Professional Documents

Culture Documents

428L2 PDF

Uploaded by

esquisofOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

428L2 PDF

Uploaded by

esquisofCopyright:

Available Formats

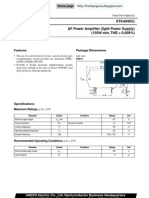

PROFET ITS428L2

Smart High-Side Power Switch

for Industrial Applications

One Channel: 60m

Status Feedback

Product Summary Package

On-state Resistance RON 60m PG-TO252-5-11

Operating Voltage Vbb(on) 4.75...41V

Nominal load current IL(NOM) 7.0A

Current limitation IL(SCr) 17A

Operating temperature Ta -30 +85C

General Description

N channel vertical power MOSFET with charge pump, ground referenced CMOS compatible input and

diagnostic feedback, monolithically integrated in Smart SIPMOS technology.

Providing embedded protective functions

Applications

C compatible high-side power switch with diagnostic feedback for 5V, 12V and 24V grounded loads in

industrial applications

All types of resistive, inductive and capacitve loads

Most suitable for loads with high inrush currents, so as lamps

Replaces electromechanical relays, fuses and discrete circuits

Basic Functions

Very low standby current

CMOS compatible input

Improved electromagnetic compatibility (EMC)

Fast demagnetization of inductive loads

Stable behaviour at undervoltage

Wide operating voltage range

Logic ground independent from load ground

Block Diagram

Protection Functions

Short circuit protection Vbb

Overload protection

Current limitation

Thermal shutdown

Overvoltage protection (including load dump) with external

resistor IN Logic

with

Reverse battery protection with external resistor

protection

Loss of ground and loss of Vbb protection ST functions OUT

Electrostatic discharge protection (ESD)

Diagnostic Function Load

PROFET

Diagnostic feedback with open drain output

GND

Open load detection in ON-state

Feedback of thermal shutdown in ON-state

Infineon Technologies AG Page 1 of 13 2006-Mar-16

PROFET ITS428L2

Functional diagram

overvoltage gate current limit VBB

protection control

+

internal charge

logic pump clamp for

voltage supply inductive load

OUT

IN temperature

sensor

ESD

LOAD

Open load

ST detection

GND

PROFET

Pin Definitions and Functions Pin configuration

(top view)

Pin Symbol Function

GND Tab = VBB

1 Logic ground

Input, activates the power switch in

2 IN

case of logical high signal

Positive power supply voltage

3 Vbb

The tab is shorted to pin 3

4 ST 1 2 (3) 4 5

Diagnostic feedback, low on failure

GND IN ST OUT

5 OUT Output to the load

Positive power supply voltage

Tab Vbb

The tab is shorted to pin 3

Infineon Technologies AG Page 2 2006-Mar-16

PROFET ITS428L2

Maximum Ratings at Tj = 25 C unless otherwise specified

Parameter Symbol Values Unit

Supply voltage (overvoltage protection see page 4) Vbb 43 V

Supply voltage for full short circuit protection Vbb 24 V

Tj Start=-40 ...+150C

dump protection1) VLoadDump = VA + Vs, VA = 13.5 V

3)

Load VLoad dump 60 V

2)

RI = 2 , RL= 4.0 , td= 200 ms, IN= low or high

Load current (Current limit, see page 5) IL self-limited A

Junction temperature Tj 150 C

Operating temperature range Ta -30 ...+85

Storage temperature range Tstg -40 ...+105

Power dissipation (DC), TC 25 C Ptot 75 W

Maximal switchable inductance, single pulse

Vbb = 12V, Tj,start = 150C, TC = 150C const.

4

(See diagram on page 9) IL(ISO) = 7 A, RL = 0 ; E )AS=0.19J: ZL 5.6 mH

Electrostatic discharge capability (ESD) IN: VESD 1.0 kV

(Human Body Model) ST: 4.0

out to all other pins shorted: 8.0

acc. MIL-STD883D, method 3015.7 and

ESD assn. std. S5.1-1993; R=1.5k; C=100pF

Input voltage (DC) VIN -10 ... +16 V

Current through input pin (DC) IIN 2.0 mA

Current through status pin (DC) IST 5.0

see internal circuit diagrams page 8

Thermal Characteristics

Parameter and Conditions Symbol Values Unit

min typ max

Thermal resistance chip - case: RthJC -- -- 1.67 K/W

junction - ambient (free air): RthJA -- -- 75

device on pcb5): -- 42 --

1)

Supply voltages higher than Vbb(AZ) require an external current limit for the GND and status pins (a 150

resistor for the GND connection is recommended).

2)

RI = internal resistance of the load dump test pulse generator

3)

VLoad dump is setup without the DUT connected to the generator per ISO 7637-1 and DIN 40839

4)

EAS is the maximum inductive switch-off energy

5)

Device on 50mm*50mm*1.5mm epoxy PCB FR4 with 6cm2 (one layer, 70m thick) copper area for Vbb

connection. PCB is vertical without blown air.

Infineon Technologies AG Page 3 2006-Mar-16

PROFET ITS428L2

Electrical Characteristics

Parameter and Conditions Symbol Values Unit

at Tj =-40...+150C, Vbb = 12 V unless otherwise specified min typ max

Load Switching Capabilities and Characteristics

On-state resistance (pin 3 to 5)

IL = 2 A; VBB 7V Tj=25 C: RON -- 50 60 m

Tj=150 C: 100 120

see diagram, page 10

Nominal load current, (pin 3 to 5)

ISO 10483-1, 6.7:VON=0.5V, TC=85C IL(ISO) 5.8 7.0 -- A

Output current (pin 5) while GND disconnected or IL(GNDhigh) -- -- 2 mA

GND pulled up6) , Vbb=30 V, VIN= 0,

see diagram page 8

Turn-on time IN to 90% VOUT: ton 30 100 200 s

Turn-off time IN to 10% VOUT: toff 30 100 200

RL = 12 ,

Slew rate on dV /dton 0.1 -- 1 V/s

10 to 30% VOUT, RL = 12 ,

Slew rate off -dV/dtoff 0.1 -- 1 V/s

70 to 40% VOUT, RL = 12 ,

Operating Parameters

Operating voltage Tj =-40 Vbb(on) 4.75 -- 41 V

Tj =+25...+150C: -- 43

Overvoltage protection7) Tj =-40C: Vbb(AZ) 41 -- -- V

Ibb=40 mA Tj =25...+150C: 43 47 52

Standby current (pin 3) 8) Tj=-40...+25C: Ibb(off) -- 5 9 A

VIN=0; see diagram on page 10 Tj= 150C: -- -- 25

Off-State output current (included in Ibb(off)) IL(off) -- 1 10 A

VIN=0

Operating current 9), VIN=5 V IGND -- 0.8 1.5 mA

6)

not subject to production test, specified by design

7)

Supply voltages higher than Vbb(AZ) require an external current limit for the GND and status pins (a 150

resistor for the GND connection is recommended. See also VON(CL) in table of protection functions and

circuit diagram page 8.

8

) Measured with load

9)

Add IST, if IST > 0, add IIN, if VIN>5.5 V

Infineon Technologies AG Page 4 2006-Mar-16

PROFET ITS428L2

Parameter and Conditions Symbol Values Unit

at Tj =-40...+150C, Vbb = 12 V unless otherwise specified min typ max

Protection Functions10)

Current limit (pin 3 to 5) IL(lim)

(see timing diagrams on page 12) Tj =-40C: 21 28 36 A

Tj =25C: 17 22 31

Tj =+150C: 12 16 24

Repetitive short circuit shutdown current limit IL(SCr)

Tj = Tjt (see timing diagrams, page 12) -- 17 -- A

Thermal shutdown time11 Tj,start = 25C: toff(SC) -- 7.5 -- ms

(see timing diagrams on page 12)

Output clamp (inductive load switch off) 41

at VOUT = Vbb - VON(CL) IL= 40 mA: VON(CL) 43 47 52 V

Thermal overload trip temperature Tjt 150 -- -- C

Thermal hysteresis Tjt -- 10 -- K

Reverse battery (pin 3 to 1) 12) -Vbb -- -- 32 V

Reverse battery voltage drop (Vout > Vbb)13)

IL = -2 A Tj=150 C: -VON(rev) -- 600 -- mV

Diagnostic Characteristics

Open load detection current IL (OL) 10 -- 500 mA

(on-condition)

10)

Integrated protection functions are designed to prevent IC destruction under fault conditions described in the

data sheet. Fault conditions are considered as "outside" normal operating range. Protection functions are

not designed for continuous repetitive operation.

11)

Device on 50mm*50mm*1.5mm epoxy PCB FR4 with 6cm2 (one layer, 70m thick) copper area for Vbb

connection. PCB is vertical without blown air.

12)

Requires 150 resistor in GND connection. The reverse load current through the intrinsic drain-source

diode has to be limited by the connected load. Note that the power dissipation is higher compared to normal

operating conditions due to the voltage drop across the intrinsic drain-source diode. The temperature

protection is not active during reverse current operation! Input and Status currents have to be limited (see

max. ratings page 3 and circuit page 8).

13)

not subject to production test, specified by design

Infineon Technologies AG Page 5 2006-Mar-16

PROFET ITS428L2

Parameter and Conditions Symbol Values Unit

at Tj =-40...+150C, Vbb = 12 V unless otherwise specified min typ max

Input and Status Feedback14)

Input resistance RI 2.5 3.5 6 k

see circuit page 8

Input turn-on threshold voltage VIN(T+) 1.7 -- 3.2 V

Input turn-off threshold voltage VIN(T-) 1.5 -- -- V

Input threshold hysteresis VIN(T) -- 0.5 -- V

Off state input current (pin 2), VIN = 0.4 V IIN(off) 1 -- 50 A

On state input current (pin 2), VIN = 5 V IIN(on) 20 50 90 A

Delay time for status with open load after switch off td(ST OL4) 100 520 900 s

(see timing diagrams on page 12)

Status output (open drain)

Zener limit voltage IST = +1.6 mA: VST(high) 5.4 6.1 -- V

ST low voltage IST = +1.6 mA: VST(low) -- -- 0.4

14)

If a ground resistor RGND is used, add the voltage drop across this resistor.

Infineon Technologies AG Page 6 2006-Mar-16

PROFET ITS428L2

Truth Table

Input Output Status

level level BTS 428L2

Normal L L H

operation H H H

Open load L Z H

H H L

Overtem- L L H

perature H L L

L = "Low" Level X = don't care Z = high impedance, potential depends on external circuit

H = "High" Level Status signal after the time delay shown in the diagrams (see fig 5. page 12)

Infineon Technologies AG Page 7 2006-Mar-16

PROFET ITS428L2

Terms Overvolt. and reverse batt. protection

+ 5V

+ Vbb

Ibb

3 R ST

I IN V

Vbb Z2

RI

IN IN

2 IL VON

PROFET OUT Logic

I ST 5

ST

4 R ST ST OUT

V V ST GND

IN

V

V

bb

1 IGND V OUT

Z1 PROFET

R

GND GND

R Load

R GND

Signal GND Load GND

Input circuit (ESD protection) VZ1 = 6.1 V typ., VZ2 = 47 V typ., RGND = 150 ,

RST= 15 k, RI= 3.5 k typ.

R In case of reverse battery the load current has to be

I

IN

limited by the load. Temperature protection is not

active

ESD-ZD I

I

I

Open-load detection in on-state

GND Open load, if VON < RONIL(OL); IN high

+ V bb

The use of ESD zener diodes as voltage clamp at DC

conditions is not recommended

Status output

VON

ON

+5V

OUT

R ST(ON) Open load

ST Logic

unit detection

ESD-

ZD

GND

ESD-Zener diode: 6.1 V typ., max 5.0 mA; RST(ON) < 375 GND disconnect

at 1.6 mA. The use of ESD zener diodes as voltage clamp at

DC conditions is not recommended.

3

Inductive and overvoltage output clamp IN

Vbb

+ V bb 2

PROFET OUT

V

Z 5

ST

4

GND

VON

V V V 1 V

bb IN ST GND

OUT

GND PROFET Any kind of load. In case of Input=high is VOUT VIN - VIN(T+) .

Due to VGND >0, no VST = low signal available.

VON clamped to 47 V typ.

Infineon Technologies AG Page 8 2006-Mar-16

PROFET ITS428L2

GND disconnect with GND pull up Inductive Load switch-off energy

dissipation

3 E bb

Vbb

IN E AS

2

ELoad

PROFET OUT

5 Vbb

IN

ST

4

GND

PROFET OUT

1

= ST EL

V V V GND L

{

V IN ST GND

bb

ZL RL ER

Any kind of load. If VGND > VIN - VIN(T+) device stays off

Due to VGND >0, no VST = low signal available.

Vbb disconnect with energized inductive

Energy stored in load inductance:

load 2

EL = 1/2LI L

3 While demagnetizing load inductance, the energy

high Vbb dissipated in PROFET is

IN

2

EAS= Ebb + EL - ER= VON(CL)iL(t) dt,

PROFET OUT

5

with an approximate solution for RL > 0 :

ST

4

GND IL L ILRL

EAS= 2R (Vbb + |VOUT(CL)|) ln (1+ |V )

1 L OUT(CL)|

Maximum allowable load inductance for

V

bb a single switch off

L = f (IL ); Tj,start = 150C,TC = 150C const.,

For inductive load currents up to the limits defined by ZL Vbb = 12 V, RL = 0

(max. ratings and diagram on page 9) each switch is

protected against loss of Vbb. ZL [mH]

Consider at your PCB layout that in the case of Vbb dis- 1000

connection with energized inductive load all the load current

flows through the GND connection.

100

10

0.1

2 7 12 17

IL [A]

Infineon Technologies AG Page 9 2006-Mar-16

PROFET ITS428L2

Typ. on-state resistance

RON = f (Vbb,Tj ); IL = 2 A, IN = high

RON [m]

175

150

125

100 Tj=150C

75

50 25C

-40C

25

0

3 5 7 9 30 40

Vbb [V]

Typ. standby current

Ibb(off) = f (Tj ); Vbb = 9...34 V, IN1,2 = low

Ibb(off) [A]

45

40

35

30

25

20

15

10

0

-50 0 50 100 150 200

Tj [C]

Infineon Technologies AG Page 10 2006-Mar-16

PROFET ITS428L2

Timing diagrams

Figure 1a: Vbb turn on: Figure 2b: Switching a lamp,

IN

IN

V bb

ST

V

OUT

V

OUT

ST open drain I

L

t

t

proper turn on under all conditions

The initial peak current should be limited by the lamp and not by the

current limit of the device.

Figure 2a: Switching a resistive load, Figure 2c: Switching an inductive load

turn-on/off time and slew rate definition:

IN IN

VOUT ST

90%

t on dV/dtoff

V

OUT

dV/dton t

off

10%

IL

I

L

I L(OL)

t t

*) if the time constant of load is too large, open-load-status may

occur

Infineon Technologies AG Page 11 2006-Mar-16

PROFET ITS428L2

Figure 3a: Short circuit Figure 5a: Open load: detection in ON-state, open

shut down by overtemperature, reset by cooling load occurs in on-state

IN other channel: normal operation

IN

t t

d(ST OL) d(ST OL)

I ST

L

I

L(lim)

I VOUT

L(SCr)

t

off(SC)

ST normal open normal

I

L

t

t

Heating up of the chip may require several milliseconds, depending

on external conditions td(ST OL) = 10 s typ.

Figure 4a: Overtemperature: Figure 5b: Open load: turn on/off to open load

Reset if Tj <Tjt

IN

IN

t

ST d(STOL4)

ST

I

L

V

OUT

T

J

Infineon Technologies AG Page 12 2006-Mar-16

PROFET ITS428L2

Published by

Package and Ordering Code Infineon Technologies AG,

All dimensions in mm St.-Martin-Strasse 53,

D-81669 Mnchen

DPAK-5 Pin: PG-TO252-5-11 Infineon Technologies AG 2006

Sales code ITS428L2 All Rights Reserved.

Ordering code SP000221220

Attention please!

The information herein is given to describe certain

+0.15

components and shall not be considered as a guarantee of

6.5 -0.05 characteristics.

A

5.7 MAX.

1) 2.3 +0.05

-0.10

Terms of delivery and rights to technical change reserved.

(5) B 0.5 +0.08

-0.04

(4.24) 1 0.1

We hereby disclaim any and all warranties, including but not

0.9 +0.20

-0.01

limited to warranties of non-infringement, regarding circuits,

0.8 0.15

descriptions and charts stated herein.

6.22 -0.2

9.98 0.5

0...0.15

Infineon Technologies is an approved CECC manufacturer.

0.51 MIN.

0.15 MAX. Information

per side 5 x 0.6 0.1 0.5 +0.08

-0.04 For further information on technology, delivery terms and

1.14 conditions and prices please contact your nearest Infineon

0.1 B Technologies Office in Germany or our Infineon

4.56

0.25 M A B Technologies Representatives worldwide (see address list).

1) Includes mold flashes on each side. Warnings

All metal surfaces tin plated, except area of cut.

Due to technical requirements components may contain

dangerous substances. For information on the types in

question please contact your nearest Infineon Technologies

Office.

Infineon Technologies Components may only be used in life-

support devices or systems with the express written

approval of Infineon Technologies, if a failure of such

components can reasonably be expected to cause the

failure of that life-support device or system, or to affect the

safety or effectiveness of that device or system. Life support

devices or systems are intended to be implanted in the

human body, or to support and/or maintain and sustain

and/or protect human life. If they fail, it is reasonable to

assume that the health of the user or other persons may be

endangered.

Infineon Technologies AG Page 13 2006-Mar-16

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- As 68 RsDocument6 pagesAs 68 Rsbatman2054100% (2)

- Engine ImmobilizerDocument51 pagesEngine ImmobilizerYargen Gonzalez100% (4)

- 1ktze Pinin-PinoutDocument11 pages1ktze Pinin-PinoutKooked100% (9)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- SolenoidDocument34 pagesSolenoidesquisof100% (2)

- SolenoidDocument34 pagesSolenoidesquisof100% (2)

- SolenoidDocument34 pagesSolenoidesquisof100% (2)

- Fuso FE - FG PartDocument156 pagesFuso FE - FG Partesquisof86% (7)

- Toyota Rav4 2008-U241e PDFDocument396 pagesToyota Rav4 2008-U241e PDFesquisof78% (9)

- Manual de Taller Chery QQDocument635 pagesManual de Taller Chery QQOrlando Parra100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Series 60 EGR Tech Guide 2005Document195 pagesSeries 60 EGR Tech Guide 2005esquisof67% (3)

- 1KR-FE Engine Control SystemDocument346 pages1KR-FE Engine Control SystemMortada Alsonni79% (19)

- 1KR-FE Engine Control SystemDocument346 pages1KR-FE Engine Control SystemMortada Alsonni79% (19)

- K41A - CVT - General InfoDocument60 pagesK41A - CVT - General Infoesquisof86% (7)

- Diagnostics SRSDocument172 pagesDiagnostics SRSesquisofNo ratings yet

- XBox 360 Hardware DebugDocument36 pagesXBox 360 Hardware DebugAlexander Rivas Alpizar100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Ssangyong PDFDocument106 pagesSsangyong PDFdaniel100% (1)

- 15 - Automatic TransaxleDocument246 pages15 - Automatic TransaxleesquisofNo ratings yet

- Abbreviations Used in This ManualDocument126 pagesAbbreviations Used in This ManualSteve Fisher100% (6)

- Yaris 1nz-Fe (Engine)Document12 pagesYaris 1nz-Fe (Engine)esquisofNo ratings yet

- SMD CatalogDocument80 pagesSMD Catalogpbradaric91% (11)

- IR Jammer 1 0Document24 pagesIR Jammer 1 01234567890awsNo ratings yet

- Engine MechanicDocument631 pagesEngine Mechanicgeorge100% (1)

- GEK - 91741A Dynamic Retarding AssemblyDocument12 pagesGEK - 91741A Dynamic Retarding AssemblyKJDNKJZEFNo ratings yet

- Laboratory Manual For Ac Electrical CircuitsDocument80 pagesLaboratory Manual For Ac Electrical CircuitsAngelo PalamingNo ratings yet

- 3c-E ToyotaDocument3 pages3c-E Toyotaesquisof91% (46)

- Mini Inverter Mini Project Report.Document34 pagesMini Inverter Mini Project Report.sravan75% (32)

- Digital VoltmeterDocument3 pagesDigital VoltmetertowfiqeeeNo ratings yet

- Hip0061 PDFDocument10 pagesHip0061 PDFesquisofNo ratings yet

- 1 Secm 03 02 PDFDocument24 pages1 Secm 03 02 PDFesquisofNo ratings yet

- Y220 WML 601Document61 pagesY220 WML 601esquisofNo ratings yet

- Code 368 PDFDocument2 pagesCode 368 PDFesquisof0% (1)

- Code 368 PDFDocument2 pagesCode 368 PDFesquisof0% (1)

- 428L2 PDFDocument13 pages428L2 PDFesquisofNo ratings yet

- VitaraDocument1 pageVitaraesquisofNo ratings yet

- Conector de Diagnóstico Pajero IoDocument3 pagesConector de Diagnóstico Pajero Ioesquisof100% (1)

- Arta - Application Note: No 1: The Arta MeasuringboxDocument10 pagesArta - Application Note: No 1: The Arta MeasuringboxAlessandro BiliottiNo ratings yet

- Chapter Overview: 3: Sensors and ActuatorsDocument93 pagesChapter Overview: 3: Sensors and ActuatorsGigiNo ratings yet

- Top252-262 Topswitch-Hx FamilyDocument50 pagesTop252-262 Topswitch-Hx FamilyAlfredo Valencia RodriguezNo ratings yet

- Force Balance Sensor TechnologyDocument5 pagesForce Balance Sensor TechnologyAngela Maribel Valdez NeyraNo ratings yet

- Luanshya Technical and Business College Management Board Diploma in Electrical Engineering Electrical Instrumentation (Dee 231)Document8 pagesLuanshya Technical and Business College Management Board Diploma in Electrical Engineering Electrical Instrumentation (Dee 231)Alfred K ChilufyaNo ratings yet

- As WS 4 X Phy 12.3 ElectricityDocument4 pagesAs WS 4 X Phy 12.3 ElectricityHemant PadalkarNo ratings yet

- CHF190104xBF Series 800 W Power RF Flanged Chip Termination/ResistorDocument1 pageCHF190104xBF Series 800 W Power RF Flanged Chip Termination/ResistorMPIMLACNo ratings yet

- Ohm's Lax Lab - Physics Lab (#10)Document4 pagesOhm's Lax Lab - Physics Lab (#10)Tasheera ThompsonNo ratings yet

- 21V FR95SDocument47 pages21V FR95SW Armando Cardoza Padilla0% (1)

- STK4048 AF Power Amplifier (Split Power Supply) (150W Min, THD 0.008%)Document8 pagesSTK4048 AF Power Amplifier (Split Power Supply) (150W Min, THD 0.008%)21210606100% (2)

- GLOSSARY OF ELECTRICAL TERMS AND SYMBOLSDocument2 pagesGLOSSARY OF ELECTRICAL TERMS AND SYMBOLSLuis RocaNo ratings yet

- Aug 55 XDocument15 pagesAug 55 XLoz LizNo ratings yet

- Electrical Quantities 6 QPDocument13 pagesElectrical Quantities 6 QPdhany aarunNo ratings yet

- Post Lab 7 - Linear and Nonlinear ResistorsDocument3 pagesPost Lab 7 - Linear and Nonlinear ResistorsJuan Carlos De DiosNo ratings yet

- Measuring Resistances in Series, Parallel and Combined CircuitsDocument10 pagesMeasuring Resistances in Series, Parallel and Combined CircuitsMartyn PereiraNo ratings yet

- AN5151Document5 pagesAN5151Hernan Ortiz EnamoradoNo ratings yet

- Led LCD TV: Service ManualDocument54 pagesLed LCD TV: Service Manualku1989No ratings yet

- Ed Grade 9 Unit Practice Test Science Electrical Principles TechnologiesDocument14 pagesEd Grade 9 Unit Practice Test Science Electrical Principles TechnologiesRadha RamineniNo ratings yet

- MTL BARRIERS FOR HOCHIKI I.S. DETECTORSDocument2 pagesMTL BARRIERS FOR HOCHIKI I.S. DETECTORSЕвгений АврушкинNo ratings yet

- SIC9762D SISemiconductorsDocument14 pagesSIC9762D SISemiconductorsVaibhavNo ratings yet

- Solutions To The Suggested Problems of Ch.27Document35 pagesSolutions To The Suggested Problems of Ch.27Blaze FrostNo ratings yet

- SV055IS5Document205 pagesSV055IS5Mario Duran100% (1)

- Module 2 Series-Parallel and ConductanceDocument25 pagesModule 2 Series-Parallel and Conductancesuga linNo ratings yet

- EEDesignLabManual v0.9 PDFDocument69 pagesEEDesignLabManual v0.9 PDFMahendra YadavNo ratings yet