Professional Documents

Culture Documents

Polycarbonate

Uploaded by

zainudinOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Polycarbonate

Uploaded by

zainudinCopyright:

Available Formats

Polycarbonate

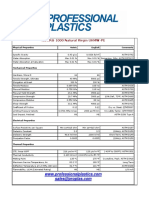

Physical Properties Metric English Comments

Specific Gravity 1.2 g/cc 0.0434 lb/in ASTM D792

Water Absorption 0.20% 0.20% Immersion, 24hr; ASTM

D570(2)

Water Absorption at Saturation 0.40% 0.40% Immersion; ASTM D570(2)

Mechanical Properties

Hardness, Rockwell M 75 75 ASTM D785

Hardness, Rockwell R 126 126 ASTM D785

Hardness, Shore D 80 80 ASTM D2240

Tensile Strength, Ultimate 72.4 MPa 10500 psi ASTM D638

Elongation at Break 100% 100% ASTM D638

Tensile Modulus 2.21 GPa 320 ksi ASTM D638

Flexural Modulus 2.41 GPa 350 ksi ASTM D790

Flexural Yield Strength 89.6 MPa 13000 psi ASTM D790

Compressive Strength 79.3 MPa 11500 psi 10% Def.; ASTM D695

Compressive Modulus 2.07 GPa 300 ksi ASTM D695

Shear Strength 63.4 MPa 9200 psi ASTM D732

Izod Impact, Notched 0.801 J/cm 1.5 ft-lb/in ASTM D256 Type A

Electrical Properties

Surface Resistivity per Square Min 1e+013 ohm Min 1e+013 ohm EOS/ESD S11.11

Dielectric Constant 3.17 3.17 1MHz; ASTM D150

Dielectric Strength 15.7 kV/mm 400 V/mil Short Term; ASTM D149

Dissipation Factor 0.0009 0.0009 1MHz; ASTM D150

Thermal Properties

CTE, linear 68F 70.2 m/m-C 39 in/in-F (-40F to 300F); ASTM E831

Thermal Conductivity 0.187 W/m-K 1.3 BTU-in/hr-ft-F

ASTM F433

Maximum Service Temperature, 121

Air C 250 F Long Term

Deflection Temperature

143 C at 1.8 MPa (264 psi) 290 F ASTM D648

Glass Temperature 145 C 293 F ASTM D3418

Flammability, UL94 (Estimated Rating)

HB HB 1/8 inch

Qualitative Processing Properties

Compliance - FDA Not Compliant

Machinability 3 1-10, 1=Easier to Machine

Service in Alcohols Acceptable

Service in Aliphatic Hydrocarbons

Limited

Service in Aromatic HydrocarbonsUnacceptable

Service in Chlorinated Solvents Unacceptable

Service in Ethers Unacceptable

Service in Ketones Unacceptable

Service in Strong Acids Unacceptable

Service in Strong Alkalies Unacceptable

Service in Sunlight Limited

Service in Weak Acids Acceptable

Service in Weak Alkalies Acceptable

All statements, technical information and recommendations contained in this database are presented in good faith, based upon tests

believed to be reliable and practical field experience. The reader is cautioned, however, that Gemini Plastics Inc and Thermo Fab Plastics,

Inc. cannot guarantee the accuracy or completeness of this information, and it is the customer's responsibility to determine

suitabil products in any given application.

You might also like

- Newnes Circuit Calculations Pocket Book: with Computer ProgramsFrom EverandNewnes Circuit Calculations Pocket Book: with Computer ProgramsNo ratings yet

- Circuit Symbols: Wires and Connections Compone NT Circuit Symbol Function of ComponentDocument7 pagesCircuit Symbols: Wires and Connections Compone NT Circuit Symbol Function of ComponentRalph MedinaNo ratings yet

- Setting Out Circular CurvesDocument21 pagesSetting Out Circular CurvesvpmohammedNo ratings yet

- Sedimentation and Centrifugation PDFDocument34 pagesSedimentation and Centrifugation PDFNilsNo ratings yet

- Heat Transfer Short Notes PDFDocument35 pagesHeat Transfer Short Notes PDFBishal BortamulyNo ratings yet

- Me 301 Chapter 10Document28 pagesMe 301 Chapter 10Melissa RokaNo ratings yet

- Nolinearities - ServoMechanisms and Rgulating System Design - TextDocument696 pagesNolinearities - ServoMechanisms and Rgulating System Design - Textsdpsk100% (1)

- TECHNICAL DATA ON SURFACE ROUGHNESS AND TEXTURE INDICATIONDocument1 pageTECHNICAL DATA ON SURFACE ROUGHNESS AND TEXTURE INDICATIONdmayhillNo ratings yet

- Mineral ProcessingDocument10 pagesMineral ProcessingMahmoud MahmoudmNo ratings yet

- Mitsubishi Chemical Advanced Materials Acetron ® LSG POM-C Copolymer Acetal, Porosity-Free, Unfilled, ExtrudedDocument2 pagesMitsubishi Chemical Advanced Materials Acetron ® LSG POM-C Copolymer Acetal, Porosity-Free, Unfilled, ExtrudedJuan Orlando Loaiza MurilloNo ratings yet

- TDS Nylon101Document2 pagesTDS Nylon101wilderness_666No ratings yet

- Mitsubishi Chemical Advanced Materials Acetron ® Food Grade Blue 50 POM-C Copolymer Acetal, Extruded (ASTM Datasheet)Document2 pagesMitsubishi Chemical Advanced Materials Acetron ® Food Grade Blue 50 POM-C Copolymer Acetal, Extruded (ASTM Datasheet)jose lealNo ratings yet

- Mitsubishi Chemical Advanced Materials Nylatron ® GSM Nylon, Cast Mos2 Filled Type 6 (Astm Product Data Sheet)Document2 pagesMitsubishi Chemical Advanced Materials Nylatron ® GSM Nylon, Cast Mos2 Filled Type 6 (Astm Product Data Sheet)Irwan SaputraNo ratings yet

- PA6, Unfilled, Cast Nylon (ASTM Data) : @frequency 1e+6 HZ @frequency 1e+6 HZDocument1 pagePA6, Unfilled, Cast Nylon (ASTM Data) : @frequency 1e+6 HZ @frequency 1e+6 HZroberto_perraciniNo ratings yet

- Lexan 9034 Data SheetDocument2 pagesLexan 9034 Data SheetAdrián PonceNo ratings yet

- Pps DatasheetDocument3 pagesPps Datasheetawdhesh ChaudharyNo ratings yet

- UHMW-PE Tivar 1000Document2 pagesUHMW-PE Tivar 1000centurion2988No ratings yet

- LEXAN™ Resin - 123R - Americas - Technical - Data - SheetDocument2 pagesLEXAN™ Resin - 123R - Americas - Technical - Data - SheetRodrigoMachadoNo ratings yet

- TKGR FLON (PTFE) density, properties, applicationsDocument1 pageTKGR FLON (PTFE) density, properties, applicationse.vicente.caballeroNo ratings yet

- LEXAN™ Resin - 241R - Americas - Technical - Data - SheetDocument2 pagesLEXAN™ Resin - 241R - Americas - Technical - Data - Sheetr92g5478cxNo ratings yet

- ALLEN 8300FR Technical Data SheetDocument2 pagesALLEN 8300FR Technical Data SheetRachit RanjanNo ratings yet

- LEXAN™ Resin - 141R - Asia - Technical - Data - SheetDocument2 pagesLEXAN™ Resin - 141R - Asia - Technical - Data - SheetTruc Thao NguyenNo ratings yet

- Quadrant EPP PVC - Polyvinyl Chloride, Type I, Grade 1: Physical Properties Metric English CommentsDocument1 pageQuadrant EPP PVC - Polyvinyl Chloride, Type I, Grade 1: Physical Properties Metric English Commentsروشان فاطمة روشانNo ratings yet

- Tds Abs Hi121hDocument2 pagesTds Abs Hi121hHuyền VũNo ratings yet

- Injection Molding Properties and Applications of HI121 PolypropyleneDocument2 pagesInjection Molding Properties and Applications of HI121 PolypropyleneHuyền VũNo ratings yet

- Lupox Gp1000H: Description ApplicationDocument2 pagesLupox Gp1000H: Description ApplicationPhuoc Thinh TruongNo ratings yet

- SABIC Innovative Plastics Lexan® 940 PC Data SheetDocument3 pagesSABIC Innovative Plastics Lexan® 940 PC Data SheetMRC RailNo ratings yet

- TIVAR® 1000 Natural Virgin UHMW-PE: Physical Properties Metric English CommentsDocument2 pagesTIVAR® 1000 Natural Virgin UHMW-PE: Physical Properties Metric English CommentsVictor AguirreNo ratings yet

- Ninjaflex 3D Printing Filament: Flexible Polyurethane Material For FDM PrintersDocument1 pageNinjaflex 3D Printing Filament: Flexible Polyurethane Material For FDM PrinterssrikanthNo ratings yet

- LED Lamp Cover Material for Light DiffusionDocument2 pagesLED Lamp Cover Material for Light DiffusionLong HomaNo ratings yet

- Injection Molding Grade: Description ApplicationsDocument2 pagesInjection Molding Grade: Description ApplicationsSangharshBhustalimathNo ratings yet

- Nominal Engineering Properties of Ryton R-4: Data SheetDocument4 pagesNominal Engineering Properties of Ryton R-4: Data SheetRakeshNo ratings yet

- LG Abs Af365bDocument2 pagesLG Abs Af365bPhung LucNo ratings yet

- KOPA KN126 enDocument1 pageKOPA KN126 enJagadeesh WaranNo ratings yet

- PC-ABS Cycoloy™ C6600Document2 pagesPC-ABS Cycoloy™ C6600countzeroaslNo ratings yet

- Lexan™ 8010 Uncoated Polished Film DatasheetDocument3 pagesLexan™ 8010 Uncoated Polished Film DatasheetTeng Yan ChanNo ratings yet

- Polycarbonate-ABS Blend (PC-ABS) : Mechanical Properties Test Method Imperial MetricDocument1 pagePolycarbonate-ABS Blend (PC-ABS) : Mechanical Properties Test Method Imperial MetricIsabel Narloch CardosoNo ratings yet

- LG Abs - Hi100hDocument2 pagesLG Abs - Hi100hqshakimNo ratings yet

- Infino Pc-Abs Hp1000xa (Natural)Document1 pageInfino Pc-Abs Hp1000xa (Natural)Rhekron PlasticsNo ratings yet

- Extrusion Molding: Description ApplicationsDocument2 pagesExtrusion Molding: Description ApplicationsbobNo ratings yet

- Injection Molding: Description ApplicationsDocument2 pagesInjection Molding: Description ApplicationsPhuoc Thinh TruongNo ratings yet

- Tds Ecozen t110gDocument1 pageTds Ecozen t110galfred quinNo ratings yet

- EPX82Document14 pagesEPX82BorisNo ratings yet

- LF410 (영문)Document1 pageLF410 (영문)coordinador.comercialNo ratings yet

- SABIC® LLDPE - 324CNJ - Global - Technical - Data - SheetDocument2 pagesSABIC® LLDPE - 324CNJ - Global - Technical - Data - Sheettechnical kmiNo ratings yet

- Physical Properties of PVC CPVC PipeDocument1 pagePhysical Properties of PVC CPVC PipeBimal DeyNo ratings yet

- Technical Data Sheet for ABS HU651Document1 pageTechnical Data Sheet for ABS HU651hugo santiago chavez godoyNo ratings yet

- LUPOX TE5100: Description ApplicationDocument2 pagesLUPOX TE5100: Description Applicationhugo santiago chavez godoyNo ratings yet

- ABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)Document1 pageABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)DiegoTierradentroNo ratings yet

- PBT GF17% DR48-7001Document2 pagesPBT GF17% DR48-7001pava16230.meNo ratings yet

- RoHS Compliant Heat Shrink Tubes for Busbar InsulationDocument2 pagesRoHS Compliant Heat Shrink Tubes for Busbar InsulationCarlos Berrospi ChacaNo ratings yet

- DoW LDPE 2685GDocument4 pagesDoW LDPE 2685Gtariquekhan143No ratings yet

- ABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)Document1 pageABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)DiegoTierradentroNo ratings yet

- 2.2.Tds Astm-Abs Lgchem Hi121Document2 pages2.2.Tds Astm-Abs Lgchem Hi121Wilda Sania MtNo ratings yet

- PPS Ryton R-4-230Document3 pagesPPS Ryton R-4-230thegeneral2040No ratings yet

- Styrolux 684D SBC Ineos TDS enDocument3 pagesStyrolux 684D SBC Ineos TDS enfabianmendez2875No ratings yet

- ABS Cycolac X37Document3 pagesABS Cycolac X37countzeroaslNo ratings yet

- ABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)Document1 pageABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)DiegoTierradentroNo ratings yet

- Shell Diala S2 Zx-A: Performance, Features & Benefits Main ApplicationsDocument3 pagesShell Diala S2 Zx-A: Performance, Features & Benefits Main ApplicationsDaniel Orlando Carballo FernándezNo ratings yet

- Abs-Er460 EngDocument2 pagesAbs-Er460 Engjdstore99No ratings yet

- ABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)Document1 pageABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)DiegoTierradentroNo ratings yet

- PC Lexan 500 10%GLDocument3 pagesPC Lexan 500 10%GLcountzeroaslNo ratings yet

- Filament Specifications Unit ValueDocument4 pagesFilament Specifications Unit ValueRoberto Gonzalo PelazNo ratings yet

- Abs Xr409H: Description ApplicationDocument2 pagesAbs Xr409H: Description ApplicationPhuoc Thinh TruongNo ratings yet

- TDS Pe 202 SP4808Document2 pagesTDS Pe 202 SP4808Desri AkbarNo ratings yet

- 002DP48 PDFDocument2 pages002DP48 PDFDiadam SharmaNo ratings yet

- Pc-Iso: Mechanical Properties Test Method ValueDocument2 pagesPc-Iso: Mechanical Properties Test Method ValuekaledioskoppNo ratings yet

- Insulating Oil Technical Data SheetDocument2 pagesInsulating Oil Technical Data SheetXavier DiazNo ratings yet

- 614 1056 1 SMDocument7 pages614 1056 1 SMzainudinNo ratings yet

- Chapter03 PDFDocument46 pagesChapter03 PDFzainudinNo ratings yet

- 2013 Motor Catalog - WebDocument84 pages2013 Motor Catalog - WebzainudinNo ratings yet

- ASTM A228 Music Wire AlloyDocument4 pagesASTM A228 Music Wire AlloyquangnhaNo ratings yet

- Chapter03 PDFDocument46 pagesChapter03 PDFzainudinNo ratings yet

- Chapter03 PDFDocument46 pagesChapter03 PDFzainudinNo ratings yet

- Chapter03 PDFDocument46 pagesChapter03 PDFzainudinNo ratings yet

- How To Make SpringsDocument62 pagesHow To Make Springsrudey18No ratings yet

- Chapter03 PDFDocument46 pagesChapter03 PDFzainudinNo ratings yet

- International standards for aluminium diecasting alloy compositions and propertiesDocument2 pagesInternational standards for aluminium diecasting alloy compositions and propertieszainudinNo ratings yet

- ASTM A228 Music Wire AlloyDocument4 pagesASTM A228 Music Wire AlloyquangnhaNo ratings yet

- SinteringDocument4 pagesSinteringukalNo ratings yet

- Metric Dowel PinsDocument1 pageMetric Dowel PinszainudinNo ratings yet

- American Fastener TablesDocument7 pagesAmerican Fastener TablesAhmed BdairNo ratings yet

- Metric Fasteners PDFDocument28 pagesMetric Fasteners PDFzainudinNo ratings yet

- Chapter 03 - Flow in PipesDocument83 pagesChapter 03 - Flow in PipesSamnang HangNo ratings yet

- Extreme Grain DeformationDocument36 pagesExtreme Grain DeformationTao Veloz VazquezNo ratings yet

- Chemical Reactors - Problems of Reactor Association 47-60: (Exam Jan'09)Document6 pagesChemical Reactors - Problems of Reactor Association 47-60: (Exam Jan'09)Alfredo ZuñigaNo ratings yet

- Model Questions PhysicsDocument10 pagesModel Questions PhysicsCharis Israel AnchaNo ratings yet

- 2-15-1466427029-1. Electrical - Ijeee - Coordinated Effect of Power System Stabilizer - Rampreet ManjhiDocument10 pages2-15-1466427029-1. Electrical - Ijeee - Coordinated Effect of Power System Stabilizer - Rampreet Manjhirobertovm2002No ratings yet

- Ch. VIII Potential Flow and Computational Fluid Dynamics: Review of Velocity-Potential ConceptsDocument5 pagesCh. VIII Potential Flow and Computational Fluid Dynamics: Review of Velocity-Potential ConceptsGerson Daniel Vargas PoloNo ratings yet

- Transformations (Solution)Document12 pagesTransformations (Solution)Amman ButtNo ratings yet

- First Semester Engineering Degree Examination: Subject Title 21PHY12/22Document3 pagesFirst Semester Engineering Degree Examination: Subject Title 21PHY12/22Nanditha ONo ratings yet

- P525/2 Chemistry Paper 2: Uganda Advanced Certificate of Education Page 1Document8 pagesP525/2 Chemistry Paper 2: Uganda Advanced Certificate of Education Page 1ArthurNo ratings yet

- Central Angles PDFDocument8 pagesCentral Angles PDFJoseph LeeNo ratings yet

- M1 Lab ReportDocument6 pagesM1 Lab Reportweimingf0% (2)

- San Carlos University of Guatemala Faculty of Engineering School of Sciences Technical language Inga. Soraya Martinez Final project Guatemala. April 22st 2019 Goldberg MachineDocument15 pagesSan Carlos University of Guatemala Faculty of Engineering School of Sciences Technical language Inga. Soraya Martinez Final project Guatemala. April 22st 2019 Goldberg MachineMaria Renee MiraldaNo ratings yet

- Models - Mixer.centrifugal PumpDocument22 pagesModels - Mixer.centrifugal Pumpcarlos tNo ratings yet

- GC-MS QuizDocument10 pagesGC-MS Quizchegu BusinessNo ratings yet

- U2 - L10 Stress Isobar or Pressure Bulb PDFDocument6 pagesU2 - L10 Stress Isobar or Pressure Bulb PDFศิวาเวช อบมาNo ratings yet

- 106 400 1 PBDocument10 pages106 400 1 PBIbtehaj Tasfin RiasatNo ratings yet

- Fluid Flow in Pipes - Lecture 1Document4 pagesFluid Flow in Pipes - Lecture 1amin_corporationNo ratings yet

- Rheological Properties of Paints PDFDocument5 pagesRheological Properties of Paints PDFAdelaida CruzNo ratings yet

- ch02b (QN 31-60) PDFDocument38 pagesch02b (QN 31-60) PDFAnonymous rpcAOp100% (1)

- WB-Mech 120 Ch07 BucklingDocument18 pagesWB-Mech 120 Ch07 BucklingMardiSantosoNo ratings yet

- Phy110 Unit V TutorialDocument18 pagesPhy110 Unit V TutorialAnsh ThakurNo ratings yet

- Optics QustionDocument6 pagesOptics Qustionsonu kumarNo ratings yet

- Scarani - Quantum Physics With PolarizationDocument21 pagesScarani - Quantum Physics With Polarizationj.emmett.dwyer1033No ratings yet

- Height & Distance-10Document26 pagesHeight & Distance-10mad_sudrocksNo ratings yet