Professional Documents

Culture Documents

Folleto - AS9100 - Aeroespacial PDF

Uploaded by

Lezly SantanaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Folleto - AS9100 - Aeroespacial PDF

Uploaded by

Lezly SantanaCopyright:

Available Formats

AS9100 Aerospace Quality Management

ABOVE AND BEYOND

Guidelines to an Aerospace Quality Management System

raising standards worldwide

Every organization, regardless of size or sector, strives

to provide a quality culture that will permeate through

every level of their organization. But establishing optimal

working practices, which can enhance profit as well as

customer satisfaction, does not happen by accident.

Todays most successful companies know the importance

of having a proven Quality Management System (QMS)

in place. Various quality management systems have been

used in the aerospace industry for many years. They have

helped the industry deliver exemplary levels of product

quality and operational safety. However, suppliers faced

the need to maintain a different QMS for each of their

large Original Equipment Manufacturers (OEM).

INTRODUCTION

2 BSI Management Systems Aerospace Quality Management

To establish a single common Aerospace Quality

Management System (AQMS), members of the

global aerospace industry worked together to

produce AS9100 and its supporting family of

standards. Its use is supported by the worlds

leading aerospace companies including Boeing,

Lockheed Martin, Northrop Grumman, Rolls

Royce Allison, General Electric Aircraft Engines

and NASA.

Your certification is a sign of acceptability Potential reduction in variation of

that helps you demonstrate your quality quality and increase in efficiency

standards to customers. Certification

Potential reduction in 2nd party

to AS9100 is associated with the

system audits

following benefits:

Common language to improve

Demonstration of operation to globally

understanding of quality requirements

recognized aerospace quality standards

Compliance with a system supported

Improved product and process quality

by regulatory bodies

Additional confidence for global

Excellent levels of traceability

sourcing

throughout the supply chain

Common quality system approach

in the supply chain for supplier/

subcontractor development

and consistency

BSI Management Systems Aerospace Quality Management 3

ISO 9001:2000 AS THE BASIS OF AS9100

AS9100 is based upon ISO 9001:2000. You will need to understand this standard,

plus what was added to generate AS9100.

ISO 9001:2000, as its core, has the principle of process management and the

Plan-Do-Check-Act cycle (see below).

ISO 9001:2000 is a process based approach to management which helps

understand what you do, rather than a procedure based approach which shows

how your activities are controlled.

This enables organizations to link business objectives with business effectiveness

more directly. The ISO 9001:2000 process approach views an organization as a

series of interacting processesthe very processes which produce the products

and services customers buy.

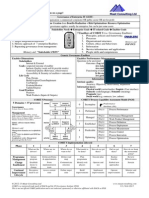

Continual improvement of the quality management system

Management

Act

Plan

Strategic Improve

Customer Measure Customer

Requirements Resource Analyze Satisfaction

Improve

Detailed Detailed

Plan Check

Realize

Do Do

Product/Service

4 BSI Management Systems Aerospace Quality Management

DEVELOPMENT OF AEROSPACE BSI CAPABILITY AND BENEFITS OF

QUALITY MANAGEMENT CERTIFICATION WITH BSI

SYSTEMS STANDARDS

BSIproviding solutions, producing results

When you choose BSI as your business partner, you are also

AS9100 contains supplements to ISO 9001:2000. This is

choosing our international reputation for excellence. We

the key difference between the two standards and is

are the largest and most respected management systems

meant to satisfy industry, internal, government and

certification body in the world. Our office locations around

regulatory requirements.

the world are regarded universally as a global service provider

AS9100 was developed by representatives from the of the highest quality and integrity.

aerospace industry in the Americas, Europe and Asia. It is

In addition to management systems certification, we offer

published in the Americas by the Society of Automotive

a range of complementary services that provide real added

Engineers (SAE).

value, including: training courses, the development of

AS9100 is the first of a family of aerospace standards and schemes, product testing and product certification.

is intended for use by aerospace manufacturers and

Here are some additional reasons to choose BSI:

suppliers. The related AS9003 is for organizations

undertaking inspection and test activities, AS9110 is a We employ aerospace assessors with extensive commercial

QMS structure for aerospace maintenance organizations, and military aerospace experience who undergo thorough

while AS9120 helps aerospace stockists/distributors. Key training and qualification processes. This ensures that when

emphasis of these related standards will be traceability. they visit your company they understand the needs and

specific requirements of your industry.

Our certification service is accredited by an independent

accreditation service, ensuring integrity of the

certification decision.

Use of the highly regarded BSI Certification Mark.

Strong links with other standards and technical

consultancies.

BSI Management Systems Aerospace Quality Management 5

THE IMPLEMENTATION AND

CERTIFICATION PROCESS

There are nine steps to implementing an AS9100 based QMS and achieving certification with BSI:

STEP 1 Before you can begin preparing your system, you will need a copy of the standard.

PURCHASE THE STANDARD You may purchase your copy at: www.sae.org

There are a large number of tools that can be very helpful at every stage of the

STEP 2

process of implementing any ISO 9001:2000 based QMS. We recommend

REVIEW SUPPORT

The Route to Registration published by BSI, which is available at:

LITERATURE AND SOFTWARE

www.bsiamericas.com/route2reg

You should begin the entire implementation process by assembling your team.

STEP 3

Responsibility for a QMS lies with top management. Therefore, it is vital that top

ASSEMBLE AN

IMPLEMENTATION TEAM management is involved at the beginning of the process with the

implementation team.

A wide range of training courses are available to assist, at every level of

STEP 4

understanding. To gain more information on training please visit:

CONSIDER TRAINING

www.bsiamericas.com/aerotraining

Using a consultant to help you through the process can be very helpful, but

STEP 5

consider the costs versus the benefits. Download BSIs 10 Tips for the Selection and

REVIEW CONSULTANCY

OPTIONS Use of a Quality Management Systems Consultant at:

www.bsiamericas.com/getthemost

STEP 6

Involve staff to use and implement your QMS through training and awareness.

IMPLEMENT YOUR QMS

The certification body is the third-party, like BSI, who assess the effectiveness of

STEP 7

your QMS and issues a certificate if you meet the requirements of the standard.

CHOOSE A

CERTIFICATION BODY Consider industry experience, geographic coverage, price and service level when

choosing your certification body.

STEP 8 The key step to certification is a certification assessment, during which your entire

GAIN CERTIFICATION AS9100 management system will be assessed.

6 BSI Management Systems Aerospace Quality Management

THE CERTIFICATION

PROCESS WITH BSI

There are seven steps to gaining certification to AS9100 with BSI:

STEP 1 You will be asked to complete a company profile. Our professionals will do

INITIAL INQUIRY everything they can to help you through this process.

STEP 2

We will forward a proposal for delivery of assessment services.

QUOTATION PROVIDED

STEP 3

Submit a formal application to us.

APPLICATION COMPLETED

STEP 4 Your principal contact with us throughout the certification process and beyond

CLIENT MANAGER will be appointed. They will have knowledge concerning the nature of your

APPOINTED business and will offer support while you develop your system.

STEP 5 An optional pre-assessment can be undertaken to review your QMS and to

PRE-ASSESSMENT establish your readiness for initial assessment.

(OPTIONAL)

The formal assessment of your system is entirely objective. It reviews the

practices youve claimed and that your system meets the requirements of

STEP 6

the standard. Once the AS9100 checklist is completed, a score is

INITIAL ASSESSMENT

calculated. You will be informed of the recommendation before the

assessment team leaves your premises.

The Initial Assessment report is independently reviewed, the formal

STEP 7 certification decision taken and, if successful, your certificate of

CERTIFICATION CONFIRMED certification is issued. Then you can begin to advertise your success and

promote your certification with us.

Your certification body will periodically visit you to ensure your system

STEP 9

continues to meet the requirements of the standard. The AS9100 checklist is

ONGOING ASSESSMENT

updated and the score is revised.

BSI Management Systems Aerospace Quality Management 7

AS9100 - AN EXPLANATION

OF THE ADDITIONAL REQUIREMENTS

SUMMARY CLAUSE 4

OF ADDITIONS QUALITY MANAGEMENT SYSTEM

The developers of AS9100 added elements to: Documentation

This aims to make documentation more specific to the

Ensure that quality in the aerospace industry is maintained

aerospace industry and helps to meet the regulatory

at the highest level, in part due to the criticality of the use

requirements set by bodies such as the FAA.

of the final product.

Configuration management

Focus on the identification and management of key

An element unique to the aerospace industry, this requires

characteristics of products.

strict control of drawings of parts and aircraft, including the

Recognize the requirements set by regulatory bodies, identification and control of manufacturing specifications,

as well as ensure records are kept and activities are external customer documents and quality records.

conducted to help meet these requirements. The ultimate

aim is to reduce the government oversight of aerospace

manufacturers and suppliers.

Recognize the complex nature of the final products and the

need to ensure complete confidence in every component of

the final product.

Recognize the use of sub-contract organizations within a

process and ensure this is effectively managed.

8 BSI Management Systems Aerospace Quality Management

The following pages detail clause-by-clause

the core concepts that have been included in

AS9100, over and above ISO 9001:2000

CLAUSE 5 GENERAL

MANAGEMENT RESPONSIBILITY NEW COMMITMENT

Roles By applying to become certified to AS9100, a company is

This gives stronger weight and importance to the role of also giving authority for OEMs and regulatory authorities

the quality manager, ensuring they have authority to make to accompany BSI on assessments and oversee activities at

changes when appropriate. Without support from senior any time this is not normal practice for companies certified

management, the role of the quality manager is useless. only to ISO 9001:2000. Regulatory authorities within the

aerospace industry have legal right of access at any time.

CLAUSE 6 Therefore a certified company is saying, We are certified,

therefore we are good all the time, come look for yourself.

RESOURCE MANAGEMENT

Work environment

This recognizes the need for strong emphasis on cleanliness

and precision required in the manufacturing of

aerospace parts.

BSI Management Systems Aerospace Quality Management 9

CLAUSE 7

PRODUCT REALIZATION

Planning Purchasing

It places an emphasis on the long term and life cycle of a This recognizes the regulatory requirements in the area of

product including support and maintenance. Aerospace supplier control. The aim is to ensure that authentic parts

parts usually have a long life cycle and require traceability are used and there is accountability and responsibility in all

from specification to disposal. This clause also includes a activities. This includes an increased role in verification of

requirement for implementing a Foreign Object Elimination product as it is received. This is when a company assumes

(FOE) process/program. responsibility for supplied parts.

Customer related processes Production and service provision

Because of the nature of this industry, emphasis is placed on This is where key characteristics come to life, and the

the subject of risk evaluation (e.g. where new technology associated importance of traceability and control through

is implemented or where demands are set for short delivery effective documentation are recognized.

time of products or services). As there are a number of

Calibration

activities that can impact risk, this subject should be given

The requirements for the control of monitoring and

special attention.

measuring devices in ISO 9001:2000 is amplified by the

Design additional provisions of AS9100.

Basic requirements are more robust due to the importance

and cost of investment often required. The additional

requirements focus on the key characteristics of products.

This is where the people, tasks and equipment are identified

and need to be classified to ensure the key characteristics are

effectively managed throughout the process.

10 BSI Management Systems Aerospace Quality Management

CLAUSE 8 MEASUREMENT, AS9100

ANALYSIS AND IMPROVEMENT CHECKLIST

General The AS9100 checklist is a fairly significant addition to the

This is necessary for gathering information and trend management systems assessment process and is the major

analysis for the long-term benefit in the aerospace industry. difference companies will see during an assessment.

In addition, it provides the need to analyze product at all

At the initial assessment or upgrade assessment, the checklist

phases, from design to the end use. Record keeping is of

is completed in full. The score will be made available through

high importance to support this activity.

the International Aerospace Quality Group (IAQG) web-

Control of non-conforming product based database, OASIS. At each continuing assessment visit,

It recognizes the need and practice in the aerospace industry the assessor completes the checklist for only those activities

for a more robust process for disposition and identification covered during the assessment and the total score is updated.

of non-conforming products. Overall it recognizes the need This score is an evaluation of effectiveness of the QMS.

to prevent a non-conforming product from entering the

This scoring methodology was added to provide a clear

industry, and allows customers to know if a part has been

and consistent assessment of an organizations ability and

reworked at any time.

performance to provide a benchmark against which continual

It also recognizes the aerospace term and practice of improvement can be measured.

conducting First Article inspection.

Corrective action

This requires the need to involve the supplier when they are

reasoned to be the root cause of the problem.

BSI Management Systems Aerospace Quality Management 11

BSI/USA/66/MS/1007/E

BSI Management Systems BSI Management Systems - Brazil

12110 Sunset Hills Road, Suite 200 Avenida Eng Luis Berrini

Reston, VA 20190-5902 N. 1400 1 Andar CEP: 04571-000

USA Brookline, Sao Paulo

Tel: 1 800 862 4977 SP

Fax: 1 703 437 9001 Brasil

Email: inquiry.msamericas@bsi-global.com Tel: +55 13 3223 5770

www.bsiamericas.com Fax: +55 13 3223 3851

Email: informacao.msamericas@bsi-global.com

BSI Management Systems Canada www.bsibrasil.com.br

6205 Airport Road, Suite 102

Mississauga, ON BSI Management Systems - Mxico

L4V 1E1 Torre Mayor

Canada Av. Paseo de la Reforma No. 505

Tel: 1 800 862 6752 Piso 41 -Suite C-

Fax: 1 416 620 9911 Col. Cuauhtemoc, C.P. 06500

Email: inquiry.canada@bsi-global.com Mxico, D.F.

Mxico

Tel: +52 55 5241 1370

Fax: +52 55 5241 1374

Email: informacion.msamericas@bsi-global.com

www.bsiamericas.com/Mexico

The BSI certification mark can be used on your stationery, literature

and vehicles when you have successfully achieved certification.

BSI Group: Standards Information Training Inspection Testing Assessment Certification

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Project Management Assignment 2Document11 pagesProject Management Assignment 2Melissa Paul75% (8)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Amul TransportDocument2 pagesAmul TransportCharles Wood83% (6)

- Checklist of ISO 9001 2015 Mandatory Documentation enDocument9 pagesChecklist of ISO 9001 2015 Mandatory Documentation enfcleong6988% (8)

- Vault Guide To The Top Insurance EmployersDocument192 pagesVault Guide To The Top Insurance EmployersPatrick AdamsNo ratings yet

- General Electric Marketing MixDocument6 pagesGeneral Electric Marketing MixMohd YounusNo ratings yet

- Codex List of Food Additive SpecificationsDocument98 pagesCodex List of Food Additive SpecificationsLezly SantanaNo ratings yet

- CXG 088e Guidelines On The Application of General Principles of Food HygieneDocument11 pagesCXG 088e Guidelines On The Application of General Principles of Food HygieneLezly SantanaNo ratings yet

- ISO 2008 To 2015 TransitionDocument6 pagesISO 2008 To 2015 TransitionA MNo ratings yet

- Diagram of ISO 9001:2015 Implementation ProcessDocument1 pageDiagram of ISO 9001:2015 Implementation ProcessanafadoNo ratings yet

- APG AuditTrail2015 PDFDocument3 pagesAPG AuditTrail2015 PDFAlberto J SorianoNo ratings yet

- APG AuditReports2015 PDFDocument5 pagesAPG AuditReports2015 PDFAlberto J SorianoNo ratings yet

- Analyzing Transactions and Double Entry LectureDocument40 pagesAnalyzing Transactions and Double Entry LectureSuba ChaluNo ratings yet

- Community Based Tourism Development PDFDocument2 pagesCommunity Based Tourism Development PDFGregoryNo ratings yet

- Financial Ratio Analysis and Working Capital ManagementDocument26 pagesFinancial Ratio Analysis and Working Capital Managementlucky420024No ratings yet

- Westpac Case Study Ed 3 PDFDocument2 pagesWestpac Case Study Ed 3 PDFAhmedHawcharNo ratings yet

- Authors LibraryDocument1,128 pagesAuthors Libraryauthoritybonus75% (12)

- Ghuirani Syabellail Shahiffa/170810301082/Class X document analysisDocument2 pagesGhuirani Syabellail Shahiffa/170810301082/Class X document analysisghuirani syabellailNo ratings yet

- Competitive Shopping AssignmentDocument5 pagesCompetitive Shopping Assignmentapi-456889565No ratings yet

- American Medical Assn. v. United States, 317 U.S. 519 (1943)Document9 pagesAmerican Medical Assn. v. United States, 317 U.S. 519 (1943)Scribd Government DocsNo ratings yet

- English For Hotel-1-1Document17 pagesEnglish For Hotel-1-1AQilla ZaraNo ratings yet

- Washer For Piston Screw: Service LetterDocument2 pagesWasher For Piston Screw: Service LetterRonald Bienemi PaezNo ratings yet

- Col 13147Document8 pagesCol 13147Lasantha DadallageNo ratings yet

- Notary CodeDocument36 pagesNotary CodeBonnieClark100% (2)

- Business Continuity Plan 2023Document8 pagesBusiness Continuity Plan 2023asdasdNo ratings yet

- Basic Economic Questions ExplainedDocument20 pagesBasic Economic Questions ExplainedRiemann SolivenNo ratings yet

- Lessons From The Enron ScandalDocument3 pagesLessons From The Enron ScandalCharise CayabyabNo ratings yet

- COBIT 5 Foundation Exam Revision On A PageDocument1 pageCOBIT 5 Foundation Exam Revision On A PageSergiö Montoya100% (1)

- InventoryDocument53 pagesInventoryVinoth KumarNo ratings yet

- Bills of ExchangeDocument31 pagesBills of ExchangeViransh Coaching ClassesNo ratings yet

- Catalogue 2012 Edition 6.1 (2012-11) PDFDocument382 pagesCatalogue 2012 Edition 6.1 (2012-11) PDFTyra SmithNo ratings yet

- Visa InterviewDocument1 pageVisa InterviewVivek ThoratNo ratings yet

- Credit Assessment On Agricultural LoansDocument84 pagesCredit Assessment On Agricultural LoansArun SavukarNo ratings yet

- B&O Annual Report 2015-16Document136 pagesB&O Annual Report 2015-16anon_595151453No ratings yet

- Suzuki Project NewDocument98 pagesSuzuki Project NewRohan Somanna67% (3)

- AWS Compete: Microsoft's Response to AWSDocument6 pagesAWS Compete: Microsoft's Response to AWSSalman AslamNo ratings yet

- Jesd 48 BDocument10 pagesJesd 48 BLina GanNo ratings yet

- Key Differences Between Islamic and Conventional BankingDocument2 pagesKey Differences Between Islamic and Conventional BankingNoor Hafizah0% (2)