Professional Documents

Culture Documents

Tablet Coater URS212

Uploaded by

عبدالعزيز بدرOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tablet Coater URS212

Uploaded by

عبدالعزيز بدرCopyright:

Available Formats

USER REQUIREMENTS Page 1 of 23

Doc ID: Tablet Coater

JETT SPECIFICATION

System URS Rev.0

Tablet Coater System June 2004

USER REQUIREMENTS TEMPLATE

FOR A TABLET COATER SYSTEM

JOINT EQUIPMENT TRANSITION TEAM

USER REQUIREMENTS Page 2 of 23

Doc ID: Tablet Coater

JETT SPECIFICATION

System URS Rev.0

Tablet Coater System June 2004

REVISION HISTORY

Rev. Date Approval Revision Summary

Vince Miller

0 06-Jun-2004 Initial issuance of the URS for industry use.

(JETT)

JOINT EQUIPMENT TRANSITION TEAM

USER REQUIREMENTS Page 3 of 23

Doc ID: Tablet Coater

JETT SPECIFICATION

System URS Rev.0

Tablet Coater System June 2004

TABLE OF CONTENTS

Project No.:

Insert the unique project number associated with this particular URS.

Document No.:

Insert the Document Identification Number and Revision.

Document Description:

Insert description of document, e.g. PURE STEAM GENERATOR, JETT Example

User Requirements Specification.

1.0 EQUIREMENTS

1.1 Capacity

Range of products

Commodities to be used (i.e., tablets, etc.)

Processed Materials to be used or involved

Production rates

1.2 Process Requirements

Quality of products and concentrations

Product limitations (i.e. temperature, humidity, pH, etc.)

1.3 Process Control

Measurement Range (Accuracy of instrumentation desired)

Temperature:

+/- 2C (Standard)

+/- 1C (Special)

+/- 0.5C (Custom)

Airflow:

+/- 5% of Full Scale (Standard)

+/- 2.5% Of Full Scale (Special)

Pan Pressure:

+/- 10% of Full Scale (Standard Negative pan pressure

maintained)

JOINT EQUIPMENT TRANSITION TEAM

USER REQUIREMENTS Page 4 of 23

Doc ID: Tablet Coater

JETT SPECIFICATION

System URS Rev.0

Tablet Coater System June 2004

Solution Flowrate:

+/- 5% of Full Scale no feedback (Standard Peristaltic)

+/- 5% of Full Scale with feedback (Peristaltic with

flowmeter)

+/- 2% of Full Scale no feedback (Standard Gear Pump)

+/- 2% of Full Scale with feedback (Gear pump with

flowmeter)

+/- 1% of Full Scale with feedback (Gear pump with weigh

scale)

Inlet Air Humidity:

Not critical

Dry at least to C Dew point

Within C to C Dew point

1.4 Functions

1.4.1 Operation

The system shall operate with a minimum of operator involvement

(loading, unloading, gun calibration, monitoring of conditions).

Operation shall be safe both from an operator and environmental

standpoint.

The system shall be operated locally at the Coater machine itself.

Control system requirements

Manual only

Manual/automatic

Cleaning requirements

Hand-Wash

Auto-Wash

Special Requirements:

JOINT EQUIPMENT TRANSITION TEAM

USER REQUIREMENTS Page 5 of 23

Doc ID: Tablet Coater

JETT SPECIFICATION

System URS Rev.0

Tablet Coater System June 2004

1.4.2 Power failure/Recovery

In the event of a power failure, the system shall protect product

against damage. The system will stop automatically upon loss of

electricity, air, or other major utility and will require operator

intervention to re-start.

Depending upon the options chosen in the overview section, the

system will:

Manually re-start based on operator inputs. (Operator

initiates power recovery sequence)

Re-start based on last state before loss of power. (System

runs through power recovery sequence when operator start

signal is given)

If there is an automatic batch reporting system, the

information shall be retained in the event of a power failure

(A UPS is required for automatic batch reporting systems).

1.4.3 Emergency Stop

The system shall have an emergency stop (E-Stop) function

designed to stop all physical movement of the machinery

immediately. The E-Stop buttons shall be located in easily

accessible areas around the machine as required by local safety

standards.

1.4.4 Alarms and Warnings

Critical alarms shall take action via interlock(s) and/or operator

procedural response to shut the equipment down and notify the

operator of the condition(s). The operator shall be required to

acknowledge the alarm before the alarm can be reset and the

system restarted. Once the alarm is reset, the operator may restart

the system.

Informational Messages shall notify the operator and take no

further action.

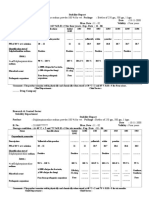

The Equipment shall have the following critical alarms, warnings

and informational messages:

JOINT EQUIPMENT TRANSITION TEAM

USER REQUIREMENTS Page 6 of 23

Doc ID: Tablet Coater

JETT SPECIFICATION

System URS Rev.0

Tablet Coater System June 2004

Response

Non-

Alarm or Informational Critical Information Operator

Critical Interlock

Message Alarm al Message Procedur

Alarm (s)

al

Emergency Stop X X

PLCOIT Communication Watchdog

(Programmable Logic ControllerOperator- X X

Interface Terminal)

Control Power Fault X X

Main Air Fault X X

Inlet Air Temperature High Fault X X

Inlet Air Temperature Low Fault X X

Inlet Airflow Low Fault X X

Plugged Gun (low flow or solution pressure

X X

high)

Nozzle Airflow Low Fault X X

Inlet Dewpoint High Fault X X

Inlet Dewpoint Low Warning X X

Motor Faults X X

Pan Pressure High Warning X X

Pan Pressure Low Warning X X

PLC Battery Low Warning X X

The list of critical alarms in the table is not intended to be a

comprehensive list of all alarms for the system. A complete alarm

list will be developed and included in the Functional Specification

document.

For a standard equipment type application, request the supplier to

submit the complete alarm list and differentiate between critical

and non-critical alarms.

Note: Consider documenting how critical and non-critical

criteria were determined.

1.5 Data and Security

Controls provided with Data Collection systems intended for use in the

manufacture of pharmaceutical products shall be required to comply with

JOINT EQUIPMENT TRANSITION TEAM

USER REQUIREMENTS Page 7 of 23

Doc ID: Tablet Coater

JETT SPECIFICATION

System URS Rev.0

Tablet Coater System June 2004

21 CFR Part 11 . The supplier shall stipulate the methods by which this

criterion is met.

1.5.1 User Interfaces

Access to all Input/Output values and system status bits shall be

provided through a data-communication link. Security for data

and operator access is provided by (User ID/Password, Card

Reader, Biometric (Fingerprint, eye scan, voice recognition, etc.),

etc.).

List the application that provides security functions to the system,

either internal via the local OIP or external via a SCADA system,

etc.

1.5.2 User Interface with Supervisors and Operators

The CONTROL PLATFORM system shall include interfaces with

the Operator and Supervisor that ensure easy, safe, and reliable

operation.

An operator-interface panel shall be provided and mounted near

the equipment or on the equipment. This panel shall provide the

necessary switches, indicators, and devices to operate the

equipment.

1.5.2.1 Language requirements

Specify language in which information will be displayed

(i.e. English, Spanish, German, Bilingual, etc.)

1.5.2.2 Display Requirements:

State the system of measurement that will be used

(English or Metric (S.I.)).

Unit(s) of

Parameter Format

measurement

Inlet Temperature (###.#) units Define the units

Exhaust Temperature (###.#) units Define the units

Inlet Airflow (###.#) units Define the units

Pan Pressure (###.#) units Define the units

Solution Flowrate (###.#) units Define the units

Total/Setpoint Spray (###.#) units Define the units

Amount

Nozzle Airflow (###.#) units Define the units

Alarms and Warnings N/A N/A

JOINT EQUIPMENT TRANSITION TEAM

USER REQUIREMENTS Page 8 of 23

Doc ID: Tablet Coater

JETT SPECIFICATION

System URS Rev.0

Tablet Coater System June 2004

Unit(s) of

Parameter Format

measurement

System Status N/A N/A

Product Temperature (###.#) units Define the units

Inlet Dewpoint (###.#) units Define the units

Other (Specify) (###.#) units Define the units

1.5.3 Interface with Other Equipment

The control system shall include the interfaces necessary to

facilitate operation and configuration. For example:

An RS-232 communications port

shall be provided.

A Modem communications port

shall be provided.

A high-speed

configuration/monitoring connection shall be provided.

The port shall be capable of being configured to communicate the

following data to a supervisory control and data acquisition

(SCADA) node (Note: the SCADA system shall be supplied and

installed by the User):

All process variables

Alarms and Warnings.

System Status (e.g. off, on,

standby states, etc.).

Other (specify)

1.5.4 Security Levels

List the total number of different access levels that will be

required. Provide a general description of the access rights for

each level (screen navigation, operational control, control loop

variable manipulation, alarm setpoint manipulation, etc.).

1.5.5 Data Collection

Consider any archiving and reporting requirements here.

None

Recorder

JOINT EQUIPMENT TRANSITION TEAM

USER REQUIREMENTS Page 9 of 23

Doc ID: Tablet Coater

JETT SPECIFICATION

System URS Rev.0

Tablet Coater System June 2004

Process Printout

Electronic process printout,

Historical Trending

Electronic process printout,

Historical Trending and interface to company network

The following shall be recorded:

Inlet Temperature

Exhaust Temperature

Inlet Airflow

Pan Pressure

Solution Flowrate

Total/Setpoint Spray amount

Nozzle Airflow

Alarms and warnings

System Status (ready, running,

etc.)

Product Temperature

Inlet Dewpoint

Other: (Specify)

1.6 Environment

Provide details of the physical environment in which the Tablet Coater

System will be operated.

1.6.1 Layout

Allocated floor space for the equipment is _____ inches by

________ inches with at least a _______inch corridor around the

periphery for the equipment.

Vertical clearance is _________ inches.

See attached drawing #________________________ (if

applicable).

Layout is specific to the size equipment being used and system

requirements of the equipment.

JOINT EQUIPMENT TRANSITION TEAM

USER REQUIREMENTS Page 10 of 23

Doc ID: Tablet Coater

JETT SPECIFICATION

System URS Rev.0

Tablet Coater System June 2004

1.6.2 Physical Conditions

Room Explosion Classification

List the critical explosion requirements for the room.

Room will be non-hazardous

Room will be Class I Div II (Zone 2) (explosive

atmosphere present at known times)

Room will be Class I Div I (Zone 1) (explosive

atmosphere present at all times)

Environmental Classification

List the critical air quality requirements for the environment.

Class 100, 10,000, or 100,000 (Federal Standard

209E)

ISO Class 5, 7, or 8 (ISO 14644-1 and ISO

14644-2)

Class A, B, C, or D (The Rules Governing

Medicinal Products in the European Union Annex 1)

Directional airflow

Airflow velocity

Number of air changes

Particle Ingress

Biohazard Level

List the critical biohazard level requirements for the

environment.

BL-1

BL-2

Rating of enclosures

List the rating requirements for enclosures in the

environment.

NEMA 1 (Open)

NEMA 12 (Oil tight)

NEMA 4 (Wash down)

NEMA 4X (Wash down and non-Corrosive)

JOINT EQUIPMENT TRANSITION TEAM

USER REQUIREMENTS Page 11 of 23

Doc ID: Tablet Coater

JETT SPECIFICATION

System URS Rev.0

Tablet Coater System June 2004

1.6.3 Cleaning Requirements

Hand-Wash

Auto-Wash

Steam Clean

1.6.4 Sterilization Requirements

Describe the type of sterilization that will be performed on or

within the Tablet Coater System and the duration the Tablet Coater

System will be exposed.

1.6.5 Intended Operating Environment:

Describe the type of operating environment that the Tablet Coater

System will be exposed to following installation.

For example:

The Tablet Coater System shall be located in a GMP environment

with a temperature range of 15 to 25 C, non-condensing humidity.

Vibration levels in operating environment are <Negligible, Slight,

or Severe>

The Seismic Zone in the operating environment is <Zone 1, Zone

2, Zone 3, Zone 4, or Zone 4A>.

(Remainder of Page Intentionally Left Blank)

JOINT EQUIPMENT TRANSITION TEAM

USER REQUIREMENTS Page 12 of 23

Doc ID: Tablet Coater

JETT SPECIFICATION

System URS Rev.0

Tablet Coater System June 2004

2.0 CONSTRAINTS

2.1 Milestones and Timelines

Based on the model outlined below, establish the project milestones with a

timeline:

BASELINE EQUIPMENT ACQUISITION MODEL

USER/(CONSULTANT if applicable) SUPPLIER

Master Validation Plan User Audit of Supplier

User Initiates

Equipment Validation Plan RFQ

Explanation to Supplier

Proposal

(Living Document) RFQ Quality Plan

l Project Plan

User Requirements Specification (URS) po sa

o

(Living Document) Pr

P.O. Functional Specification

Proposal Analysis (Traceable to URS)

Approval Detailed Design

Review Functional Specification Documentation

(traceable to Functional Specification)

Approval

Review Detailed Design System Acceptance Test

Specifications (IQ/OQ)

Hardware

Software

Review System

Approva

Acceptance Test Specifications l System Acceptance

Testing and Results

(User Witness Optional)

Integrate with Validation

Documentation (as appropriate) Maintenance & Support

Documentation

JOINT EQUIPMENT TRANSITION TEAM

USER REQUIREMENTS Page 13 of 23

Doc ID: Tablet Coater

JETT SPECIFICATION

System URS Rev.0

Tablet Coater System June 2004

2.2 Equipment Constraints

Describe the operating constraints that the [equipment/system] will be

required to meet.

For example:

2.2.1 Environmental Conditions

The Tablet Coater System is to be used at the following

environmental conditions:

Altitude ________ ft above sea level

2.2.2 Process air enters in from

Indoor Temperature: C

Outdoor Temperature:

Minimum: C

Maximum: C

Climatic conditions:

Winter dry bulb C

Winter wet bulb C

Summer dry bulb C

Summer wet bulb C

2.2.3 Equipment Generated Vibration

The maximum allowable equipment vibration generated during

operation is <value>.

2.3 Compatibility and Support

Include any requirements for compatibility with other User systems. In

the examples provided below, fill in blanks with the appropriate

information. Delete areas that are not applicable to this application.

2.3.1 CONTROL PLATFORM Controllers

The Supplier shall utilize Control Platform

Controllers that shall include a communications port.

The Supplier shall provide documentation that the program

(embedded software) was developed and coded utilizing

program development and documentation software.

JOINT EQUIPMENT TRANSITION TEAM

USER REQUIREMENTS Page 14 of 23

Doc ID: Tablet Coater

JETT SPECIFICATION

System URS Rev.0

Tablet Coater System June 2004

The supplier shall indicate the use of custom or bespoke code

within the equipment, and shall supply licensing of the custom

code for the life of the equipment.

An escrow agreement shall be required in the event the supplier

cannot support the supplied custom software any longer. In such

instances, the source code and all information regarding the source

code shall be given to the user in a timely fashion to prevent

downtime of the equipment.

2.3.2 Preferred Vendor List

If necessary attach any critical preferred vendors. Refrain from

driving the supplier into customizing his equipment package.

If the vendor wishes to deviate from the Preferred Instrumentation

List, a listing of the proposed components and instrumentation

sub-vendors indicating type and model numbers shall be submitted

with the quotation, along with an explanation of why the deviation

is recommended.

2.3.3 Utilities

The utilities and space involved needs to be discussed prior to

purchasing the equipment. Obviously, the actual equipment size is

but a small part of the entire scope of work necessary to implement

a larger system. The unit and its support equipment must be able to

be installed in current building facilities.

The User shall ensure that the following utilities are available and

that the utility supply lines and piping are terminated with fittings

or connections, which are compatible with those described on the

Customer Connection Drawings.

The Supplier shall specify utility data, which is marked with a

triangle. Utility data, which are not specified or marked with a

triangle, shall be brought to the attention of the User. These data

shall be specified (by the User or the Supplier) and shall be

approved by both the User and the Supplier before system design

begins.

Base Utilities Worksheet

Related Discharges

Volume

pH

Temperature

JOINT EQUIPMENT TRANSITION TEAM

USER REQUIREMENTS Page 15 of 23

Doc ID: Tablet Coater

JETT SPECIFICATION

System URS Rev.0

Tablet Coater System June 2004

Materials

Electricity

______ VAC ____ Hertz

Phases

Amperage

Uninterruptible Power Supply (Define Use)

Control Air

Pressure

For example:

_______ PSIG (must be clean, dry ISA instrument

quality air, capacity to be determined by size of

equipment). Recommend at least 90 PSIG

constant air pressure for all equipment, unless

specified.

Other Utility Requirements

Provide details regarding any other utility systems

that are required to support operation of the

equipment/system.

2.4 Availability

The Tablet Coater System is intended to be operated [Continuously,

Regularly, __ hours per day, __ hours per week].

Operation of the Tablet Coater System shall be suspended, and the system

shall be available for preventative maintenance or routine service [__

hours per week, __ continuous hours per week, __ days per month, __

weeks per year].

2.5 Procedural Constraints

2.5.1 Product Contact Materials

Describe any local procedural requirements such as local

standards, which must be adhered to if applicable.

All piping welds and product contact welds shall meet ASME and

3A specification requirements. Product contact metal to be (316L

Stainless Steel, 316 Stainless Steel, 304 Stainless Steel, etc.)

JOINT EQUIPMENT TRANSITION TEAM

USER REQUIREMENTS Page 16 of 23

Doc ID: Tablet Coater

JETT SPECIFICATION

System URS Rev.0

Tablet Coater System June 2004

List critical requirements for surface finish, roughness, etc..

Other standards are attached. The Supplier shall adhere to the

indicated sections only.

2.5.2 Product in Contact with Materials

All product contact parts should be considered. The Tablet Coater

System will be used for (aqueous solutions, low LEL (lower

explosion limit) solvents, high LEL solvents, etc.).

2.5.3 Noise Level Constraints

Insert your own noise level constraint requirements here.

For example:

The noise level generated during operation of the Tablet Coater

System will not exceed 85 dB from 3 feet away.

2.5.4 EMI / RFI levels are:

Insert your own electrical and radio frequency noise immunity and

emission requirements here.

For example:

The Tablet Coater System [will/will not] be used in an area where

two-way radio communication devices are in operation. The

Tablet Coater System shall meet CE requirements for electrical

noise immunity and emissions.

2.5.5 Containment

2.5.5.1 Explosion Protection

This section is only valid if the product being used is

highly reactive. Insert containment guidelines here (i.e.

Bar Construction with isolation and suppression, 10 Bar

construction with isolation only, Closed-Loop Nitrogen

System, etc.).

2.5.5.2 Product

This section is only valid if the product being used is

highly reactive. The system comes standard with inlet

prefilters and HEPA prefilters. Insert containment of

product guidelines here (i.e. HEPA filtration of exhaust,

HEPA filtration with bag in-bag out isolation of exhaust,

scrubber system, cyclone separator system, thermal

oxidizer system, evaporator, etc.).

JOINT EQUIPMENT TRANSITION TEAM

USER REQUIREMENTS Page 17 of 23

Doc ID: Tablet Coater

JETT SPECIFICATION

System URS Rev.0

Tablet Coater System June 2004

2.5.6 Labeling

All equipment and control wiring shall be labeled and identified.

2.6 Maintenance

Describe the expected hardware and software maintenance support

including: ease of maintenance, expansion capability (software only),

likely enhancements (software only), expected lifetime and long-term

support.

System shall be maintained on a schedule as indicated by the supplier.

Supplier is to provide (at minimum) the following maintenance

instructions:

1. All sub-systems provided (Maintenance and operation manuals

of vendor equipment)

2. A comprehensive lubrication list and recommended lubrication

schedule

3. A comprehensive recommended maintenance (regular

recommended inspection intervals, wear points, recommended

spare parts list)

4. Supplier shall supply ______ Copies of Operation, Installation,

Maintenance and de-commissioning manuals

3.0 LIFE-CYCLE

3.1 Development

If S88 is to be applied to the equipment being acquired, it should be

referenced in this section of the document.

The Supplier shall provide a Quality and Project Plan as part of their

proposal. The Supplier shall have a quality system in place. Internal

quality procedures shall be available for the Users review.

The Supplier shall provide a Project Manager for the project to provide a

single communication point with the User.

The project shall utilize the GAMP methodology when developing the

system and documentation.

3.2 Testing

Describe the Supplier testing requirements. Reference the Validation Test

Plan, Factory Acceptance Test, special tests, etc. This section should also

include required amount of demonstrated run time, any special materials

necessary to complete testing, integration testing, etc.

JOINT EQUIPMENT TRANSITION TEAM

USER REQUIREMENTS Page 18 of 23

Doc ID: Tablet Coater

JETT SPECIFICATION

System URS Rev.0

Tablet Coater System June 2004

In order to verify system performance, the User shall witness the

execution of the Factory Acceptance Test procedures. The Supplier shall

notify the User _______ weeks in advance of the start of this test.

The Factory Acceptance Test Specification shall be submitted to the User

for review and approval prior to execution. A minimum of _______

weeks shall be allowed for the User to review and to comment and/or

approve the Factory Acceptance Test Specification.

Refer to the Equipment Validation Plan for applicable procedures.

3.3 Delivery

The [equipment/system], with all options, equipment, and the

documentation listed below, shall be delivered to the Users receiving

dock.

3.3.1 Documentation

Installation, operation, and maintenance instruction documentation

for the system shall be developed to a level that is comprehensible

to a high school graduate.

The Supplier shall use the formats described in the GAMP

Supplier Guide, Current Version, to produce the documentation.

The Supplier shall provide the documentation for preliminary

review. The Supplier shall provide documentation reflecting as-

built condition with final delivery.

All final documents shall be shipped with transmittals that identify

them as contractually required documents. All final documents

and drawings shall reflect as-built condition.

All documents shall be written in the language of the destination

country and supplied with hard copies and electronic versions in

the format identified for each document:

Project Plan Microsoft Word 97 (*.doc)

User Requirements Specification Microsoft Word 97 (*.doc)

Functional Specification/Requirement Microsoft Word 97 (*.doc)

Design Specifications Microsoft Word 97 (*.doc)

Controls Test Microsoft Word 97 (*.doc)

Hardware Installation Test Microsoft Word 97 (*.doc)

Operational Test Microsoft Word 97 (*.doc)

JOINT EQUIPMENT TRANSITION TEAM

USER REQUIREMENTS Page 19 of 23

Doc ID: Tablet Coater

JETT SPECIFICATION

System URS Rev.0

Tablet Coater System June 2004

Factory Acceptance Test Microsoft Word 97 (*.doc)

Operator, Maintenance and Service Manuals Microsoft Word 97 (*.doc)

Process and Instrumentation Diagram (P&ID) AutoCAD version 12.0 (*.dxf)

Instrument Listing Microsoft Word 97 (*.doc) or Excel 97 (*.xls)

Control Schematics AutoCAD version 12.0 (*.dxf)

Control Panel Assembly Drawings AutoCAD version 12.0 (*.dxf)

Equipment Assembly Drawings AutoCAD version 12.0 (*.dxf)

Bill of Materials Microsoft Word 97 (*.doc) or Excel 97 (*.xls)

Spare Parts List Microsoft Word 97 (*.doc) or Excel 97 (*.xls)

Component Cut Sheets Microsoft Word 97 (*.doc) or Excel 97 (*.xls)

CONTROL PLATFORM Program Printout and Disk File XXX Program Development format

OIP Configuration Printout and Disk File XXX Program Development format

3.4 Support

Describe what support activities are required after acceptance. The

paragraphs outlined below provide some areas for consideration.

3.4.1 Start-up Support (list available options)

3.4.1.1 Training (list training options available)

3.4.2 Post Start-up Support (list post-startup support available)

3.4.2.1 Technical Support

Telephone (Voice or Modem)

Replacement Parts Availability List (Normal lead times

shall be listed)

3.4.2.2 User Site Support

Preventative Maintenance (list maintenance contracts

available)

System Improvements (supplier shall notify user of any

improvements available on a regular basis)

JOINT EQUIPMENT TRANSITION TEAM

USER REQUIREMENTS Page 20 of 23

Doc ID: Tablet Coater

JETT SPECIFICATION

System URS Rev.0

Tablet Coater System June 2004

4.0 GLOSSARY

If necessary, attach a glossary, which includes definitions of terms that may be

unfamiliar to the Supplier or terminology that may have meanings specific to

entries on this User Requirements Check sheet.

For example (example list is not intended to be complete):

Acronym Definition

SCADA Supervisory Control and Data Acquisition

S.I. International System of Units (Metric)

NEMA National Electric Manufacturers Association

RFQ Request for Quote

PO Purchase Order

IQ Installation Qualification

OQ Operational Qualification

ISA International Society for Measurement and Control

PSIG Pounds per square inch gauge

ASME American Society of Mechanical Engineers

HEPA High Efficiency Particle Arrestance

HEPA filtered air is 99.97% free of all particulate down to 0.3

microns (including bacteria, fungal and other opportunistic

microbiological).

C Degrees Celsius

BL Biohazard Level

CFR Code of Federal Regulations

dB Decibels

EMI Electro-Magnetic Interference

ft Feet

GUI Graphic User Interface

HMI Human Machine Interface

HVAC Heating, Ventilation, and Air Conditioning

ISO International Organization for Standardization

JOINT EQUIPMENT TRANSITION TEAM

USER REQUIREMENTS Page 21 of 23

Doc ID: Tablet Coater

JETT SPECIFICATION

System URS Rev.0

Tablet Coater System June 2004

Acronym Definition

JETT Joint Equipment Transition Team

LEL Lower Explosion Limit

OIP Operator Interface Panel

RFI Radio Frequency Interference

URS User Requirement Specification

VAC Voltage Alternating Current

JOINT EQUIPMENT TRANSITION TEAM

USER REQUIREMENTS Page 22 of 23

Doc ID: Tablet Coater

JETT SPECIFICATION

System URS Rev.0

Tablet Coater System June 2004

5.0 REFERENCES

List references that were used in preparing this document or that provide

additional details, such as:

Equipment Validation Plan

Current revision of GAMP Guidelines

Vendor Piping Certification (if applicable)

Customer Connection Diagram

Approved Instrumentation List

Process Flow Diagram

21 CFR Part 11

National Electric Code

S88

JOINT EQUIPMENT TRANSITION TEAM

USER REQUIREMENTS Page 23 of 23

Doc ID: Tablet Coater

JETT SPECIFICATION

System URS Rev.0

Tablet Coater System June 2004

6.0 APPROVAL

Insert your companys standard approval page at the appropriate position in the

document or utilize the sample approvals listed below. The approval

process/requirements should be outlined in the Equipment Validation Plan.

This document has been reviewed by the User Project Manager and approved for use by the

Supplier.

Printed/Typed Name Signature Date

This document has been reviewed by the User Quality Assurance Group and approved for

use by the Supplier.

Printed/Typed Name Signature Date

This document has been reviewed by the Supplier Project Manager and approved for use by

the Supplier Project Team.

Printed/Typed Name Signature Date

Other approvals as necessary may be included, such as the Technical Services Groups,

User Groups, Engineering, etc. as required.

JOINT EQUIPMENT TRANSITION TEAM

You might also like

- SopDocument6 pagesSopعبدالعزيز بدرNo ratings yet

- PDA Technical Report No. 33: John AlbrightDocument11 pagesPDA Technical Report No. 33: John Albrightعبدالعزيز بدر0% (1)

- BW Report (Rivo)Document56 pagesBW Report (Rivo)عبدالعزيز بدرNo ratings yet

- Uncontrolled When Printed: University Health Network/Mount Sinai Hospital, Department of MicrobiologyDocument50 pagesUncontrolled When Printed: University Health Network/Mount Sinai Hospital, Department of Microbiologyعبدالعزيز بدرNo ratings yet

- TR3313 TocDocument7 pagesTR3313 Tocعبدالعزيز بدرNo ratings yet

- Measurement Uncertainty 2007 - WaccessDocument34 pagesMeasurement Uncertainty 2007 - Waccessعبدالعزيز بدرNo ratings yet

- Validation of Method in Microbial Limit Tests For Two Types of Health FoodsDocument4 pagesValidation of Method in Microbial Limit Tests For Two Types of Health Foodsعبدالعزيز بدرNo ratings yet

- Routine AssayDocument2 pagesRoutine Assayعبدالعزيز بدرNo ratings yet

- M INIIDHVDocument2 pagesM INIIDHVعبدالعزيز بدرNo ratings yet

- Example Microbiology Measurement Uncertainty CalculationsDocument10 pagesExample Microbiology Measurement Uncertainty Calculationsعبدالعزيز بدرNo ratings yet

- Stability Testing: Hua YinDocument53 pagesStability Testing: Hua Yinعبدالعزيز بدرNo ratings yet

- WC 500162136 e Me A Process ValidationDocument15 pagesWC 500162136 e Me A Process Validationعبدالعزيز بدرNo ratings yet

- Impartiality enDocument6 pagesImpartiality enعبدالعزيز بدرNo ratings yet

- MdiEgyptian Drug AuthorityDocument2 pagesMdiEgyptian Drug Authorityعبدالعزيز بدرNo ratings yet

- Product Monograph: (Acetylsalicylic Acid Chewable Tablets, USP) 81 MGDocument31 pagesProduct Monograph: (Acetylsalicylic Acid Chewable Tablets, USP) 81 MGعبدالعزيز بدرNo ratings yet

- For Routine AssayDocument1 pageFor Routine Assayعبدالعزيز بدرNo ratings yet

- Product MonographDocument33 pagesProduct Monographعبدالعزيز بدرNo ratings yet

- NOT Completed YETDocument1 pageNOT Completed YETعبدالعزيز بدرNo ratings yet

- 9egyptian Drug AuthorityDocument3 pages9egyptian Drug Authorityعبدالعزيز بدرNo ratings yet

- Thyme OilDocument9 pagesThyme Oilعبدالعزيز بدرNo ratings yet

- Sulphaquinoxaline: 1000 Cfu/gm For Bacteria, 100 Cfu/gm For FungiDocument2 pagesSulphaquinoxaline: 1000 Cfu/gm For Bacteria, 100 Cfu/gm For Fungiعبدالعزيز بدرNo ratings yet

- Waters Breeze SoftwareDocument1 pageWaters Breeze Softwareعبدالعزيز بدرNo ratings yet

- Uncertainty Calculation For Cmu Output Level Test at - 130 DBM and 3 S Meas. TimeDocument1 pageUncertainty Calculation For Cmu Output Level Test at - 130 DBM and 3 S Meas. Timeعبدالعزيز بدرNo ratings yet

- Coating Foods and Pharmaceuticals With Shellac Edible Polymer Using Environmentally Friendly ProcessDocument2 pagesCoating Foods and Pharmaceuticals With Shellac Edible Polymer Using Environmentally Friendly Processعبدالعزيز بدرNo ratings yet

- ActionDocument1 pageActionعبدالعزيز بدرNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)