Professional Documents

Culture Documents

Joint Report

Uploaded by

homerCODOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Joint Report

Uploaded by

homerCODCopyright:

Available Formats

Project Revision 0

Address

Document

GRAITEC INNOVATION

www.graitec.com Designed by Date 01/25/2017

17 Burospace 91572 Bivres Verified by Date 01/25/2017

Moment End Plate Report

Maximum Work Ratio 91.26 % Passed

Table of Contents

1 Joint description.................................................................................................................................................. 3

2 Load combinations description.......................................................................................................................... 5

3 Design Assumptions............................................................................................................................................ 5

4 Compression verifications.................................................................................................................................. 6

4.1 Compression resistance of the beam.............................................................................................................................6

4.2 Column web panel in shear...........................................................................................................................................7

4.2.1 Tensioned/Compressed Stiffeners Resistance..............................................................................................7

4.3 Column web buckling...................................................................................................................................................8

4.4 Column web panel in transverse compression..............................................................................................................8

5 Stiffeners verifications...................................................................................................................................... 11

6 Tension verifications......................................................................................................................................... 12

6.1 Column web in tension verification............................................................................................................................12

6.2 Column flange in bending verification.......................................................................................................................12

7 Shear verifications............................................................................................................................................. 13

7.1 Shear yielding verification of the plate.......................................................................................................................13

8 Bending moment verifications.......................................................................................................................... 14

8.1 Bending moment resistance........................................................................................................................................14

8.2 Joint bending moment verification.............................................................................................................................14

9 Weld verifications............................................................................................................................................. 15

9.1 Weld dimension conditions.........................................................................................................................................15

9.2 Weld verification by Real Moment (weld design method: Simplified).....................................................................15

10 Rotational Stiffness........................................................................................................................................... 15

10.1 Stiffness coefficients for basic joint components (EN 1993-1-8, Table 6.11)...........................................................15

10.2 Rotational Stiffness Classification..............................................................................................................................16

10.3 Rotational stiffness calculation...................................................................................................................................16

11 Warning and error messages........................................................................................................................... 17

Steel Connection Designer 2017

01-25-2017, 08:57:31 Page 1 of 17

Project Revision 0

Address

Document

GRAITEC INNOVATION

www.graitec.com Designed by Date 01/25/2017

17 Burospace 91572 Bivres Verified by Date 01/25/2017

Steel Connection Designer 2017

01-25-2017, 08:57:31 Page 2 of 17

Project Revision 0

Address

Document

GRAITEC INNOVATION

www.graitec.com Designed by Date 01/25/2017

17 Burospace 91572 Bivres Verified by Date 01/25/2017

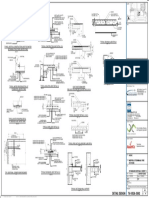

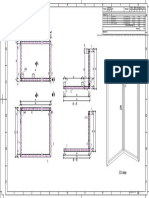

1 Joint description

Beam IPE270 Section Class 1)

Material: S235

Dimensions

Column IPE330 Section Class 1)

Material: S235

Dimensions 2 x Main Stiffener

Material: S235

2 x Main Stiffener

Material: S235

Steel Connection Designer 2017

01-25-2017, 08:57:31 Page 3 of 17

Project Revision 0

Address

Document

GRAITEC INNOVATION

www.graitec.com Designed by Date 01/25/2017

17 Burospace 91572 Bivres Verified by Date 01/25/2017

Steel Connection Designer 2017

01-25-2017, 08:57:31 Page 4 of 17

Project Revision 0

Address

Document

GRAITEC INNOVATION

www.graitec.com Designed by Date 01/25/2017

17 Burospace 91572 Bivres Verified by Date 01/25/2017

2 Load combinations description

Comb. Load Combination Comb. V M N

Index Description Type (kN) (kNm) (kN)

102 1x[1 G] -10.00 -30.00 10.00

103 1.35x[1 G] -13.50 -40.50 13.50

104 1x[1 G]+1.5x[2 Q] -47.50 -75.00 55.00

105 1.35x[1 G]+1.5x[2 Q] -51.00 -85.50 58.50

Maximum Efforts -10.00 -30.00 58.50

Minimum Efforts -51.00 -85.50 10.00

The torsor is defined in the member's local system!

3 Design Assumptions

Design standards

EN 1993-1-1 Design of Steel Structures. General Rules and Rules for Buildings

EN 1993-1-8 Design of Steel Structures. Design of Joints

EN 1992-1-1 Design of Concrete Structures. General Rules and Rules for Buildings

EN 1993-1 National Annex: General Eurocode.

Units

Dimensions: m Area: cm

Forces: kN Inertia modulus: m

Bending moments: kNm Inertia Moment: cm

Stresses: MPa Rotational Stiffness: kNm/rad

Angles:

Bolts

The shear plane passes through the THREADED part of the bolt.

T-Stub Failure Method: Method 1

Prying Effect: Auto

Approximate value for the transformation parameter, according to Table 5.4:

Bolt tension reduction factor, according to EN 1090:

Steel Connection Designer 2017

01-25-2017, 08:57:31 Page 5 of 17

Project Revision 0

Address

Document

GRAITEC INNOVATION

www.graitec.com Designed by Date 01/25/2017

17 Burospace 91572 Bivres Verified by Date 01/25/2017

Safety Coefficients

Structural steel Structural concrete:

Corrosion conditions

EN 10025, the steel is used unprotected (without improved atmospheric corrosion resistance).

Conventions

Tension is considered positive (compression is considered negative).

Bending moment is considered positive if clockwise (in above elevation).

Strong axis of the profile is considered "y-y" and weak axis "z-z".

Application domain:

The joint members are "I" or "H" construction steel profiles.

The height of the profiles (without haunches) does not exceed 600 mm.

On the plates, there are two vertical bolt rows.

4 Compression verifications

4.1 Compression resistance of the beam

Beam cross section design bending moment resistance reduced if necessary, to allow for shear force. Its formula is

shown below.

The profile is class 1, so the moment resistance of the section is calculated using the plastic modulus:

EN1993-1-1. 6.2.5

The Design Combined Compression Resistance of the Beam Flange and the Adjacent Compression Zone of the Beam

Web:

EN 1993-1-8, 6.2.6.7

Steel Connection Designer 2017

01-25-2017, 08:57:31 Page 6 of 17

Project Revision 0

Address

Document

GRAITEC INNOVATION

www.graitec.com Designed by Date 01/25/2017

17 Burospace 91572 Bivres Verified by Date 01/25/2017

4.2 Column web panel in shear

EN 1993-1-8 6.2.6.1(1)

The column web slenderness satisfies the condition given in EN 1993-1-8 6.2.6.1(2), so the web panel in shear

resistance will be calculated following the design methods provided in 6.2.6.1(2) to 6.2.6.1(14).

Check relation:

Combination: 1.35x[1 G]+1.5x[2 Q]

hf - is calculated according to EN 1993-1-8, 6.2.7, Figure 6.15;

The column web panel in shear resistance for a stiffened column is the sum of the column web panel in shear for the

unstiffened column and the stiffener resistance, EN 1993-1-8 6.2.6.1(2):

4.2.1 Tensioned/Compressed Stiffeners Resistance

Work Ratio: 91.26 % Passed

Steel Connection Designer 2017

01-25-2017, 08:57:31 Page 7 of 17

Project Revision 0

Address

Document

GRAITEC INNOVATION

www.graitec.com Designed by Date 01/25/2017

17 Burospace 91572 Bivres Verified by Date 01/25/2017

4.3 Column web buckling

Check relation:

Combination: 1.35x[1 G]+1.5x[2 Q]

Column web buckling design force:

Column web buckling design resistance:

EN 1993-1-1 6.3.1.1 (6.41)

The column web is stiffened, so:

Buckling length:

The imperfection coefficient is chosen according to EN 1993-1-1, tables 6.1 and 6.2:

EN 1993-1-1 6.3.1.2

EN 1993-1-1 6.3.1.2

EN 1993-1-1 6.3.1.2

EN 1993-1-1 6.3.1.1

(6.41)

Work Ratio: 38.81 % Passed

4.4 Column web panel in transverse compression

Check relation:

Combination: 1.35x[1 G]+1.5x[2 Q]

Steel Connection Designer 2017

01-25-2017, 08:57:31 Page 8 of 17

Project Revision 0

Address

Document

GRAITEC INNOVATION

www.graitec.com Designed by Date 01/25/2017

17 Burospace 91572 Bivres Verified by Date 01/25/2017

There are no web plates, so, EN 1993-1-8, 6.2.6.2. (6):

The resistance of the column web in transverse compression is equal to the web crushing or the buckling resistance,

whichever is the smallest:

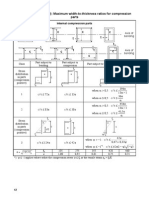

EN 1993-1-8, Table 6.3

Steel Connection Designer 2017

01-25-2017, 08:57:31 Page 9 of 17

Project Revision 0

Address

Document

GRAITEC INNOVATION

www.graitec.com Designed by Date 01/25/2017

17 Burospace 91572 Bivres Verified by Date 01/25/2017

The column web in transverse compression force exceeds the column web resistance.

The column web resistance will be calculated by adding the compressed stiffeners resistance.

Horizontal Stiffener

Radius of gyration

Slenderness classification

The stiffeners slenderness is Class 1

EN 1993-1-1 6.3.1.3 (6.50)

EN 1993-1-1 6.3.1.2 (6.49)

EN 1993-1-1 6.3.1.2, Table 6.2

EN 1993-1-1 6.3.1.2 (6.49)

Work Ratio: 50.23 % Passed

Steel Connection Designer 2017

01-25-2017, 08:57:31 Page 10 of 17

Project Revision 0

Address

Document

GRAITEC INNOVATION

www.graitec.com Designed by Date 01/25/2017

17 Burospace 91572 Bivres Verified by Date 01/25/2017

5 Stiffeners verifications

Steel Connection Designer 2017

01-25-2017, 08:57:31 Page 11 of 17

Project Revision 0

Address

Document

GRAITEC INNOVATION

www.graitec.com Designed by Date 01/25/2017

17 Burospace 91572 Bivres Verified by Date 01/25/2017

6 Tension verifications

Combination: 1.35x[1 G]+1.5x[2 Q]

Tension effective force:

6.1 Column web in tension verification

Check relation:

EN 1993-1-8, 6.2.6.3

Tensioned stiffeners resistance

Work Ratio: 56.40 % Passed

6.2 Column flange in bending verification

Check relation:

EN 1993-1-8, 6.2.6.3

EN 1993-1-8, 4.10 (2), 4.6

EN 1993-1-8, 4.10 (2), 4.6a

Tensioned stiffeners resistance

Work Ratio: 54.66 % Passed

Steel Connection Designer 2017

01-25-2017, 08:57:31 Page 12 of 17

Project Revision 0

Address

Document

GRAITEC INNOVATION

www.graitec.com Designed by Date 01/25/2017

17 Burospace 91572 Bivres Verified by Date 01/25/2017

7 Shear verifications

7.1 Shear yielding verification of the plate

Verification is not required.

Steel Connection Designer 2017

01-25-2017, 08:57:31 Page 13 of 17

Project Revision 0

Address

Document

GRAITEC INNOVATION

www.graitec.com Designed by Date 01/25/2017

17 Burospace 91572 Bivres Verified by Date 01/25/2017

8 Bending moment verifications

8.1 Bending moment resistance

EN 1993-1-8, 5.4.4 (5.16)

EN 1993-1-1, 6.2.3 (2)

The design axial force (NEd) from the connected member exceeds 5% of the design plastic resistance of its cross

-section (Npl,Rd). The rules from chapter 6.3 (EN 1993-1-8) are no longer valid.

8.2 Joint bending moment verification

Check relation:

Combination: 1.35x[1 G]+1.5x[2 Q]

Work Ratio: 83.81 % Passed

Steel Connection Designer 2017

01-25-2017, 08:57:31 Page 14 of 17

Project Revision 0

Address

Document

GRAITEC INNOVATION

www.graitec.com Designed by Date 01/25/2017

17 Burospace 91572 Bivres Verified by Date 01/25/2017

9 Weld verifications

9.1 Weld dimension conditions

Minimum Throat Thickness

EN 1993-1-8, 4.5.2 (2)

Stiffener Weld Passed

Stiffener Weld Passed

Minimum Length

EN 1993-1-8, 4.5.1 (2)

Stiffener Weld Passed

Stiffener Weld Passed

9.2 Weld verification by Real Moment (weld design method: Simplified)

10 Rotational Stiffness

10.1 Stiffness coefficients for basic joint components

(EN 1993-1-8, Table 6.11)

The column web is stiffened, so the stiffness coefficient for the column web panel in shear and for the

column web panel in compression will be infinity:

EN 1993-1-8, Table 6.11

Stiffness coefficient for column web in panel shear

EN 1993-1-8, Table 6.11

z - distance to the first bolt row

Stiffness coefficient for column web in tension

Steel Connection Designer 2017

01-25-2017, 08:57:31 Page 15 of 17

Project Revision 0

Address

Document

GRAITEC INNOVATION

www.graitec.com Designed by Date 01/25/2017

17 Burospace 91572 Bivres Verified by Date 01/25/2017

EN 1993-1-8, 6.3.1 (6.27)

10.2 Rotational Stiffness Classification

a) if the joint is contained in a braced structure (the bracings reduce at least 80% of displacement)

The joint is considered Semi-rigid. EN 1993-1-8, 5.2.2.5 (1)

b) if the joint is contained in an unbraced structure (the bracings reduce less than 80% of displacement)

The joint is considered Semi-rigid. EN 1993-1-8, 5.2.2.5 (1)

10.3 Rotational stiffness calculation

EN 1993-1-8, 5.1.2 (4)

Stiffness ratio:

Shape factor:

EN 1993-1-8, 6.3.1, Table 6.8

Secant stiffness:

EN 1993-1-8, 5.1.2 (4)

EN 1993-1-8, 5.1.2 Figure 5.1

EN 1993-1-8, 5.1.2 Figure 5.1

EN 1993-1-8, 5.1.2 Figure 5.1

Steel Connection Designer 2017

01-25-2017, 08:57:31 Page 16 of 17

Project Revision 0

Address

Document

GRAITEC INNOVATION

www.graitec.com Designed by Date 01/25/2017

17 Burospace 91572 Bivres Verified by Date 01/25/2017

11 Warning and error messages

Type Description

The design axial force (NEd) of the connected member exceeds 5% of the design plastic resistance of its cross-section

Warning (Npl,Rd). The rules from chapter 6.3 (EN 1993-1-8) are no longer valid.

Combinations: 104, 105

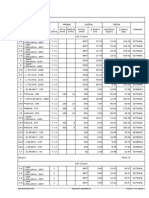

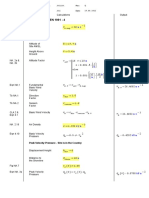

Verification Combination Force Resistance Work Ratio Status

Column web panel in

1.35x[1 G]+1.5x[2 Q] 358.35 kN 392.67 kN 91.26 % Passed

shear:

Bending moment: 1.35x[1 G]+1.5x[2 Q] 85.50 kNm 102.02 kNm 83.81 % Passed

Column web in tension: 1.35x[1 G]+1.5x[2 Q] 358.35 kN 635.39 kN 56.40 % Passed

Column flange in

1.35x[1 G]+1.5x[2 Q] 358.35 kN 655.60 kN 54.66 % Passed

bending:

Column web in

1.35x[1 G]+1.5x[2 Q] 299.85 kN 596.94 kN 50.23 % Passed

compression:

Column web buckling: 1.35x[1 G]+1.5x[2 Q] 299.85 kN 772.56 kN 38.81 % Passed

Maximum Work Ratio: 91.26 % Passed

Steel Connection Designer 2017

01-25-2017, 08:57:31 Page 17 of 17

You might also like

- Conception Analysis and Design of A 3d Steel BuildingDocument87 pagesConception Analysis and Design of A 3d Steel BuildinggunasekaranNo ratings yet

- Anker Vrska KompletDocument4 pagesAnker Vrska KompletstojanovalidijaNo ratings yet

- Case Study of A 40 Story BRBF Building Located in Los AnegelesDocument30 pagesCase Study of A 40 Story BRBF Building Located in Los AnegelesMREFAATNo ratings yet

- New Cyprus Museum Part C 4Document12 pagesNew Cyprus Museum Part C 4Arnold TunduliNo ratings yet

- Base PlateDocument2 pagesBase PlateEosNo ratings yet

- SKILLS BasePlate EN PDFDocument82 pagesSKILLS BasePlate EN PDFandibolNo ratings yet

- Introduction To Operations ResearchDocument84 pagesIntroduction To Operations ResearchSergio Del Angel PineteNo ratings yet

- S002 76-10526-Detail Design: FOR 400 & 200 THKDocument1 pageS002 76-10526-Detail Design: FOR 400 & 200 THKMazen IsmailNo ratings yet

- Pinned Base Plates 18Document1 pagePinned Base Plates 18pawkomNo ratings yet

- Structural Engineering Report: Project: Location: Client: Code: SGE Job NoDocument31 pagesStructural Engineering Report: Project: Location: Client: Code: SGE Job NoWalid Abou HassanNo ratings yet

- Doseme Egilme ACI (2 Sira-EN)Document1 pageDoseme Egilme ACI (2 Sira-EN)OktayNo ratings yet

- Aisiwin v8 ManualDocument28 pagesAisiwin v8 ManualGnabBangNo ratings yet

- Detail Joint & End SlabDocument1 pageDetail Joint & End SlabTaufiq Ur RahmanNo ratings yet

- Column PMM EnvelopeDocument23 pagesColumn PMM EnvelopeKutty MansoorNo ratings yet

- Eurocode Yük KombinasyonlarıDocument12 pagesEurocode Yük KombinasyonlarıVefa OkumuşNo ratings yet

- Fenet d3613 Dle Advanced Finite Element Contact BenchmarksDocument62 pagesFenet d3613 Dle Advanced Finite Element Contact BenchmarkstonisugusNo ratings yet

- MBK Elaborat 1Document42 pagesMBK Elaborat 1Ksenija PejkovicNo ratings yet

- 2018 - 0510 AAD Gebze - IMO - TBDY2018 GDTDocument46 pages2018 - 0510 AAD Gebze - IMO - TBDY2018 GDTdrsteelNo ratings yet

- BEAMDESIGN XLSMDocument4 pagesBEAMDESIGN XLSMSaurabh PednekarNo ratings yet

- Fillet Welding On Gussets and LugsDocument1 pageFillet Welding On Gussets and LugsSeungmin PaekNo ratings yet

- Manual-14 en Pile PDFDocument12 pagesManual-14 en Pile PDFvedranNo ratings yet

- Design of Steel Structural BuildingDocument47 pagesDesign of Steel Structural BuildingbhvramanaNo ratings yet

- General Structural Notes Drawing List: Sheet Title Sheet NoDocument7 pagesGeneral Structural Notes Drawing List: Sheet Title Sheet NoAzllina Anuar100% (1)

- Reinforced Concrete BeamsDocument28 pagesReinforced Concrete BeamsEdriane Jude MalemNo ratings yet

- Column Input Data: No Area of Each ReinforcementDocument12 pagesColumn Input Data: No Area of Each ReinforcementMatiur Rahman BasumNo ratings yet

- ConSteel Verification ManualDocument123 pagesConSteel Verification Manualseljak_veseljakNo ratings yet

- The - Thickness - of - Base - Plate - by - The - LRFD - The - I - Section Column - and - ConcreteDocument9 pagesThe - Thickness - of - Base - Plate - by - The - LRFD - The - I - Section Column - and - ConcretejscuencaNo ratings yet

- Beam - Deflection CheckDocument8 pagesBeam - Deflection CheckEko Bayu AjiNo ratings yet

- Klase Poprecnog Preseka ECDocument2 pagesKlase Poprecnog Preseka ECbobbynebaNo ratings yet

- Tugas 02 - Beton LanjutDocument2 pagesTugas 02 - Beton LanjutsalmanNo ratings yet

- Design Spectrum According To Eurocode 8Document6 pagesDesign Spectrum According To Eurocode 8BN NGNo ratings yet

- Bolted Bracket DesignDocument2 pagesBolted Bracket Designharoub_nasNo ratings yet

- Primeri Ec3Document0 pagesPrimeri Ec3jelenavukojeNo ratings yet

- Advance Steel Behind The Camera - The Secret To Easy DrawingsDocument13 pagesAdvance Steel Behind The Camera - The Secret To Easy DrawingsrfnNo ratings yet

- Bolted Slip Resistant Connection EC3Document2 pagesBolted Slip Resistant Connection EC3cretz2No ratings yet

- Details Guide For Etabs AnalysisDocument1 pageDetails Guide For Etabs AnalysisaikalessNo ratings yet

- IPB K Staticki ProracunDocument98 pagesIPB K Staticki ProracunFodor ZoltanNo ratings yet

- Danh Gia Lien Ket Ban de Chan Cot ThepDocument2 pagesDanh Gia Lien Ket Ban de Chan Cot ThepNguyen Duc CuongNo ratings yet

- Column Base Plate (Small Eccentricity) v2.0Document3 pagesColumn Base Plate (Small Eccentricity) v2.0Shamik GhoshNo ratings yet

- Purlin Sizer Structural Calculations: Telephone 323462 Facsimile 323632 E-Mail Carl - Bauer@info - BWDocument1 pagePurlin Sizer Structural Calculations: Telephone 323462 Facsimile 323632 E-Mail Carl - Bauer@info - BW_jessecaNo ratings yet

- 1 - Ec3 1 8Document6 pages1 - Ec3 1 8dmardetkNo ratings yet

- Doc9 5 4 PDFDocument5 pagesDoc9 5 4 PDFAnonymous dSFbLxc90% (1)

- M Simpson SCRI Forum BIM Structural Design ArupDocument68 pagesM Simpson SCRI Forum BIM Structural Design ArupJoel Juanpere ComasNo ratings yet

- Elements of Soil Mechanics, 8th Edition Example 8.5Document42 pagesElements of Soil Mechanics, 8th Edition Example 8.5Ako BogdaNo ratings yet

- Staticki Proracun Krivajnog MehanizmaDocument18 pagesStaticki Proracun Krivajnog Mehanizmasssf-dobojNo ratings yet

- Drvo BetonDocument131 pagesDrvo BetonSonja DragovicNo ratings yet

- Design of Circular BeamDocument2 pagesDesign of Circular BeamShane BondNo ratings yet

- Buckling Analysis K Value CalculatorDocument3 pagesBuckling Analysis K Value Calculatorrodriguez.gaytanNo ratings yet

- Book PDFDocument583 pagesBook PDFMercedez Benz100% (1)

- Poglavlje 3.4 StubisteDocument29 pagesPoglavlje 3.4 Stubistefk0205No ratings yet

- Steady Flow in Pipes: BTB 323/ Cse 352 Hydraulics Edwin K. Kanda, PHDDocument19 pagesSteady Flow in Pipes: BTB 323/ Cse 352 Hydraulics Edwin K. Kanda, PHDErick WanduNo ratings yet

- Do It Yourself 1Document63 pagesDo It Yourself 1Nguyen Duc CuongNo ratings yet

- Stage Construction e TabsDocument10 pagesStage Construction e TabsLim Wee BengNo ratings yet

- Space Frame (Abcm - Sem Ix)Document4 pagesSpace Frame (Abcm - Sem Ix)Tahesin PathanNo ratings yet

- Compression StiffenersDocument12 pagesCompression StiffenersZsuzsaNo ratings yet

- Calcul CofrajeDocument3 pagesCalcul CofrajeMunteanu AlinaNo ratings yet

- 1.7.2 Wind BracingDocument3 pages1.7.2 Wind BracingMonica Arlita Tasya WijoyoNo ratings yet

- Graitec Beam ReportDocument46 pagesGraitec Beam ReportChanel CuteNo ratings yet

- Test Beam ReportDocument35 pagesTest Beam Reportkheang mengNo ratings yet

- DD Cen TS 1992-4-1-2009Document68 pagesDD Cen TS 1992-4-1-2009Kovacs Zsolt-IstvanNo ratings yet

- List 001 Sklopovi - A3-A3 Advance SteelDocument1 pageList 001 Sklopovi - A3-A3 Advance SteelhomerCODNo ratings yet

- Rencana BM PaningkabanDocument2 pagesRencana BM PaningkabanafrisdazulfiNo ratings yet

- Joint ReportDocument17 pagesJoint ReporthomerCODNo ratings yet

- Joint ReportDocument17 pagesJoint ReporthomerCODNo ratings yet

- Nadstresnice Svih LamelaDocument13 pagesNadstresnice Svih LamelahomerCODNo ratings yet

- RegionsDocument1 pageRegionshomerCODNo ratings yet

- Century of Genius 5 Famous People To Contribute in Science and TechnologyDocument6 pagesCentury of Genius 5 Famous People To Contribute in Science and TechnologyJack HererNo ratings yet

- Q2 Lesson 1Document43 pagesQ2 Lesson 1Sheena AragoNo ratings yet

- Level 1:basic Problems: NeetDocument16 pagesLevel 1:basic Problems: Neettanmoy bhattacharjeeNo ratings yet

- Methods of Drug EvaluationDocument3 pagesMethods of Drug EvaluationDestroyer GamerNo ratings yet

- Design Basis of Boilers Iniitial Filling Pump Rev.1Document1 pageDesign Basis of Boilers Iniitial Filling Pump Rev.1Shameer Majeed. ANo ratings yet

- Laporan Kerja Ptaktik Pabrik Gula BungamayangDocument81 pagesLaporan Kerja Ptaktik Pabrik Gula BungamayangArdiSaputraNo ratings yet

- Qada Qadar Dan Parallel UniverseDocument14 pagesQada Qadar Dan Parallel Universeambiya086114No ratings yet

- Lesson Plan ECEDocument3 pagesLesson Plan ECEVenkatesan SwamyNo ratings yet

- Wind Loads Is en 1991-1-4Document1 pageWind Loads Is en 1991-1-4David O'MearaNo ratings yet

- Handbook of Polymer FoamsDocument304 pagesHandbook of Polymer FoamsMarcos Gilardi100% (2)

- Acceleration vs. Time GraphDocument16 pagesAcceleration vs. Time Graphlea pagusaraNo ratings yet

- Physics Malaysian Matriculation Semester 1 Notes CompleteDocument474 pagesPhysics Malaysian Matriculation Semester 1 Notes CompleteJay Bee96% (68)

- Self Assessment MCQs - Students1Document2 pagesSelf Assessment MCQs - Students1JunaidKhanNo ratings yet

- Kinematics of Rectilinear Motion Form 2Document7 pagesKinematics of Rectilinear Motion Form 2Mohammad BatainehNo ratings yet

- Water Pumps and Pumping SystemsDocument46 pagesWater Pumps and Pumping SystemsMohamed100% (1)

- YCEF Presentaion-Derivation of Wind LoadingDocument57 pagesYCEF Presentaion-Derivation of Wind LoadingVictor OmotoriogunNo ratings yet

- OML751 Testing of MaterialsDocument39 pagesOML751 Testing of MaterialsVikashini GNo ratings yet

- Strength of MaterialsDocument1 pageStrength of MaterialsJames CENo ratings yet

- Seismaic Behaviour of Isloated BridgesDocument41 pagesSeismaic Behaviour of Isloated Bridgespraveenpv7100% (1)

- EF2260 ThermalDocument48 pagesEF2260 ThermaliordacheNo ratings yet

- 1491306950894tseamcet 2016 LastranksDocument23 pages1491306950894tseamcet 2016 LastranksMohammed Abdulwajid SiddiquiNo ratings yet

- Unit h556 01 Modelling Physics Sample Assessment MaterialsDocument48 pagesUnit h556 01 Modelling Physics Sample Assessment MaterialsY4NISMTNo ratings yet

- Lab 1 - Moles Molecules and GramsDocument3 pagesLab 1 - Moles Molecules and Gramsapi-239474533No ratings yet

- Fundamentals of Heat and Mass Transfer 7th Edition Incropera Solutions Manual20190709 74173 2j05lf PDFDocument20 pagesFundamentals of Heat and Mass Transfer 7th Edition Incropera Solutions Manual20190709 74173 2j05lf PDFAndiNo ratings yet

- TrichelDocument12 pagesTrichelafgaleanoNo ratings yet

- I0qm BalunDocument2 pagesI0qm BalunDundo SakićNo ratings yet

- Fisa Tehnica AHU-01Document9 pagesFisa Tehnica AHU-01Liviu ToaderNo ratings yet

- Positive: Atomic Structure WorksheetDocument4 pagesPositive: Atomic Structure WorksheetAnahat SinghNo ratings yet

- 2022 Springer Nature Fully Open Access JournalsDocument36 pages2022 Springer Nature Fully Open Access JournalsEntertainment HubNo ratings yet

- Freezing PointDocument3 pagesFreezing PointJeremy TaylorNo ratings yet