Professional Documents

Culture Documents

RESUME

Uploaded by

Alam MD Sazid0 ratings0% found this document useful (0 votes)

58 views5 pagesOriginal Title

RESUME.docx

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

58 views5 pagesRESUME

Uploaded by

Alam MD SazidCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 5

RESUME

K.O. SUNOD KUMAR

DME + AWS-CWI + CSWIP 3.1 + ASNT L II

(Saudi Aramco Certified SAP#

Street

Address )

Objectives & Goals

To aspire challenging and dynamic career in Mechanical, Piping, Welding

Quality controls Quality assurance, where I can apply and improve my

knowledge and experience.

Profile

More than 12 years of experience as QA/QC Mechanical, Welding Inspector &

Piping Engineer for projects related to Oil & Gas, Petrochemicals, Water

and Steels of esteemed organization like Saudi Aramco, SABIC, Reliance

India etc and with Multinational company like Snamprojetti, Shaw Stone &

Webster, SINOPEC, Metal Services Company, CAT Co, Saudi Techint, Tekfen,

VAI India, SULZER India, CONCAST at Saudi Arabia and India.

Skills and Strength

* Good knowledge of Construction, Inspection, Testing, Pre-commissioning

and Commissioning Related to Pipelines/Piping, Rotary & Static

Equipments, Mechanical Structures, Vessels, Tanks etc for Oil, Gas,

Petrochemicals, Water and Steel Industries.

* Good knowledge of NDT activities.

* Good knowledge in preparation of Hydro test Packages.

* Good knowledge in preparation of QCP, ITP, WPS & PQR.

* Good knowledge of ASME, API, Saudi Aramco, SABIC, AWS and other

International Stds.

* Capable of handling group of Inspectors and Workmen.

Educational & Technical Qualifications

* Diploma In Mechanical Engineering From BTE Kerala (1994- 97)

* AWS-Certified Welding Inspector (Certificate No.-04010981)

* ASNT Level II in UT, RT, PT& MPT.

* CSWIP 3.1 (Certificate No.- 40381)

Achievements

* Saudi Aramco Certification for 7 projects (SAP# 70005115).

* Worked as Saudi Aramco Project Inspection Department Mechanical

Inspector.

Seminars

* IS0 9001-2002 AUDIT

Computer Skills

* Microsoft Office & AutoCAD 2000

Driving License

Have valid LMV License for India and Saudi Arabia.

Work Experience

Experiences in Abroad

1. Company : Saudi Aramco (Northern Area Project

Inspection Dept.)

Designation : QA/QC Mechanical Inspector (SAPID)

Duration : Aug 2009 to Aug 2010

Job Description : Carrying out inspection jobs under Maintain

Potential and Pipelines Division of Saudi Aramco Northern Area Projects

Inspection Department. Projects related Cross country Pipelines, Well

Head Connections, Trunk Lines, Plant Piping, Tie Ins, Hot-tap Jobs.

Duties and Responsibilities

* Provide quality assurance and quality monitoring for capital

projects to ensure that contractor's quality personnel and

processes are effective.

* Provide technical support to Project Management in resolving

problems concerning inspection methods and procedures of

completing works within the scope and intent of applicable codes

and standards.

* Co-ordination with the vendor inspection department for the shop

fabricated tanks, heat exchangers and pressure vessels

* Review and approval of WPS according to project requirements

* Review and approval of QC inspectors for contractor and

subcontractor according to Schedule 'Q' (contract document)

requirements

* Review, approval and issue of job clearance card for welders

according to their qualification done by approved third party

company.

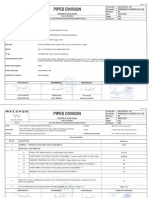

* Review and approval of QC documents like QCP, ITP, QCS, Method

statements etc.

* Review, evaluate and monitor the weekly report from different

contractors and subcontractors.

* Delegated jobs from the field supervisors to prepare weekly

highlight, weekly project quality status (PQS), calculate project

quality index (PQI) etc.

* Surveillance and witnessing of Daily Construction Activities as

per ITP.

* Review and punch listing of Pressure test package and witnessing

the Pressure Test

* Attending weekly QA/QC Meeting.

* Witnessing and Review of NDE Activities.

* Witnessing PWHT, Hardness Testing, Pneumatic Testing.

* Witnessing HOT-TAP Activities.

* Witnessing Application of Coating, Fabrication, Holiday Test,

Backfilling etc

* Focus Assessment of contractor

* Making and Closing out Exceptional Items List and Participating in

MCC.

2. Company : Shaw Stone & Webster

Client : YANSAB Petrochemicals Co. (SABIC)

Project : Butane and BTX

Position : QA/QC Welding/ Piping Inspector

Duration : April 2008 to July 2009

Duties and Responsibilities

* Review and Approval of Welding/ Piping QA/QC Documents.

* Witnessing WQT, PQR

* Sarvaliance and witnessing of Daily Construction Activities as per

ITP

* Attending weekly QA/QC Meeting

* Review of PWHT chart, PMI and NDT reports

* Coordination with client QA/QC

* Witnessing Application of Coating, Fabrication, Erection etc

* Review and punch listing of Pressure test package

* Witnessing the Pressure Test of Piping and Valves.

* Participating in Final Walk Through

* Reinstatement of Final Piping

3. Company : Snamprogetti, KSA

Client : Saudi Aramco, KSA

Project : Gas Treat & Compression Facilities (GTC),

Hawiyah

Position : Lead-Welding Inspector

Duration : Jan. 2007 to March 2008

4. Company : Metal Services Company, KSA

Client : Saudi Aramco, KSA

Project : Additional Asphalt Handling Facilities at

Rastanura

Refineries and DR-1 Abqiaq Pump Station

Position : Welding Inspector

Duration : March 2006 to Nov. 2006

5. Company : Saudi TECHINT

Client : Saudi Aramco

Project : Haradh Al-Crude Increment Facilities (GOSP-

III)

Position : Welding Inspector

Duration : March 2005 to Feb. 2006

6. Company : TEKFEN Inc, KSA

Client : Saudi Aramco

Project : QUAD-1 Pipeline & Supporting Facilities

Position : Welding Inspector

Duration : Aug 2004 to Feb 2005

Duties and Responsibilities

* Carrying out WQT, WPS, PQR as per ASME Sec IX

* Controlling storage and release of materials as per P&ID

* Controlling the filler wires and electrodes as per ASME Sec. IIC and

WPS.

* Assisting in preparation of Inspection Formats, Procedure and QCPs and

submitting.

* Witnessing Preparation and inspection of Hydro testing of valves.

* Controlling the welding joints as per Isometric Drawings and

preparation of Weld Maps.

* Piping Inspection of Jacketed Piping, Equipment Piping etc

* Inspection of Cross country Pipelines, Trunklines etc

* Joint fit-up inspection and welding inspection of C.S, S.S, Copper,

Alloy steels, dissimilar metals etc and maintaining daily reports.

* Preparation Daily Fit-up, Weld Visual Reports and Inspection

Checklists.

* Controlling the Hot-tap, Tie-in and Temperature Tie-in joints.

* Inspection of Painting, Sandblasting, and FBE coating.

* Coordination with client and raising NCR's & RFI's.

* Coordination with NDT & Coating contractors

* Controlling the NDT jobs as per Project specification and reviewing

reports

* Preparation of welder performance reports on Weekly basis.

* Controlling the Preheat & PWHT and reviewing the PWHT Charts and

Hardness reports.

* Checking and rectification of the punch list and taking approval and

release from the client for Hydro test.

* Preparation of Hydro test Package.

* Carrying out the Inspection of Hydro test.

* Carrying out the Alignment and Leveling Inspection of Structures &

Equipments.

Experiences in India

1. Company : Kairali Engg. Pvt Ltd, Mumbai, India

Position : QA/QC Mechanical Inspector

Duration : March 2000 to July 2004

i. Client : Concast India Ltd, Mumbai

Project : 6/11M Radius 3 Strand Continuous

Casting

Machine, 30T Ladle Furnace and Fume

Extraction

System at SJK steels Co.ltd, AP, India.

ii. Client : VAI India Pvt Ltd, New Delhi

Project : 35T Vacuum Degassing Plant at

Aarthy SSL &

Vardhaman Steels, Punjab, India

iii. Client : Sulzer India Ltd, Pune

Projects : Revamping of Columns at IOCL, Gujarat &

Fabrication and Installation of Trays of

Columns

at Reliance Refineries, Jamnagar, India

Duties and Responsibilities

* Coordination of site activities

* Carrying out WQT, WPS, PQR as per ASME Sec IX and AWS D1.1

* Dimensional and Assembly/Fit-up inspection of Structural Components

like Columns, Beams, Chimmineys, Ducts, Equipment Platforms etc

* Inspection of Welding, Painting & Sandblasting.

* Inspection Piping of Oil, Gas and Utilities.

* Daily and Shutdown Maintenance of steel plant equipments and

accessories like Furnace, Filters, Silencers, Heat Exchangers, Rotary

Equipments, Pumps etc

* Shut down Maintenance of Columns at Refineries.

* Package Preparation and witnessing of Hydro test

* Responsible for Daily Production & QA/QC Documents

* Co-ordination with Third party Inspectors and client inspectors

* Coordinating with NDT Personnel and reviewing reports.

* Commissioning and Pre-commissioning Jobs of the projects.

2. Company : Technical Engg and Inspection

Services, Mumbai

Position : Site Supervisor cum NDT Inspector

i. Client : GG Dandaker Steel Works Ltd.,

Maharashta

Project : Fabrication of Parboiling Tanks

and Structures

Duration : Jun1999 to Feb2000

ii. Client : Dharamsi Morarji Chemicals,

Maharashta

Project : Deactivated Chemical Plant

Expansion Project

And Maintenance jobs

Duration : Dec 1998 to May1999

Duties and Responsibilities

* Coordination of site activities

* Installation of Pressure Vessels, Equipments, Structures and Piping at

chemical Plant

* Fabrication of square & conical tanks.

* Final Inspection and Dispatch of Tanks and Related Structures.

* Preparation of Quality Control Documents.

* Carrying out and reviewing of NDT

3. Company : Machine Tool Prototype Factory (Indian

Ordnance

Factories), Maharashtra

Position : Technical Apprenticeship (Mechanical)

Duration : Nov1997 to Nov1998

4. Company : Radiographic Services (I) Pvt. Ltd,

Mumbai

Position : NDT Technician (RT, PT & MPT)

Duration : Jun 1997 to Oct 1997

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- DPT Test Report FormatDocument1 pageDPT Test Report FormatAlam MD SazidNo ratings yet

- Osha Training CertificateDocument1 pageOsha Training CertificateAlam MD Sazid100% (2)

- Peneterant Testing For NDT - Procedure Details - Latest FinalDocument8 pagesPeneterant Testing For NDT - Procedure Details - Latest FinalAlam MD Sazid100% (1)

- Radiography Test Inspection Free NDT Sample Procedure 1 4Document5 pagesRadiography Test Inspection Free NDT Sample Procedure 1 4Alam MD SazidNo ratings yet

- SAES-Y-101 Custody Metering of Hydrocarbon GasesDocument38 pagesSAES-Y-101 Custody Metering of Hydrocarbon GasesZubair RaoofNo ratings yet

- MPAPS Master IndexDocument15 pagesMPAPS Master Indexmpedraza-1100% (3)

- Sawaed PT Report No. 02 For SWCC Jubail Emergency LineDocument1 pageSawaed PT Report No. 02 For SWCC Jubail Emergency LineAlam MD SazidNo ratings yet

- CV Faisal ZAFAR SHAHIDDocument6 pagesCV Faisal ZAFAR SHAHIDAlam MD SazidNo ratings yet

- MTC - Rel-01 (Rev.00)Document16 pagesMTC - Rel-01 (Rev.00)Alam MD SazidNo ratings yet

- NSH-DALM-JERP-WPS-11-P2 Rev.00Document10 pagesNSH-DALM-JERP-WPS-11-P2 Rev.00Alam MD SazidNo ratings yet

- Limak - Sawaed WpsDocument1 pageLimak - Sawaed WpsAlam MD SazidNo ratings yet

- Peneterant Testing For NDT Procedure Details LatestDocument7 pagesPeneterant Testing For NDT Procedure Details LatestAlam MD SazidNo ratings yet

- Welding Proposed Pwps For Our Jubail WorkDocument2 pagesWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- Letter From Man Industries India For MD Sazid AlamDocument1 pageLetter From Man Industries India For MD Sazid AlamAlam MD SazidNo ratings yet

- P6022mab Amd 128 11541 01 - S4Document1 pageP6022mab Amd 128 11541 01 - S4Alam MD SazidNo ratings yet

- Limak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Document2 pagesLimak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Alam MD SazidNo ratings yet

- List of WPS (Jerp) PDFDocument2 pagesList of WPS (Jerp) PDFAlam MD SazidNo ratings yet

- WPSDocument2 pagesWPSAlam MD Sazid100% (1)

- Accoutnt Statement PDFDocument3 pagesAccoutnt Statement PDFAlam MD SazidNo ratings yet

- Prime Minister Employment Generation ProgrammeDocument1 pagePrime Minister Employment Generation ProgrammeAlam MD SazidNo ratings yet

- Seed License Documents NewDocument8 pagesSeed License Documents NewAlam MD SazidNo ratings yet

- P6022mab Amd 128 11095 04 - S1 PDFDocument1 pageP6022mab Amd 128 11095 04 - S1 PDFAlam MD SazidNo ratings yet

- Passport Copy For Mr. PeterDocument1 pagePassport Copy For Mr. PeterAlam MD SazidNo ratings yet

- Signed Acceptance of Job OfferDocument2 pagesSigned Acceptance of Job OfferAlam MD Sazid0% (1)

- SWCC Acceptance Notice For Rel No.29-100inchx20.62mm WTDocument3 pagesSWCC Acceptance Notice For Rel No.29-100inchx20.62mm WTAlam MD SazidNo ratings yet

- Matterials Consignmnt PaperDocument7 pagesMatterials Consignmnt PaperAlam MD SazidNo ratings yet

- Curriculum Vitae New 2017 MD Sajid AlamDocument6 pagesCurriculum Vitae New 2017 MD Sajid AlamAlam MD SazidNo ratings yet

- Alishar SP 2Document84 pagesAlishar SP 2Alam MD SazidNo ratings yet

- Experience LetterDocument1 pageExperience LetterAlam MD Sazid50% (2)

- Attachment B - MSDS Fibagel UV LV ResinDocument4 pagesAttachment B - MSDS Fibagel UV LV ResinAlam MD SazidNo ratings yet

- SWCC-MTC Lot 25 (80in X 15.88mm) - 142Document22 pagesSWCC-MTC Lot 25 (80in X 15.88mm) - 142Alam MD SazidNo ratings yet

- Ficha Tecnica Canal Strut Recubierto de PVC PDFDocument1 pageFicha Tecnica Canal Strut Recubierto de PVC PDFCrls Armnd CNo ratings yet

- An Overview of The Pipeline Defect Assessment Manual (Pdam)Document13 pagesAn Overview of The Pipeline Defect Assessment Manual (Pdam)Jorge Altamirano100% (1)

- TECE Floor Universalpanel TI GB 2014 BrosuraDocument13 pagesTECE Floor Universalpanel TI GB 2014 BrosuraPodariu CosminNo ratings yet

- Ecrl FS01 - Tunjung - Ugc - Schedule HDocument14 pagesEcrl FS01 - Tunjung - Ugc - Schedule Hlkt_pestechNo ratings yet

- Astm B622Document6 pagesAstm B622Mohammad ShamimNo ratings yet

- General Manual TrussDocument10 pagesGeneral Manual TrussjillianixNo ratings yet

- 15156-2-2003 (BS en Iso)Document50 pages15156-2-2003 (BS en Iso)mayav1No ratings yet

- Tetrasteel 800 BrochureDocument4 pagesTetrasteel 800 BrochurejcrandleNo ratings yet

- DG SET-Technical Specs PDFDocument26 pagesDG SET-Technical Specs PDFankur yadavNo ratings yet

- C692Document7 pagesC692dinhtung2210100% (1)

- Excel: 2000 STL Illustrated Parts BreakdownDocument48 pagesExcel: 2000 STL Illustrated Parts BreakdownJefersson Roberth Mercado SaavedraNo ratings yet

- Dp&T-Sup Centrifugal Pumps Specification: 0 Original IssueDocument19 pagesDp&T-Sup Centrifugal Pumps Specification: 0 Original IssueAllyson LisboaNo ratings yet

- Plant Commissioning and StartupDocument31 pagesPlant Commissioning and StartupEric Fisher100% (5)

- Example Problem in Computing For A Single FamilyDocument19 pagesExample Problem in Computing For A Single FamilyBreillan SerranoNo ratings yet

- Pipe Cleaning: Inside Diameter Pipe CleanerDocument1 pagePipe Cleaning: Inside Diameter Pipe CleanerЮрийNo ratings yet

- Infraset Product Catalogue (2014)Document55 pagesInfraset Product Catalogue (2014)Christian JordaanNo ratings yet

- BS 5254-1976 (Specification For Polypropolyne Waste Pipe and Fittings)Document18 pagesBS 5254-1976 (Specification For Polypropolyne Waste Pipe and Fittings)minsara madtNo ratings yet

- 16.12 W77 AGS Vic Ring (Ingles)Document6 pages16.12 W77 AGS Vic Ring (Ingles)Jesus JavierNo ratings yet

- Types of Pipes, Classification of PipesDocument4 pagesTypes of Pipes, Classification of PipeschkibiNo ratings yet

- Field Service Manual For Proprietary Connections: VoestDocument46 pagesField Service Manual For Proprietary Connections: VoestHanyNo ratings yet

- Installation Manual: D 909 / 910 B/FL 1011 / F / 2011 B/FM 1011 F / 2011 B/FL 912/913/914/C B/FL 413 F / 513 /C / CPDocument290 pagesInstallation Manual: D 909 / 910 B/FL 1011 / F / 2011 B/FM 1011 F / 2011 B/FL 912/913/914/C B/FL 413 F / 513 /C / CPnenadNo ratings yet

- Eng BD Fta301Document9 pagesEng BD Fta301Lazar LilaNo ratings yet

- Heat Transfer EngineeringDocument9 pagesHeat Transfer Engineeringhamzashafiq1No ratings yet

- Hydrophore Set (Mectron Engineering)Document2 pagesHydrophore Set (Mectron Engineering)KelvinNo ratings yet

- Industrial Refrigeration: Components and ControlsDocument1,094 pagesIndustrial Refrigeration: Components and ControlsSudharshan ReddyNo ratings yet

- Installation and Leakage Testing Method Statement of Drainage Piping (Ground Zero)Document2 pagesInstallation and Leakage Testing Method Statement of Drainage Piping (Ground Zero)Al Mumeen Construction ServicesNo ratings yet

- Hose Reel Catalogue 2018Document12 pagesHose Reel Catalogue 2018FrancisNo ratings yet

- Api Buttress Connection Data SheetDocument7 pagesApi Buttress Connection Data SheetHanyNo ratings yet