Professional Documents

Culture Documents

Rapid: Black End (BE) White End (WE) Ntut

Uploaded by

Amri RsylnaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rapid: Black End (BE) White End (WE) Ntut

Uploaded by

Amri RsylnaCopyright:

Available Formats

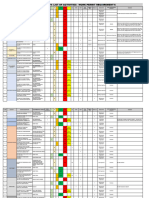

PROJECT ORGANIZATION CHART BY AREA

QTY OF

Plan for Supervisor REMARKS ORGANIZATION CHART

PROJECT

PROJECT

Sharing supervisor 1. Total NOS of supervisor require is 6 peoples

Supv-01 RAPID

- AO Line Replacement Project

- Schenck Weight Feeder Control System Upgrade PHASE

#2

Supv-02 BLACK END WHITE END

NTUT

AREA CATEGORY

- Zirconium (BE) (WE)

- Cooler Tubesheet

9

Supv-03

- Centrifuge

- Schenck Weight Feeder CRITICA CRITICA

- AO Line NORMAL / L NORMAL / NORMAL /

L

MAJOR WORK MAJOR WORK MAJOR WORK

Dedicated suoervisor Compressor Air Drier Replacement Project

Dump Conveyor - Supv-04 1. 8 Tie-in points & can be manageable 1. TK-417 : 1. TK-401 :

Air Drier Compressor - Supv-05 REPLACE COMPRESSOR

Dump Conveyor Structure Replacement, Phase #2 CALCINER AIR DRIER

NORMAL HOUR

1. Manageable but a lot of work COOLER TUBE REPLACEMENT

SHEET PROJECT

Replace Calciner Cooler Tubesheet (Emergent) (EMERGENT)

1. Manageable. 2. TK-433 :

2. Constraint for WE start-up. 3 DUMP

CONVENYOR

STRUCTURE

REPLACEMENT,

PHASE #2

Centrifuge No.2 Work

1. Manageable 1. TK-414 :

1. CENTRIFUGE 1. TK-354 :

NO.2 WORK SCHENCK ZIRCONIUM

EXTENDED HOUR

New Precipitation Tank No 2 TANK

WEIGHT FEEDER

1. 24 Hours just for brick installation REPLACEMENT

2. TK-383 : CONTROL

2. Other works will be extended hours PROJECT

NEW SYSTEM

PRECIPITATION UPGRADE PHASE

Zirconium Tank Replacement Project

TANK NO.2 #2

1. TR92 can't be produced if zirconium tank delay 4

2. Critical Lifting

Schenck Weight Feeder Control System Upgrade PHASE #2

1. Ball mill will be critical project since it is single stream line.

Dedicated suoervisor AO Line Replacement Project

Boiler Feed Water - Supv-06 1. No risk interm of schedule (manageable)

1. TK-422 : 1. TK-396 :

2. Standby unit for dispersal switching train (supply acid ore to reactor

AO LINE BOILER FEED

for further reaction)

REPLACEMENT WATER PIPELINE

PROJECT & VALVE

Boiler Feed Water Pipeline & Valve Replacement Project

REPLACEMENT

2 SHIFT

1. Time constraint & area conjusted.

PROJECT

2. Application line for boiler start-up.

3. A lot of installation piping work. 2

BE NORMAL / MAJOR BE CRITICAL WE NORMAL NTUT NORMAL / MAJOR NTUT CRITICAL

QTY PROJECT PER CONDITION

3 1 2 2 1

QTY PROJECT PER AREA 4 2 3

TOTAL 9

You might also like

- 2955 0240 03 - XRVS 476 CD T3 APP - XRVS 1000 CD6 T3 APP ASL BOOK PDFDocument262 pages2955 0240 03 - XRVS 476 CD T3 APP - XRVS 1000 CD6 T3 APP ASL BOOK PDFJason0% (1)

- Weatherford McMurry GLM - Gas Lift MandrelDocument25 pagesWeatherford McMurry GLM - Gas Lift MandrelYovaraj KarunakaranNo ratings yet

- P94 1170 PDFDocument4 pagesP94 1170 PDFeduardonemoNo ratings yet

- AP NirvanaOF Manual v3Document456 pagesAP NirvanaOF Manual v3Bùi Việt100% (2)

- Dimensi Panel-Cad-2010-MIT-Rev-04-SD-MIT-FABS-CCEP-EL-HVAC-013Document1 pageDimensi Panel-Cad-2010-MIT-Rev-04-SD-MIT-FABS-CCEP-EL-HVAC-013Wijaya GultomNo ratings yet

- TP - 01 Welding For Split TeeDocument1 pageTP - 01 Welding For Split TeeLeonardo ManurungNo ratings yet

- Almagwa List of Activities R2 27112023Document2 pagesAlmagwa List of Activities R2 27112023Mohamed RizwanNo ratings yet

- Assembly Line-1 Skill Matrix: Minimum Skill Required L-2 L-2 L-2 L-2 L-2 L-2 L-2 L-2 L-2 L-2 L-2 L-2 L-2 L-2 L-2 L-2Document1 pageAssembly Line-1 Skill Matrix: Minimum Skill Required L-2 L-2 L-2 L-2 L-2 L-2 L-2 L-2 L-2 L-2 L-2 L-2 L-2 L-2 L-2 L-2artiNo ratings yet

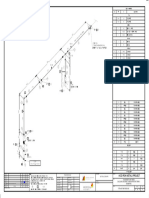

- Isometric DrawingDocument1 pageIsometric DrawingDeva JonesNo ratings yet

- Qaqc Organization ChartDocument1 pageQaqc Organization ChartAshishNo ratings yet

- Maintenance Central Workshop Result Inspection ElectricalDocument6 pagesMaintenance Central Workshop Result Inspection ElectricalMuhammad ArifinNo ratings yet

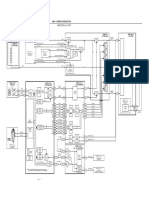

- System ArchitectureDocument1 pageSystem ArchitectureAkbar AffandyNo ratings yet

- 506-PPA.3101-ISO-001 Sheet 2 Drainage Roompad 3101-ModelDocument1 page506-PPA.3101-ISO-001 Sheet 2 Drainage Roompad 3101-ModellewihonawiNo ratings yet

- Air BrakeDocument37 pagesAir Brakenirmal malviya100% (1)

- Almagwa List of Activities R1 26112023Document4 pagesAlmagwa List of Activities R1 26112023Mohamed RizwanNo ratings yet

- High Chiept PCR & Maint - BWPDocument27 pagesHigh Chiept PCR & Maint - BWPMuhammadSyarifudinNo ratings yet

- Manual Welding Report (Gravity Line) : DateDocument10 pagesManual Welding Report (Gravity Line) : DateEs KnNo ratings yet

- Daily Report - RDMP - PT KPU (17 March 2022)Document63 pagesDaily Report - RDMP - PT KPU (17 March 2022)dhea novitaNo ratings yet

- PWPS Skid & Piping Nitrogen Vaporizer PackageDocument6 pagesPWPS Skid & Piping Nitrogen Vaporizer PackageAlvin ZulkarnainNo ratings yet

- Dimensi Panel Cad 2010 Mit Rev 04 SD Mit Fabs Ccep El Hvac 005Document1 pageDimensi Panel Cad 2010 Mit Rev 04 SD Mit Fabs Ccep El Hvac 005Wijaya GultomNo ratings yet

- Isometric Sewer Line Layout: Note: BOD Department of Public Works and Highways Raul C. AsisDocument1 pageIsometric Sewer Line Layout: Note: BOD Department of Public Works and Highways Raul C. AsisbeaNo ratings yet

- Ae2 Comp Insta Guide Na enDocument2 pagesAe2 Comp Insta Guide Na enAnonymous rrD8UKYNXNo ratings yet

- Gad PSVDocument1 pageGad PSVNARAYAN DESAINo ratings yet

- 1778-4711-WD-DWG-006I - Line 4711-105-WCS-15-Q235A - CommentDocument6 pages1778-4711-WD-DWG-006I - Line 4711-105-WCS-15-Q235A - CommentAsyifa AldanaNo ratings yet

- CMS Sequence Block Diagram - BH PlatformDocument1 pageCMS Sequence Block Diagram - BH PlatformShemvakNo ratings yet

- Block Diagram UtilitiesDocument10 pagesBlock Diagram UtilitiesDilanka RajithamalNo ratings yet

- (2021.05.04) Ga Office Ft. Tanjung Pandan Rev.bDocument1 page(2021.05.04) Ga Office Ft. Tanjung Pandan Rev.bAL FarabiNo ratings yet

- Flow Diagram Symbols: - Panel0MountedmortDocument1 pageFlow Diagram Symbols: - Panel0MountedmortToàn Nguyễn CảnhNo ratings yet

- MD (BD) - Eql-Cep-In-1001 Instrument Index Rev0 PDFDocument4 pagesMD (BD) - Eql-Cep-In-1001 Instrument Index Rev0 PDFKook PengNo ratings yet

- W113 76-10526-Detail Design: U1 U2 U3 U4 U5 U6 UCDocument1 pageW113 76-10526-Detail Design: U1 U2 U3 U4 U5 U6 UCMazen IsmailNo ratings yet

- 1778-4307-MP-DWG-042 - 0 Line 4307-015-LCC-80-HDPE-2-ModelDocument1 page1778-4307-MP-DWG-042 - 0 Line 4307-015-LCC-80-HDPE-2-ModellewihonawiNo ratings yet

- GIP2 IPFSIL-EXE-RTSB (TASB) - 000-INC-TDS-0002 - RevB (Datasheet) (1) - 4Document1 pageGIP2 IPFSIL-EXE-RTSB (TASB) - 000-INC-TDS-0002 - RevB (Datasheet) (1) - 4Kacip BolaNo ratings yet

- GE AMX4 Block DiagramsDocument9 pagesGE AMX4 Block Diagramszach tuttle100% (1)

- SA1-A SA25-A: Type 4 Type 4 Flap-ValveDocument2 pagesSA1-A SA25-A: Type 4 Type 4 Flap-Valvemperez352No ratings yet

- Single Line Diagram Fire Alarm System Area Metering Akatara Project-R3Document1 pageSingle Line Diagram Fire Alarm System Area Metering Akatara Project-R3PandaNo ratings yet

- Saudi Arabian Oil Company: VA-291301 001 P 0A2 K11 RestrictedDocument1 pageSaudi Arabian Oil Company: VA-291301 001 P 0A2 K11 Restrictedsaleem naheedNo ratings yet

- 0169-013-SHS-200-20G-H80 Sheet 1-ModelDocument1 page0169-013-SHS-200-20G-H80 Sheet 1-ModellewihonawiNo ratings yet

- Equipment list-GX09Document3 pagesEquipment list-GX09Muthazhagan SaravananNo ratings yet

- Dimensi Panel Cad 2010 Mit Rev 04 SD Mit Fabs Ccep El Hvac 002Document1 pageDimensi Panel Cad 2010 Mit Rev 04 SD Mit Fabs Ccep El Hvac 002Wijaya GultomNo ratings yet

- PCR Autolube Intecs PDFDocument27 pagesPCR Autolube Intecs PDFstrong holdNo ratings yet

- Valtek FlowpakDocument12 pagesValtek FlowpakRaphael AndradeNo ratings yet

- Cessna 525 Engine SystemDocument14 pagesCessna 525 Engine SystemCesar BanchoffNo ratings yet

- Hvac Layout DiagramDocument14 pagesHvac Layout DiagramPamellaNo ratings yet

- Anderson Greenwood LCP SeriesDocument6 pagesAnderson Greenwood LCP SeriesHafziNo ratings yet

- Muc 12. Ebook - KRH - Engl - 01Document5 pagesMuc 12. Ebook - KRH - Engl - 01HongLam LÊNo ratings yet

- Typical 400kV TRF (HV) Bay View (GIS MODULE)Document1 pageTypical 400kV TRF (HV) Bay View (GIS MODULE)Amarjit KulkarniNo ratings yet

- Nonlinear AP ModifiedDocument37 pagesNonlinear AP ModifiednehaNo ratings yet

- Konika Minolta PDFDocument26 pagesKonika Minolta PDFfigtertuanNo ratings yet

- 506-Ppa.4711-Iso-070 - 0 - 4508-087-HML-80-Q235Document1 page506-Ppa.4711-Iso-070 - 0 - 4508-087-HML-80-Q235lewihonawiNo ratings yet

- SCX 4521FDocument15 pagesSCX 4521FadycrsNo ratings yet

- Your Basic Refrigeraion System: SVASD - MAY 26, 2011Document71 pagesYour Basic Refrigeraion System: SVASD - MAY 26, 2011RASHEED YUSUFNo ratings yet

- Daily Report 25 Sep 2011Document1 pageDaily Report 25 Sep 2011Nathaniel Williams100% (1)

- Workscope Job Assignment Small Aircraft WG12 Periode (44 & 45) 28 Oct - 03 November 2022 Rev.00Document7 pagesWorkscope Job Assignment Small Aircraft WG12 Periode (44 & 45) 28 Oct - 03 November 2022 Rev.00Panji PrakosoNo ratings yet

- CM0202, Compressor DWG-2Document2 pagesCM0202, Compressor DWG-2ansariiqbal9570No ratings yet

- P110a Data SheetDocument1 pageP110a Data SheetZaw Htet WinNo ratings yet

- Daily Report 20 September 2021Document4 pagesDaily Report 20 September 2021HADINo ratings yet

- Design Analysis: Proposed 1 Unit 2 CL Building For Capiniahan Primary SchoolDocument1 pageDesign Analysis: Proposed 1 Unit 2 CL Building For Capiniahan Primary SchoolPauline Joy AquinoNo ratings yet

- SWB2 To VICP Electrical Tie-In Project: Emerg. Ps Es Ps JB PsDocument1 pageSWB2 To VICP Electrical Tie-In Project: Emerg. Ps Es Ps JB PsYogesh MittalNo ratings yet

- Road SuperelevationDocument1 pageRoad SuperelevationDelfin Necerio ZoletaNo ratings yet

- Bombardier CRJ 200-Power PlantDocument46 pagesBombardier CRJ 200-Power Plantjuan carlos balderas silva100% (1)

- Changes Route UpdatedDocument3 pagesChanges Route UpdatedAmri RsylnaNo ratings yet

- 3 2 N Pdms X (Left) Navis Pdms X (Right) Navis E: Pt. Mcdermott IndonesiaDocument1 page3 2 N Pdms X (Left) Navis Pdms X (Right) Navis E: Pt. Mcdermott IndonesiaAmri RsylnaNo ratings yet

- Links KuliahDocument1 pageLinks KuliahAmri RsylnaNo ratings yet

- Ga Size Common-LadderDocument1 pageGa Size Common-LadderAmri RsylnaNo ratings yet

- Professional - 2Document3 pagesProfessional - 2Amri RsylnaNo ratings yet

- Drawing Quality AwarenessDocument2 pagesDrawing Quality AwarenessAmri RsylnaNo ratings yet

- Changes Route UpdatedDocument3 pagesChanges Route UpdatedAmri RsylnaNo ratings yet

- DS 003Document121 pagesDS 003Amri RsylnaNo ratings yet

- Piping Design PresentationDocument40 pagesPiping Design PresentationArun Zac100% (2)

- Insulation Calculation For 36 In1Document19 pagesInsulation Calculation For 36 In1Amri RsylnaNo ratings yet

- Install Spoolgen - Intergraph Spoolgen - 2019 - Installation-Dikonversi PDFDocument1 pageInstall Spoolgen - Intergraph Spoolgen - 2019 - Installation-Dikonversi PDFAmri RsylnaNo ratings yet

- AfrizanirmanDocument1 pageAfrizanirmanAmri RsylnaNo ratings yet

- Pipe-Wall-Thk-Calc-ShtDocument2 pagesPipe-Wall-Thk-Calc-ShtAmri RsylnaNo ratings yet

- CommandbaruDocument1 pageCommandbaruAmri RsylnaNo ratings yet

- AristarDocument1 pageAristarAmri RsylnaNo ratings yet

- Natural Gas Pipe Sizing1Document19 pagesNatural Gas Pipe Sizing1Amri RsylnaNo ratings yet

- NPSHaDocument9 pagesNPSHarajkamal_eNo ratings yet

- About PPD CertificationDocument14 pagesAbout PPD CertificationAmri RsylnaNo ratings yet

- INPEX MaselaDocument1 pageINPEX MaselaAmri RsylnaNo ratings yet

- Plant Layout Specification Equipment Layout NOVI-dikonversiDocument34 pagesPlant Layout Specification Equipment Layout NOVI-dikonversiAmri RsylnaNo ratings yet

- Simulasi Gaji 6 Hari KerjaDocument23 pagesSimulasi Gaji 6 Hari KerjaAmri RsylnaNo ratings yet

- Lead LayoutDocument2 pagesLead LayoutAmri RsylnaNo ratings yet

- How To Set Up MDS in PDMSDocument17 pagesHow To Set Up MDS in PDMSAmri Rsylna100% (2)

- Anil-STRC DERMOTTDocument1 pageAnil-STRC DERMOTTAmri RsylnaNo ratings yet

- INPEX MaselaDocument1 pageINPEX MaselaAmri RsylnaNo ratings yet

- NizamDocument2 pagesNizamAmri RsylnaNo ratings yet

- Link TegDocument2 pagesLink TegAmri RsylnaNo ratings yet

- INPEX MaselaDocument1 pageINPEX MaselaAmri RsylnaNo ratings yet

- Boiler Types and ClassificationsDocument27 pagesBoiler Types and Classificationsabid Qayum alviNo ratings yet

- S&T Stainless Catalogue May 2016 01Document76 pagesS&T Stainless Catalogue May 2016 01AnthonyNo ratings yet

- Safety Valve Technical DetailsDocument5 pagesSafety Valve Technical DetailsvineethvskkdNo ratings yet

- Turbine & AuxilariesDocument64 pagesTurbine & Auxilariesulhatolkargmailcom100% (1)

- PSV LeserDocument10 pagesPSV LeserArif LametNo ratings yet

- Dual Trial 030315Document20 pagesDual Trial 030315Carlos José Granados OportaNo ratings yet

- Model: Af - 12: SIZE: 12 X 12 InchDocument1 pageModel: Af - 12: SIZE: 12 X 12 InchvinodNo ratings yet

- Chapter 6 Vacuum Pumps: April 2008Document28 pagesChapter 6 Vacuum Pumps: April 2008GopalVarthyaNo ratings yet

- Sa Valve LVF, Firsa, Newmans & Noreva Vendor ListDocument2 pagesSa Valve LVF, Firsa, Newmans & Noreva Vendor Listkhan4luvNo ratings yet

- How To Calculate TDH & NPSHDocument2 pagesHow To Calculate TDH & NPSHvishnuNo ratings yet

- BoilerDocument31 pagesBoilerCHE.ENG1734No ratings yet

- Ce6303-Mechanics of FluidsDocument10 pagesCe6303-Mechanics of FluidsDineshNo ratings yet

- V-Cone Ficha TécnicaDocument2 pagesV-Cone Ficha TécnicaIrving Uc Fernandez100% (1)

- Tutorial - Routing Pipes and Tubes in SolidworksDocument7 pagesTutorial - Routing Pipes and Tubes in Solidworkschoks0070% (1)

- Essentials of Turbomachinery in CFD PDFDocument135 pagesEssentials of Turbomachinery in CFD PDFPaladin64No ratings yet

- BOILERDocument36 pagesBOILERAditya Aggarwal100% (1)

- Flow of Water Through Schedule 40 Steel Pipe: Table B8.8Document2 pagesFlow of Water Through Schedule 40 Steel Pipe: Table B8.8LUDERNo ratings yet

- Unit-2 1Document69 pagesUnit-2 1DSIT MECHANICALNo ratings yet

- Solution:: Problem 1: Consider An Air Standard Cycle in Which The Air Enters The Compressor at 1.0 Bar and 20°C. TheDocument7 pagesSolution:: Problem 1: Consider An Air Standard Cycle in Which The Air Enters The Compressor at 1.0 Bar and 20°C. Theabhineet thakurNo ratings yet

- MSS SP-93 (1999) - DPDocument9 pagesMSS SP-93 (1999) - DPshganesh81100% (2)

- HVO Pump - Case C - ReportDocument45 pagesHVO Pump - Case C - ReportNKNo ratings yet

- Flowmeter SelectionDocument1 pageFlowmeter Selectionnahuelcarballido100% (1)

- 18R11A04P6 INTERNSHIP REPORT - (1) (2) WDocument70 pages18R11A04P6 INTERNSHIP REPORT - (1) (2) WSharath Chandra100% (4)

- Sol problemPS5 PDFDocument13 pagesSol problemPS5 PDFyagoNo ratings yet

- 4.11.4 Steam Pipe Sizing and DesignDocument3 pages4.11.4 Steam Pipe Sizing and DesignSaurabh VijNo ratings yet

- Flange Disassembly - An Underrated Source of Safety IncidentsDocument8 pagesFlange Disassembly - An Underrated Source of Safety IncidentsMohamed HassanNo ratings yet

- 2.0 Intro To Hydraulics, Pneumatics & PLC's Notes PDFDocument22 pages2.0 Intro To Hydraulics, Pneumatics & PLC's Notes PDFDannyNo ratings yet

- 600 ClassDocument1 page600 ClassKRNo ratings yet

- Datasheet Pneumatic Actuator With SolenoidDocument1 pageDatasheet Pneumatic Actuator With SolenoidHotnCrispy CrispyNo ratings yet

- SKU Name & Description Link To Website Price in R (Excl. Vat)Document29 pagesSKU Name & Description Link To Website Price in R (Excl. Vat)icumba6180No ratings yet