case Study in Yenagoa, Bayelsa State, NigeriaDocument9 pagesMorphometric Analysis of The Ekole River As A Consequence of Climate Change: A Case Study in Yenagoa, Bayelsa State, NigeriaIJAERS JOURNALNo ratings yet

- Sociodemographic and Clinical Profile of Women With Uterine Cervical Cancer Attended in An Oncological Hospital in The State of Acre, BrazilDocument9 pagesSociodemographic and Clinical Profile of Women With Uterine Cervical Cancer Attended in An Oncological Hospital in The State of Acre, BrazilIJAERS JOURNALNo ratings yet

- Modeling of Geological and Geophysical Data, Onshore Field of Potiguar Basin, Northeastern BrazilDocument5 pagesModeling of Geological and Geophysical Data, Onshore Field of Potiguar Basin, Northeastern BrazilIJAERS JOURNALNo ratings yet

- Humanization in Undergraduate Medical Education: The Brazilian Learner's PerspectiveDocument12 pagesHumanization in Undergraduate Medical Education: The Brazilian Learner's PerspectiveIJAERS JOURNALNo ratings yet

- Mining and Its Impacts On Environment and Health With Special Reference To Ballari District, Karnataka, IndiaDocument7 pagesMining and Its Impacts On Environment and Health With Special Reference To Ballari District, Karnataka, IndiaIJAERS JOURNALNo ratings yet

- Assessment of The Risk of Cardiovascular Diseases and Its Relationship With Heart Rate Variability in Physically Active and Sedentary IndividualsDocument13 pagesAssessment of The Risk of Cardiovascular Diseases and Its Relationship With Heart Rate Variability in Physically Active and Sedentary IndividualsIJAERS JOURNALNo ratings yet

- Does Blended Learning Approach Affect Madrasa Students English Writing Errors? A Comparative StudyDocument12 pagesDoes Blended Learning Approach Affect Madrasa Students English Writing Errors? A Comparative StudyIJAERS JOURNALNo ratings yet

- The Psychologist's Role in The Process of Listening To Children Victims of Sexual Violence in Legal ProceedingsDocument8 pagesThe Psychologist's Role in The Process of Listening To Children Victims of Sexual Violence in Legal ProceedingsIJAERS JOURNALNo ratings yet

- Midterm Exam Result Ce199-1l 2Q1920Document3 pagesMidterm Exam Result Ce199-1l 2Q1920RA CarpioNo ratings yet

- Propeller forces and typesDocument2 pagesPropeller forces and typesEdison Gutierrez CapunoNo ratings yet

- Pneumatic Tyres: CMR Engineering CollegeDocument17 pagesPneumatic Tyres: CMR Engineering CollegeHemanth Rama Krishna YernagulaNo ratings yet

- Hot Rolled Sheet Pile SHZ Catalogue PDFDocument2 pagesHot Rolled Sheet Pile SHZ Catalogue PDFkiet eelNo ratings yet

- 02-OceanStor Dorado 3 Highlights and 9 Must-Know Points 1.0Document5 pages02-OceanStor Dorado 3 Highlights and 9 Must-Know Points 1.0QQNo ratings yet

- Logic CHPT71Document27 pagesLogic CHPT71Eronjosh FontanozaNo ratings yet

- Leroy Somer 3434c - GB-NyDocument28 pagesLeroy Somer 3434c - GB-NyCris_eu09100% (1)

- Introduction to Continuous Optimization for Machine LearningDocument10 pagesIntroduction to Continuous Optimization for Machine LearningMarcos OliveiraNo ratings yet

- The Professional DesktopDocument318 pagesThe Professional Desktopalintuta2No ratings yet

- Notes Measures of Variation Range and Interquartile RangeDocument11 pagesNotes Measures of Variation Range and Interquartile RangedburrisNo ratings yet

- User Mode I. System Support Processes: de Leon - Dolliente - Gayeta - Rondilla It201 - Platform Technology - TPDocument6 pagesUser Mode I. System Support Processes: de Leon - Dolliente - Gayeta - Rondilla It201 - Platform Technology - TPCariza DollienteNo ratings yet

- Astm D5501Document3 pagesAstm D5501mhmdgalalNo ratings yet

- Inferential Statistics: Estimation and Confidence IntervalsDocument19 pagesInferential Statistics: Estimation and Confidence IntervalsHasan HubailNo ratings yet

- DSD - Assignment 1 2018Document3 pagesDSD - Assignment 1 2018Naveen KumarNo ratings yet

- Ce010 601 Design of Steel Structures Ce PDFDocument5 pagesCe010 601 Design of Steel Structures Ce PDFPrakash rubanNo ratings yet

- MSYS-1 0 11-ChangesDocument3 pagesMSYS-1 0 11-ChangesCyril BerthelotNo ratings yet

- 4495 10088 1 PBDocument7 pages4495 10088 1 PBGeorgius Kent DiantoroNo ratings yet

- Design of Shaft Straightening MachineDocument58 pagesDesign of Shaft Straightening MachineChiragPhadkeNo ratings yet

- Indian Standards List As On Jan2009Document216 pagesIndian Standards List As On Jan2009Vasudeva Pavan VemuriNo ratings yet

- Biology - Physics Chemistry MCQS: Gyanm'S General Awareness - November 2014Document13 pagesBiology - Physics Chemistry MCQS: Gyanm'S General Awareness - November 2014santosh.manojNo ratings yet

- Solvent based printing inks applicationsDocument34 pagesSolvent based printing inks applicationsAmna liaquatNo ratings yet

- Control Lights with SOU-1 Twilight SwitchDocument1 pageControl Lights with SOU-1 Twilight SwitchjsblNo ratings yet

- VLSI Design: Introduction & Motivation Introduction & MotivationDocument33 pagesVLSI Design: Introduction & Motivation Introduction & MotivationPriyanka SharmaNo ratings yet

- Notifier Battery Calculations-ReadmeDocument11 pagesNotifier Battery Calculations-ReadmeJeanCarlosRiveroNo ratings yet