Professional Documents

Culture Documents

Pipe Thickness Calculation AS Per ASME 31.3

Uploaded by

Anonymous Iev5ggSROriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipe Thickness Calculation AS Per ASME 31.3

Uploaded by

Anonymous Iev5ggSRCopyright:

Available Formats

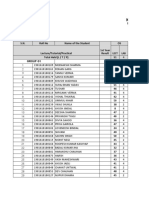

Pipe Thickness Calculation : ASME 31.

Pipe thickness Calculation AS per ASME 31.3

Considering thickness t =PD/2(SE+PY)

Input Data:

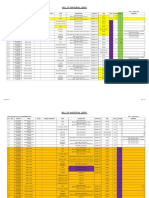

Sl no Description Unit Pipe-1 Pipe -2 Pipe -3 Pipe -4 Pipe -5 Reference

1 Pipe O.D.(D) inch 24 24 24 24 24

2 Design Pressure (P) psig 550 550 550 550 550

3 Quality Factor (E) (Considering ERW PIPE) 0.85 0.85 0.85 0.85 0.85 (Table A-1B of ANSI B31.3)

4 Quality Factor (E) (Considering SEAMLESS PIPE) 1 1 1 1 1 (Table A-1B of ANSI B31.3)

5 Pipe Material: ASTM A 312 Gr.TP304L ASTM A 312 Gr.TP304L ASTM A 106 Gr.B API 5L Grade X-70 ASTM A 333 Gr.6

6 Stress Value for Material(S) ksi 1.0 3 20 27 20 (Table A-1of ANSI B31.3)

7 Design Temperature deg. F 1400 1200 270 380 200

8 Coefficient (Y) 0.4 0.4 0.4 0.4 0.4 (Table 304.1.1of ANSI B31.3)

9 Negative Mill tollerance (x) % 12.5 12.5 12.5 12.5 12.5

Calculation:

SAW PIPE

1 Thickness of Pipe Wall (t)=PD/2(SE+PY) inch 6.17 2.72 0.38 0.28 0.38 ASME 31.3, Para 304.1.2

2 Corrossion Allowances (tc) inch 0.125 0.125 0.125 0.125 0.125

3 Minimum reqd. thickness (tm) = t+tc inch 6.293 2.841 0.508 0.407 0.508

4 Req. thick including mill tollerance Tm = tm/(1-x/100) inch 7.192 3.247 0.581 0.465 0.581

SEAMLESS PIPE

1 Thickness of Pipe Wall (t) inch 5.41 2.34 0.33 0.24 0.33 ASME 31.3, Para 304.1.2

2 Corrossion Allowances (tc) inch 0.125 0.125 0.125 0.125 0.125

3 Minimum reqd. thickness (tm) = t+tc inch 5.535 2.465 0.451 0.365 0.451

4 Req. thick including mill tollerance Tm = tm/(1-x/100) inch 6.326 2.818 0.516 0.417 0.516

345439089.xls Page1 of 11 02/14/2017

Pipe Thickness Calculation : ASME 31.3

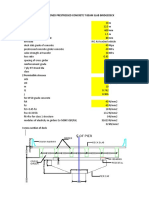

Design & Operating Data given in Tender Document

The Design & Operating Data of 24" Pipeline is as follow:

Design Code: ASME B31.3/ASME B 31.8

Flange Rating: 300#

Design Pressure(Psig): 550

Design Temperature (F): 200

Operating Pressure(Psig): 240(Min)/400-420(Normal)/435(Max)

Operating Temperature (F): 70(Min)/100(Normal)/120(Max)

Line size X W.T. (inches): 24" x 0.375 API 5L Gr. X52

Corrosion Allowance (inches): 0.125

Process Gas: Normal -HP LEAN DRY Gas with max 0.02% H2S

Emergency -Wet HP gas (saturated) with max.

1% H2S

Cathodic Protection:- NACE RP 0169, RP 0286, RP 0177,

RP 0193, RP 0388 & API 651

345439089.xls Page2 of 11 02/14/2017

You might also like

- Pipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)Document1 pagePipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)farhadNo ratings yet

- ASME B31 8 Riser CalcDocument12 pagesASME B31 8 Riser CalcEmmanuel LawrenceNo ratings yet

- Pipe Wall Thickness CalculationDocument8 pagesPipe Wall Thickness CalculationRAGHVENDRA PRATAP SINGH0% (1)

- Cong Thuc Tinh Toan Piping ThicknessDocument108 pagesCong Thuc Tinh Toan Piping ThicknessTruong Ngoc SonNo ratings yet

- Wall Thickness Calculation Followed B31.8 PDFDocument3 pagesWall Thickness Calculation Followed B31.8 PDFBPCL HCULOBS100% (1)

- Branch (1) Calculations: Pipe Branch Reinforcement Per ASME B31.1b - 2009 Power Piping CodeDocument2 pagesBranch (1) Calculations: Pipe Branch Reinforcement Per ASME B31.1b - 2009 Power Piping Codedeua2004No ratings yet

- Brance Pipe CALDocument6 pagesBrance Pipe CALKlaikangwol AnuwarnNo ratings yet

- Above Ground Piping Wall Thickness CalculationsDocument7 pagesAbove Ground Piping Wall Thickness Calculationslutfi awn100% (1)

- Technical Notes - B31.3Document36 pagesTechnical Notes - B31.3Amit Pandey100% (1)

- Hydrostatic Test Pressure CalculationDocument1 pageHydrostatic Test Pressure Calculationmohd as shahiddin jafriNo ratings yet

- ASME B31.3 CalculatorDocument144 pagesASME B31.3 CalculatorLeoNo ratings yet

- Asme Seccion Viii Div. 1 Ed 2015 Calculos MecanicoDocument72 pagesAsme Seccion Viii Div. 1 Ed 2015 Calculos MecanicoSivateja NallamothuNo ratings yet

- Reinf S1Document2 pagesReinf S1tasingenieriaNo ratings yet

- Pipe Wall Thickness Calculation Using ASME B31.4Document21 pagesPipe Wall Thickness Calculation Using ASME B31.4YusepSúarðiNo ratings yet

- Pdesign: 100 Barg Line Pipe Material: API Grade X60Document64 pagesPdesign: 100 Barg Line Pipe Material: API Grade X60Luong NgoNo ratings yet

- Hydrostatic Test Pressure Calculation: Pipe DataDocument2 pagesHydrostatic Test Pressure Calculation: Pipe DataAkram AlhaddadNo ratings yet

- Ancor Flanges Asme ViiiDocument3 pagesAncor Flanges Asme ViiiAnjani PrabhakarNo ratings yet

- Piping Calculation Program For ASME B31 1 CodeDocument3 pagesPiping Calculation Program For ASME B31 1 CodeAMIT100% (2)

- SU Blind Plate ThicknessDocument2 pagesSU Blind Plate Thicknessmanoj19801226100% (1)

- Pipes. Pressure and Wall Thickness Equations and Data For A Straight Pipe. ASME B31.1 and B31.3.odsDocument100 pagesPipes. Pressure and Wall Thickness Equations and Data For A Straight Pipe. ASME B31.1 and B31.3.odsNaufal FirmansyahNo ratings yet

- 4 2500 (F347H)Document2 pages4 2500 (F347H)siddhesh_guessNo ratings yet

- FittingsDocument50 pagesFittingsashokNo ratings yet

- Document Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking PlantDocument49 pagesDocument Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking Plantsusa2536No ratings yet

- Pipe Thickness Calculation For Straight Pipe Under Internal PressureDocument7 pagesPipe Thickness Calculation For Straight Pipe Under Internal PressureMakhdoom Ibad HashmiNo ratings yet

- Code Comparison ASME B31.1 Vs B31.3 Vs B31.8Document27 pagesCode Comparison ASME B31.1 Vs B31.3 Vs B31.8khaireddinNo ratings yet

- Asme Sa 333 Grade 6 PipesDocument1 pageAsme Sa 333 Grade 6 PipesFerroPipENo ratings yet

- Piepline Thickness CalculationDocument6 pagesPiepline Thickness CalculationAneeq NaufalNo ratings yet

- PY SEW Do P T: Pipe Wall Thickness Calculation SheetDocument1 pagePY SEW Do P T: Pipe Wall Thickness Calculation Sheetanon_714194540No ratings yet

- Miter Bend Calculation: E W S D T' BDocument4 pagesMiter Bend Calculation: E W S D T' BSong TaoNo ratings yet

- Piping Calc'sDocument1 pagePiping Calc'sJoe BetkerNo ratings yet

- Thickness Calculation of Pressure Vessel ShellDocument17 pagesThickness Calculation of Pressure Vessel ShellVishnuGK100% (1)

- Trunnion Calcualtion SheetDocument22 pagesTrunnion Calcualtion SheetAbhijit0% (1)

- BCM Naphtha Pipeline Parameters ComparisonDocument1 pageBCM Naphtha Pipeline Parameters Comparisonข้าวเม่า ทอดNo ratings yet

- Pipe Thickness Design Calculation 1500 MMDocument1 pagePipe Thickness Design Calculation 1500 MMSatish Kumar MauryaNo ratings yet

- Shree Satyanarayan Industrial Suppliers Pvt. LTD.: Carbon Steel Pipe Hydrostatic Test Calculation SheetDocument1 pageShree Satyanarayan Industrial Suppliers Pvt. LTD.: Carbon Steel Pipe Hydrostatic Test Calculation SheetSalman KhanNo ratings yet

- PRESSURE DESIGN AND REINFORCEMENT OF STRAIGHT PIPES AND BRANCH CONNECTIONSDocument5 pagesPRESSURE DESIGN AND REINFORCEMENT OF STRAIGHT PIPES AND BRANCH CONNECTIONSUmar Aslam0% (1)

- Welding Calculation ModulDocument5 pagesWelding Calculation ModulricardoNo ratings yet

- Minimum Pipe Wall Thickness and MAWP SI Final ProtectedDocument11 pagesMinimum Pipe Wall Thickness and MAWP SI Final Protectedjsfscibd100% (1)

- Page No Doc. No. Revision Design Calculation For Set In, Set On Nozzle With and Without Pad and Self Reinforced NozzleDocument25 pagesPage No Doc. No. Revision Design Calculation For Set In, Set On Nozzle With and Without Pad and Self Reinforced Nozzleabdelrahman KhalidNo ratings yet

- API 510 Bolted Flat Head ThicknessDocument11 pagesAPI 510 Bolted Flat Head ThicknessAleiser Quevedo Acuña100% (1)

- Determine Shell ThicknessDocument53 pagesDetermine Shell ThicknessRajul MuraliNo ratings yet

- ASME B31.3 wall thickness calcDocument11 pagesASME B31.3 wall thickness calcAnonymous wIPMQ5rhNo ratings yet

- Pipe Wall Thickness Calculation @MechEngineersDocument77 pagesPipe Wall Thickness Calculation @MechEngineersHeri KurniawanNo ratings yet

- API 570 Exam CalculationsDocument2 pagesAPI 570 Exam Calculationssnehal.deshmukhNo ratings yet

- Wall Thickness Calculation of 36in Gas PipelineDocument1 pageWall Thickness Calculation of 36in Gas PipelineLU1228100% (3)

- Sa 420Document10 pagesSa 420Widya widyaNo ratings yet

- INTERNAL PRESSURE CALCULATIONS FOR PIPING & PIPELINESDocument89 pagesINTERNAL PRESSURE CALCULATIONS FOR PIPING & PIPELINESCastro Quinteros WinstonNo ratings yet

- Branch Reinforcement Pad Requirement CalculationDocument1 pageBranch Reinforcement Pad Requirement Calculations.mladinNo ratings yet

- Calculate Shell and Stem ThicknessDocument16 pagesCalculate Shell and Stem Thicknesspatiltushar79No ratings yet

- GC11 Pipe Thickness CalcDocument1 pageGC11 Pipe Thickness CalcsrinivasanNo ratings yet

- Carbon Steel ASME B36.10M Stainless Steel ASME B36.19M Cu-Ni Brass Bronze Thermoplastic ThermosettingDocument9 pagesCarbon Steel ASME B36.10M Stainless Steel ASME B36.19M Cu-Ni Brass Bronze Thermoplastic ThermosettingkaviramanNo ratings yet

- 8 AS4041 ASME B31 3 Pipe Wall ThicknessDocument12 pages8 AS4041 ASME B31 3 Pipe Wall Thicknesswhah11No ratings yet

- ASME B31.8 Riser CalcDocument12 pagesASME B31.8 Riser CalcSalz EngineeringNo ratings yet

- Asme B31.8Document14 pagesAsme B31.8omar equihua100% (1)

- ASME B31.8 Wall Thickness CalculationDocument23 pagesASME B31.8 Wall Thickness Calculationisrar khan100% (2)

- PIPELINE WALL THICKNESS CALCULATIONSDocument24 pagesPIPELINE WALL THICKNESS CALCULATIONSMohsin RazaNo ratings yet

- Required Thicknesses of Pipe or Tube Per ASME B31.3 - 2012 Process Piping CodeDocument3 pagesRequired Thicknesses of Pipe or Tube Per ASME B31.3 - 2012 Process Piping CodeAlex Javier Garzon OrduñaNo ratings yet

- SampleCalculationspipingB3132008 PDFDocument13 pagesSampleCalculationspipingB3132008 PDFsosatlantiqueNo ratings yet

- Pipe Wall Thickness CalculationDocument1 pagePipe Wall Thickness Calculationmahesh070No ratings yet

- DGN Status 16.Document2 pagesDGN Status 16.Anonymous Iev5ggSRNo ratings yet

- Safety Valve Reaction Foce Calculation: Isometric: 10Lbg10Br192, Rev. A Project: Kat065 Raslaffan BDocument4 pagesSafety Valve Reaction Foce Calculation: Isometric: 10Lbg10Br192, Rev. A Project: Kat065 Raslaffan BAnonymous Iev5ggSRNo ratings yet

- Grooved Kempchen PDFDocument11 pagesGrooved Kempchen PDFAnonymous Iev5ggSRNo ratings yet

- Ami Product Guide CatalogDocument50 pagesAmi Product Guide CatalogAnonymous Iev5ggSRNo ratings yet

- 06-086-098 Weld Ring GasketsDocument13 pages06-086-098 Weld Ring GasketsRitesh VishambhariNo ratings yet

- Support Span Calculation FRP.Document2 pagesSupport Span Calculation FRP.Anonymous Iev5ggSRNo ratings yet

- 04 044 052 Spiroflex Spiral Wound GasketsDocument9 pages04 044 052 Spiroflex Spiral Wound Gasketsgazwang478No ratings yet

- Pipe List Working LATESTDocument2 pagesPipe List Working LATESTAnonymous Iev5ggSRNo ratings yet

- Gr91 - DS2a2009 - Released Version by ECCC April09Document3 pagesGr91 - DS2a2009 - Released Version by ECCC April09Anonymous Iev5ggSRNo ratings yet

- 06-086-098 Weld Ring GasketsDocument13 pages06-086-098 Weld Ring GasketsRitesh VishambhariNo ratings yet

- FGD Bill of Materials for 693MW Power ProjectDocument4 pagesFGD Bill of Materials for 693MW Power ProjectAnonymous Iev5ggSRNo ratings yet

- Stock Flanges Include Socket Weld, Butt Weld, NPTF and SAE StraightDocument4 pagesStock Flanges Include Socket Weld, Butt Weld, NPTF and SAE StraightAnonymous Iev5ggSRNo ratings yet

- Pipe Dimension and Support Span TableDocument4 pagesPipe Dimension and Support Span TableAnonymous Iev5ggSRNo ratings yet

- Everything You Need to Know About GRP PipesDocument24 pagesEverything You Need to Know About GRP PipesmgjorNo ratings yet

- Pipe Thickness Calculation AS Per ASME 31.3Document11 pagesPipe Thickness Calculation AS Per ASME 31.3Anonymous Iev5ggSRNo ratings yet

- Snow Load As Weight Per MM Calculation 330Document1 pageSnow Load As Weight Per MM Calculation 330Anonymous Iev5ggSRNo ratings yet

- Coade Piping Stress Analysis SeminarDocument66 pagesCoade Piping Stress Analysis SeminarAnonymous Iev5ggSRNo ratings yet

- Structural Detailing in SteelDocument253 pagesStructural Detailing in Steelandrugrasu100% (27)

- Senior Flexonics Expansion JointsDocument93 pagesSenior Flexonics Expansion JointssunethbabuNo ratings yet

- Bourdon Effect in CAESAR II: Intergraph CASDocument3 pagesBourdon Effect in CAESAR II: Intergraph CASAnonymous Iev5ggSR100% (1)

- Turbocompressor For Aeration STC-GO - SiemensDocument6 pagesTurbocompressor For Aeration STC-GO - SiemensAnonymous Iev5ggSRNo ratings yet

- Diagrams Indicating Terminal PointsDocument6 pagesDiagrams Indicating Terminal PointsAnonymous Iev5ggSRNo ratings yet

- STEAM TURBINE 3 Design and MaterialsDocument19 pagesSTEAM TURBINE 3 Design and MaterialsHandayani Kesumadewi100% (2)

- Tractebel Engineering Pvt. LTD.: GGNA-G-01136-123 Rev 00Document4 pagesTractebel Engineering Pvt. LTD.: GGNA-G-01136-123 Rev 00Anonymous Iev5ggSRNo ratings yet

- En-13480 Allowable Stresses SH - Intergraph CADWorx & AnalysisDocument7 pagesEn-13480 Allowable Stresses SH - Intergraph CADWorx & AnalysisAnonymous Iev5ggSRNo ratings yet

- PipeHanger DesignEngineering Catalog PDFDocument84 pagesPipeHanger DesignEngineering Catalog PDFRaheem_kaNo ratings yet

- Safety Valve Reaction Foce Calculation: Isometric: 10Lbg10Br192, Rev. A Project: Kat065 Raslaffan BDocument4 pagesSafety Valve Reaction Foce Calculation: Isometric: 10Lbg10Br192, Rev. A Project: Kat065 Raslaffan BAnonymous Iev5ggSRNo ratings yet

- Pipe Size CalculationDocument28 pagesPipe Size CalculationAnonymous Iev5ggSR100% (1)

- DM Water SystemDocument1 pageDM Water SystemAnonymous Iev5ggSRNo ratings yet

- LISEGA Catalog 2010Document7 pagesLISEGA Catalog 2010Olivier RioNo ratings yet

- Analysis and Design of Doubly Reinforced BeamDocument1 pageAnalysis and Design of Doubly Reinforced BeamLouise DiazNo ratings yet

- Research HighlightDocument209 pagesResearch HighlightMuhammad Noor KholidNo ratings yet

- Department of Electronics and Communication Engineering: Siruganur, Tiruchirappalli - 621 105Document3 pagesDepartment of Electronics and Communication Engineering: Siruganur, Tiruchirappalli - 621 105susan williamNo ratings yet

- Ahmed ArafiaDocument6 pagesAhmed ArafiaAbhilash PaulNo ratings yet

- VIT Campus, Jaipur: Leading Engineering College of Rajasthan/ Best Infrastructure & PlacementDocument85 pagesVIT Campus, Jaipur: Leading Engineering College of Rajasthan/ Best Infrastructure & PlacementOnkar BagariaNo ratings yet

- SATR-J-6501 - Rev 0 PDFDocument5 pagesSATR-J-6501 - Rev 0 PDFAdel KlkNo ratings yet

- PT I Girder Design 20mDocument18 pagesPT I Girder Design 20msamirbendre1No ratings yet

- Final TT-End Sem - Spring Sem2022-23 - 13.04.2023Document4 pagesFinal TT-End Sem - Spring Sem2022-23 - 13.04.2023Ritwik NandiNo ratings yet

- Ethics Position PaperDocument8 pagesEthics Position Papercwise2100% (1)

- SAP EWM - Part+Entitled+to+Dispose,+Owner+and+CustodianDocument8 pagesSAP EWM - Part+Entitled+to+Dispose,+Owner+and+CustodianRajesh KumarNo ratings yet

- 42 GCSC PDFDocument6 pages42 GCSC PDFMary MorseNo ratings yet

- Data Structures Question BankDocument32 pagesData Structures Question BankMuhammad Anas RashidNo ratings yet

- Slab Girder BridgeDocument42 pagesSlab Girder BridgeAslam Saifi100% (2)

- 7m OCT W Solar LightDocument4 pages7m OCT W Solar LightBelal ElsayedNo ratings yet

- Chapter 5Document78 pagesChapter 5Retno Yuniarsih Marekhan IINo ratings yet

- ITP Box Setting On CHB or Macro WallDocument3 pagesITP Box Setting On CHB or Macro WallRitchie OcampoNo ratings yet

- CNC machining centre SCM ACCORD 40Document2 pagesCNC machining centre SCM ACCORD 40cokicisneNo ratings yet

- 2nd Year Weekly Attendance Even Sem 2020-2021Document608 pages2nd Year Weekly Attendance Even Sem 2020-2021Jos BatlarNo ratings yet

- MSC TrainingCatalogDocument55 pagesMSC TrainingCatalogcallum687No ratings yet

- Ground AnchorsDocument31 pagesGround AnchorsHammer HeadNo ratings yet

- LECTURE 1 Kinematics Fundamentals PDFDocument79 pagesLECTURE 1 Kinematics Fundamentals PDFNik ZulhilmiNo ratings yet

- P&ID-Essential Piping and Instrument DiagramDocument23 pagesP&ID-Essential Piping and Instrument DiagramAmirNo ratings yet

- Monitor ferrous buildup on overhead magnetsDocument2 pagesMonitor ferrous buildup on overhead magnetsCarlos AcevedoNo ratings yet

- Advances in CFS Structures Research 2013-2014Document16 pagesAdvances in CFS Structures Research 2013-2014Miguel TachaNo ratings yet

- Flexible Pavement Design Spreadsheet ImportantDocument10 pagesFlexible Pavement Design Spreadsheet ImportantAnonymous bUtSDElMTMNo ratings yet

- Pavement Design: SEPTEMBER, 2006 Road Design Manual 7-0Document18 pagesPavement Design: SEPTEMBER, 2006 Road Design Manual 7-0amofaevansNo ratings yet

- Amie Lab ProjectguideDocument8 pagesAmie Lab ProjectguidekskumargieNo ratings yet

- Gul Nawaz Khan Mahar: Shahbaz Gul House Near Awais Quarni Masjid Raiti Line Work Shop Road SukkurDocument2 pagesGul Nawaz Khan Mahar: Shahbaz Gul House Near Awais Quarni Masjid Raiti Line Work Shop Road Sukkuradil chishtiNo ratings yet

- Assignment 5 - Machine DesignDocument1 pageAssignment 5 - Machine DesignmrinalsinghrawatNo ratings yet