Professional Documents

Culture Documents

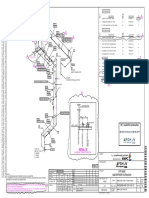

A336

Uploaded by

Alam MD Sazid0 ratings0% found this document useful (0 votes)

4 views8 pagesndt

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentndt

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views8 pagesA336

Uploaded by

Alam MD Sazidndt

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 8

qq) Designation: A 336/A 336M ~ 89

Standard Specification for

Steel Forgings, Alloy, for Pressure and High-Temperature

Parts’

“This standard is sued under the fixed designation A 336/A 336M: th

{eat of orginal adoption oF, inthe case of revision, the year of last revision,

feapproval. A superscript epsilon ()indiaes an

1. Scope

1.1 This specification? covers both ferritic and austenitic

steel forgings for boilers, pressure vessels, high-temperature

paris, and associated equipment.

1.2 Forgings made of steel grades listed in Specification

‘A 335/A 335M, may also be ordered under this specification,

‘The chemical, tensile, heat treatment, and marking require-

ments of Specification A 335/A 335M shall apply, except the

forging shall conform to the chemical requirements of Table

1 of Specification A 335/A 335M only with respect to heat

analysis. On check analysis they may deviate from these

limits to the extent permitted in Table 2 of this specification.

1.3 Supplementary Requirements SI to $9 are provided

for use when additional testing or inspection is desired.

These shall apply only when specified individually by the

purchaser in the order.

1.4 The values stated in either inch-pound units or SI

(metric) units are to be regarded separately as standards.

Within the text and tables, the SI units are shown in

brackets. The values stated in each system are not exact

equivalents; therefore, each system must be used indepen-

dent of the other. Combining values from the two systems

may result in nonconformance with the specification.

1.5 Unless the order specifies the applicable “M” specifi-

cation designation, the material shall be furnished to the

inch-pound units.

Referenced Documents

2.1 ASTM Standards:

‘A275/A 275M Method for Magnetic Particle Examina-

tion of Steel Forgings?

'A.335/A 335M Specification for Seamless, Ferritic Alloy

Steel Pipe for High-Temperature Service®

‘A370 Methods and Definitions for Mechanical Testing of

Steel Products**

‘A 188 Specification for Steel Forgings, General Require-

ments?

E 112 Method for Determining Average Grain Size®

"This pesfication is under the jucsdcton of ASTM Committe A! on Stee

Staines Stel and Related Alloys and isthe direct responsiblity of Subcommites

‘AD106 on Stel Forgings and Bilt

Current editian approves Aug. 25, 1989. Published October 1989. Originally

published as A'396~55 T. Last previous edition A 336/A 336M ~ 88.

For ASME Boiler and Pressure Vesel Cede applications ve related Speci

cation $A-336 in Seton I ofthat Code.

Annual Book of ASTM Standards, Vol 01.05.

* Anmial Book of ASTM Standard, Vol 01.01

5 Annual Book of ASTM Standards, Vol 01.03.

‘annual Book of ASTM Standards, Vol 03.0.

162

1: number immediately fllowing the designation indicates the

‘A oumber in parentheses indicates the year of lst

oral change since the lst revision oF reapproval.

E 165 Practice for Liquid Penetrant Inspection Method”

2.2 Other Standard:

‘ASME Boiler and Pressure Vessel Code, Section 1X,

Welding Qualifications*

3. Ordering Information and General Requirements

3.1 In addition to the ordering information required by

Specification A788, the purchaser shall include with the

inquiry and order a detailed drawing, sketch, or written

description of the forging. The intended use shall be stated if

5.1 is applicable.

3.2 Material supplied to this specification shall conform

to the requirements of Specification A788, which outlines

additional ordering information, manufacturing require-

ments, testing and retesting methods and procedures,

marking, certification, product analysis variations, and addi-

tional supplementary requirements.

3.3 If the requirements of this specification are in conflict

with the requirements of Specification A 788, the require-

‘ments of this specification shall prevail

4, Melting and Forging

4.1 In addition to the melting and forging requirements of

Specification A 788 which may be supplemented by Supple-

mentary Requirement S8, the following conditions apply:

4.1.1 Austenitic grades of steel shall not be produced by

the open-hearth process.

4.1.2 A sufficient discard shall be made to secure freedom

from injurious pipe and undue segregation.

Nore 1—Because of difficulties in retaining, nitrogen, vacuum

melting or remelting processes should not be specified for Grades

F3OAN, F304LN, F3I6N, F3I6LN and FXM-11

5. Machining

5.1. Forged pressure vessels for steam power service shall

have the inner surface machined or ground. Unfired pressure

‘vessels shall have the inner surfaces sufliciently free of scale

‘to permit inspection.

5.2 When rough machining is performed, it may be done

either before or after heat treatment.

6, Heat Treatment

6.1 The ferritic steel forgings shall be annealed or normal-

ized and tempered but alternatively may be liquid quenched.

and tempered when mutually agreed upon between the

> Annual Book of ASTM Standards, Vol 03.03

+ Rinllable fom the Amencan Society of Mechanical Engineer. 345 Eas 47¢h

St. New York, NY 10017,

) A 336/A 336M

TABLE 1 Chemical Requirements

_ Composition, %

Ferrite Stee

Cass

Element FFI FIIA, rie SS Fe FSA* 9

Carbon 020-030 010-030 —«005-015 010-020 OiSmax O25max O15 max O12 max

Manganese 060-080 030-080 030-060 030-080 030-060 «60mm «030-060 100 man

Phosphorus. max 0025, 0.025 0.005 0025 0.025 02s 0.025 0028.

Sulu, max 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.025

Silicon 020-035 050-100 050-1100 0.10-060 «0 S0max = S0max 080-1001 Oo mex

Nickel 050 ™max 0.50 max 050 max

Grromum 100-150 ¥00-150 © ago-r10 40-60, 40-60 800-1000 115-135,

Molyodenm 040-060 045-065 o4s-o6 045-065 045-085 O4S-065 080-110,

(tase

Elorent Fa1, FOIA #22, F224 ~FRMDTCO

Garoon (005-015 005-075 O01 max

Manganese 030-080 030-060 0.40 max

Phosphorus, max 01025, 0.025 0.025

Sur, max 0.025 0.025 2.028

Siicon 0.50 max 050mae O40 max

Nox 0.50 max®

Comin 265-025 © 2oo2sn © 250-275

Molybdenum 080-105 090-150 75-150,

Vanadium

Copper 0.20 max

ogen 0.015 max

Colurbiam 005-020

Element Cass F31 Fav

Garton 006-012 010-015

Manganese 030-050 0.30-0.00

Phosprons, max 0025 0.020

‘Sur, mae 0.025 0.020

‘Sticon 020-050 010

Neko 0.40 max

(Chromium 300-950 265-225

Metyoaonn 085-105 090-1110

Vanadium 018-025 020-020

(Cotrm 006-0110

Nitrogen 003-007

‘Auman (0.08 max

Boron 0.001-0.003

Thar 0.015.0.095

163

(i) A 336/A 336M

panandde se wnaunon ova yo 1880} PAIN

au atssuco 990 ssp voRseD "wrUAeL “S10 24 61 PALES YOR

9g feu wryese Aereuony) % 0) Ueuk 90u 10U VE

"4030 ve 204! 104 pu

5 oquks vonesynvopr 4 joqws voneagivap au

geo eu sown va

py ‘Suoa "Bagh 80d ce ne sono xo, soneapD0 NISY

Se sem S561 01 SOON [LOGED UNUAKEL! $20) VE SSID RHO OL

uneven,

anewe,

164

hb A 336/A 336m

loss]

0

noses) noves

soe}

oe|

oe

se

‘aaag SWEET

000 09 | =

seas ou

(eam

‘tuans 5404

‘Swowounbou ensue @ STEVE

165

Gb) A 336/a 336M

manufacturer and the purchaser. For Class F91 forgings the

normalizing temperature shall be in the range of 1900 to

2000°F {1040 to 1095°C]. Normalizing or liquid quenching

shall be followed by tempering at a subcritical temperature,

Minimum tempering temperature shall be 1100°F [595°C],

except for the following classes:

Minimum Tempering

ss ‘Temperature, FC]

Fe 1130 620),

Fil 1130 (620),

Fuia. 1130 (6201,

Fup 1130 (620),

Fs 1930 (675),

1230 (675),

FRA 1280 {675}

FV 1350 [673]

Fa 1250 65}

F 1330 (730)

6.2 All austenitic material shall be furnished in the

heat-treated condition. The heat treatment shall consist of

heating the material to a minimum temperature of 1900°F

[1040°C] except for Classes F321H, F347H, and F348H,

which shall be solution treated at 1925°F [10S0°C] min.

imum, Solution treatment shall be followed by quenching in

water or rapidly cooling by other means.

6.2.1 Class FXM-I1 and FXM-19 shall be solution an-

nealed at 1950 + 25°F (1065 + 15°C].

6.2.2 Class F46 shall be solution annealed at temperatures

in the range 2010-2140°F [1100-1170°C} followed by water

quenching or other means of rapid cooling,

7. Chemical Composition

7.1 Heat Analysis—The heat analysis obtained from sam-

pling in accordance with Specification A788 and shall

comply with Table 1

7.2 Product Analysis—The manufacturer shall use the

Product analysis provision of Specification A 788 to obtain a

Product analysis from a forging representing each heat or

multiple heat, Boron is not subject to product analysis. The

purchaser may also make this determination in accordance

with Specification A 788,

8. Mechanical Properties

8.1 General Requirements—The material shall conform

to the requirements for mechanical properties prescribed in

Table 2. The largest obtainable tension test specimen as

specified in Methods and Definitions A 370 shall be used.

8.1.1 The longitudinal axis of the specimens shall be

parallel to the direction of major working of the forging,

except when Supplementary Requirement S2 is specified.

For upset disk forgings, the longitudinal axis of the test

specimen shall be in the tangential direction,

8.1.1.1 The longitudinal axis of the specimen shall be

located midway between the parallel surfaces of the test

extension if added to the periphery of disks or midway

between the center and surface of solid forgings. For hollow

forgings, the longitudinal axis of the specimens shall be

located midway between the center and outer surfaces of the

wall. When separately forged test blocks are employed. as

defined in 8.1.3, the tension test specimens shall be taken

from a location which represents the midwall of the heaviest

section of the production forgings. When specimens are

required from opposite ends, they shall be taken from the

166

diagonal corners of an axial plane. Alternatively. and when

specified, the specimens shall be taken in accordance with

Supplementary Requirement $3.

8.1.2 Except as specified herein, tests for acceptance shall

be made after heat treatment has been completed in accord-

ance with Section 6. When the ends of the cylindrical

forgings are closed in by reforging, the cylindrical forgings

may be normalized and tempered or annealed and sted

before reforging, After reforging, the entire forging shall be

reheat-treated in the same manner and at the same temper

ature range as employed when the forging was heat treated

before cerification testing,

8.1.3 When mutually agreed upon between the manufac.

turer and the purchaser, test specimens may be machined

from a specially forged block suitably worked and heat

treated with the production forgings. Such a special block

shall be obtained from an ingot, slab. or billet from the same

heat used to make the forgings it represents. This block shall

receive essentially the same type of hot-working and forging

reduction as the production forgings; however, a longitudi-

nally forged bar with dimensions not less than T by T by 37

may be used to represent a ring forging. The dimension 7

shall be representative of the heaviest effective cross section

of the forging. For quenched and tempered forgings for

which tests are required at both ends by 8.2.3 and 8.2.4,

separately forged test blocks are not allowed.

Note 2—in using separately forged test blocks attention is drawn to

the effect of mass differences between the production forgings and the

test blocks. This can be particularly significant for the ferritic grades

‘when forgings are normalized and tempered or quenched and tempered.

8.2 Number and Location of Tests—The number and

location of tests are based on forging length, weight, and heat

treatment and shall be as prescribed below. The length and

‘weight to be used for this purpose shall be the shipped length

and weight of forgings produced individually or the aggregate

shipped length and weight of all pieces cut from a multiple

forging.

8.2.1 Annealed or Normalized and Tempered Alloy Steel

Forgings:

8.2.1.1 For forgings weighing 5000 tb (2250 ke] or less at

the time of heat treatment. one tension test shall be taken

from one forging per heat, per heat treatment charge. When

heat treatment is performed in continuous type furnaces

with suitable temperature controls and equipped with re-

cording pyrometers so that complete heat treatment records

are available, a tempering charge may be considered as any

continuous run not exceeding an 8 h period.

8.2.1.2 For forgings and forged bars weighing over 5000 Ib

{2250 kg] at the time of heat treatment, one tension test shall

bbe taken from each forging

8.2.2 Quenched and Tempered Forgings

8.2.2.1 For quenched and tempered forgings weighing

000 Ib (2250 kg] or less at the time of heat treatment, but

not exceeding 12 ft [3.7 m] in length, one tension test shall be

taken from one forging per heat, per heat treatment charge.

When heat treatment is performed in continuous type

furnaces with suitable temperature controls and equipped

with recording pyrometers so that complete heat treatment

records are available, a tempering charge may be considered

as any continuous run not exceeding an 8 h period

8.2.2.2 For quenched and tempered forgings and forged

@) A 336/A 336M

bars weighing over $000 to 10 000 Ib [2250 t0 4500 kg) at the

time of heat treatment, but not exceeding 12 ft (3.7 m} in

length, one tension test shall be taken from each forging,

8.2.2.3 Quenched and tempered forgings that exceed 12 ft

[3.7 m] in length shall be tension tested at both ends of the

forging under test.

8.2.2.4 For quenched and tempered forgings and forged

bars weighing more than 10 000 tb [4500 kgm] at the time of

hheat treatment, two tension tests shall be taken from each

forging. These shall be offset 180" from each other except

that when the length excluding test prolongations exceeds

three times the diameter or equivalent thickness one shall be

located at each end of the forging.

9. Grain Size

9.1 For classes F304H, F316H, F309H, F310H, F321H,

F347H and F348H, the grain size of the forgings shall be

ascertained according to Method E 112, after solution treat-

ment. One sample shall be examined for each tensile

specimen required in 8.2, and shall be taken from the tension

test location. The grain size shall be number 6, or coarser

over at least 75 % of the surveyed area.

10, Workmanship, Finish, and Appearance

10.1 When ferritic forgings have been heat treated by

quenching and tempering. all accessible surfaces shall subse.

quently be examined for quench cracks by the magnetic

particle method in accordance with Method A 275/A 275M.

11, Repair Welding

11.1 Repair welding of forgings may be permitted but

only at the option of the purchaser. Such repair welds shall

bbe made in accordance with Section IX of the ASME Boiler

& Pressure Vessel Code.

12, Marking

12.1 In addition to the marking requirements of Specifi-

cation A 788, the specification marking shall be followed by

the letter A for annealed, N for normalized and tempered or

Q for liquid quenched and tempered as applicable.

13. Test Reports

13.1 The certification

requirements of Specific

‘A 788 shall apply.

SUPPLEMENTARY REQUIREMENTS

One or more of the following supplementary requirements shall apply only when specified by the

purchaser in the inquiry, contract, and order. Details of these supplementary requirements shall be agreed

upon between the manufacturer and the purchaser,

SI. Rough Turning and Boring

S1.1 The position of the rough turning and boring in the

sequence of manufacturing operations shall be specified.

$2. Transverse Tension Test

$2.1 Instead of test specimens taken in accordance with

8.1.1, the longitudinal axis of the test specimens shall be

transverse to the direction of major working of the forging.

The results shall conform with requirements of Table 2, with

the exception of the ductility limits which shall be as

prescribed in Table S1.1

$3. Alternative Test Specimen Requirements

S3.1 The test requirements for materials of the ASME

Boiler and Pressure Code, Section Ill. Article NB-2223.3

shall be used in place of that specified in 8.1.1.1

S4. Hydrostatic Test

S4.1 A hydrostatic pressure test shall be applied. The

details of the test, including its position in the sequence of

manufacturing operations, shall be specified.

SS. Stabilization Heat Treatment

$5.1, When specified, Classes F347 and F321 shall receive

TABLE $1.1. Ductity Limits

Gass

Ai iA Frs Fa FA Fea eA

a a a

Thor st

z

Reiter 99 85H

7 —— —

|r204rssna04 soa |raoa ron) r210|-a104rx6|rav6 rane. raven) ranen crs) oe7 ever roeelrsean]#M*| lear

Se pF) PP)? T=) ™|=[ ==] [S| es wy e wl w lapse lols

torn | |

norco | | Head |

| |

radirion| 25 | 95 | 25 | as | a as | as| as | a5} a5 | a5 | a5 | as fas | os far] a5 [as] a5 | a5 | 0 [uo

of area | \

ma |

167

jb a 336/a 336m

tabilization treatment, which shall consist of holding the

orging at 1500 10 1600°F [815 t0 870°C}. for not less than 2

vfin. of thickness and then cvoling in the furnace of in still

ir

6. Liquid Penetrant Exan n

6.1 Afier ferritic forgings have been heat treated by

juenching und tempering, all accessible surfaces shall be

nspected for quench cracks by the liquid penetrant method

n accordance with Practice F165 as an alternative to

nagnetic particle examination.

37. Marking

$7.1 Forgings shall be marked at a location indicated by

he purchaser in the purchase order or drawing

38. Forging Requirements

$8.1 Large drum forgings shall be made from solid cast

ngots, punched. bored. or tzepanned. oF from hollow ingots

ast in metal molds. The walls of the hollowed or hollow

gots shall be reduced in thickness at least one-half by

orging on mandrels,

$8.2 Drum forgings with one solid closed end may be

ollow forged in closed dies or on a draw bench provided the

actal is worked thoroughly

8.3 Drum forgings, either with open ends or one solid

closed end. may also be produced by hot extrusion provided

the metal is worked thoroughly.

$8.4 Small drum forgings may be made as solid forgings.

subsequently bored. provided the purchaser agrees 10 this

method of forging. The cross-sectional area of the solid

forgings shall have a reduction by forging from that of the

ingot in the ratio of not less than 3:1

8.5 Small sections or component parts of pressure ves-

sels, which are to be subsequently assembled to form drums,

may be made by expanding on a mandrel under a press or

hammer. by hot extrusion or by ring rolling methods.

provided the wall thickness is reduced at least one-half in the

process.

$8.6 Heads or covers shall be forged as disks, upset from

blocks cut from ingots or billets. The length of block before

upsetting shall be at least twice the thickness of the as-forged

head or cover.

S9. Individual Forging

$9.1 Forgings, whether identical or not identical, shall be

produced individually. They shall not be forged in’ multiple

and separated prior to or after heat treatment,

$9.2 The shape and size of individual forgings shall be

agreed between the manufacturer and the purchaser by

means of a forging drawing or the purchase order,

‘ihe American Society for Testing and Meters akes no positon respecting the validly of any patent rights asserted in connection

tn any item mentioned inthis stangars. Users ofthis standard are expressly advised thal Geermination othe vat of any such

alent rights, and the sk of intangement of such righ, are ently their own responsibilty.

Ts standard is subject revision at any time by the responsible technica! comvmttee and must be reviewed evey five years and

itnot ese, eter reapproved or withcrawn. Your comments ae ited ee for revision of ths slander efor alte! anced

{and should be ae

eto ASTM Headquarters. Your commarts wil receive carelulconsieratian at¢ meeting ofthe responsible

{echnical commitee, which you may afer. you fea nat your comments have net recewved a ar eating you Sheu Make your

views known tothe ASTM Commitee on Standards, 1916 Race St. Phiedeloha, PA 79103,

168

@) A 336/A 336M

bars weighing over $000 to 10 000 Ib [2250 t0 4500 kg) at the

time of heat treatment, but not exceeding 12 ft (3.7 m} in

length, one tension test shall be taken from each forging,

8.2.2.3 Quenched and tempered forgings that exceed 12 ft

[3.7 m] in length shall be tension tested at both ends of the

forging under test.

8.2.2.4 For quenched and tempered forgings and forged

bars weighing more than 10 000 tb [4500 kgm] at the time of

hheat treatment, two tension tests shall be taken from each

forging. These shall be offset 180" from each other except

that when the length excluding test prolongations exceeds

three times the diameter or equivalent thickness one shall be

located at each end of the forging.

9. Grain Size

9.1 For classes F304H, F316H, F309H, F310H, F321H,

F347H and F348H, the grain size of the forgings shall be

ascertained according to Method E 112, after solution treat-

ment. One sample shall be examined for each tensile

specimen required in 8.2, and shall be taken from the tension

test location. The grain size shall be number 6, or coarser

over at least 75 % of the surveyed area.

10, Workmanship, Finish, and Appearance

10.1 When ferritic forgings have been heat treated by

quenching and tempering. all accessible surfaces shall subse.

quently be examined for quench cracks by the magnetic

particle method in accordance with Method A 275/A 275M.

11, Repair Welding

11.1 Repair welding of forgings may be permitted but

only at the option of the purchaser. Such repair welds shall

bbe made in accordance with Section IX of the ASME Boiler

& Pressure Vessel Code.

12, Marking

12.1 In addition to the marking requirements of Specifi-

cation A 788, the specification marking shall be followed by

the letter A for annealed, N for normalized and tempered or

Q for liquid quenched and tempered as applicable.

13. Test Reports

13.1 The certification

requirements of Specific

‘A 788 shall apply.

SUPPLEMENTARY REQUIREMENTS

One or more of the following supplementary requirements shall apply only when specified by the

purchaser in the inquiry, contract, and order. Details of these supplementary requirements shall be agreed

upon between the manufacturer and the purchaser,

SI. Rough Turning and Boring

S1.1 The position of the rough turning and boring in the

sequence of manufacturing operations shall be specified.

$2. Transverse Tension Test

$2.1 Instead of test specimens taken in accordance with

8.1.1, the longitudinal axis of the test specimens shall be

transverse to the direction of major working of the forging.

The results shall conform with requirements of Table 2, with

the exception of the ductility limits which shall be as

prescribed in Table S1.1

$3. Alternative Test Specimen Requirements

S3.1 The test requirements for materials of the ASME

Boiler and Pressure Code, Section Ill. Article NB-2223.3

shall be used in place of that specified in 8.1.1.1

S4. Hydrostatic Test

S4.1 A hydrostatic pressure test shall be applied. The

details of the test, including its position in the sequence of

manufacturing operations, shall be specified.

SS. Stabilization Heat Treatment

$5.1, When specified, Classes F347 and F321 shall receive

TABLE $1.1. Ductity Limits

Gass

Ai iA Frs Fa FA Fea eA

a a a

Thor st

z

Reiter 99 85H

7 —— —

|r204rssna04 soa |raoa ron) r210|-a104rx6|rav6 rane. raven) ranen crs) oe7 ever roeelrsean]#M*| lear

Se pF) PP)? T=) ™|=[ ==] [S| es wy e wl w lapse lols

torn | |

norco | | Head |

| |

radirion| 25 | 95 | 25 | as | a as | as| as | a5} a5 | a5 | a5 | as fas | os far] a5 [as] a5 | a5 | 0 [uo

of area | \

ma |

167

You might also like

- R016611Document4 pagesR016611Alam MD SazidNo ratings yet

- QD62-H-103 DocumentationDocument16 pagesQD62-H-103 DocumentationAlam MD SazidNo ratings yet

- Welding Proposed Pwps For Our Jubail WorkDocument2 pagesWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- List of WPS (Jerp) PDFDocument2 pagesList of WPS (Jerp) PDFAlam MD SazidNo ratings yet

- Limak - Sawaed WpsDocument1 pageLimak - Sawaed WpsAlam MD SazidNo ratings yet

- Cathodic ProtectionDocument52 pagesCathodic Protectionredback666100% (2)

- Third Party QC For SWCC Man IndiaDocument1 pageThird Party QC For SWCC Man IndiaAlam MD SazidNo ratings yet

- CV Faisal ZAFAR SHAHIDDocument6 pagesCV Faisal ZAFAR SHAHIDAlam MD SazidNo ratings yet

- Sawaed PT Report No. 02 For SWCC Jubail Emergency LineDocument1 pageSawaed PT Report No. 02 For SWCC Jubail Emergency LineAlam MD SazidNo ratings yet

- DPT Test Report FormatDocument1 pageDPT Test Report FormatAlam MD SazidNo ratings yet

- Request for Welding Procedure ApprovalDocument10 pagesRequest for Welding Procedure ApprovalAlam MD SazidNo ratings yet

- Peneterant Testing For NDT - Procedure Details - Latest FinalDocument8 pagesPeneterant Testing For NDT - Procedure Details - Latest FinalAlam MD Sazid100% (1)

- WPSDocument2 pagesWPSAlam MD Sazid100% (1)

- ISO 9001, 14001, 45001 certified companyDocument1 pageISO 9001, 14001, 45001 certified companyAlam MD SazidNo ratings yet

- ISO 9001, 14001, 45001 certified companyDocument1 pageISO 9001, 14001, 45001 certified companyAlam MD SazidNo ratings yet

- Limak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Document2 pagesLimak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Alam MD SazidNo ratings yet

- SAWAED'S LIQUID PENETRANT TEST PROCEDUREDocument7 pagesSAWAED'S LIQUID PENETRANT TEST PROCEDUREAlam MD SazidNo ratings yet

- Limak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Document2 pagesLimak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Alam MD SazidNo ratings yet

- P6022mab Amd 128 11541 01 - S4Document1 pageP6022mab Amd 128 11541 01 - S4Alam MD SazidNo ratings yet

- Shop Materials Confidential Use OnlyDocument1 pageShop Materials Confidential Use OnlyAlam MD SazidNo ratings yet

- Signed Acceptance of Job OfferDocument2 pagesSigned Acceptance of Job OfferAlam MD Sazid0% (1)

- Understanding Process DrawingsDocument25 pagesUnderstanding Process Drawingspippo2378793No ratings yet

- Accoutnt Statement PDFDocument3 pagesAccoutnt Statement PDFAlam MD SazidNo ratings yet

- PID SymbolsDocument18 pagesPID SymbolsAnonymous f9EEXptHCNo ratings yet

- Prime Minister Employment Generation Programme DetailsDocument1 pagePrime Minister Employment Generation Programme DetailsAlam MD SazidNo ratings yet

- ch9 1Document38 pagesch9 1Karam AlmasriNo ratings yet

- Piping Isometric Drawings GuideDocument857 pagesPiping Isometric Drawings GuideHugo Ruiz67% (3)

- Seed License Documents NewDocument8 pagesSeed License Documents NewAlam MD SazidNo ratings yet

- 13 April (GulfJobPaper - Com) PDFDocument4 pages13 April (GulfJobPaper - Com) PDFAlam MD SazidNo ratings yet

- Experience LetterDocument1 pageExperience LetterAlam MD Sazid50% (2)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)