Professional Documents

Culture Documents

Iso 2009

Uploaded by

Aditya Pratap0 ratings0% found this document useful (0 votes)

47 views1 pageISO 2009

Original Title

ISO 2009

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentISO 2009

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

47 views1 pageIso 2009

Uploaded by

Aditya PratapISO 2009

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

'-r:- .i 3ai i{: 6 f\.1 -!L' r' . ! -.! ti }-1j ;, -! .i .

_ __ iL J.\,, lI il'ii'li.i ,

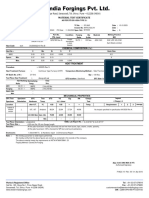

OUALITY ASSURANCE PROCEDI JRE

Ct!stomer-TRF Limitcd.

Item SLEW GEAR ory_ 0t No.

Drg No sl(-zal I

Material GS-42CrMo4

P.O No-45o004 1 934l3o/BMHE

DESCRIPTION.

EXTENTOfCHTC(

SIL Own Standard IAA% IA0% P by SIL

c% 0.38 0.45, Si% 0.25-0.50, Mn%

Chemical Compositjon 0.s0 0.80, P% 0.035 Max, S% 0.035

GS 42CrM04 P by SlL, W by TRF

Max, Cr% 0.90-1.20, Mo% 0.15 Speciro Analysis Each Heat

(cHP)

0.2s

3 Heat Treatment Normalise & Tempered EN 10293 Each Castifg 100% P by SlL. R ByTRF

MechanicalPropefties Ts-8s Kslmm2 (Min),

GS-42CrMo4 Destructive Test

Hardness-250115 BHN Each Heat

(cHP)

ASTM A 609 Level ll

NDT

Non Destructiive Tesi Each Component P by SlL, W byTRF

Magnetic Particle Test ASTM A 903 Levelll

6 Dimension & Surface Finish Drawing & ISO-2768-1 Class-M

iivirJ r{ voP lcrweerr rwo,ornr segmnrs shall be 1.o max.Contact area shall be 0.50olo

min, {2} MpT shaltbe done by Ftourocent yoke

condition belore teeth cuttina All relevant rest i.e chemical & Physical shall Metho;;lthi.l.,M;hineL

be carried out pieces.

trom hteSratrest (3)joint shoutd be located centrally between two

teeth. ln case of any ambiSuily approved drg wi prevail over eAp.

1=-KF..

larjf-ln athjhlr pi t rtd.

CHP=Customer Hold Point

F. epfitdfiA.

\l'r v"

You might also like

- List of CompaniesDocument5 pagesList of Companiesdeep nikil60% (5)

- Seamless carbon steel pipe data sheetDocument4 pagesSeamless carbon steel pipe data sheetOmkar100% (3)

- Materials Data for Cyclic Loading: Aluminium and Titanium AlloysFrom EverandMaterials Data for Cyclic Loading: Aluminium and Titanium AlloysRating: 1 out of 5 stars1/5 (1)

- Astm A536-84 2019 PDFDocument6 pagesAstm A536-84 2019 PDFRio Witcandra100% (1)

- ASTM A53 Data Sheet PDFDocument3 pagesASTM A53 Data Sheet PDFmarcelomaster88No ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Sae J 434 PDFDocument10 pagesSae J 434 PDFAditya Pratap100% (2)

- Sae J 434 PDFDocument10 pagesSae J 434 PDFAditya Pratap100% (2)

- 1900 - EC2157-signedDocument4 pages1900 - EC2157-signedDeepak HoleNo ratings yet

- PREMIER STEEL Premier Steel Test Certificate Provides Chemical and Mechanical AnalysisDocument1 pagePREMIER STEEL Premier Steel Test Certificate Provides Chemical and Mechanical AnalysisMechtek LabNo ratings yet

- 1300 EC1986 SignedDocument4 pages1300 EC1986 SignedDeepak HoleNo ratings yet

- 1300 EC2192 SignedDocument4 pages1300 EC2192 SignedDeepak HoleNo ratings yet

- 30ETH06 30ETH06S 30ETH06-1: Hyperfast RectifierDocument9 pages30ETH06 30ETH06S 30ETH06-1: Hyperfast RectifierAdrian NascimentoNo ratings yet

- 4555 70 03 Ec2125 1111Document4 pages4555 70 03 Ec2125 1111Deepak HoleNo ratings yet

- 1299 EC2153 SignedDocument5 pages1299 EC2153 SignedDeepak HoleNo ratings yet

- European Steel and Alloy GradesDocument2 pagesEuropean Steel and Alloy Gradesfarshid KarpasandNo ratings yet

- Material Test Certificate: TechnipfmcDocument4 pagesMaterial Test Certificate: TechnipfmcDeipak HoleNo ratings yet

- 3030 2sin1 (CRI80) - LEMWS36X - Family DatasheetDocument30 pages3030 2sin1 (CRI80) - LEMWS36X - Family DatasheetGiancarloRichardRivadeneyraMirandaNo ratings yet

- Wps PQRDocument7 pagesWps PQRsobariNo ratings yet

- Material Comparison Aisi 1006, SWRM6, Swch18a, Swch22aDocument1 pageMaterial Comparison Aisi 1006, SWRM6, Swch18a, Swch22aCahyo ArdoyoNo ratings yet

- 1591 EC2213 SignedDocument5 pages1591 EC2213 SignedDeepak HoleNo ratings yet

- 1299 Ec1650Document4 pages1299 Ec1650Deepak HoleNo ratings yet

- 9SMNPB28K-14.00 Hex Tc.Document1 page9SMNPB28K-14.00 Hex Tc.Mechtek LabNo ratings yet

- P5 T5 Engl PDFDocument3 pagesP5 T5 Engl PDFshantilalNo ratings yet

- P5 T5 Engl PDFDocument3 pagesP5 T5 Engl PDFshantilalNo ratings yet

- European Steel and Alloy Grades: X6Crnicus18-9-2 (1.4570)Document2 pagesEuropean Steel and Alloy Grades: X6Crnicus18-9-2 (1.4570)farshid KarpasandNo ratings yet

- 4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsDocument1 page4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsidontlikeebooksNo ratings yet

- 1300 - Ec0313Document5 pages1300 - Ec0313Deepak HoleNo ratings yet

- 60EPU02Document8 pages60EPU02Adam SchwemleinNo ratings yet

- 1299 - EC0583Document5 pages1299 - EC0583Deipak HoleNo ratings yet

- QA RMS 611 Forging 01S18110005 - Rev - 05Document2 pagesQA RMS 611 Forging 01S18110005 - Rev - 05AnilkumarchalliNo ratings yet

- ISO 6892:1998 and IS 1608:2005 tensile test data uncertaintyDocument1 pageISO 6892:1998 and IS 1608:2005 tensile test data uncertaintySvapneshNo ratings yet

- 6 in Ferrule 316 SS HN 150522 Cert ST160129-07 Zhejiang Stellar Pipe Industry Co., LTDDocument1 page6 in Ferrule 316 SS HN 150522 Cert ST160129-07 Zhejiang Stellar Pipe Industry Co., LTDJennifer FrenchNo ratings yet

- Aaepl: TDC No. AAEPL/RM/lDocument2 pagesAaepl: TDC No. AAEPL/RM/lSandip PandeNo ratings yet

- 1466 - EC0044Document5 pages1466 - EC0044Deipak HoleNo ratings yet

- Pygas SpecDocument1 pagePygas SpecFadlul Akbar HerfiantoNo ratings yet

- European Steel and Alloy Grades: X17Crni16-2 (1.4057)Document2 pagesEuropean Steel and Alloy Grades: X17Crni16-2 (1.4057)farshid KarpasandNo ratings yet

- 1426-EC1942Document3 pages1426-EC1942Deipak HoleNo ratings yet

- A106 Pipe MTCDocument2 pagesA106 Pipe MTCSocial FactsNo ratings yet

- ASTM A106 Data SheetDocument4 pagesASTM A106 Data Sheetmarcelomaster88No ratings yet

- MTX Exp No.1 19ms006 Kartik BhagatDocument10 pagesMTX Exp No.1 19ms006 Kartik BhagatKartik BhagatNo ratings yet

- European Steel and Alloy Grades: Alloy Standards Search About Us EN 10149-2Document2 pagesEuropean Steel and Alloy Grades: Alloy Standards Search About Us EN 10149-2farshid KarpasandNo ratings yet

- 1299 - Ec0176Document4 pages1299 - Ec0176Deipak HoleNo ratings yet

- 1.14.1 MTC-11372 - Tube - 1 TUBINGDocument1 page1.14.1 MTC-11372 - Tube - 1 TUBINGgroupj.sr.servicesNo ratings yet

- 1 4501 Super Duplex TubesDocument3 pages1 4501 Super Duplex TubesAlma JakirovićNo ratings yet

- 1590 EC2249 SignedDocument5 pages1590 EC2249 SignedDeepak HoleNo ratings yet

- European Steel and Alloy Grades: Alloy Standards Search About Us EN 10225Document2 pagesEuropean Steel and Alloy Grades: Alloy Standards Search About Us EN 10225farshid KarpasandNo ratings yet

- Hyundai Welding Co., LTDDocument3 pagesHyundai Welding Co., LTDblahNo ratings yet

- 1426 Ec2262Document3 pages1426 Ec2262Deepak HoleNo ratings yet

- En 353Document3 pagesEn 353anush_swaminathanNo ratings yet

- Bourns SRP1265C 4R7MDocument6 pagesBourns SRP1265C 4R7MWalter Martin Paz HolguinNo ratings yet

- Timetal: Ti - 1 0 V-2 F e - 3 A LDocument2 pagesTimetal: Ti - 1 0 V-2 F e - 3 A LBüyüleyici GözlerNo ratings yet

- Technical Evaluation Sheet: Kishan Forge, RajkotDocument3 pagesTechnical Evaluation Sheet: Kishan Forge, RajkotRajoo PrajapatiNo ratings yet

- Millsheet Pipa Spindo - 01Document4 pagesMillsheet Pipa Spindo - 01Mellany SeprinaNo ratings yet

- High Efficiency Solid State Amplifiers - 1Document44 pagesHigh Efficiency Solid State Amplifiers - 1wingchaoNo ratings yet

- 0 032000MHZ-XDocument2 pages0 032000MHZ-Xstudem.bogNo ratings yet

- D72307 TC2 PDFDocument2 pagesD72307 TC2 PDFshivdas bichukaleNo ratings yet

- Eng DS Ptf-Family A5Document8 pagesEng DS Ptf-Family A5Ido DamariNo ratings yet

- Analytical Report Shows Diesel Fuel Contaminated With Light FractionDocument1 pageAnalytical Report Shows Diesel Fuel Contaminated With Light FractionAgus DaniNo ratings yet

- Impedance Relay Timing Test Report: DobleDocument9 pagesImpedance Relay Timing Test Report: DobleBarry79xNo ratings yet

- SR3020PT Thru SR30150PT: Creat by ArtDocument5 pagesSR3020PT Thru SR30150PT: Creat by Artsasan hatamiNo ratings yet

- European Steel and Alloy Grades: X1Crnimocun20-18-7 (1.4547)Document2 pagesEuropean Steel and Alloy Grades: X1Crnimocun20-18-7 (1.4547)farshid KarpasandNo ratings yet

- Creep-Fatigue Interactions in Equiaxed and Single Crystal Ni-Base SuperalloysDocument6 pagesCreep-Fatigue Interactions in Equiaxed and Single Crystal Ni-Base SuperalloysMaryam TorfehNo ratings yet

- Department of Transportation Federal Aviation AdministrationDocument11 pagesDepartment of Transportation Federal Aviation AdministrationhichamNo ratings yet

- 583 2 PDFDocument48 pages583 2 PDFShahazad ShaikNo ratings yet

- En 13835Document12 pagesEn 13835Aditya PratapNo ratings yet

- Tata Steel Grate Bar Normal - Type 4 DirDocument6 pagesTata Steel Grate Bar Normal - Type 4 DirAditya PratapNo ratings yet

- Sample Smart and Balanced Resume PDFDocument3 pagesSample Smart and Balanced Resume PDFidaNo ratings yet

- Recommendations For Industry - COVID 19 - 28042020 - Final Ver - 01Document10 pagesRecommendations For Industry - COVID 19 - 28042020 - Final Ver - 01Aditya PratapNo ratings yet

- Din 17007Document8 pagesDin 17007Aditya Pratap100% (1)

- CV - 2020 07 06 030753Document1 pageCV - 2020 07 06 030753Aditya PratapNo ratings yet

- En 10297Document46 pagesEn 10297Aditya PratapNo ratings yet

- Press Release On Extension of Lockdown and Issue of New Guidelines DT 01.05.2020Document7 pagesPress Release On Extension of Lockdown and Issue of New Guidelines DT 01.05.2020The WireNo ratings yet

- Doerrenberg Steel Foundry EnglishDocument16 pagesDoerrenberg Steel Foundry EnglishAditya PratapNo ratings yet

- Sample Smart and Balanced Resume PDFDocument3 pagesSample Smart and Balanced Resume PDFidaNo ratings yet

- Resolve ATM ComplaintDocument1 pageResolve ATM ComplaintSand StromNo ratings yet

- 015 Asme Sec Ii A Sa 105 Sa 105M PDFDocument9 pages015 Asme Sec Ii A Sa 105 Sa 105M PDFSujeet PrasadNo ratings yet

- AS1444 2007 Wrought Alloy Steels Standard Hardenability H Series and Hardened and Tempered To Design PDFDocument69 pagesAS1444 2007 Wrought Alloy Steels Standard Hardenability H Series and Hardened and Tempered To Design PDFMarco CruzNo ratings yet

- Astm G8-96Document8 pagesAstm G8-96Melgi159No ratings yet

- Jis G4051 PDFDocument13 pagesJis G4051 PDFAditya PratapNo ratings yet

- G 28 PDFDocument5 pagesG 28 PDFAditya PratapNo ratings yet

- JIS G5501-1995 Gray Iron CastingsDocument12 pagesJIS G5501-1995 Gray Iron CastingsNicole Keith100% (2)

- Brake Disc Stdz. Draft Spec UploadingDocument14 pagesBrake Disc Stdz. Draft Spec UploadingAditya PratapNo ratings yet

- Astm A 536 - 84Document5 pagesAstm A 536 - 84César Cristov León OrtegaNo ratings yet

- AS1444 2007 Wrought Alloy Steels Standard Hardenability H Series and Hardened and Tempered To Design PDFDocument69 pagesAS1444 2007 Wrought Alloy Steels Standard Hardenability H Series and Hardened and Tempered To Design PDFMarco CruzNo ratings yet

- Founding - Technical Conditions of Delivery: BSI Standards PublicationDocument28 pagesFounding - Technical Conditions of Delivery: BSI Standards PublicationAditya Pratap100% (1)

- Disclosure To Promote The Right To InformationDocument13 pagesDisclosure To Promote The Right To Informationanand.bharadwajNo ratings yet

- Outokumpu Steel Grades Properties Global StandardsDocument20 pagesOutokumpu Steel Grades Properties Global StandardsLance BlackstarNo ratings yet

- Din 17007Document8 pagesDin 17007Aditya Pratap100% (1)

- Special Steel Sheet: Cat - No.B1E-005-05Document16 pagesSpecial Steel Sheet: Cat - No.B1E-005-05wahyuNo ratings yet

- Is 7478 2011Document15 pagesIs 7478 2011sarath6725No ratings yet

- GE Turbine Fuel SpecsDocument24 pagesGE Turbine Fuel SpecsA H RanaNo ratings yet

- Embankment Verification ExampleDocument5 pagesEmbankment Verification ExampleDeepthiNo ratings yet

- 50 TMSS 03 R0Document0 pages50 TMSS 03 R0renjithas2005No ratings yet

- Local Bodies 3Document19 pagesLocal Bodies 3umzzNo ratings yet

- FULL CERAMIC BEARINGS TECHNICAL GUIDEDocument13 pagesFULL CERAMIC BEARINGS TECHNICAL GUIDEKatasterNo ratings yet

- Latching Assignment PLC Ladder LogicDocument4 pagesLatching Assignment PLC Ladder LogicsalonyNo ratings yet

- First Part Lab ManualDocument6 pagesFirst Part Lab ManualInfo EsocketNo ratings yet

- Production of Aniline by Hydrogenation of NitrobenzeneDocument15 pagesProduction of Aniline by Hydrogenation of Nitrobenzeneananya srivastavaNo ratings yet

- Calculating Expansion TanksDocument4 pagesCalculating Expansion TanksanescuveronicaNo ratings yet

- Manual Sany Mantenimiento PDFDocument681 pagesManual Sany Mantenimiento PDFLampart100% (9)

- T100 Thrusters PropellerDocument15 pagesT100 Thrusters PropellerNikhilkrishna NairNo ratings yet

- MTP Profile PDFDocument2 pagesMTP Profile PDFYano BekawantoNo ratings yet

- AIGOSTAR 300000HFA Panini Maker NoticeDocument9 pagesAIGOSTAR 300000HFA Panini Maker NoticeSYLVIENo ratings yet

- Rolling Friction FundamentalsDocument19 pagesRolling Friction FundamentalsMuhammad AliNo ratings yet

- Gear Failures PDFDocument19 pagesGear Failures PDFermaksan0% (1)

- Mueller Co Series 2361 RWGV FormDocument1 pageMueller Co Series 2361 RWGV FormLarry Wayne Sumpter, JrNo ratings yet

- Iron Cast Iron Wrought IronDocument18 pagesIron Cast Iron Wrought IronvelavansuNo ratings yet

- Dyeing of 100% Polyester Fabric With Disperse Dye by Exhaust Method.Document6 pagesDyeing of 100% Polyester Fabric With Disperse Dye by Exhaust Method.Naimul Hasan100% (1)

- Concrete Admixture Product Information SheetDocument3 pagesConcrete Admixture Product Information SheetTeodor BaniskiNo ratings yet

- 6.3 - MCB & MCCBDocument25 pages6.3 - MCB & MCCBAnonymous qJXSQDSoE100% (2)

- 1kz-Te Cooling System PDFDocument14 pages1kz-Te Cooling System PDFwill meridith100% (2)

- Overhead Line Design GuideDocument35 pagesOverhead Line Design GuideiaessackjeeNo ratings yet

- Vineet Report 8th Sem1Document33 pagesVineet Report 8th Sem1PRINT WHEELSNo ratings yet

- Sony Dsc-w630 Ver1.1 Level2Document25 pagesSony Dsc-w630 Ver1.1 Level2Alberto MorenoNo ratings yet

- Loan Application FormDocument3 pagesLoan Application FormRijal Abd ShukorNo ratings yet

- Pile Soil InteractionDocument250 pagesPile Soil Interactionnallay1705100% (3)

- 4.VFD Spec. Rev.1Document35 pages4.VFD Spec. Rev.1wado11100% (1)

- Multi Zone Completion OptionsDocument6 pagesMulti Zone Completion OptionsTong ChaipanyakulNo ratings yet