Professional Documents

Culture Documents

Eil-Piping NDT PDF

Uploaded by

Mohammad Rawoof0 ratings0% found this document useful (0 votes)

447 views19 pagesOriginal Title

EIL-PIPING NDT.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

447 views19 pagesEil-Piping NDT PDF

Uploaded by

Mohammad RawoofCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 19

ust & adore wen at

aera tq are fatter

STANDARD SPECIFICATION FOR

NON DESTRUCTIVE EXAMINATION

REQUIREMENTS OF PIPING

Tacs [anus conven evo mea [EST] OS aeg |

18.04.95 [ISSUED IN CONFORMITY WITH STD PMS REV-2] MP AKG NS AS

ov. a isin a sr anoAno oEEATEN sa [em [ern nie

DATE REVISION ey | ohecxeo | convenon [Gaarmwan Si

STANDARD SPECIFICATION FOR |___SPECIFICATION _| REV

ENGINEERS INDIA LIMITED ION DESTRUCTIVE EXAMINATION 6-44-0016 4

REQUIREMENTS OF PIPING mer arie

be reproduced |

tod

CONTENTS

TITLE

i GENERAL.

2 VISUAL EXAMINATION

3. NON DESTRUCTIVE EXAMINATION

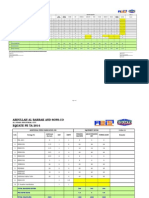

4. TABLE-I (with applicable Notes to Table-t)

PAGE NO.

STANDARD SPECIFICATION FOR

NON DESTRUCTIVE EXAMINATION

REQUIREMENTS OF PIPING

ENGINEERS INDIA LIMITED

‘NEW DELHI

SPECIFICATION _| REV

6-44-0016 4

Page 2 of 19

1. GENERAL.

1.1 SCOPE

Tot be reproduced

This specification covers the general requirements for the non destructive examination of shop

& field fabricated piping,

1.2 RELATED CODES & ENGINEERING STANDARDS

’A4 210x297

Referred codes / standards are as follows. Latest editions of the Codes/Standards referred to

shall be followed.

a) ASME Boiler & Pressure Vessel Codes, Section V & VIII (Div.1) including addenda

b) ASME B31.3

swar's express agracment at they

©) ASME BI6.5 & B16.34

4) ASTM E10

©) Standard Specification for Piping Material 6-44-0005

f) Standard Specification for Welding 6-77-0005

8) Standard Specification for Fabrication & Erection of Piping 6-44-0012

h) Standard Specification for Pressure Testing of Piping Systems 6-44-0017

1) Welding Specification for the Fabrication of Piping 6-77-0001

j) Design Guide for Radiography Requirement 8-77-0010

2. VISUAL EXAMINATION

2.1 Weld shall be visually inspected wherever accessible in accordance with the following

requirements

‘Property of ENGINEERS INDIA LIMITED. They are mer

3 2) Internal misalignment 1.5 mm or less

b) Cracks or lack of fusion None permitted

©) Incomplete penetration Depth shall not exceed

(For other than 100% ‘The lesser of 0.8 mm or 0.2 times thickness of

radiography butt-weld) thinner component joined by butt-weld

‘The total length of such imperfections shall not

exceed 38 mm in any 150 mm of weld length

d) Surface porosity and Not permitted

exposed slag inclusions

(4.7 mm nom, wall thickness

and less)

STANDARD SPECIFICATION FOR |__SPECIFICATION __| REV

ENGINEERS INDIA LIMITED

NEW DELHI

NON DESTRUCTIVE EXAMINATION 6-44-0016 4

REQUIREMENTS OF PIPING Page 3 of 19

3 ©) Concave root surface For single sided welded joints, concavity of the root

e (Suck up) surface shall not reduce the total thickness of joint,

z including reinforcement, to less than the thickness of

: the thinner of the components being joined

2 | i Weld ripples irregularities 2,5 mm or less.

33 2) Lack of uniformity in bead 2.5 mm or less.

28 width

a5 h) Lack of uniformity of leg 2.5 mm or less.

* = Jength

BB 1) Unevenness of bead 2.0 mm or less.

gs j) Weld undercutting 0.8 mm or 1/4 thickness of thinner components

#H Joined by butt weld, whichever is less. (shall be

3 smooth finished)

: k) Overlap 1.5 mm ot less

=e » Bead deflection 2.5 mm or less

es m) External weld reinforcement and internal weld protrusion (when backing rings are not

ae used) shall be fused with and shall merge smoothly into the component surfaces. The

is height of the lesser projection of external weld reinforcement or internal weld

nel protrusion from the adjacent base material surface shall not exceed the following

limits:

33] Wall thickness of thinner Weld reinforcement or internal weld protrusion

26 component joined by butt (mm) max

23 weld (mm)

28]

32] 6.4 and under 16

se] Over 6.4 -12.7 3.2

BS Over 12.7 -25.4 4.0

2 Over 25.4 48

e| n) Throat thickness of fillet welds

BE Nominal thickness of the thinner component x 0.7 or more.

©) Flattening

Flattening of a bend, as measured by difference between the nominal oulside diameter

and minimum or maximum diameter at any cross section shall not exceed 5 % of the

nominal outside diameter of pipe

P) Reduction of wall thickness

Reduction of wall thickness of a bend, as measured by difference between the nominal

thickness and minimum thickness shall not exceed 10 % of the nominal wall thickness

of pipe

STANDARD SPECIFICATION FoR |__SPECIFICATION _| REV

ENGINEERS INDIA LIMITED | NON DESTRUCTIVE EXAMINATION 6-44-0016 4

REQUIREMENTS OF PIPING eager

3

‘xpress agreement

Futea)-s07 Ad

=y of ENGINEERS INDIA LIMITED. Th

nya written co

22

3

3.2

33

Welds having any of imperfections which exceed the limitations specified in various clauses

of 2.1 shall be repaired by welding, grinding or overlaying etc. Number of times of repair

welding for the same weld, however shall conform to applicable notes to Table 1- Note

6(b)b.5

NON DESTRUCTIVE EXAMINATION

‘The type and extent of weld examination shall be in accordance with Table-1. All visual and

supplementary methods of girth weld examination shall be in accordance with ASME B31.3

and the requirements of this standard,

‘Welds between dissimilar materials shall be examined by method & to the extent required for

the material having the more stringent examination.

Certain categories of critical piping are classified under inspection Class IV (100%

radiography) as follows:

a) High Pressure Classes above 600 #

b) Severe Cyclic As defined by ASME B31.3.

©) Low Temperature Below temperature of -45°C & all materials.

4) Critical Service Hydrogen, Oxygen, NACE, Caustic, Chlorine &

such other critical services.

©) High Alloys 5 Cr & above for all pressure classes.

) High Temperature Above 500°C

ENGINEERS INDIA LIMITED

NEW DELHI

STANDARD SPECIFICATION FOR |__SPECIFICATION | REV

NON DESTRUCTIVE EXAMINATION 6-44-0016 L4

REQUIREMENTS OF PIPING Page 5 of 18

[REV

[4

Page 6 of 19)

SPECIFICATION

6-44-0016

STANDARD SPECIFICATION FOR

NON DESTRUCTIVE EXAMINATION

REQUIREMENTS OF PIPING

1: SSVI NONOSdSNI

NOLLVNIAWX4 (THM dO LNILXA F SdAL “SSVIO | 1 TEV

(sjou aqquondde qua) -ATAVL

262x012 PY LOs-1P9L-Ua

seth eyt Wawoaibe ssordxe &,Ja%s0109 40 D9

‘poanposdes oq

ENGINEERS INDIA LIMITED

NEW DELHI

S

sam r emnos | catos | estos] ssa

IL: SSV19 NOLLIG4SNI

(G.LNOD) NOLLVNINVXA TAM AO LNALXS 7% Td AL “SSVTO | 1 ATV.

usex01z

aun 24

205-19)

lg0iDe ss0xceo s,20m0109 By) YO PeULO} AjHOW B18 ABUL “CLINT WICNI SHINIONS Jo Auodosd ay} ove eU

REV

Page 7 of 19

‘SPECIFICATION

6-44-0016

STANDARD SPECIFICATION FOR

NON DESTRUCTIVE EXAMINATION

REQUIREMENTS OF PIPING

ENGINEERS INDIA LIMITED

NEW DELHI

@

REV

4

Page 8 of 19

‘SPECIFICATION

6-44-0016

STANDARD SPECIFICATION FOR

NON DESTRUCTIVE EXAMINATION

REQUIREMENTS OF PIPING

Il = SSV19 NOMLOGASNI

(G.LNO) NOLLVNINVXS (TAM IO LNSLXS % Gd AL 'SSW19 | 1 TTAVL

ipoonpoxsor a9

262%0.

fog

bY 1091991113 “9

wowaerbe ssexdxo s,s0mo110

ENGINEERS INDIA LIMITED

NEW DELHI

©

REV

Page 9 of 19

‘SPECIFICATION

6-44-0016

STANDARD SPECIFICATION FOR

NON DESTRUCTIVE EXAMINATION

REQUIREMENTS OF PIPING

(GLNOD) IIL: SSV19 NOLLOAdSNI

(GLNOD) NOLLWNINWX4 CTAM AO LNALXA IAAL “SSVTO: | ATAVL

ENGINEERS INDIA LIMITED

NEW DELHI

S

(GLNOD) Ill: SSVTD NOLLIGdSNI

(G.LNOD) NOLLVNINVX4 OTAM dO LNALXS P AdAL “SSWT9 | 1 ATAVL

REV

4

Page 10 of 19

‘SPECIFICATION

6-44-0016

STANDARD SPECIFICATION FOR

NON DESTRUCTIVE EXAMINATION

REQUIREMENTS OF PIPING

$Y £09-1991-713 “28n papuow ai 10) somo

uowisaibe ssaKx9 s s0Mmouoq auf UO PauEe} A)

1uasv0D UIA ® Aa p

218 AYL “O3LINT VIGNI SU33NIONG Jo AUodoxd ay} ave Yewto} Sx UO UOAI SHELOp puE UBI=H ‘CuImesP a4.

ow

x2 “posh 2 poise

RS INDIA LIMITED

NEW DELHI

@ ENGINE!

REV

4

Page 11 of 19

‘SPECIFICATION

6-44-0016

REQUIREMENTS OF PIPING

STANDARD SPECIFICATION FOR

NON DESTRUCTIVE EXAMINATION

(Q.LNOD) III | SSV19 NOLLOTASNI

(“GLNOD) NOLLVNINVXS GTM dO LNILXA P dd AL “SSVIO © | ATEVL

9 paidos

naezn

ENGINEERS INDIA LIMITED

NEW DELHI

S

peanpoxdes aq rou

‘out 1842 wautoaibe sseicxe 5,30%01109 out

Ble]?

« 3

2] |8]

e/g)"

3/8

=

AB

=

&

z

eo

REg

2

52:

eee

cath] suo] cauow ] cain | caton | caion 5$4

‘ero 2%

wou ven] vr | ww ; cua

sone ng venver oer! 8 25

Hee ‘ gee

one ae

Vettes wv 00 vas ah g

wer | seo | sont YEN | asdev | ow saan | samt | a3

20g

7 - - gon

7 7 7 — a t > TF 7 z Bz

Taare Tao °2

wrtgr | Naa | Sen | “cae | ine 3

vonievt | sonia | soviiw | asses | inns a

: (csi sv> =

severe GRR TaN TONAL ‘oat wat | oovs | ami | ones | ote =

ze

AL: SSV'1D NOLLOAdSNI a i

23

(GQLNOO) NOLLWNINVX4 TAM JO LNALXS 9 TAAL 'SSV1O 1 TEV ee

a

i=

Go

2

&

@)+|?

zI*]s

al |?

ale

s/8

ale

5

«&

= aie Lee

age |u| a |e ot 232

[|e REE

wa : Sx5

: » | sau) sous zu

wee | canvas cue

soot oon | snatenorse BEG

: . Sos

: fe

con i ~ = iF =

woe i £53

: 7 gag

- a 7 : 7 : — 7 : t zou

5S

am °2

ao nak a

i ste &

= S68, | sos0 i g

Saar Gian a aitonw | 2a = 5

5

st

(°GLNOD) Al : SVT NOLLOAASNI Bz

2

(CGLNOD) NOLLVNINVX CTEM JO INILXG 9 UAL 'SSVTO | 1 TTYL ae

o

2

a

2

a

2h WO pauioy AYU ave AANL “GLIA WIG SUBSNIONG Jo AUodes! By 0 18} S41 UO LOMB SIE. p Ce)

[REV

Page 14 of 19

SPECIFICATION

6-44-0016

REQUIREMENTS OF PIPING

STANDARD SPECIFICATION FOR

NON DESTRUCTIVE EXAMINATION

(°GLNOO) Al: SSV19 NOLLOAdSNI

CGLNOO) NOLLYNINVX4 OTAM JO LNALXA ® AdAL “SSVTO * 1 ATEVL

{62x01 vy Los-IPa

ays eur wuowaaibe ssoudxa 5,1

yosdes 2q 104

ENGINEERS INDIA LIMITED

NEW DELHI

S

zlele

wl?

c 3

z| | 4

Fg

9/9

E

a3

2

5

«&

: = ty 58

sos 7 Beg

232

el lee 52:

Esa

a a an 009 saunas siu

ome = O86

gee

oa i Ss eevee 2

: a st | ate BEG

5o8

=

Cn ie os ee

: aug

7 ry tr 7 7 7 * . * gag

2 ; 7 : zoe

z

ae] rae 5S

2

(NOD) AL: SSV19 NOLLOAASNI

(GLNOD) NOLLVNINVXS GTM HO LNILXS AdAL “SSVTO

TaTav

‘peonpoidos aq 104

ENGINEERS INDIA LIMITED

NEW DELHI

©

Applicable Notes to Table-T

1 Branch welds shall consist of the welds between the pipe & reinforcing element (if any),

nozzles & reinforcing element and the pipe & nozzle under the reinforcing element

Reinforcing element to be interpreted as pads, saddles, weldolets, sockolets ete

Seal welds of threaded joints shall be given the same examination as socket welds.

Unless specifically stated, all materials shall be for "Non-IBR™ service.

4. The Magnetic Particle & the Liquid Penetrant method of examination shall be in accordance

with Section V of the ASME Boiler and Pressure Vessel Code, Article VIL and VI

respectively. The entire area of the accessible finished weld surface shall be examined

Selected root runs, subject to a maximum of 10%, before finished weld, may also be

examined, at the discretion of the engineer-in-charge.

a) Wherever MP / LP testing is specified, either MP or LP test may be used. But

wherever only MP test is specified, MP method of examination may be used only if

MP examination is impracticable in the field as concurred by EIL site-in charge.

intended use, EiL-1641-307 Ad 210x297

b) ‘Random 10%" of Liquid Penetrant / Magnetic Particle test shall mean testing, by

applicable test, one weld for each ten welds or less made by the same welding

procedure or operator or both. Similarly "Random 20%" shall mean testing, by

applicable test, one weld for each five welds or less made by the same welding

procedure or operator or both.

1 borrower

©) When Liquid Penetrant examination is specified, the surface shall be free of peened

discontinuities. Abrasive blast cleaning shall be followed by light surface grinding

prior to Liquid Penetrant examination.

4) Inspection shall be performed in the welds excluding those for which radiography has

been done.

€) Girth weld, branch weld, attachment weld & socket weld of 3-1/2 Ni steel shall be

Liquid Penetrant tested only when welded with austenitic material where MP test has

been specified.

5. Radiography

a) andom 10% or 20% radiography" shall mean examining not less than one from

each 10 welds or less in case of "Random 10% radiography” or one from each five

welds or less in case of "Random 20% radiography” made by the same welding

procedure or welder or both, Irrespective of percentage. no. of welds to be

radiographed shall be minimum 1. However first two welds made by each welder

shall also be radiographed in case of "Random radiography”. Welds selected for

examination shall not include flange welds and shall be radiographed for their entire

length. However, where it is impossible or impracticable to examine the entire weld

length of field welds for either random or 100% radiography, and if the same

impossibility is agreeable to EIL site-in- charge, then a single 120 deg. exposure of

the weld length may be given a Magnetic Particle test or Liquid Penetrant test

However in such cases for ferro-magnetic materials, only MP test shall be acceptable

for classes higher than 600#

ed, except

‘oxhibited o

STANDARD SPECIFICATION FOR |__SPECIFICATION __| REV

ENGINEERS INDIA LIMITED | yon DESTRUCTIVE EXAMINATION 6-44-0016 4

eee REQUIREMENTS OF PIPING

Page 16 of 19

b) —_In-process examination shall not be substituted for any required radiographic

examination.

©) Number of radiographs per one circumferential weld shall be as per ASME Sec.V

Articles 2 and 22.

6. When radiography or other non destructive inspection is specified, acceptance criteria for

repairs or defects shall be as follows:

a) In _case of 100% examination, any unacceptable weld shall be repaired and

reinspected

b) If required random examination reveals a defect requiring repair, then

b.1 Two additional examinations of same type shall be made of the same kind of

item (if welded joint, then by the same welding procedure or operator or

both).

b.2 If the group of items examined as required by b.1 above is acceptable, the

items requiring repair shall be repaired or replaced and reexamined as

required and all items represented by this additional examination shall be

accepted.

b.3 If any of the items examined as required by b.1 above reveals a defect

requiring repair, two further comparable items shall be examined for cach

defective item found by examination.

b4 If all the items examined as required by b.3 are acceptable, the items

requiring repair shall be repaired or replaced and reexamined as required, and

all items represented by this further examination shall be accepted.

ame weld before

b.S Number of times repair welding could be done for the

acceptance shall be as follows:

Material No, of times repair welding is allowed

C:S. upto 300 # 3 or less

CS. above 300 # 2 or less

Killed steel 2 or less

Low alloy steel 2 or less

Austenitic $.S. 2 or less

3.5 Ni steel 2 or less

Al & Al base alloy 2 or less

Cu & Cu base alloy 2 or less

Others 2 or less

STANDARD SPECIFICATION FoR |__ SPECIFICATION

REV

ENGINEERS INDIA LIMITED | yo DESTRUCTIVE EXAMINATION, 6-44-0016

a

Cee REQUIREMENTS OF PIPING

Page 17

of)

b.6 Welds not found acceptable for allowed number of times of repair as per b.5

above shall be replaced and reexamined.

b.7 If any of the items examined as required by b.4 above reveals a defect

requiring repair, all items represented by these examinations shall be either:

repaired or replaced and reexamined as required

- fully examined and tepaired or replaced as necessary, and

reexamined as necessary

Hardness Test

a) Hardness test for each weld (unless mentioned otherwise in NDT Table-t ) shall be

im accordance with ASTM specification E10, ASME B31.3 and as called for in NDT

Table-V/PMS(Piping Material Specification), and shall be made after final heat treat

‘ment (wherever heat treatment is specified in welding specification). All welds which

are given heat treatment shall be hardness tested, A minimum of 10% of welds of hot

formed and hot bent materials in each heat treatment batch which are furnace heat

treated and 100% of those which are locally heat treated, shall be hardness tested. The

hardiness limit applies to the weld and heat affected zone. Hardness tests of the heat

affected zone shall be made at a point as near as practicable to the edge of the weld

One test per weld shall be performed

b) Hardness test where specifically called out in Table-I of NDT or in PMS, shall be

carried out irrespective of thickness and to the extent (éage) as mentioned therein.

©) For C-0.5 Mo steels, a minimum of 10% of welds shall be hardness tested.

4) Following hardness values shall be maintained

Base Metal Group Maximum

Hardness

(BHN/RC)

cs 238BHN/RC22

CS (NACE) 200BHN

Cr 0.5% oF less 225BHN

Cr >0.5% & upto 2% 225BHN

Cr 2.25%-3%(C < 0.15%) 241BHN

Cr 2.25%-3%(C > 0.15%) 241BHN

Cr 53% & upto 10% 241BHN

18/8 SS (NACE) RC22

©) Incase hardness values are mentioned in both welding specifications (6-77-0005) &

table given in Note-7(d), the lower of the two values shall be applicable

STANDARD SPECIFICATION FoR |__SPECIFICATION | REV

ENGINEERS INDIA LIMITED | WON DESTRUCTIVE EXAMINATION 6-44-0016 4

REQUIREMENTS OF PIPING eisai

5 8. For IBR service lines, following IBR requirements shall apply in addition to the notes 4, 5,

B 6, 7, 12 and Table I. In case of conflict between above notes and these requirements, the more

b stringent ones shall apply. IBR piping shall be erected of IBR inspector approved material and

7 construction procedure. Erected piping shall be hydrotested, inspected and approved by IBR

inspector.

3 a) Piping over 102 mm (4") bore

5 10% of welds made by each welder on a pipeline with a minimum of two welds per

z welder, selected at random, shall be subjected to radiography

: b) Piping 102 mm (4") bore and under, but not less than 38 mm (1-1/2") bore

BB ‘Two percent of welds made by each welder on a pipeline with a minimum of one weld

6 per welder, selected at random, shall be subjected to radiography or may be cut for

2S visual examination and tests.

2 °) Piping less than 38 mm (1.5") bore :

2 Special tests are not normally required but 2% of welds by each welder on a pipe line

5 ‘may be cut out from the pipeline for the visual examination and bend tests.

a) Retests

If any test specimen is unsatisfactory, two further weld specimens for retests shall be

selected from the production welds and subjected (o tests. In the event of failure of

any retest specimens, the production welds carried out by this welder subsequent to

the previous test shall be given special consideration.

9. For fabricated fittings LP test shall be done on the final pass of welding only, in addition to

visual examination.

10. For mitres and fabricated reducers, LP / MP test shall be done on root pass in addition to

radiography applicable to circumferential joint of respective piping class

11, For branch connections, LP/MP test shall be done on root pass and final pass.

12. As per TAC requirements, 10% of the butt weld joints shall be radiographed, however, 50%

of these butt weld joints shall be field weld joinis

13, In addition to 100% radiography, butt weld joints for A16A and BL6A classes shall be wet

fluorescent magnetic particle tested

14, For lined specs, testing (MP/LP/Radiography etc.) shall be performed before lining

STANDARD SPECIFICATION FOR | SPECIFICATION _| REV

ENGINEERS INDIA LIMITED | NON DESTRUCTIVE EXAMINATION 6-44-0016 4

REQUIREMENTS OF PIPING Paes ia si8

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 8 Inch Flange MTCDocument8 pages8 Inch Flange MTCMohammad Rawoof100% (1)

- Astm D2321 (2000) PDFDocument10 pagesAstm D2321 (2000) PDFMohammad Rawoof100% (1)

- API Individual Certification Programs: MD RawoofDocument1 pageAPI Individual Certification Programs: MD RawoofMohammad RawoofNo ratings yet

- A1Document13 pagesA1Mohammad RawoofNo ratings yet

- Musnell Colour SystemDocument55 pagesMusnell Colour SystemMohammad RawoofNo ratings yet

- ANCC ProfileDocument35 pagesANCC ProfileMohammad RawoofNo ratings yet

- Boilers - Water Treating 0Document26 pagesBoilers - Water Treating 0Mohammad RawoofNo ratings yet

- AB4Document14 pagesAB4Mohammad RawoofNo ratings yet

- BHN ProcedureDocument13 pagesBHN ProcedureMohammad Rawoof100% (2)

- Astm D 2583Document4 pagesAstm D 2583Mohammad Rawoof100% (4)

- Fuel Burner & Firebox Operation & ControlDocument33 pagesFuel Burner & Firebox Operation & ControlMohammad Rawoof50% (2)

- Additional FabricationDocument7 pagesAdditional FabricationMohammad Rawoof100% (1)

- Furnaces - Equipment DescriptionDocument23 pagesFurnaces - Equipment DescriptionMohammad RawoofNo ratings yet

- Boiler Operation & ControlDocument56 pagesBoiler Operation & ControlMohammad Rawoof100% (2)

- Vents & Fire Protection System For Storage TanksDocument24 pagesVents & Fire Protection System For Storage TanksMohammad Rawoof100% (2)

- Api 570 - 02 Asme B 31.3Document12 pagesApi 570 - 02 Asme B 31.3Mohammad RawoofNo ratings yet

- PSV'S Job Completion Certificates: Saudi Kayan TurnaroundDocument1 pagePSV'S Job Completion Certificates: Saudi Kayan TurnaroundMohammad RawoofNo ratings yet

- TIAC Standards 2005 e PDFDocument201 pagesTIAC Standards 2005 e PDFMohammad RawoofNo ratings yet