Professional Documents

Culture Documents

Mine Ventilation: Standard of Mine Ventillation

Uploaded by

kurtOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mine Ventilation: Standard of Mine Ventillation

Uploaded by

kurtCopyright:

Available Formats

MINE VENTILATION 1

MINE VENTILATION

Mine Ventilation is the Circulation of the fresh air at all working place to dilute

& remove the noxious gases for making the mine environment comfortable and

safe.

OR

The provision of a directed flow of fresh and return air along all underground

roadways, traveling roads, workings, and service parts.

STANDARD OF MINE VENTILLATION

The mine air is not comparable to the atmospheric air due to the various factors.

Polluting it evidently the air circulating underground invariably be free from any

pollution and the level of oxygen should not be lower than 19% to achieve it, the

adequately of air matching with the following quantization parametric must be

ensured it.

Oxygen should not be less than 19%

Fire damp should not be more than 1%

Carbon dioxide should not be exceed 0.5%

Carbon Mono-oxide should not exceed 0.01%

Stink damp should not be more than 0.002%

Nitrous oxide should not be more than 0.0005%

Nitrogen should not be exceed more than 80%

Wet bulb temperature should not exceed 72F dry bulb

Dust particles size should not be less than 10 microns weight density

should not be more than 7 per cube meter of air.

By : Izhar Mithal Jiskani ( http://miningmuet.webs.com )

MINE VENTILATION 2

OBJECTIVES

These may be set out briefly as fellow

To provide adequately supply of fresh air in all parts of the mine where

persons are to work or pass so as to maintain their bodily health safety and

comfort,

To dilute and remove the noxious gases such as CO2 H2S, CO and nitrous

fumes which have harmful effect on health.

To dilute and noxious inflammable gas Such as CH4 and so as to prevent

the occurrence of an explosives..

To cool the working places in deep mine and render atmospheric

conditions as to heat and moisture for the conduct of efficient work

To remove or dissipate dust produced in the getting cool and the driving of

road ways through salacious Slater.

TYPES OF MINE VENTILATION

NATURAL VENTILATION

Natural ventilation depends upon the difference in elevation of the surface and

mine working and the difference in air temperature inside and outside the mine.

Temperature variations at the surface in most parts of the world exceed 100 F

between summer and winter extremes. Mine temperature vary little, except in

shafts, and near portals and farther the working are from the surface openings,

the less seasonal variation in temperature. Therefore, the temperature difference

and hence the magnitude of the natural ventilation, depends largely upon the

temperature at the surface and its floatation.

By : Izhar Mithal Jiskani ( http://miningmuet.webs.com )

MINE VENTILATION 3

Deep mines do not necessarily have good natural ventilation, rather than depth.

Mines in mountains have strong natural ventilation because of difference in

elevation of the opening. Mines which are both deep and hot enjoy good natural

ventilation, but the flow is generally stronger in cold climates than in warm.

If may be concluded than, that natural ventilation fluctuates, is unstable and is

unreliable. It is strongest in winter and weakest in summer and the natural

ventilation should never be considered as main source of circulation. It becomes

obvious that control over it must be exercised. Control devices in use for

mechanical ventilation can also be utilized to keep the natural ventilation in

control.

MECHANICAL VENTILATION

The fresh air is supplied and controlled through fans & ducting. If a fan while

working on a mine is exhausting air there from, the fan is then, due to centrifugal

force, creating a partial vacuum at its center or axis; the extent of this vacuum

depends on the peripheral or rim speed of the fan. The peripheral speed at which

a fan should run depends altogether on its construction. While some fans may

stand a rim speed of 16,000 ft. per minute, others will not stand more than 5000

ft. per minute. When the inlet of the fan is connected to the mine the only air that

can get to the fan must pass through the mine, and hence the ventilating current

is maintained as long as the fan runs. When the fan is running the pressure of the

air is always less at the inlet of the fan than outside, and the difference between

this pressure and the pressure of the atmosphere is the pressure producing

ventilation, or the extent to which a vacuum is approached by the fan. Many

differently constructed fans are being used for the purpose of ventilating mines.

The End

By : Izhar Mithal Jiskani ( http://miningmuet.webs.com )

You might also like

- Environmental Scenario in Indian Mining Industry - an OverviewFrom EverandEnvironmental Scenario in Indian Mining Industry - an OverviewNo ratings yet

- Pme 310 1Document9 pagesPme 310 1Anonymous 72KAVTrQTANo ratings yet

- Ventilation Planning OlDocument97 pagesVentilation Planning Olenjam yasankNo ratings yet

- 04 PPT Mine Fan General PresentationDocument52 pages04 PPT Mine Fan General PresentationHeri WibowoNo ratings yet

- Chapter-2-Underground Environment - Mine VentilationDocument23 pagesChapter-2-Underground Environment - Mine VentilationSahil SokhalNo ratings yet

- Auxiliary VentilationDocument20 pagesAuxiliary VentilationNikhil Asha JainNo ratings yet

- Cooling Power of Mine AirDocument16 pagesCooling Power of Mine AirVihari RahulNo ratings yet

- 9.2 Ventilation Netword Analysis - Network AnalysisDocument10 pages9.2 Ventilation Netword Analysis - Network AnalysisDeepakKattimani100% (1)

- Mine Ventilation LabDocument23 pagesMine Ventilation LabOolasyar KhattakNo ratings yet

- Unit 4Document6 pagesUnit 4Sai KumarNo ratings yet

- Laboratory Manual: Core Drilling MachineDocument5 pagesLaboratory Manual: Core Drilling MachineAshish VermaNo ratings yet

- Natural VentilationDocument4 pagesNatural VentilationAnonymous jhetHANo ratings yet

- 1.10 Mine Gases - Methane IVDocument9 pages1.10 Mine Gases - Methane IVDeepakKattimaniNo ratings yet

- Lecture CompactionDocument38 pagesLecture Compactionhasshos100% (2)

- Report Setting OutDocument25 pagesReport Setting Outaqilah dianaNo ratings yet

- " Deepening and Widening of Shafts" .A PresentationDocument18 pages" Deepening and Widening of Shafts" .A PresentationCraig Thomas100% (1)

- Heat 4e Chap02 LectureDocument48 pagesHeat 4e Chap02 LectureSubho Samanta100% (4)

- Ascensional and Descensional VentilationDocument5 pagesAscensional and Descensional VentilationP Taviti NaiduNo ratings yet

- Using Fans in Series and ParallelDocument3 pagesUsing Fans in Series and Parallelvalentinlupascu33No ratings yet

- Thick Seam MiningDocument10 pagesThick Seam MiningAjeet KumarNo ratings yet

- Unconfined Compression Tests PDFDocument6 pagesUnconfined Compression Tests PDFHansen A JamesNo ratings yet

- 1.6 Mine Gases - Gas DrainageDocument8 pages1.6 Mine Gases - Gas DrainageDeepakKattimaniNo ratings yet

- C2-Consistency Cement PasteDocument4 pagesC2-Consistency Cement PasteMuhamad FarhanNo ratings yet

- Free and Forced VortexDocument8 pagesFree and Forced Vortexsmh khanNo ratings yet

- Compaction TestDocument4 pagesCompaction Testmira asyafNo ratings yet

- Suspended Sediment SamplingDocument46 pagesSuspended Sediment SamplingŔaɓiɳ ṨhtNo ratings yet

- Gully Excursion ReportDocument9 pagesGully Excursion ReportYhemmy Lhawal JummyNo ratings yet

- Basic Types of Fans Used For Ventilating Underground MinesDocument15 pagesBasic Types of Fans Used For Ventilating Underground MinesNag Raj RockssNo ratings yet

- Advanced Mine VentilationDocument95 pagesAdvanced Mine Ventilationshibam200100% (1)

- 1.8 Mine Gases - Sampling of Mine AirDocument9 pages1.8 Mine Gases - Sampling of Mine AirDeepakKattimaniNo ratings yet

- 8.5 Mechanical Ventilation - Fan Characteristic CurvesDocument7 pages8.5 Mechanical Ventilation - Fan Characteristic CurvesDeepakKattimani100% (1)

- Methane Layering in MinesDocument5 pagesMethane Layering in MinesAnurag TripathyNo ratings yet

- Strings & DTM's.labDocument14 pagesStrings & DTM's.labAndry DepariNo ratings yet

- Application of Highwall Mining in IndiaDocument12 pagesApplication of Highwall Mining in IndiaSatish kumarNo ratings yet

- Aerodynamic of AircraftDocument73 pagesAerodynamic of AircraftAmirul Fikry SamsudinNo ratings yet

- 26th March 2002 Room and Pillar Mechanised MiningDocument59 pages26th March 2002 Room and Pillar Mechanised MiningCraig ThomasNo ratings yet

- Heavy Mineral Concentration in BangladeshDocument2 pagesHeavy Mineral Concentration in BangladeshApu DeyNo ratings yet

- Best Practices of Reclamation in MiningDocument16 pagesBest Practices of Reclamation in MiningTanmaya PingNo ratings yet

- Equivalent OrificeDocument2 pagesEquivalent OrificeSami Faizaan100% (2)

- Precaution For Fly LevellingDocument1 pagePrecaution For Fly LevellingJohn TeyNo ratings yet

- Humidity and Heat in MinesDocument45 pagesHumidity and Heat in MinesAhsan AliNo ratings yet

- Course Overview Mining Machinery 17Document20 pagesCourse Overview Mining Machinery 17Abhijeet ShrivastavaNo ratings yet

- Assignment On U Nderground Metal MiningDocument38 pagesAssignment On U Nderground Metal MiningAyush tiwari100% (1)

- Chapter 4 Underground Coal MiningDocument58 pagesChapter 4 Underground Coal Miningrishav baishyaNo ratings yet

- Softening Point of BitumenDocument2 pagesSoftening Point of BitumenYasir DharejoNo ratings yet

- Advanced Coal Mining and MechanizationDocument2 pagesAdvanced Coal Mining and MechanizationRiswan RiswanNo ratings yet

- Spray PatternatorDocument6 pagesSpray PatternatortongocharliNo ratings yet

- Civil-Iii-Surveying-I 10CV34 - Notes PDFDocument105 pagesCivil-Iii-Surveying-I 10CV34 - Notes PDFAS Animesh Sinha84% (25)

- Engineering Geology IIDocument12 pagesEngineering Geology IIRehan HakroNo ratings yet

- TheodoliteDocument36 pagesTheodolitesikandar_shah100No ratings yet

- PRACTICAL NO. 6 (2.5kg 4.5kg Rammer)Document5 pagesPRACTICAL NO. 6 (2.5kg 4.5kg Rammer)slawek780303No ratings yet

- Soil CompactionDocument30 pagesSoil CompactionJherome ManuelNo ratings yet

- Aggregate Crushing Value: IS: 2386 (Part IV) - 1963)Document1 pageAggregate Crushing Value: IS: 2386 (Part IV) - 1963)SANJAY KUMAR SINGHNo ratings yet

- DL Balancing DiagramDocument7 pagesDL Balancing DiagramJay Yadav100% (1)

- ACstatementDocument15 pagesACstatementAfifa SyedNo ratings yet

- Mine Environment & Ventilation Notes by Mining Gyan PDFDocument239 pagesMine Environment & Ventilation Notes by Mining Gyan PDFSikun SahooNo ratings yet

- VENTILATIONDocument16 pagesVENTILATIONMwine Isaac NormanNo ratings yet

- Ventilation and Lighting in BuildingsDocument17 pagesVentilation and Lighting in BuildingsT N Roland Bourge100% (1)

- Ventilation: Composition of Air 1Document30 pagesVentilation: Composition of Air 1ShyaM Lal DewasiNo ratings yet

- Ventilation: BY Sathish MudraboinaDocument11 pagesVentilation: BY Sathish MudraboinaGR KannaNo ratings yet

- Hazardous WasteDocument2 pagesHazardous WasteIzhar Jiskani100% (2)

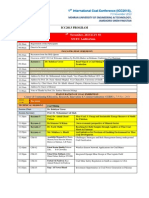

- ICC2013 ProgramDocument5 pagesICC2013 ProgramIzhar JiskaniNo ratings yet

- Rock BurstDocument2 pagesRock BurstIzhar Jiskani100% (1)

- Importance of Mine Surveying in Mining IndustryDocument3 pagesImportance of Mine Surveying in Mining IndustryIzhar Jiskani88% (16)

- Mine FiresDocument7 pagesMine FiresIzhar Jiskani100% (2)

- EARTHQUAKEDocument1 pageEARTHQUAKEIzhar JiskaniNo ratings yet

- FutureGen, Kyoto Protocol, Gasification, In-Situ Coal Gasification, Coal BeneficiationDocument2 pagesFutureGen, Kyoto Protocol, Gasification, In-Situ Coal Gasification, Coal BeneficiationIzhar JiskaniNo ratings yet

- Coal Mining MethodsDocument2 pagesCoal Mining MethodsIzhar JiskaniNo ratings yet

- Formation of Coal & Theories Associated With Coal FormationDocument2 pagesFormation of Coal & Theories Associated With Coal FormationIzhar Jiskani100% (2)

- Rank of CoalDocument2 pagesRank of CoalIzhar Jiskani0% (1)

- TransformerDocument2 pagesTransformerIzhar JiskaniNo ratings yet

- Erosion & Agents of ErosionDocument2 pagesErosion & Agents of ErosionIzhar JiskaniNo ratings yet

- Lakhra Coal Mine ReportDocument4 pagesLakhra Coal Mine ReportIzhar Jiskani25% (4)

- Formation of Sedimentary RocksDocument2 pagesFormation of Sedimentary RocksIzhar JiskaniNo ratings yet

- Volcanoes, Its Eruption, Types, Geographical Distribution & ProductsDocument3 pagesVolcanoes, Its Eruption, Types, Geographical Distribution & ProductsIzhar JiskaniNo ratings yet

- Geology, Its Main Branches, Relationship With Other Sciences & Role in Mining EngineeringDocument5 pagesGeology, Its Main Branches, Relationship With Other Sciences & Role in Mining EngineeringIzhar Jiskani57% (7)

- Stages in The Life of A MineDocument5 pagesStages in The Life of A MineIzhar Jiskani86% (7)

- Role of Geology in Mining IndustryDocument2 pagesRole of Geology in Mining IndustryIzhar Jiskani81% (21)

- Interior of EarthDocument2 pagesInterior of EarthIzhar JiskaniNo ratings yet

- DC Generator, Basic Principle of Operation, Construction & Working PrincipleDocument3 pagesDC Generator, Basic Principle of Operation, Construction & Working PrincipleIzhar Jiskani62% (13)

- Electrical Measurements, Types of Electrical Instruments & Different Types of Voltmeter and AmeterDocument9 pagesElectrical Measurements, Types of Electrical Instruments & Different Types of Voltmeter and AmeterIzhar Jiskani50% (2)

- Igneous Rocks Classification, Composition, Formation, Texture & Uses)Document3 pagesIgneous Rocks Classification, Composition, Formation, Texture & Uses)Izhar JiskaniNo ratings yet