Professional Documents

Culture Documents

Tracking and Tensiong - 2007 PDF

Uploaded by

nitin9860Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tracking and Tensiong - 2007 PDF

Uploaded by

nitin9860Copyright:

Available Formats

Processandconveyorbelting

Tracking and tensioning

Introduction 1

Whypreventmistracking 1

Causesofmistracking 2

Explanationofmistracking 3

Tensioningofthebelt 4

Methodstocorrectmistracking 5

Conveyorbeltproblemsandcures 8

Introduction

Therearemanyopinionsabouttensioningandtrackingofconveyorbelting.Ammeraal

Beltechhasgainedmuchexperiencewiththisphenomenon.Withregardtotensioningof

conveyorbeltingincombinationwithtracking,anextensiveknowledgeisavailable.This

modulegivesdirectionstopreventthenegativeinfluencescausedbymistrackingofconveyor

beltinginpractice.

Why prevent mistracking

Thecausesofmistrackingare:

maintenanceheadaches;

downtime;

beltdamage;

damageofequipment(overtensioning);

productdamage.

Maintenance headaches

Theroundtheclockeconomyisaskingforanextensionoftheoperatinghoursof

productionplants.Thismayresultinmaintenanceproblemscausedbymistrackingofthe

beltatanytimeduringthedayornight.Ingeneralthetechnicalservicecanbecalledto

solvetheseproblems,butthisisexpensiveandunpleasant.

Downtime

Mostofthecompaniesworkaccordingtoaproductionplan.Incaseofdowntimethereis

noproductionandthecompanyisfacinglackofearnings.Downtimehastobepreventedat

alltimes.

Belt damage

Ingeneralprocessandconveyorbeltingarevaluablepartsoftheconveyor.Mistrackingof

thebeltisusuallyresultinginconsiderablebeltdamage.Thisdamagecanusuallynotbe

repaired.Itresultsinhighandunexpectedexploitationcostsoftheequipment.Correct

tensioningandtrackingofbeltingcanpreventthis.

AmmeraalBeltech January2007 CD1-TRAPage1of10

Processandconveyorbelting

Tracking and tensioning

Equipment damage

Whenmountingthebeltwithtoomuchbelttensionusuallymuchdamageiscausedtothe

installation.Aninstallationisdesignedfortheapplication.Abelttensionhigherthan

calculatedwillcausebendingofthedrumsandshafts.Alsotheloadonthebearingswill

increase.Thisalwaysresultsinashorterservicelifeandpossibleunexpectedcosts.

Product damage

Productdamagehastobepreventedatalltimes.Incaseoffood

productionitisintolerablethatnon-foodsubstancesendupinthefood

product.Abeltrunningagainstmachinepartsbecauseofmistracking

resultsinfrayingedges.Theseparticleswilleventuallycontaminatethe

product.Thiscanbepreventedbyproperbelttensioningandtracking.

Causes of mistracking

Belt

Whenthebelt:

doesnothaveanevenlengthontheleftandrightsides;

hasdifferencesinthicknessontheleftandrightsides;

showsdifferentwearontheleftandrightsides;

isnotsplicedstraight;

iscurvedordeformed;

thisresultsinadifferenceinsurfacepressureand/orfrictiononthepulleydrive.

Othercausescanbe:

Anincorrectbelttension.Whenthetensionistoolow,thebeltwillgoinevery

direction.Whenthetensionistoohigh,thereisnocorrectionpossiblebecausethebelt

cannotslipsidewaysonthepulleys.

Anincorrectfabricconstruction(nottwistedSZ).

Fabricnotinthecorrectposition(angle)inthebelt(obliqueweft).

Pulleys

Causescanbethatthepulleysarenotparalleltoeachotherandsquarelyonthebelt.Orthe

pulleysarenothorizontal.Anotherreasonisadifferenceincoefficientoffrictionoverthe

pulleylength(wrongshape,pollution,wear)orthereisadifferenceindiameterononeside

towardstheother.

Note: Belt widthandpulleylengthmustgear.

Product

Possiblecausesareanasymmetricload,incline/decline,loading/unloadingononeside,or

temperaturedifferencesincombinationwiththeloadingsystem.

AmmeraalBeltech January2007 CD1-TRAPage2of10

Processandconveyorbelting

Tracking and tensioning

Frame

Theframemightnotbestable.

Belt support

Thesliderbedisperhapsnothorizontalorthereisadifferenceinsurfacesmoothness.

Rollersmaybemountedinatiltedpositionoroutoftheperpendicular.Diameterdifferences

cancauseproblemsaswellaspollution.

Various causes

Therecanbemorereasonsformistracking,likeabeltcleaner,sideskirts,knifeedge

transfersorweatherinfluences(wind).

Explanation of mistracking

Rule: Abeltreachingadrum/pulleywillgetadeflectionfromthefirstcontactbetween

beltanddrum/pulley.Asaconsequencethebeltisrunningtothedirectionwhereitis

touchingtheturningdrumorpulley.

Cylindrical pulleys

Beltrun

Whenapulleyisnotplacedsquaretothebelt,itwillresultinthe

situationasshowninfig.1.Thebeltwillmovetotheleftasanut

doesoverathreadedpin,withaspeedofDtg.

Inthemostextremecasethebeltwillfoldonthedrum.

Thebeltwillruntothesidewiththelowesttension.

Thebeltrunsinthedirectionoftheperpendicularlinetothe

contactline. Fig. 1

Thebeltrunsinthedirectionwhereittouchestheturning

drumorpulleyfirst.

Conical pulleys Beltrun

Fig.2showsthatthebeltmovestotherightonconditionthatthe

shaftsofthepulleysareparalleltoeachother.Thebeltwillrunto

thesidewiththehighesttension.

Asaresultofspeedandtensiondifferencethebeltwillshow

ahorizontalbendingjustbeforeittouchesthedrum.

Thereforethebeltwilltouchthedrumsomewhathigher(in

directionofbiggestconicaldiameter). Fig. 2

AmmeraalBeltech January2007 CD1-TRAPage3of10

Processandconveyorbelting

Tracking and tensioning

Support rollers (tracking rollers) Beltrun

Thebeltwillruninthedirectionoftheperpendicularlineonthe

contactline(fig.3).

Rule: Abelt,runningagainstapulleyorroller,willgetaside

deviationofthefirstcontactspot*betweenbeltandpulley/roller.

Fig. 3

Fixed sliding strips or scrapers Beltrun

Abeltrunningonanon-movingsupportwill,contrarytoroller

support,deviateinthedirectionofthelastcontactspotbetween

beltandsupport.

Inpracticethesupportoffixedstripsconsistsof:

sliderbed,beginningofthebedmustbesquareonthebelt;

slidingstrips; Fig. 4

scrapers.

Thesamephenomenonoccursincasethesupportrollersdonotturnorturnwithdifficulty.

Tensioning of the belt

Thebelttensionhasadirectrelationwiththetrackingbehaviour.Toomuchtensionresultsin

verynervousbeltbehaviourandexcessivewearofmachinerycomponentslikebearingsand

shafts.Toomuchtensioncanevenresultinabreakingoftheshafts.Toolittletensiongives

beltslippageonthedrivedrumandresultsinnotfollowingthecrowning.

Beforemountingthebeltontheinstallationitisadvisabletoleavethebeltfortwelvehours

intheroomwherethebeltisgoingtobeused.

Whentheoldbeltisremoved,theinstallationcanbecleaned.Thenthebeltcanbemounted;

ifnecessaryitcanbemadeendlessonsite.

Theinstallationhastobeprovidedwithatensioningdevice;inmostcasesthisisthetail

drum.Thetensioninglengthoftheinstallationis1%ofthebeltlength.

Thebelthastobetensionedaftermounting.Thebestwaytodothisistomarktwolines

(withapitchof1000mm)atbothbeltsideswitharedpen.Thentensionthebeltleftand

rightequallyupto1003mm=0.3%pretension.Incaseofheavierloadover50kg/m2the

belttensioncanbeincreasedto0.5%.

Incaseofaninstallationwithaknifeedgethisprocedureisnotapplicable.Inthiscase

tensionthebeltonarunninginstallationtotheextentthatslippagedoesnotexistanymore.

AmmeraalBeltech January2007 CD1-TRAPage4of10

Processandconveyorbelting

Tracking and tensioning

Methods to correct mistracking

Fixed tracking possibilities or adjustable by hand:

Crowningofthepulleys.

Trackingrollers:flattrackingroller,snubpulley,adjustingtroughassembly,

V-rollers/strips.

Fixedprovisionsontheconveyor:siderollers,sideguides.

Fixedprovisiononthebelt.

Trackingropes,trackingstrips,guiderollers.

Variabletracking:withuseofthebelt,trackingdeviceswithowndrive.

Crowning of the pulleys

Emergency solution or test

Convexpulley:ideal Cylindricalpulleywith Apply non slip tape on a

Shape,difficulttomake conicalsides:imitationof cylindrical pulley

theconvexmodel

Dimension Length partition Pulley length mm

(drivepulleydia.80-300mm)

Diameterdifference=1%

butmaximum4mm A B A

D1= 101 A B A D2 D1

upto400 1/3 1/3 1/3

D2 100 400-800 1/4 2/4 1/4

800-1200 1/5 3/5 1/5

D1=largestdiameter NB:pulleylength= 1200-1600 1/6 4/6 1/6

D2=smallestdiameter beltwidth+50mm over1600 300 300

Which pulleys to be crowned:

1. Drivedrum.

2. Drivedrumsandtaildrumswhentheconveyorislongerthan4xthebeltwidth.

Recommendations:

Inprinciplethepulleysandrollersmustbeadjustable(e.g.bolt10inhole12).

Pulleyspreferablynotatthebuttend.

Forhighbeltspeeds(v=2m/s)balancethepulleys.

Nevercrowntheknifeedgesorsetthemoutofsquare.

AmmeraalBeltech January2007 CD1-TRAPage5of10

Processandconveyorbelting

Tracking and tensioning

Tracking rollers

Flat (snub) tracking rollers

15-30

Mountthetrackingrollersinaspotwithlowbelttension

(usuallybeforethereturnpulley).Thearcofcontactmustbe

between15and30.Below15thecontactbetweenbelt

10%W

andpulleyistooshort,over30youwilladdtensionwhich

againwillcausemistracking.Theremustbesufficientfriction 300-600

betweentrackingrollerandbelt(e.g.non-sliplagging). Tensioning-/taildrum

andtrackingidler

Whenthebeltisheavilypolluted,mountingontheinsideof

thebeltispossible.

Adjusting snub/stow pulleys

Theprincipleisthesameastheadjustingtroughassemblythat

ismountedupsidedown.Mountinreturnpartonbothbelt

edges,undersomebelttensionandfarfromenddrums(6

toe-in,15downwardstolateralhorizontalline).When

mistrackingbeltmustrun-uphighertotherollinordertoface

moreresistant.

Adjusting trough assemblies

Inpracticeoneoneachfivetroughassembliesisanadjustingone.

Note:Think of the proper mounting, because adjusting trough

assemblies are for one running direction. The rollers have to be

mounted toe-in (see sketch).

V-strips (flat belt)

ThisChevron-shapedprofileispushingthebelttothecenter

andcanonlybeusedincaseofheavybelts(over3kg/m2).By

thethrustlightbeltsmightfold.

Side rollers

Theseareonlysuitableforheavy,thickbeltingof10mm

thickness.Theyaremeantfortemporarymistracking,andnota

continuoussolution.

Note: Support rollers and trough assemblies can also be slightly adjusted.

Fixed provisions on the conveyor

Thesideguideisonlysuitableforcorrectingtemporarymis-

trackingandforlateralstablebelts;notforverythinbelts.Itis

nocontinuoussolution.Thematerialofthesideguideise.g.

beechwoodornylon.

Note: The guide must be bevelled at the side where the belt is going in.

Do not mount the guide close to the exit side of a return drum.

AmmeraalBeltech January2007 CD1-TRAPage6of10

Processandconveyorbelting

Tracking and tensioning

Fixed provisions on the belt

Ropes

V-guidesandguideropes(squareandrectangular)canbeapplied

onthecentrelineofthebeltoratthesidesofthebelt.Theguide

tracksontheframeandnotonthepulley.Thepulleydiameterfor

V-guidesis6xtheheightoftheguide,forsquareandrectangular

ropes10xtheheight.

Strips

Guidestripsareusuallyappliedonthesidesofthebelt,thestrip

tracksontheframeandnotonthepulley.Aone-plystripneedsa

pulleydiameterof1.2xtheminimumpulleydiameterofthebelt

andatwo-plystrip1.4x.WhenAmtelstripsareused,thepulley

diametermustbe10xthestripthickness.

Note: V-guides, ropes and strips have a free space towards the pulley on the bottom side.

Only the belt is driven. If not, the guide will tear off the belt because of the differences in

circumference speed.

Rollers/cams

Guiderollers/camsareappliedincasesoflonglastinglateralforces

andhighdemandsonrunningstraight.

Variable tracking

Tracking with use of the belt

Aflattrackingrollerismountedonthebottomsideofthebelt,in

theupperpartinfrontofloadingpoints,approx.2000mm

beforethereturnpulley.

Principle:whenthebeltgoestotherightside,thetrackingroller

willattherightsideturnintherunningdirectionofthebelt.Asa

resultofthis,thebeltwillbeguidedbacktothecentre.Thisis

influencedbybeltweight,productweightandfrictionbetween

beltandroller.

Trackingtroughassembliesareusedforbeltingwithoneortworunningdirections.

Theassembliesareautomaticallyadjusting.

Beltwithonerunningdirection Beltwithtworunningdirections

AmmeraalBeltech January2007 CD1-TRAPage7of10

Processandconveyorbelting

Tracking and tensioning

Tracking devices with own drive

Becauseofthelargescaleofpossibilitiesintrackingequipment,welimitourselvestoa

numberofdistinguishingcharacteristics:

Drive:pneumatic,pneumatic/hydraulic,electric.

Amountoftracking:minimum/maximum,proportional.

Manneroftracking:byfriction(seetrackingroller),byclampingthebelt(Foxwell),by

influencingthebelttension.

Mannerofsignalising:bydirectbeltcontact(pneumatictracer,microswitch),without

contact(ultrasonar,photocell,pneumatic,approximationswitch).

Conveyor belt problems and cures

Stretch and slippage Belt: stretchesexcessively

slipsandsqueals

Tracking Belt: creepspartlytooneside

creepstooneside

creepsatonespotonly

creepstoonesideatheadpulley

creepstoonesideattailpulley

wandersirregularly

Splice and fastener Beltfastenerspullingout

Splicefailure

The belt Plyseparation

Excessivetopsidewear

Excessivepulleysidewear

Excessiveedgeswear

Coversofteningandcracking

Cause Cure

Stretch and slippage

Belt stretches excessively

Tensiononbelttoohigh Reducetensiontoapointwherebeltwill

runwithoutslippage;lagdrivepulley

Conveyorunder-belted Replacewithheavierorwiderbelt

Materialbuild-uponpulleys/rollers Cleanpulleys/rollers

Frozenrollers Removeicingontherollerstoincrease

frictionbetweenbeltanddrum

Excessivepositivetake-upforce Provideself-compensatingtake-up(spring

loadedorcounter-weight)

Belt slips and squeals

Belttoolooseinsufficienttraction Lagdrivepulley;increasetensionslightly

betweenbeltandpulley

Conveyorunder-belted Replacewithheavierorwiderbelt

AmmeraalBeltech January2007 CD1-TRAPage8of10

Processandconveyorbelting

Tracking and tensioning

Tracking

Belt creeps partly to one side

Beltsplicecrooked Re-splice

Beltendsatfastenersnotslitsquare; UseaT-squareforslittingperfectlysquare;

fastenersnotjoinedsquarely replacewithcorrectsizefasteners

Belt slips creeps to one side

Improperbeltload Loadindirectionofbeltrun,atbeltspeed,

centredonbelt

Frozenrollers;rollersnotproperlylocated Lubricaterollers,improvemaintenance;

(oblique) relocateimproperlyplacedrollersand

checkalignmentwithaT-square

Frameorstructurecrookedornotlevelbelt Checkalignmentbystretchingastring

shiftstolowside alongframeedge,makecorrection;level

structure

Materialbuild-uponpulleys/rollers Cleanandimprovemaintenanceby

mountingscrapersorothercleaningdevice

Pulleys/rollersoutofline/oblique Re-checkandsquarewithaT-square

againstconveyoredge

Belt creeps at one spot only

Roller(s)-usuallyinfrontoftroublespot- Move(indirectionofbeltrun)thatroller

outofline(notperpendicularwithcentre endtowhichthebelthasshifted

line)Alsosee4.2,4.3and4.4

Belt creeps to one side at head pulley

Headpulleyorprecedingrollersoutofline Realignthepulley/rollersperpendicularto

(notperpendicularwithcentreline) beltcentreline,ormove(indirectionof

beltrun)thatpulley/rollerendtowhich

thebelthasshifted

Belt creeps to one side at tail pulley

Tailpulleyorclosereturnrollersareoutof Realignthepulleyperpendiculartobelt

line/oblique(notperpendicularwith centreline,ormove(indirectionofreturn

centreline) beltrun)thatpulley/rollerendtowhich

Alsosee4.2,4.3and4.4 thebelthasshifted

Belt wanders irregularly

Conveyorover-beltedasbeltistoostiffto Replacewithproperbeltoruselarger

properlyrunoverappliedpulleydiameter pulleydiameter

Improperoroff-centreloadingcancause Correctloadingprocedureoruseabelt

belttowander withV-guide

Splice and fastener

Belt fasteners pulling out

Incorrectsizefastenersapplied Re-lacewithpropersizefasteners

Excessivetensiononbelt Reducetensiontoapointwherebeltwill

runwithoutslip;lagdrivepulley

Pulleystoosmallforbeltthickness Uselargerpulleydiameterorathinnerbelt

ifpractical

Belttensiontoohighcausedbyslippage Increasepulleydiameterstoreducebelt

tensionandtheeffectofstiffnessof

fastenerorapplyanendlesssplicedbelt

Splice failure

Beltspeed/tensiontoohigh(duetospeed Increasepulleydiameterstoreducespeed

differencetop/bottomsideofbeltand differenceandheatingup

innerheatingupduetosharpbendingover

toosmalldrums)

AmmeraalBeltech January2007 CD1-TRAPage9of10

Processandconveyorbelting

Tracking and tensioning

Pulleystoosmall Increasethepulleydiameter

Bendingofspliceinlateraldirection Removethecauseofbendingorapplyan

othersplice(e.g.T-splice)

The belt

Ply separation

Edgeofbeltwornorbrokendueto Checkalignmentofframe,pulleysand

excessiverubbing rollers

Pulleydia.toosmallforappliedbeltor Increasepulleydia.;reducetension(also

excessivetensiononbelt see1.3)

Damagebyabrasives,acid,heat,chemicals, Selectaproperlyresistantbelt

mildeworoil

Toomuchpulleycrowning Checkcrowningrecommendations

Excessive top side wear

Materialbuild-uponpulleys/rollers Cleanandimprovesupervision;install

scrapersorothercleaningdevice

Excessiveimpactofmaterialonbelt Reduceimpactorusecushionrollersatthe

impactpoints

Dirty,frozenormis-alignedreturnrollers Improvemaintenanceandsupervision;re-

alignrollersbyusingaT-squareagainst

conveyoredgeandrollers

Excessive pulley side wear

Beltslippingondrivepulley Lagdrivepulley;installsnubrollerfor

betterwraparounddrivepulley;slightly

increasebelttension

Materialbuild-uponbeltbottomside Removeaccumulationandinstallscrapers

tokeepthebottomsideofthebeltclean

Frozenordirtyrollers Lubricaterollers;improvemaintenance

Laggingsafetyscrewsprotrudingpulley Tightenscrewsandreplacelagging

lagging

Excessive edges wear

Beltedgesarefoldinguponconveyor Usestifferbeltifpractical;providemore

guardsorframe lateralclearance;smoothenroughareason

guardsorframe

Sideloadingcausesbelttoshifttoopposite Improvebyloadingindirectionofbeltrun;

sideandtorubexcessively useabeltwithV-guide

Materialbuild-uponpulleyswillsidetrack Installscraperstoprevent;build-upwill

belt forcethebeltagainsttheframe;applya

beltwithV-rope

Cover softening and cracking

Damagebyabrasives,acids,heat, Useproperlyresistantbelt

chemicals,mildeworoil

Pulleydiametertoosmallforbeltthickness Increasepulleydiameterorusemore

flexiblebelt

Excessivebelttension Reducetension;lagdrivepulleyorprovide

self-compensatingtake-up

AmmeraalBeltech January2007 CD1-TRAPage10of10

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- List of CompaniesDocument5 pagesList of Companiesdeep nikil60% (5)

- Empirical Finance with R and RmetricsDocument186 pagesEmpirical Finance with R and RmetricsDhruvShah0% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Troubleshooting Auto Cutting Atom - Ver1.0Document15 pagesTroubleshooting Auto Cutting Atom - Ver1.0Etsis Sari PujanggiNo ratings yet

- Civil Engineering Applications of Ground Penetrating Radar 2015 PDFDocument373 pagesCivil Engineering Applications of Ground Penetrating Radar 2015 PDFnitin986067% (3)

- (Mary Anne Pilger) Multicultural Projects Index T (BookFi)Document163 pages(Mary Anne Pilger) Multicultural Projects Index T (BookFi)nitin9860No ratings yet

- (Ebook - PDF - Graphic Design) - Learn How To DrawDocument133 pages(Ebook - PDF - Graphic Design) - Learn How To DrawBalachandran NavaratnasamyNo ratings yet

- Circular No. 23862 Schedule of Charges Case No. 195 of 2017 08.10.2018Document10 pagesCircular No. 23862 Schedule of Charges Case No. 195 of 2017 08.10.2018nitin9860No ratings yet

- ELAN Series 5BB P-Type PERC Bifacial PV ModulesDocument2 pagesELAN Series 5BB P-Type PERC Bifacial PV Modulesnitin9860No ratings yet

- FlaskDocument302 pagesFlaskRony JacobNo ratings yet

- Solar Panel Stand Installation Guide for 3 Panels 330w-350wDocument2 pagesSolar Panel Stand Installation Guide for 3 Panels 330w-350wnitin9860No ratings yet

- Islamic Art and Geometric DesignDocument25 pagesIslamic Art and Geometric DesignVero100% (7)

- Car 3 PDFDocument1 pageCar 3 PDFNidhi SharmaNo ratings yet

- User Manual: SeriesDocument78 pagesUser Manual: SeriesFrancisco DiasNo ratings yet

- Leading Experts in Islamic FinanceDocument238 pagesLeading Experts in Islamic FinanceZX Lee100% (1)

- (Ewald C.-O.) Mathematical Finance Continuous Tim (BookFi)Document129 pages(Ewald C.-O.) Mathematical Finance Continuous Tim (BookFi)nitin9860No ratings yet

- (International Monetary Fund. Government Finance S (BookFi)Document585 pages(International Monetary Fund. Government Finance S (BookFi)nitin9860No ratings yet

- Rural Finance and Credit Infrastructure in China PDFDocument392 pagesRural Finance and Credit Infrastructure in China PDFJuan Ruiz-UrquijoNo ratings yet

- 4th Geometry Festival, Budapest (BookFi)Document6 pages4th Geometry Festival, Budapest (BookFi)nitin9860No ratings yet

- Emerson TV LD320EM5 User ManualDocument47 pagesEmerson TV LD320EM5 User Manualnitin9860No ratings yet

- Mi TV 2 55': Take Out Components Take Out TV According To The ImageDocument5 pagesMi TV 2 55': Take Out Components Take Out TV According To The Imagenitin9860No ratings yet

- LG RU-20LA61 Service ManualDocument21 pagesLG RU-20LA61 Service Manualnitin9860No ratings yet

- LG Rz-26lz50 Ml-041a LCD TV Service ManualDocument37 pagesLG Rz-26lz50 Ml-041a LCD TV Service ManualAli Karayani100% (1)

- Service Manual for Colour LCD Television Models TX-32LX60F, TX-32LX60P, TX-26LX60F, TX-26LX60PDocument56 pagesService Manual for Colour LCD Television Models TX-32LX60F, TX-32LX60P, TX-26LX60F, TX-26LX60Pnitin9860No ratings yet

- TV LG 15la6r LCD Service - ManualDocument33 pagesTV LG 15la6r LCD Service - Manualppstone100% (1)

- Mi TV Bar: AccessoriesDocument5 pagesMi TV Bar: Accessoriesnitin9860No ratings yet

- Plasma Monitor/Tuner: Service ManualDocument48 pagesPlasma Monitor/Tuner: Service Manualnitin9860No ratings yet

- Mi TV 2 55': Take Out Components Take Out TV According To The ImageDocument5 pagesMi TV 2 55': Take Out Components Take Out TV According To The Imagenitin9860No ratings yet

- Mi TV 2 55': Take Out Components Take Out TV According To The ImageDocument5 pagesMi TV 2 55': Take Out Components Take Out TV According To The Imagenitin9860No ratings yet

- LG LCD TV Rz-23Lz41 Service ManualDocument36 pagesLG LCD TV Rz-23Lz41 Service Manualnitin9860No ratings yet

- Safari Storme Muscled For More BrochureDocument4 pagesSafari Storme Muscled For More Brochurecharan_p@rediffmail.comNo ratings yet

- D-Link India CCTV Products Warranty and Safety Information - Feb 2019Document11 pagesD-Link India CCTV Products Warranty and Safety Information - Feb 2019nitin9860No ratings yet

- Reliving Letter1Document2 pagesReliving Letter1nitin9860No ratings yet

- SY35U PART FILTER PERIODICAL SERVICEDocument2 pagesSY35U PART FILTER PERIODICAL SERVICEIman SantosaNo ratings yet

- Flow Diagram SymbolsDocument5 pagesFlow Diagram SymbolshussainNo ratings yet

- LNG Ships: by F. R. ChowdhuryDocument6 pagesLNG Ships: by F. R. ChowdhuryThusitha DalpathaduNo ratings yet

- Floor ReportDocument4 pagesFloor ReportStephen Gallagher0% (1)

- HD8765 47 PDFDocument109 pagesHD8765 47 PDFArsenie GeorgeNo ratings yet

- Precios y Cantidades de Recursos Requeridos Por TipoDocument3 pagesPrecios y Cantidades de Recursos Requeridos Por TipoWilder Huaman MuñozNo ratings yet

- Daewoo Motors Internship ReportDocument20 pagesDaewoo Motors Internship ReportAli Asher50% (2)

- Experimental Investigation of Resistance Spot Welding of Duplex Stainless SteelDocument5 pagesExperimental Investigation of Resistance Spot Welding of Duplex Stainless SteelM.SoundarrajanNo ratings yet

- Loan Application FormDocument3 pagesLoan Application FormRijal Abd ShukorNo ratings yet

- Transformer Life Extension by On-Line Continuous Oil Treatment and MonitoringDocument73 pagesTransformer Life Extension by On-Line Continuous Oil Treatment and Monitoringمحمد الأمين سنوساويNo ratings yet

- Method of Scaffolding WorksDocument25 pagesMethod of Scaffolding WorksFarrukh Javed100% (1)

- Leaflet Uniswitch CBCDocument2 pagesLeaflet Uniswitch CBCFahmi CumiNo ratings yet

- Service Manual: Air ConditionerDocument70 pagesService Manual: Air Conditionerboroda2410No ratings yet

- Cold Lime Soda Softening ProcessDocument10 pagesCold Lime Soda Softening ProcessSaurabh JadhavNo ratings yet

- AURORA KN95 Face Mask Introduction 2020Document23 pagesAURORA KN95 Face Mask Introduction 2020victorcamposNo ratings yet

- Local Bodies 3Document19 pagesLocal Bodies 3umzzNo ratings yet

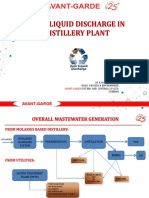

- Avant-Garde Mr. K Mohan KumarDocument46 pagesAvant-Garde Mr. K Mohan KumarSivakumar SelvarajNo ratings yet

- Recycling ConcreteDocument56 pagesRecycling ConcreteReshmita PallaNo ratings yet

- Manganese Steel 3401Document1 pageManganese Steel 3401kazdoelahNo ratings yet

- Vendors ListDocument59 pagesVendors ListGoliBharggav100% (1)

- Fema 267Document164 pagesFema 267chavico17100% (1)

- CNC Instructables PDFDocument13 pagesCNC Instructables PDFNadim AhmedNo ratings yet

- APEF - Electrochemistry - Multiple Choice Questions - Page 1 of 2Document2 pagesAPEF - Electrochemistry - Multiple Choice Questions - Page 1 of 2alyaa sheirNo ratings yet

- Battery Manufacturing: Etools Home: Scope - References - Glossary - Viewing / Printing Instructions - CreditsDocument146 pagesBattery Manufacturing: Etools Home: Scope - References - Glossary - Viewing / Printing Instructions - CreditsLo Siento de VerdadNo ratings yet

- ZF Astronic Bus Repair Manual Level 1-2-1337 751 101 2003Document8 pagesZF Astronic Bus Repair Manual Level 1-2-1337 751 101 2003Bette98% (48)

- Block Diagram Pulp PT TELDocument1 pageBlock Diagram Pulp PT TELEra MileniaNo ratings yet

- Cement Properties and Testing MethodsDocument22 pagesCement Properties and Testing Methodsankit kasanaNo ratings yet