Professional Documents

Culture Documents

Mechanical Nonlin 13.0 WS 09A Diagnostics

Uploaded by

Jym GensonCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mechanical Nonlin 13.0 WS 09A Diagnostics

Uploaded by

Jym GensonCopyright:

Available Formats

Customer Training Material

Workshop 9A

Contact Diagnostics

ANSYS Mechanical

Structural Nonlinearities

ANSYS, Inc. Proprietary Release 13.0

2011 ANSYS, Inc. All rights reserved. WS9A-1 April 2011

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics Customer Training Material

Goal

Diagnose convergence trouble with surface body contact model

Model Description

3D Spring plate Surface Body

3D Rigid Target Body

Linear steel material

Meshed with 3D SHELL elements

Spring Fixed support at one end, A

Rigid Body displaced into Spring 19mm

ANSYS, Inc. Proprietary Release 13.0

2011 ANSYS, Inc. All rights reserved. WS9A-2 April 2011

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics Customer Training Material

Steps to Follow:

Restore Archive browse for file W9a-diagnostics.wbpz

Save as

File name: W9a-diagnostics

Save as type: Workbench Project Files (*.wbpj)

ANSYS, Inc. Proprietary Release 13.0

2011 ANSYS, Inc. All rights reserved. WS9A-3 April 2011

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics Customer Training Material

The project Schematic should look like the

picture to the right.

From this Schematic, you can see that the

Engineering (material) Data and Geometry have

already been defined (green check marks).

It remains to set up and run the FE model in

Mechanical

Highlight the Engineering Data Cell and open by

clicking on the Right Mouse Button

(RMB)=>Edit to verify the linear material

properties.

Verify that the units are in Metric(Tonne,mm,..)

system. If not, fix this by clicking on

Utility Menu=>Units=>Metric(Tonne, mm,..)

ANSYS, Inc. Proprietary Release 13.0

2011 ANSYS, Inc. All rights reserved. WS9A-4 April 2011

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics Customer Training Material

Return to Project Schematic

Utility Menu > Return to Project

Double click on the Model Cell to open the FE Model (Mechanical

Session) (or RMB=>Edit)

ANSYS, Inc. Proprietary Release 13.0

2011 ANSYS, Inc. All rights reserved. WS9A-5 April 2011

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics Customer Training Material

Once inside the Mechanical application, verify the working unit system

Unit > Metric (mm,kg,N,s,mV,mA)

The spring assembly is already set up with frictionless contact pairs, a fixed

boundary condition and a displacement load on the rigid component.

Highlight the entities beneath each folder to become familiar with the model

and to confirm that it is properly supported and loaded and ready to solve.

ANSYS, Inc. Proprietary Release 13.0

2011 ANSYS, Inc. All rights reserved. WS9A-6 April 2011

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics Customer Training Material

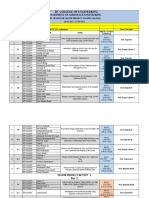

Confirm the Analysis Settings Specifications as

shown:

Run the Solution

ANSYS, Inc. Proprietary Release 13.0

2011 ANSYS, Inc. All rights reserved. WS9A-7 April 2011

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics Customer Training Material

After solution run is complete, highlight the Solution Information folder

and scroll to near the bottom of the output.

The model solves without error.

ANSYS, Inc. Proprietary Release 13.0

2011 ANSYS, Inc. All rights reserved. WS9A-8 April 2011

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics Customer Training Material

Review the Total Deformation results.

Something is wrong. The contact relationship between the two parts has

obviously failed.

ANSYS, Inc. Proprietary Release 13.0

2011 ANSYS, Inc. All rights reserved. WS9A-9 April 2011

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics Customer Training Material

With 25 initial substeps and Auto Time Stepping turned On, the contact should

have engaged. In an effort to determine the problem, we will evaluate what the

initial condition of the contact pairs are.

Highlight the Connections Folder: RMB> Insert> Contact Tool

Highlight the Contact Tool: RMB>Initial Information>Generate Initial Contact

Results. This will run a partial solve to establish initial contact parameters

(i,e. Initial status, gap, penetration, etc).

ANSYS, Inc. Proprietary Release 13.0

2011 ANSYS, Inc. All rights reserved. WS9A-10 April 2011

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics Customer Training Material

Review the Initial Contact Information.

Note the following:

The two active pairs both have an initial status of Far Open

Both pairs have a pinball radius of 4mm. Is 4mm enough?

ANSYS, Inc. Proprietary Release 13.0

2011 ANSYS, Inc. All rights reserved. WS9A-11 April 2011

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics Customer Training Material

By studying a profile of the undeformed geometry we can see that the

initial gap is less then 1.50mm. Hence, the Pinball Radius of 4mm should

be sufficient for this contact pair to be in an initial status of near-open.

Rigid Target

Spring

ANSYS, Inc. Proprietary Release 13.0

2011 ANSYS, Inc. All rights reserved. WS9A-12 April 2011

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics Customer Training Material

Highlight the contact region representing the contact between the spring

and target.

In order for contact to work properly, the contact element normals must be facing

the target element normals.

Recall that surface bodies are meshed with shell elements that have a top and a

bottom face. The reason this contact pair is not working is because the contact

normals are on the wrong side of the surface body with normals that face away

from the target. This needs to be reversed.

Target element

normal direction

Contact element

normal direction

ANSYS, Inc. Proprietary Release 13.0

2011 ANSYS, Inc. All rights reserved. WS9A-13 April 2011

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics Customer Training Material

From the details window of the contact region, switch the contact shell face

from Bottom to Top . The red color highlighting the contact side should

switch.

ANSYS, Inc. Proprietary Release 13.0

2011 ANSYS, Inc. All rights reserved. WS9A-14 April 2011

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics Customer Training Material

Highlight the Solution Information Branch

Set Newton-Raphson Residuals = 3

This will save force imbalance data for the last

3 Newton-Raphson iterations. This is

especially helpful information for

troubleshooting troubling contact convergence

problems.

Rerun the solution

ANSYS, Inc. Proprietary Release 13.0

2011 ANSYS, Inc. All rights reserved. WS9A-15 April 2011

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics Customer Training Material

From the Solution Information Branch, the contact is now engaging, but

the solution fails to converge after several iterations.

ANSYS, Inc. Proprietary Release 13.0

2011 ANSYS, Inc. All rights reserved. WS9A-16 April 2011

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics Customer Training Material

These first two converged substeps likely represent the trivial solutions

that occur as the small gap between the two parts is being closed and no

contact has been made yet.

This first spike in the Newton-Raphson residual (measure

of imbalance) likely occurs at the point when contact first

engages. From there on out, the solution struggles and

fails after two bisections and many iterations to find a

balance.

ANSYS, Inc. Proprietary Release 13.0

2011 ANSYS, Inc. All rights reserved. WS9A-17 April 2011

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics Customer Training Material

A plot of Newton-Raphson Residual (measure of force imbalance in the model)

confirms that the point where contact is engaged is the source of the highest

imbalance .

ANSYS, Inc. Proprietary Release 13.0

2011 ANSYS, Inc. All rights reserved. WS9A-18 April 2011

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics Customer Training Material

Highlight both Contact Regions and change the

contact specifications in the details window.

Augmented Lagrange is

recommended for general

contact

Reducing the contact

stiffness factor will reduce

the calculated force

generated at the contact

surface and thereby reduce

the imbalance

Re-run the solution

ANSYS, Inc. Proprietary Release 13.0

2011 ANSYS, Inc. All rights reserved. WS9A-19 April 2011

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics Customer Training Material

The solution now converges very nicely with no bisections

ANSYS, Inc. Proprietary Release 13.0

2011 ANSYS, Inc. All rights reserved. WS9A-20 April 2011

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics Customer Training Material

Review the Total Deformation results.

Although this solution is now converged, notice the excessive penetration.

This is because, by default the shell contact detection points are at the

midplane of the shells.

This can be remedied by adding a command object to the contact elements

with the following command: KEYOPT,cid,11,1 (refer to Element manual

documentation on CONTA174 and the KEYOPT command)

This command will include an adjustment for the shell thickness.

ANSYS, Inc. Proprietary Release 13.0

2011 ANSYS, Inc. All rights reserved. WS9A-21 April 2011

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics Customer Training Material

EXTRA CREDIT !!

Highlight each Contact Region

and RMB > Insert > Commands

Inside the command object and

type the command as shown

* Refer to Element Reference documentation on

CONTA174 along with Command Manual

documentation on KEYOPT

Re-run the solution

ANSYS, Inc. Proprietary Release 13.0

2011 ANSYS, Inc. All rights reserved. WS9A-22 April 2011

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics Customer Training Material

Review the Total Deformation results as before.

Shell thickness is now properly accounted for.

ANSYS, Inc. Proprietary Release 13.0

2011 ANSYS, Inc. All rights reserved. WS9A-23 April 2011

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Metocean Data PDFDocument101 pagesMetocean Data PDFJym Genson100% (1)

- Topaz Mamlaka Vss Feb2016Document7 pagesTopaz Mamlaka Vss Feb2016Jym GensonNo ratings yet

- LR EN 10204 Type 3Document2 pagesLR EN 10204 Type 3Jym GensonNo ratings yet

- Grade 7 ExamDocument3 pagesGrade 7 ExamMikko GomezNo ratings yet

- Topaz Johor Vss Jul2015Document6 pagesTopaz Johor Vss Jul2015Jym GensonNo ratings yet

- Topaz Jafiliya Vessel Spec Aug2016Document8 pagesTopaz Jafiliya Vessel Spec Aug2016Jym GensonNo ratings yet

- Caspian Endeavour Vessel Spec Apr2014Document6 pagesCaspian Endeavour Vessel Spec Apr2014Jym GensonNo ratings yet

- Topaz Khubayb Vessel Spec Sep2016Document9 pagesTopaz Khubayb Vessel Spec Sep2016Jym GensonNo ratings yet

- Topaz Khobar Khuwair Karama Khalidiya Vessel Spec Oct2015 PDFDocument7 pagesTopaz Khobar Khuwair Karama Khalidiya Vessel Spec Oct2015 PDFJym GensonNo ratings yet

- Topaz Jurong Vss Sep2015Document6 pagesTopaz Jurong Vss Sep2015Jym GensonNo ratings yet

- Topaz Jumeirah Vessel SpecsDocument7 pagesTopaz Jumeirah Vessel SpecsJym GensonNo ratings yet

- Topaz Master 85t Ahtsv Vessel Spec Feb2018lrDocument6 pagesTopaz Master 85t Ahtsv Vessel Spec Feb2018lrJym GensonNo ratings yet

- Topaz Karzakkan Vessel Spec Aug2016Document7 pagesTopaz Karzakkan Vessel Spec Aug2016Jym GensonNo ratings yet

- Topaz Mariner 85t Ahtsv Vessel Spec Feb2018lrDocument6 pagesTopaz Mariner 85t Ahtsv Vessel Spec Feb2018lrJym GensonNo ratings yet

- Topaz Oryx Vessel Spec May2016Document8 pagesTopaz Oryx Vessel Spec May2016Jym GensonNo ratings yet

- Topaz Khubayb Vessel Spec Sep2016Document9 pagesTopaz Khubayb Vessel Spec Sep2016Jym GensonNo ratings yet

- Topaz Legend Vessel SpecsDocument6 pagesTopaz Legend Vessel SpecsJym GensonNo ratings yet

- LR EN 10204 Type 3 - 1Document4 pagesLR EN 10204 Type 3 - 1Jym GensonNo ratings yet

- 2002 I So Peon AssessmentDocument9 pages2002 I So Peon AssessmentJym GensonNo ratings yet

- Planned Maintenance System Manual: Integrated Management System (Ims)Document63 pagesPlanned Maintenance System Manual: Integrated Management System (Ims)Jym GensonNo ratings yet

- Marine Survey Practice - Notes Relative To Shell and Deck Plate RepairsDocument3 pagesMarine Survey Practice - Notes Relative To Shell and Deck Plate RepairsJym GensonNo ratings yet

- Planned Maintenance System Manual: Integrated Management System (Ims)Document63 pagesPlanned Maintenance System Manual: Integrated Management System (Ims)Jym GensonNo ratings yet

- Wave SpectraDocument15 pagesWave SpectraPNNo ratings yet

- Marine Survey Practice - Intermediate and Periodical SurveyDocument3 pagesMarine Survey Practice - Intermediate and Periodical SurveyJym GensonNo ratings yet

- No. No.94 Guideline For Application of UR S31 Rev.4Document1 pageNo. No.94 Guideline For Application of UR S31 Rev.4Jym GensonNo ratings yet

- Marine Survey Practice - Initial Survey of HullDocument3 pagesMarine Survey Practice - Initial Survey of HullJym GensonNo ratings yet

- Marine Survey Practice - Failure and DamageDocument10 pagesMarine Survey Practice - Failure and DamageJym GensonNo ratings yet

- No. 106 IACS Guideline For Rule Development - Ship Structure No. 106Document54 pagesNo. 106 IACS Guideline For Rule Development - Ship Structure No. 106Jym GensonNo ratings yet

- Iacs Class Key RoleDocument7 pagesIacs Class Key RoleJym GensonNo ratings yet

- Rec. No. 134 pdf2342 PDFDocument13 pagesRec. No. 134 pdf2342 PDFJym GensonNo ratings yet

- PyhookDocument23 pagesPyhooktuan tuanNo ratings yet

- Technology Management 1Document38 pagesTechnology Management 1Anu NileshNo ratings yet

- Carriage RequirementsDocument63 pagesCarriage RequirementsFred GrosfilerNo ratings yet

- SMC 2D CADLibrary English 1Document590 pagesSMC 2D CADLibrary English 1Design IPGENo ratings yet

- Laboratory Manual (CIV 210) Engineering Surveying (2018-19) (For Private Circulation Only)Document76 pagesLaboratory Manual (CIV 210) Engineering Surveying (2018-19) (For Private Circulation Only)gyanendraNo ratings yet

- Mastertop 1230 Plus PDFDocument3 pagesMastertop 1230 Plus PDFFrancois-No ratings yet

- Excon2019 ShowPreview02122019 PDFDocument492 pagesExcon2019 ShowPreview02122019 PDFSanjay KherNo ratings yet

- Log Building News - Issue No. 76Document32 pagesLog Building News - Issue No. 76ursindNo ratings yet

- Theories of International InvestmentDocument2 pagesTheories of International InvestmentSamish DhakalNo ratings yet

- The Indonesia National Clean Development Mechanism Strategy StudyDocument223 pagesThe Indonesia National Clean Development Mechanism Strategy StudyGedeBudiSuprayogaNo ratings yet

- 15.053/8 February 7, 2013: More Linear and Non-Linear Programming ModelsDocument42 pages15.053/8 February 7, 2013: More Linear and Non-Linear Programming ModelsShashank SinglaNo ratings yet

- Project ManagementDocument11 pagesProject ManagementBonaventure NzeyimanaNo ratings yet

- Kahneman & Tversky Origin of Behavioural EconomicsDocument25 pagesKahneman & Tversky Origin of Behavioural EconomicsIan Hughes100% (1)

- Movie Piracy in Ethiopian CinemaDocument22 pagesMovie Piracy in Ethiopian CinemaBehailu Shiferaw MihireteNo ratings yet

- Quick Help For EDI SEZ IntegrationDocument2 pagesQuick Help For EDI SEZ IntegrationsrinivasNo ratings yet

- AnticyclonesDocument5 pagesAnticyclonescicileanaNo ratings yet

- MASONRYDocument8 pagesMASONRYJowelyn MaderalNo ratings yet

- Mixed Up MonstersDocument33 pagesMixed Up MonstersjaneNo ratings yet

- Chapter13 PDFDocument34 pagesChapter13 PDFAnastasia BulavinovNo ratings yet

- Role of Personal Finance Towards Managing of Money - DraftaDocument35 pagesRole of Personal Finance Towards Managing of Money - DraftaAndrea Denise Lion100% (1)

- Organizational ConflictDocument22 pagesOrganizational ConflictTannya AlexandraNo ratings yet

- Introduction-: Microprocessor 68000Document13 pagesIntroduction-: Microprocessor 68000margyaNo ratings yet

- Revenue and Expenditure AuditDocument38 pagesRevenue and Expenditure AuditPavitra MohanNo ratings yet

- DarcDocument9 pagesDarcJunior BermudezNo ratings yet

- Review1 ScheduleDocument3 pagesReview1 Schedulejayasuryam.ae18No ratings yet

- PM CH 14Document24 pagesPM CH 14phani chowdaryNo ratings yet

- ISO 9001 2015 AwarenessDocument23 pagesISO 9001 2015 AwarenessSeni Oke0% (1)

- Module 1: Overview of Applied Behaviour Analysis (ABA)Document37 pagesModule 1: Overview of Applied Behaviour Analysis (ABA)PriyaNo ratings yet

- Outdoor Air Pollution: Sources, Health Effects and SolutionsDocument20 pagesOutdoor Air Pollution: Sources, Health Effects and SolutionsCamelia RadulescuNo ratings yet