Professional Documents

Culture Documents

8501 00 1550 - C

Uploaded by

cheng_cheng1234Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

8501 00 1550 - C

Uploaded by

cheng_cheng1234Copyright:

Available Formats

VBEAM Theory of Operation

SYSTEM OVERVIEW

The VBEAM system is a flashlamp excited pulsed dye laser which delivers energy at a

wavelength of 595 nm and a pulse width between 0.45 ms to 40 ms. This laser system has

the Dynamic Cooling Device (DCD) built into it which provides a short spray burst of cryogen

prior to firing the laser pulse. The laser head is designed to deliver a minimum of 100,000

pulses. A unique MegaDye cartridge stores enough dye to provide 100,000 pulses to the

customer before a replacement cartridge is required. Laser energy is delivered through a

handpiece and optical fiber which are both user replaceable parts. The handpiece contains

the cryogen spray valve, bubble sensor, fiber delivery system, and fingerswitch. Four spot

sizes are currently available. They are 5mm, 7mm, 10mm, and an elliptical spot of 3mm x

10mm. Single laser pulses can be delivered by pressing the trigger switch and then releasing,

or if the trigger switch is held, multiple pulses will be emitted.The nominal repetition rate of the

laser is up to 1.5 Hz. At higher energy density settings and after normal head degradation, the

repetition rate will be less than 1.5 Hz.

The VBEAM operates from an input line voltage of 185 VAC to 260 VAC at 50/60 Hz. There

are no adjustments required on the laser to operate over this voltage range. The VBEAM

system does not contain an isolation transformer. All of the components that are directly

connected to the AC input were chosen for low line leakage current to ensure the systems

meets the leakage current requirements of IEC-601 and UL2601. Maximum current drawn by

the laser system is 19 A at 230 VAC input. At this power consumption level, the thermal load

from the laser system is 15,700 Btu/hr. Under nominal consumption levels, the thermal load

in the Ready state will be 9231 Btu/hr. When the laser is in Standby state (non-pulsing), the

thermal load decreases to 1991 Btu/hr.

The VBEAM system is fully air cooled. All fans used are operated from 24 VDC so their

performance is constant for low or high AC input line voltage and for 50 or 60 Hz power

sources. There are a total of six fans in the system. One is built into the high voltage power

supply. Two fans are mounted to the front of the frame and cool the modulator area. One fan

is in the AC Section to cool the DCD canister. Two fans are mounted to the water cooled

heat exchanger and are the only fans that are switched on and off by the firmware. All other

fans turn on as soon as the system is powered on.

The deionized water system is maintained at 60C (140F) to provide optimum performance

from the laser head. The dye solution is also maintained at 60C (140F) through a liquid-to-

liquid heat exchanger. A 1000 watt heater and air-cooled heat exchanger regulate the water

at its proper temperature which in turn heat the dye solution to its proper temperature. An

initial warm-up time of approximately 20 minutes (from a cold start) is required for the

deionized water and dye solution to be at the correct operating temperature. This time varies

depending on the ambient temperature in the room and the line voltage. (At low line voltage

the heater's output power is less than 1000 watts). The warm-up time of the cryogen canister

is about 25 minutes. Thus the system warm-up time is typically 20 to 25 minutes depending

on whether the DCD is on or off.

A wavelength monitor assembly is included to monitor the wavelength in the system. When

the wavelength decreases, the firmware turns on the inject pump which adds triplet quencher

8501-00-1550 Revision C Candela PROPRIETARY Page1 of 22

VBEAM Theory of Operation

(COT) to the dye reservoir. The added COT displaces some of the dye from the dye cartridge

which increases the absorbance to its proper level to correct the wavelength.

An MC68HC812 microprocessor based system controller is used to monitor and direct all

system functions. A diagnostic connector located at the bottom center of the front panel will

provide a communications port for an external computer. It gives the service technician

access to system status and control functions for repair and maintenance. A DB9 male to

female communications cable can be used when connecting the diagnostic port to the

external computer.

For purposes of technical review, the laser can be divided into three major subsections. They

are: 1) Optics, 2) Fluids, and 3) Electronics. Each section will be addressed in this theory of

operation. The system firmware will not be discussed here unless it is required to explain the

functioning of the laser. For detailed information on the system firmware see the following

documents: 1) Firmware Requirements Specification (1010-06-1000), 2) Firmware Design

Specification (1010-01-1000), and 3) VBEAM Flowcharts (1010-02-1000).

OPTICAL SYSTEM

A block diagram of the optical system is shown in Figure 1. The optical components located

inside the laser system are the laser rail and the calibration port. The laser rail contains the

laser head, beam splitter assembly, beam shutter assembly and fiber receptacle assembly.

The delivery system, consisting of the optical fiber and handpiece are connected into the front

of the laser.

Laser Head

The laser head contains one flashlamp (5 mm bore, 400 torr), a dye cell, water jacket and two

mirrors. The max reflector, mounted at the rear of the laser head, is ideally a 100% mirror.

Laser light is reflected back and forth through the laser cavity between the max reflector and

the output coupler. The output coupler is a partial reflector that allows approximately 30% of

the laser energy to pass through it.

Operation of the laser head at higher energy output levels could reduce the lifetime of the

head. Therefore, maximum delivered energy and fluences are determined by a set maximum

head energy of 10J and realistic delivery system between 65 % to 85% transmission.

A metal cover is mounted over the laser rail to protect the optics from dust contamination. It

also protects the service technician from the high voltages present in the vicinity of the laser

head and from optical hazards. Unless required for trouble-shooting, the laser should not be

pulsed with the laser cover removed. If the cover is removed, it should be replaced as soon as

possible and the laser should never be left with the laser cover off.

8501-00-1550 Revision C Candela PROPRIETARY Page 2 of 22

VBEAM Theory of Operation

Figure 1 - Optical Block Diagram

The laser head is simmered when entering Ready. The simmer start pulse applies a high

voltage pulse (peak amplitude 10 KV) to the laser cavity. When the laser is in Ready state,

never touch the laser head or rest test equipment on it. It is only a triggerswitch away from

being pulsed. Also, whenever the laser system is in Ready, but not simmering there is 1300

VDC applied to two terminals of the flashlamp. Therefore, use extreme caution when

servicing the laser head.

8501-00-1550 Revision C Candela PROPRIETARY Page 3 of 22

VBEAM Theory of Operation

Beam Shutter

The beam shutter allows laser light to pass on to the fiber coupling lenses when it is

energized. Normally it is not energized so it blocks any laser light exiting the partial reflector

end of the laser head. A ceramic block is mounted to the surface of the beam shutter blade so

that it is in line with the laser beam when the shutter is in the blocking position. The ceramic

block reflects most of the laser energy that hits it and absorbs the rest. The reflected laser

light is dispersed in a divergent pattern. The beam shutter normally does not get hit with laser

energy. As a result, it is not designed to withstand repeated high energy pulses from the laser

head. The beam shutter is used solely as a safety device to prevent laser energy from exiting

the laser system under fault conditions.

The beam shutter is controlled by hardware and firmware. It cannot be opened unless the

triggerswitch is depressed and the firmware command is present. An optical switch on the

shutter assembly is used to sense the position of the shutter. The sensor is positioned so that

it detects infrared light from the LED side of the optical switch when the shutter is in the laser

beam path. When the shutter is energized and moves out of the beam path, the infrared light

is blocked by the back end of the shutter blade. The firmware will only allow the laser system

to enter the Ready state if the beam shutter is blocking the laser beam path in Standby state.

Fiber Receptacle

The fiber receptacle assembly contains two lenses that are used to couple the laser beam

onto the end of the fiber. The lenses are designed and located so that the proximal tip of the

fiber is at the image plane of the output end of the dye cell. This gives a uniform beam profile

on the fiber and causes the laser beam diameter to be 0.8mm diameter resulting in maximum

coupling efficiency and lifetime. The lenses are held in place with o-rings that help keep them

centered in the beam path, but fine alignment is still necessary. For new receptacles, this

alignment is done on a fixture at the factory. The lenses are designed to be field replaceable

and alignable. If lens replacement is performed, it is important to note the orientation of the

existing lenses so that the new lenses are installed properly. The proximal end of the fiber is

inserted into the fiber receptacle and locked into position with a threaded fitting on the fiber

assembly.

The beamsplitter assembly, beam shutter assembly, and fiber receptacle are all precisely

located on the rail, but an optical alignment is still required for the laser head and receptacle.

Beamsplitter and Wavelength Detector

The beamsplitter assembly is between the laser head and beam shutter assembly. This

assembly splits off 2 % from the main beam into two photodiodes - one for the head detector

and one for the wavelength monitoring. The head detector monitors the energy being

delivered to the patient and will send signals to the CPU I/O PCB; firmware will then

determine if there is a fault. The Wavelength detector monitors the wavelength being

delivered to the patient and will send a signal to the CPU I/O PCB; firmware will then

determine if there is a fault.

8501-00-1550 Revision C Candela PROPRIETARY Page 4 of 22

VBEAM Theory of Operation

Calport

The VBEAM Calport measures the energy out the handpiece. The Calport contains two

microswitches that sense when the handpiece is fully inserted in the Calport. A ball plunger in

the bottom of the Calport provides pressure against the handpiece to prevent it from falling

out after it is inserted.

Laser energy from the handpiece is directed through ceramic disks, then an acetal cylinder

and onto a photodiode sensor. The ceramic disks and acetal cylinder provide a scattering

volume that both attenuates and scatters the light. The high level of scattering nearly

eliminates Calport sensitivity to misalignment of the spot at the input face. The photodiode

sensor is mounted on the Calport Energy PCB. The photodiode circuit on the Calport Energy

PCB converts the optical sample of the laser beam energy to a current pulse. This current

pulse is sent to the Calport energy detector circuit on the CPU I/O PCB. There, it is processed

and calibrated before being sent on to the firmware to measure the actual energy into the

Calport.

The VBEAM operating fluence range is currently 3 - 25 J/cm2; depending on the spot size.

There are four difference spot sizes that correspond to specific fluence levels. The conversion

factors used to convert energy to fluence are shown in

Table 1.

Spot Size Conversion Factor

5 mm 5.09 x External Meter Energy

7 mm 2.60 x External Meter Energy

10 mm 1.27 x External Meter Energy

3X10 mm 4.24 x External Meter Energy

Table 1. Energy to Fluence Conversion Factors

The available energy density settings for each spot size and the external energy meter value

associated with that spot size are shown in Tables 2A and 2B.

8501-00-1550 Revision C Candela PROPRIETARY Page 5 of 22

VBEAM Theory of Operation

TABLE 2A: Spot Size Fluence Ranges (Pulse width = 1.5ms 40ms)

7mm Spot Size Tx = 80% 3x10mm Spot Size Tx = 80% 10mm Spot Size Tx = 80% 5mm Spot Size Tx = 40%

Fluence Delivered Head Fluence Delivered Head Fluence Delivered Head Fluence Delivered Head

Energy Energy Energy Energy Energy Energy Energy Energy

(J) (J) (J) (J) (J) (J) (J) (J)

4.0 1.54 1.92 7.0 1.65 2.06 3.0 2.36 2.95 4.0 0.79 1.96

4.5 1.73 2.16 7.5 1.77 2.21 3.5 2.75 3.44 4.5 0.88 2.2

5.0 1.92 2.41 8.0 1.88 2.36 4.0 3.14 3.93 5.0 0.98 2.46

5.5 2.12 2.65 8.5 2.00 2.50 4.5 3.53 4.42 5.5 1.08 2.7

6.0 2.31 2.89 9.0 2.12 2.65 5.0 3.93 4.91 6.0 1.18 2.94

6.5 2.50 3.13 9.5 2.24 2.80 5.5 4.32 5.40 6.5 1.28 3.2

7.0 2.69 3.37 10.0 2.36 2.95 6.0 4.71 5.89 7.0 1.37 3.44

7.5 2.89 3.61 10.5 2.47 3.09 6.5 5.11 6.38 7.5 1.47 3.68

8.0 3.08 3.85 11.0 2.59 3.24 7.0 5.50 6.87 8.0 1.57 3.92

8.5 3.27 4.09 11.5 2.71 3.39 7.5 5.89 7.36 8.5 1.67 4.18

9.0 3.46 4.33 12.0 2.83 3.53 9.0 1.77 4.42

9.5 3.66 4.57 12.5 2.95 3.68 9.5 1.87 4.66

10.0 3.85 4.81 13.0 3.06 3.83 10.0 1.96 4.9

10.5 4.04 5.05 13.5 3.18 3.98 10.5 2.06 5.16

11.0 4.23 5.29 14.0 3.30 4.12 11.0 2.16 5.4

11.5 4.43 5.53 14.5 3.42 4.27 11.5 2.26 5.64

12.0 4.62 5.77 15.0 3.53 4.42 12.0 2.36 5.9

12.5 4.81 6.01 15.5 3.65 4.57 12.5 2.45 6.14

13.0 5.00 6.25 16.0 3.77 4.71 13.0 2.55 6.38

13.5 5.20 6.49 16.5 3.89 4.86 13.5 2.65 6.62

14.0 5.39 6.73 17.0 4.01 5.01 14.0 2.75 6.88

14.5 5.58 6.98 17.5 4.12 5.15 14.5 2.85 7.12

15.0 5.77 7.22 18.0 4.24 5.30 15.0 2.95 7.36

18.5 4.36 5.45

19.0 4.48 5.60

19.5 4.59 5.74

20.0 4.71 5.89

20.5 4.83 6.04

21.0 4.95 6.19

21.5 5.07 6.33

22.0 5.18 6.48

22.5 5.30 6.63

23.0 5.42 6.77

23.5 5.54 6.92

24.0 5.65 7.07

24.5 5.77 7.22

25.0 5.89 7.36

8501-00-1550 Revision C Candela PROPRIETARY Page 6 of 22

VBEAM Theory of Operation

TABLE 2B: Spot Size Fluence Ranges (Pulse width = 0.45ms)

7mm Spot Size Tx = 80% 3x10mm Spot Size Tx = 80% 10mm Spot Size Tx = 80% 5mm Spot Size Tx = 40%

Fluence Delivered Head Fluence Delivered Head Fluence Delivered Head Fluence Delivered Head

Energy Energy Energy Energy Energy Energy Energy Energy

(J) (J) (J) (J) (J) (J) (J) (J)

4.0 1.54 1.92 7.0 1.65 2.06 3.0 2.36 2.95 4.0 0.79 1.96

4.5 1.73 2.16 7.5 1.77 2.21 3.5 2.75 3.44 4.5 0.88 2.2

5.0 1.92 2.41 8.0 1.88 2.36 4.0 3.14 3.93 5.0 0.98 2.46

5.5 2.12 2.65 8.5 2.00 2.50

6.0 2.31 2.89 9.0 2.12 2.65

6.5 2.50 3.13 9.5 2.24 2.80

7.0 2.69 3.37 10.0 2.36 2.95

7.5 2.89 3.61 10.5 2.47 3.09

8.0 3.08 3.85 11.0 2.59 3.24

11.5 2.71 3.39

12.0 2.83 3.53

12.5 2.95 3.68

13.0 3.06 3.83

Delivery System

The delivery system consists of two assemblies. The main part is the handpiece assembly

that contains the cryogen valve, bubble sensor, trigger switches, and the electrical cable and

cryogen tubing that connects to the front of the laser system. The fiber assembly with HP spot

size slider slides into the handpiece and is easily removable so that the customer can change

HP spot size sliders. Each HP spot size slider has an associated resistor mounted in it that is

connected to the handpiece cable. This allows the firmware to determine which HP spot size

slider is attached.

The VBEAM fiber is a 1.0 mm diameter fiber. A fiber scrambler is attached several inches

from the connector at the proximal end of the fiber to homogenize the beam profile. The

proximal end connector has a screw locking mechanism that slides into the fiber receptacle

on the front of the laser and secures it in place. The distal end of the fiber connects to the HP

spot sliders. A ball plunger in the handpiece and a slot in the HP spot size slider assembly

are used to lock the slider assembly in place. Nominal fiber transmission is 85%.

A distance gauge for each of the spot sizes is attached to the end of the handpiece and held

in place by an o-ring. The distance gauge serves as an aiming guide and also keeps the

cryogen spray confined to an area set by the size of the white circular plastic ring that is

attached at the end of the distance gauge. The circular ring is 2 mm larger in diameter than

the laser spot size.

The handpiece body can be disassembled by removing the three screws on the side of the

handpiece. All the internal parts can be serviced if required. The electrical cable connects into

the Handpiece PCB with an eight pin connector. The Handpiece PCB contains the optical

sensor used for the bubble detector, the two independent trigger switches, the switch cover

and mounting bracket, and the connector for the cryogen spray valve. The Handpiece PCB is

8501-00-1550 Revision C Candela PROPRIETARY Page 7 of 22

VBEAM Theory of Operation

press fit into the handpiece body and held into position when the two halves are screwed

together. The same method is used to hold the cryogen valve into position. The flat portions

of the valve head must be lined up against the inside of handpiece body sides in order for the

two halves to be closed properly. Also, the small piece of tubing protruding from the end of

the cryogen valve can be lined up with four set screws for correct cryogen aiming.

Whenever the handpiece is taken apart, several items must be re-tested. These include

checking that the valve functions properly, that the cryogen aiming is accurate, and that the

calibration of the bubble sensor is correct. The cryogen aiming should be tested with a 10 mm

distance gauge and the spray duration set at 20 ms. The spray can be tested by using the

purge button so lasing is not necessary. Spraying onto a black piece of paper generally gives

the most visible spray pattern. The cryogen spray should fill the diameter of the distance

gauge, be centered in the distance gauge, and it should not be spraying onto the edge of the

distance gauge ring. If the bubble sensor needs to be adjusted it can be done without opening

the handpiece. The bubble sensor adjustment potentiometer can be accessed through the

small hole in the side of the handpiece.

Whenever maintenance or repair of the laser system is required be sure to adhere to the

following safety statements:

WARNING

During servicing of the laser system use only safety eyewear known to have an

optical density of 5.9 or more at 591 - 597 nm. Safety eyewear designed for use

with other laser systems may not provide adequate protection.

During servicing of the laser head, the service technician should never contact

the laser head cavity while the system is on because it could be at voltages as

high as 10,000 volts.

8501-00-1550 Revision C Candela PROPRIETARY Page 8 of 22

VBEAM Theory of Operation

FLUID SYSTEM

The VBEAM contains two separate fluid systems; a deionized water system and dye solution system

that regulates the temperature of the laser head at 60C (140F). The total water capacity of this

system is approximately 1.8 liters and 1.4 liters for the dye solution without the dye cartridge volume.

A block diagram detailing the fluid system is shown in Figure 2.

Figure 2 - Fluid Block Diagram

8501-00-1550 Revision C Candela PROPRIETARY Page 9 of 22

VBEAM Theory of Operation

For the DI fluid system a centrifugal pump is used to circulate the deionized water in the

system. The pump is mounted directly under the water reservoir. Typical pump output

pressure generated is 15.8 PSI (measured at the pump outlet) with a nominal flow rate of 1.1

GPM. The water flow and pressure are not adjustable.

The pump output flows up to the laser head on the upper chassis. The tubing connection

between the pump and the laser head has several components in it. First a pressure switch is

located just after the DI pump to detect water pressure. If there is not enough pressure out of

the pump, the pressure switch will activate the software to display a fault. The DI fluid system

may be low on water or has a leak. The laser should be turned off at this point, until a service

technician can look at the laser. The DI pump is directly wired to the mains; therefore after

this fault is detected, the pump is still on and can damage the DI pump if there is no water in

the system.

Water then flows from the pressure switch to the laser head and enters a parallel path about

half way up to the head. The parallel path consists of a DI cartridge and a bypass tube. Most

of the water travels through the bypass tube. Approximately 5% of the flow is through the DI

cartridge. The cartridge contains a deionizing section to maintain the purity of the water (high

resistivity).

The laser head output is connected to the DI heat exchanger. The heat exchanger is cooled

with two 24 VDC fans which are controlled by the firmware. The fans are mounted on the

heat exchanger and pulls air up from the bottom of the laser fluid compartment. Exhaust air

exits the fluid compartment out the rear of the laser chassis. A foam filter in the bottom of the

fluid compartment minimizes the amount of dust picked up by the incoming air. The foam filter

must be changed at regular intervals to prevent restriction of the cooling air.

The output of the heat exchanger is connected to the heater manifold. The heater manifold

contains a single 1000 watt heater, the DI temperature sensor, and a thermal

overtemperature switch. If an overtemperature problem occurs that cannot be corrected by

the firmware or hardware, then the thermal overtemperature (OT) switch will open which

removes 24 VDC power from the main relay thus turning off the entire laser system. The OT

switch is self resetting. After it opens, it typically takes from 10 to 20 minutes for it to reset

itself. The heater is disabled by the firmware when the triggerswitch is depressed. This is

done to limit the AC input current drawn by the system during pulsing of the laser. The heater

is not required when pulsing since the majority of the pulsed energy goes into the DI water in

the laser head. The temperature sensor is a solid state device that is used in conjunction with

circuits on the CPU I/O PCB which allows the firmware to monitor the temperature of the

water. The temperature sensor operates with very low current levels (340uA). If the

connection between the temperature sensor and the system wiring harness becomes wet, the

calibration of the temperature circuit will be affected. The drain valve is located after the

heater manifold and is manually operated to remove water from the system. It is located at

the lowest point in the DI fluid system.

The output from the heater manifold flows through a liquid to liquid heat exchanger, then to

the DI reservoir; which completes the DI loop. This liquid to liquid exchanger will pass the

heat from the heated DI water to the dye solution. The dye solution will heat to the same

temperature as the DI water 60C (140F). The dye solution will track the DI water system.

The combination of the 1000 watt heater in the heater manifold and the heat exchanger fans

work together to maintain the water in the laser system at 60C (140F). The temperature is

8501-00-1550 Revision C Candela PROPRIETARY Page 10 of 22

VBEAM Theory of Operation

regulated to 2C to ensure good efficiency and stability and to minimize variations from

different laser heads. For best accuracy, the temperature sense circuit should only be

calibrated with both the heater and heat exchanger fans off. This ensures that the water

temperature measured by the external sensor in the reservoir is at the same temperature as

the sensor in the heater manifold.

The firmware uses two set points to control the heater and fans. The heater is turned on

whenever the water temperature is at 59.5C or less. The heat exchanger fans are turned on

whenever the water temperature is at 60.5C or greater. There is some undershoot and

overshoot in the water temperature at each of these set points. The firmware over

temperature fault is set for 66C. The laser will not go into the Ready state if this fault is

present. Normally, the firmware should declare an over temperature fault before the over-

temperature thermostat turns off the laser. If this does not happen, then most likely the

temperature sensor is bad or miscalibrated. The firmware will also declare an over-

temperature fault if the temperature read is less than 5C. This is because if the temperature

is less than 5C, the firmware assumes the temperature sensor has failed or become open

circuited. Also, if the temperature drops below 55.5C while in the Ready state, a fault will be

displayed.

The second fluid loop is the dye fluid system. The dye solution system consists of a 50/50

mixture of ethylene glycol and deionized water. This solution flows from a dye pump that is a

positive displacement pump continuously circulating the dye at 1.5 GPM. An adjustment

screw on the pump head allows for proper set up of the flow rate. At 1.5 GPM a typical

system will produce 36 PSI at the pump head. The output of the pump is sent to the Dye

cartridge, particle (bubble) filter, the laser head, the liquid-to-liquid heat exchanger then into

the dye reservoir; which completes the dye loop.

The COT inject pump is used to transfer COT from the COT bottle into the dye reservoir.

COT is required to maintain the correct dye absorbance, affecting the wavelength. The COT

concentration slowly decreases in a system, mostly as a function of time or usage due to

evaporation. Wavelength will be checked at the end of calibration. If the wavelength is low

but within specifications, sufficient COT will be added to bring the laser back to its target

wavelength. If the wavelength is found to be below specifications, an extended COT addition

and delay cycle will occur. During this time a flashing hourglass symbol will be displayed on

the calibration message. At this time sufficient COT will be added to restore proper

wavelength. The addition of COT takes place at a rate of 11.3 milliliters per nanometer. This

will be followed by a mandatory 3 minute mixing delay period. At the end of the mixing delay,

the laser will automatically repeat the calibration process. If the wavelength was not restored

after the extended COT cycle, a fault will be indicated. If the initial wavelength check shows

that the wavelength is significantly out of range, then a fault will be indicated and no COT will

be added to the system. COT is not user replaceable. Field Service must replace the COT

bottle.

The dye and water pumps are directly wired to the mains in the laser system so as soon as

the laser is turned on, the pumps will turn on. Again, damage to the DI pump can occur if it is

turned on with no water. A pressure switch is located just after the DI water pump to

determine when there is insufficient water to operate the laser.

8501-00-1550 Revision C Candela PROPRIETARY Page 11 of 22

VBEAM Theory of Operation

ELECTRICAL SYSTEM

Control System

A block diagram of the control system is shown in Figure 3. All the CPU circuits and

Input/Output interface circuits are located on the CPU I/O PCB that is the heart of the control

system. This PC board is located behind the front panel of the laser system. The board is

easily accessible by removing the front panel of the laser system. The CPU I/O PCB

interfaces with all the other PC boards in the laser system except the 24 VDC Power Supply

PCB. The user interface is accomplished with a touch screen display that allows the customer

to control the laser functions such as energy level, cryogen spray time, laser state, etc.

Feedback to the user is provided by a VGA display which provides status messages and

laser system operating parameters.

A brief description of the main circuits on the CPU I/O PCB follows. The SCR and Modulator

PCB will be discussed in the section on the Modulator.

CPU I/O PCB (Schematic 7111-80-2280)

The CPU I/O PCB functions as the brain of the laser system. It contains the EPROM that

stores the control system firmware for the VBEAM and an MC68HC812 microprocessor that

directs all commands for proper operation of the laser. It directly interfaces with the touch

screen and VGA display. An 8-bit microprocessor bus is used on the board to control and

monitor all laser system functions.

A single serial RS-232 port exists on the board so that a maintenance terminal or modem can

be connected to the laser. The port is located on the bottom center in the front of the frame.

The CPU I/O PCB also provides distribution of all the 24-volt power used in the laser except

for the modulator section. Connector J9 receives the 24 volts generated by the HVPS. It is

partitioned into three separate groups of 24 volts that are each fused either by a 3.15 A or a

5.0 A fuse. Fusing is required because the HVPS will source between 8 and 9 amps of

current if the 24 volts is shorted to ground. Fusing limits the amount of fault current a failed

component would be subjected too. It also allows larger gauge wiring (smaller diameter) to be

used on low current signals.

8501-00-1550 Revision C Candela PROPRIETARY Page 12 of 22

VBEAM Theory of Operation

Figure 3 - Control System Block Diagram

The CPU I/O PCB provides isolation and signal conditioning for the entire VBEAM systems

analog and digital signals. All digital output commands are buffered by U29, U36 and U44

which are driver ICs (integrated circuits).

Almost all the signals that interface with the CPU circuits are electrically isolated on different

grounds to prevent noise problems with the processor. The main exception to this is the

signals to and from the touch screen and VGA display. These are logic level signals that

are connected to the front panel and the display with short cables. The digital inputs and

outputs are all optically isolated using opto isolator ICs. The analog signals to and from the

high voltage power supply (HVPS) are isolated using op amp isolation ICs (U23 and U27 on

schematic page 5) which have a 1500 VAC isolation rating.

8501-00-1550 Revision C Candela PROPRIETARY Page 13 of 22

VBEAM Theory of Operation

To accomplish the signal isolation requirements, there are four isolated ground returns

present on this board. The various returns and their functions are listed below in Table 3.

Return Associated Power Supply Associated Circuits

D +5 VDC CPU and logic circuits

(+5 V/ 15 V DC/DC PS)

A 15 VDC Analog circuits

(+5 V/ 15 V DC/DC PS) (temp circuits, energy circuits)

B +24 VDC Digital I/O and Bubble Sense circuits

C Isolated 15 VDC ( 15VDC_HV) HVPS interface circuits

Table 3 - CPU I/O PCB Returns

The following CPU I/O circuits will be reviewed here: 1) Beam Shutter Circuit; 2) Trigger

Circuit; 3) Bubble Sense Circuit; 4) DAC and ADC Circuits; 5) High Voltage Power Supply

Interface Circuits; 6) Calport Energy Detector Circuit; 7) DI Temperature Circuit; and 8) DCD

Pressure Circuit. Due to their simplicity, the basic on/off I/O circuits will not be discussed.

1. Beam Shutter Circuit (schematic page 3)

The beam shutter can only be opened if both the firmware commands it and either the

fingerswitch or footswitch is depressed or the handpiece is in the cal port. The fingerswitch,

footswitch and handpiece in cal port signals are all generated by redundant switches. The

fingerswitch signals originate in the handpiece and are sent to the input of U39B. (They are

also connected to U35 so the firmware can sense the position of the trigger switch.) The

footswitch signals originate in the air footswitch, which then is converted to an electrical signal

by S1 and S2. (They are connected to the input U39C and also U35 so the firmware can

sense the position of the trigger switch.) The finger switch signals, which are normally high,

must both be low so that the output of U39B can change from a high to a low, indicating the

fingerswitch is depressed. The same situation is true for the cal port switches that are

connected to the input of U39D. The output of U39D will only be low when both cal port

switches are depressed, indicating the handpiece is fully inserted in the cal port. The output of

U39B, U39C and U39D are connected to the inputs of U40C. This IC functions as an NAND

gate so that if either input is low, the output will be high. The output of U40C is connected to

an RC circuit (R177, C138) providing a small delay to prevent timing problems between the

hardware and firmware beam shutter opening signals. After the RC circuit, the signal passes

through U40B that simply inverts the signal to a low when the hardware is commanding the

shutter to open. The output of U40B is connected to an input of U39A. The other input to

U39A is the firmware signal that commands the shutter to open. The output of U39A will only

be low if both inputs are low. A low is required to open the beam shutter. This provides the

safety feature that both the hardware and firmware commands must exist in order to open the

beam shutter. A low output on U39A draws current through the diode side of optoisolator U53.

8501-00-1550 Revision C Candela PROPRIETARY Page 14 of 22

VBEAM Theory of Operation

When diode current flows through U53 it turns on Q12 by raising the gate voltage to

approximately 15 volts. This makes Q12s drain terminal low, allowing current flow from

capacitor C156, through the beam shutter coil, then through Q12 and into ground. Initially, a

high current flows because C156 is charged to +24 volts. However, after a few hundred

milliseconds, C156 discharges to a level determined by the four dropping resistors (R238,

R239, R240, and R241) and the resistance of the shutter coil. This new voltage level is

approximately 15 volts. This circuit provides sufficient stored electrical energy to open the

shutter quickly. Then, after the shutter is opened, the current is reduced to limit the power

dissipated in the shutter coil.

2. Trigger Circuit (schematic page 4)

The four trigger pulses are generated by firmware depending on the front panel settings.

They are sent from the CPU chip through U29 a driver IC chip. The output from U29 is a low

signal that turns on an optical driver as in J15, J16, J17 and J18. The electrical signal is

converted into an optical signal for isolation purposes. This optical signal is then sent by a

1000 micron plastic fiber to the SCR Trigger PCB. This PCB will enable the lamp to fire. A

detail discussion of the SCR Trigger PCB is described in the Modulator section further on.

3. Bubble Sense Circuit (schematic page 7)

The bubble sense circuit uses a slotted optical switch located in the handpiece for the bubble

detection sensor. The cryogen tube is located in the center of the slot so the photosensor in

the switch detects the light transmitted through the cryogen tube. The sensor is calibrated

with cryogen in the tube. When the tube is empty the transmission of light through it drops by

approximately 50%.

The circuit works by having the slotted optical switch in the feedback loop of op amp U54A.

The phototransistor output of the optical switch is connected to the inverting input pin of U54A

through resistor R242. The noninverting pin of U54A is connected to a 10-volt reference

created by U61, R231, and R234. The output of U54A is connected to the LED portion of the

slotted optical switch through resistor R243. The output voltage of U54A adjusts itself to a

level that provides sufficient current in the LED of the optical switch so that its phototransistor

can generate 10 volts at pin 2 of U54A. Under this condition, the feedback loop is in

regulation and the output voltage of U54A is adjusted to 7.75 VDC with the cryogen tubing

full. The adjustment is a potentiometer in the handpiece that shunts some of the

phototransistor output current to ground. When the cryogen tube becomes empty (bubbles

exist), the phototransistors output drops and op amp U54A compensates for this by raising its

output voltage to drive more current into the slotted switch LED. Op amp U54As output

voltage is monitored by U54B which is configured as a comparator. The reference voltage for

this comparator is 10 volts, which is connected to its inverting input. The output of U54A is

connected to the noninverting input of U54B. When this input goes above 10 volts, then the

output of U54B switches from a low to high state. The high state stops current flow through

the diode half of optoisolator U50 which is the signal that eventually connects into the

firmware to inform it that a bubble exists. Resistor R222 provides a small amount of

hysteresis for U54B to prevent oscillations when it switches states.

8501-00-1550 Revision C Candela PROPRIETARY Page 15 of 22

VBEAM Theory of Operation

4. Digital-to-Analog Converter (DAC) and Analog-to-Digital Converter (ADC)

Circuits (schematic pages 14 and 16)

The only signal that requires the DAC (U24) is the high voltage power supply program voltage

signal. However, four analog signals are processed through an external 12-bit ADC chip U22.

Also there are five analog signals and one spare processed directly through an internal 8-bit

ADC port of the CPU chip U26. The energy signals, calport, head, WL and HV sample go

through the external 12-bit ADC chip U24. The water temperature, DCD pressure, HP

detection, and two touch screen signals go directly into the CPU chip to be processed. The

communication between the DAC and ADC to the CPU is obtained through the SPI bus. A

stable 5 volt reference chip U16 is use for the CPU analog port and the external ADC. Two

precision resistors R123 and R124 divide down this 5 volt reference to a 2.5 volt reference for

the DAC.

The DAC and ADC used in this laser system are both 12-bit types. Full scale on each device

is 5 VDC so the minimum resolution is 1/(212) x 5V = 1.22 mV. The DAC and ADC share data

transfers on the SPI bus to the CPU chip. The CPU chip can send data to and receive data

from the ADC chip; it is bi-directional. The CPU only sends data to the DAC chip. Once the

firmware selects either chip select then the data transfer begins.

5. High Voltage Power Supply (HVPS) Interface Circuits (schematic page 5)

There are four signals associated with the high voltage power supply (HVPS). Two of them

are analog signals (HVPS Program Voltage or HVPS Ref and HVPS Sample) and the other

two are digital (HVPS Inhibit and HVPS fault). HVPS Program Voltage is the signal that tells

the HVPS what voltage to charge to and HVPS Sample is the signal that provides feedback

on the actual high voltage level. HVPS Inhibit is basically an on/off input signal. It does not

remove AC line voltage from the HVPS but it will prevent it from charging. The HVPS fault

signal is generated if the HVPS experiences an over temperature or over voltage fault.

The Program Voltage signal comes from the firmware as a 12 bit digital number. It is

converted to an analog signal at the DAC (U24). The DAC output is isolated by U23 and then

its level is reduced by approximately 10% by the voltage divider consisting of R131, and

R130. Potentiometer R131 is used to calibrate the actual high voltage to the value set by the

firmware. For 3.5KV output, the DAC generates 5 volts which then is reduced to 4.5 volts by

the resistor divider. This results in a program voltage transfer function of 0.777KV/V at the

input to the HVPS.

The high voltage sample signal from the HVPS has a ratio of 8V=3500V. This signal is

divided down by R139 and R132 (potentiometer) to allow for adjustment of the signal. This is

then isolated by U27 and has a transfer function same as the Program Voltage 0.777KV/V.

So at 3.5KV the sample voltage is set for 4.5 volts. Then it is sent to the ADC chip U22 so it

can be processed and sent to the CPU chip to be read by the firmware.

6. Calport Energy Detector Circuit

There are three energy detector circuits on this board (labeled head, wavelength and calport).

The wavelength and head circuits are exactly the same. The calport circuit is the same as the

other two circuits except for the gain circuit. Since these three circuits are so similar only the

calport will be discussed.

8501-00-1550 Revision C Candela PROPRIETARY Page 16 of 22

VBEAM Theory of Operation

A photodiode on the Energy PCB located on the backside of the calport assembly converts a

sample of the laser light pulse directed into the calport to a current pulse. The current pulse

is sent to op amp U2B on this board. This op amp integrates the current pulse using C13 and

thus the amount of charge (or voltage) on C13 is proportional to the laser energy. The

firmware keeps C13 discharged just before the trigger pulse by controlling an analog switch

U5. The firmware opens U5 just before each trigger pulse; which allows C13 to charge up

proportional to the energy pulse. The output of U2B is a negative pulse with a decay time

constant much greater than the original laser pulse. Since the output of U2B is both a small

voltage and negative it is sent to an inverting op amp U2A for amplification gain=4.12 and

inversion to a positive signal. Potentiometer (R18) is used to adjust the amount of signal into

U2A for calibration to the laser energy. R10 is adjusted to remove any offsets in the circuitry

so the voltage level at TP2 is zero when the laser is not pulsed. Capacitor C8 and R22 form a

noise filter before the signal reaches the input of the peak hold circuit.

U3B, U3A, and their associated circuitry form the peak hold circuit which captures the peak

level of the output of U2A and holds it at TP1. The circuit only samples signals at its input

when the reset transistor (Q3) is off. The firmware controls Q3 through driver chip U36. After

the laser is pulsed, the peak hold circuit stores the voltage that is proportional to the energy in

the calport. The transfer function is 4 J per volt. The output of the peak hold circuit (TP1) is

connected to the ADC U22 so the firmware can read the energy level.

7. DI Temperature Circuit

The DI temperature sensor is an IC temperature transducer (AD590) with an output current of

1 A/K. The K stands for Kelvin degrees which are 273 degrees greater than Celsius

degrees (e.g. 0C = 273K). The temperature sensor is mounted in the DI heater manifold.

Electrically, it is connected between the -15 VDC and the inverting input of op amp U20B.

Connected to the inverting input of U20B is an adjustable current source formed by R83 and

R86. This current source is powered by the 5 volt reference from U19A. Potentiometer R83

is adjusted so that 273 A flows through R86. This 273 A current source is used to cancel

out 273 A of current from the temperature transducer which effectively changes its output

from 1 A/K to 1 A/C. Keep in mind that ideally no current flows in or out of U20B pin 6

and it is at zero volts (virtual ground). For temperatures above 0C the temperature

transducer draws more current than 273 A, so the output of op amp U20B must increase to

supply the required current through R102. Because R102 is a 100 K resistor the output of

U20B is 0.1 V/C. Capacitor C65 provides noise filtering for the circuit.

The output of U20B is sent through R95 to the input of the CPU (U26). This input of the CPU

is an ADC input and then the firmware can interpret the water temperature.

8. DCD Pressure Circuit

The DCD pressure sensor has a range of 0 to 150 PSI with a 300 PSI maximum over-

pressure value. This pressure sensor has internal circuitry which runs off 5 volts and has a

voltage output scale of 4.50 volts and a 0.5 volt offset. The sensor transfer function is 26.7

millivolts per PSI. The pressure sensor is mounted to the brass tee fitting that the DCD

canister output connects to. Electrically, it is connected between the +5 volt reference, analog

ground (A_GND) and its output voltage is across R84 a potentiometer and R79 a resistor to

analog ground which allows calibration of the pressure circuit. The circuit is calibrated with an

external pressure meter connected to the HP cryogen connector on the front bezel. The

8501-00-1550 Revision C Candela PROPRIETARY Page 17 of 22

VBEAM Theory of Operation

signaled is sent to the CPU (U26), to an ADC input so the firmware can interpret the DCD

pressure. The maximum pressure reading is at 4.5 volts which corresponds to 150 PSI. A

DCD pressure fault is declared by the firmware if the pressure exceeds 135 PSI.

MODULATOR

A simplified schematic of the modulator section is shown in Figure 4. When the laser goes

into the Ready State the simmer power supply is enabled. It automatically sends out trigger

pulses at a 30 Hz rate to the simmer start transformer in an attempt to initiate simmer current.

These pulses are stepped up to approximately 5 KV on the secondary of the simmer start

transformer. The high voltage secondary is connected directly to the laser head cavity.

These pulses create an electrical field inside the laser head which helps to breakdown the

flashlamp. The output voltage of the simmer power supply is 1300 volts before the lamp is lit.

After the lamp is lit the simmer output voltage drops down to approximately 300 volts.

The Pulse Forming Network (PFN) has four separate capacitors and one choke network that

produces four electrical pulse widths of approximately 250 microseconds (full width half

maximum or FWHM) at maximum voltage of 3.5KV. The PFN capacitor is constructed as a

single unit that houses all four capacitors. The PFN choke is a foil construction type which

helps reduce resistive losses in the PFN. The PFN, at its maximum voltage of 3.5 KV,

produces a peak current of 950 amperes per network. At maximum power, the RMS current

through the PFN and flashlamp is about 25 amperes. The PFN pulse discharge occurs when

each SCR s (silicon controlled rectifiers) is triggered on. There are four individual PFN

pulses, therefore four SCR modules. Each module contains two 2200 volt SCRs. The

modules are mounted directly to the laser chassis for heatsinking. Their triggers are

generated by the SCR Trigger PCB. These triggers are controlled by the firmware depending

on the front panel settings.

The high voltage power supply is rated for 2.5 KJ/s. For most energies, this allows laser

operation up to 1.5 Hz repetition rate. When the input energy is above approximately 1700

Joules, the repetition rate decreases due to an increase in the time it takes the power supply

to charge the PFN capacitor. The high voltage power supply also contains an integral 24-volt

DC power supply, rated at 6 amperes. The power supply is inhibited by the firmware for the

length of the set pulse width plus a fixed 50 milliseconds after all the PFNs discharge to

ensure the flashlamp current has reached zero before voltage is reapplied. The high voltage

power supply is built by an outside vendor and is covered by a one-year warranty by the

manufacturer. It has no field serviceable parts. The power supply features include: short

circuit protection, open circuit protection, internal over temperature shut down, air cooled, and

power factor correction circuitry. The internal power supply fan pulls up air from the bottom of

the laser system and blows it through the power supply. The air exhausts out through vents in

the back of the laser.

8501-00-1550 Revision C Candela PROPRIETARY Page 18 of 22

VBEAM Theory of Operation

Figure 4 - Modulator Block Diagram

The Modulator PCB (schematic 7111-80-2300), which is mounted on top of the SCR Trigger

PCB, has three charging channels which allow the capacitors to charge to specific voltage

levels. Each charging channel is controlled by the firmware dependent on the corresponding

laser energy set on the front panel. It also contains high value resistance bleeder resistors to

discharge any energy stored in the capacitors after the laser is turned off. There is a manual

dump resistor rod attached to this laser to provide a quick discharge of the high voltage. This

dump resistor rod is used by service personnel to discharge the high voltage. There is a neon

lamp on the board that illuminates whenever the high voltage is greater than approximately

300 volts on capacitor C4. This serves as a safety reminder that high voltage is present.

CAUTION: If the neon bulb is not lit, there may still be lethal voltages present on capacitors

C1, C2 or C3. Service personnel should always verify the voltage on the capacitors with a

meter and high voltage probe before servicing the modulator.

SCR Trigger PCB

The SCR Trigger PCB (schematic 7111-80-2320) receives the four trigger pulses from the

CPU I/O PCB and generates a signal to trigger the four dual SCR modules to pulse the

flashlamp. The four trigger timing signals are controlled by the firmware. The timing is

dependent on the input setting from the front panel by the user.

The primary function of the SCR Trigger PCB is to provide isolated trigger circuits for the four

SCRs modules that are used to trigger the four PFN pulses. This isolation is provided by

optical signals. The trigger pulses from the CPU I/O PCB are optically isolated by optical

drivers J17, J16, J15 and J13. The SCR Trigger PCB uses optical receivers J16, J22, J23

and J15 to receive the trigger signals from the CPU I/O PCB.

8501-00-1550 Revision C Candela PROPRIETARY Page 19 of 22

VBEAM Theory of Operation

There are four identical SCR trigger circuits on this PCB. Therefore only SCR trigger #1 will

be discussed. The optical signal received into J16, from the CPU I/O PCB, will allow Q8 to

turn on. Having Q8 on will put a low into the high-speed MOSFET driver chip U5 pin 2. U5

will put a high on the output pin 7 which in turn will turn on the FET Q6. T4 will then have

about 24VDC across its input. T4 has a dual output winding, which will turn on both SCRs in

the SCR #1 module.

There are two sets of balancing resistors used to ensure equal voltage sharing between the

two SCRs. Each set contains four 750K, 2W resistors. The SCRs also have snubber circuits

connected across them to prevent voltage spikes when they turn off. C31 is the snubber

capacitor for the first SCR. D46 and D33 are required to prevent a high current discharge of

C31 through the SCR when it first turns on. Instead, the capacitor is discharged through

resistors R83, R84 and R85, R76.

The high voltage output from the simmer power supply is routed through this board so that

the simmer current can be measured and a simmer sense signal can be created. The current

is measured across the 10 , 1% resistors R11 and R12. The simmer current is set to 150

milliamperes by measuring the voltage across these resistors while turning the adjustment on

the simmer power supply. The voltage should be 750 millivolts for 150 milliamps of simmer

current (20 mA/0.1V).

The simmer sense signal is developed by creating a 7.8 volt source using zener diodes D4

and D9. This provides current for the optical driver J8. The output of J8 is sent back to the

CPU I/O PCB. LED D1 lights to indicate when simmer current is flowing.

The 24VDC Power Supply PCB (schematic 7111-80-2330) supplies 24V to the simmer power

supply, Modulator PCB and the SCR Trigger PCB. This PCB has the simmer start

transformer mounted on it. Resistors (R4-R7) connected in parallel with the primary are used

to limit the voltage applied to the trigger transformer. If they are shorted or bypassed, the

simmer start pulse applied to the laser head cavity could increase to almost 10 KV. This

much voltage is not required to light the lamp for simmering and can cause high voltage

breakdown problems on the laser head.

LASER SAFETY INTERLOCK CIRCUIT

There is one hardware interlock circuits in the laser to prevent lasing. The safety interlock

circuit is performed in the system wiring. It consists of the CDRH connector and the DI heater

manifold overtemperature (OT) switch. Each of these devices functions as a normally closed

switch and they are connected in series with one another. They are part of the circuit that

provides coil current for the main relay. If one of them becomes open, the relay current flow is

interrupted. This opens the main relay and shuts down all power to the laser system except

the 24 VDC on the AC Distribution PCB. The laser cannot be turned on again until all the

interlock switches are closed.

8501-00-1550 Revision C Candela PROPRIETARY Page 20 of 22

VBEAM Theory of Operation

The CDRH interlock is a connector located on the back of the laser. It is provided so the

physician can connect an external door switch to it. If the door is opened while the physician

is lasing, the laser will be shut down and lasing prevented.

The DI heater manifold OT switch will turn off power to the laser if a fault occurs in the heater

circuit that allows the manifold temperature to exceed 79C. Normally the firmware would

declare a water overtemperature fault before the OT switch opens unless a serious fault

exists in the heater circuit.

DCD (Dynamic Cooling Device)

The DCD canister is warmed up with a 48-watt heater. Typical warm-up time is 25 minutes.

The number of pulses available per cryogen canister is shown in Table 4. These are the

values displayed on the front panel after the Canister Count has been reset. When the

canister count gets to zero, the firmware will not allow the laser to be pulsed unless the DCD

is turned off (or the reset button is pressed).

Spray Duration (msec) Pulses/Canister

20 16,217

30 10,812

40 8,108

50 6,486

60 5,405

70 4,633

80 4,054

90 3,603

100 3,243

Table 4. Cryogen Pulses Per Canister

The DCD purge duration is the same as the selected pulse duration setting. When the system

is purged, it counts as a pulse and deducts from the total pulses available.

LINE VOLTAGE REQUIREMENTS

The VBEAM operates over a wide input line voltage range of 185 to 260 VAC at 50/60 Hz. There are

no adjustments required for the laser to operate across this range since it has no isolation

transformer. Virtually all the AC power for the laser system is fused and distributed from the AC

8501-00-1550 Revision C Candela PROPRIETARY Page 21 of 22

VBEAM Theory of Operation

Distribution PCB. The only exception to this is the power for the HVPS which is taken off the load

side of the main relay. No fusing is required for the HVPS since it is fused internally.

Accuracy

The references made to components in the laser system and on pc boards was accurate at

the time this theory of operation was written. However, future changes and upgrades may

cause errors if they impact this document and it is not revised. Therefore, in the event a

discrepancy between the Theory of Operation and the actual system documentation is

discovered, it should be assumed that the system documentation is correct.

Service Note

Whenever maintenance or repair of the laser system is required be sure to adhere to the

following safety statement:

WARNING

The electrical hazards present during servicing of the VBEAM can be extremely

dangerous and lethal if proper precautions are not taken. The VBEAM should be

serviced only by qualified technicians who have received appropriate training on

the VBEAM from Candela, and who are familiar with the safety considerations

discussed in this section.

8501-00-1550 Revision C Candela PROPRIETARY Page 22 of 22

You might also like

- 02 Ease StressDocument2 pages02 Ease Stresscheng_cheng1234No ratings yet

- 27 Eat BetterDocument2 pages27 Eat Bettercheng_cheng1234No ratings yet

- 21 Sidestep PitfallsDocument2 pages21 Sidestep Pitfallscheng_cheng1234No ratings yet

- 04Document1 page04cheng_cheng1234No ratings yet

- Chapter 1Document45 pagesChapter 1cheng_cheng1234No ratings yet

- 01 Get MotivatedDocument2 pages01 Get Motivatedcheng_cheng1234No ratings yet

- BarrettD 2013TheInterpretationofDreams In-KushidaC A Ed TheEncyclopediaofSleepVol 1pp 129-131Document7 pagesBarrettD 2013TheInterpretationofDreams In-KushidaC A Ed TheEncyclopediaofSleepVol 1pp 129-131Adrian RosuNo ratings yet

- Archetypes To Help With Literary AnalysisDocument7 pagesArchetypes To Help With Literary Analysismmaurno79% (34)

- HB RopeDocument104 pagesHB Ropemuhammad-ahmed-salman-2537No ratings yet

- Plain Pre Glued Dowel Pin FaqDocument2 pagesPlain Pre Glued Dowel Pin Faqlbkumar87No ratings yet

- Three Blind MiceDocument4 pagesThree Blind Micecheng_cheng1234No ratings yet

- Tree Top On The Tree TopDocument1 pageTree Top On The Tree Topcheng_cheng1234No ratings yet

- London Bridge Is Falling DownDocument9 pagesLondon Bridge Is Falling Downcheng_cheng1234No ratings yet

- Case Drain Issues With Pumps and MotorsDocument15 pagesCase Drain Issues With Pumps and Motorscheng_cheng1234No ratings yet

- The World As It Is...Document1 pageThe World As It Is...cheng_cheng1234No ratings yet

- ISO 2768-2 PreviewDocument2 pagesISO 2768-2 Previewcheng_cheng1234No ratings yet

- ISO 2768 1 Preview PDFDocument2 pagesISO 2768 1 Preview PDFcheng_cheng1234No ratings yet

- Pet AnimalDocument1 pagePet Animalcheng_cheng1234No ratings yet

- 677 TiDocument1 page677 Ticheng_cheng1234No ratings yet

- Iso 8501Document4 pagesIso 8501cisar0007100% (2)

- Steel Wire RopeDocument1 pageSteel Wire Ropecheng_cheng1234No ratings yet

- Agma VS ApiDocument14 pagesAgma VS ApiSimbu ArasanNo ratings yet

- Steel Technical CablesDocument37 pagesSteel Technical Cablesgreat2007No ratings yet

- Surface PreparationDocument8 pagesSurface PreparationimyparkarNo ratings yet

- PACK ThisDocument1 pagePACK Thischeng_cheng1234No ratings yet

- Standard For Blasting ISO 8501 1Document2 pagesStandard For Blasting ISO 8501 1Roberto Silva100% (3)

- Surface CoatingDocument18 pagesSurface Coatingaaftab ahmed100% (1)

- Sis 05 5900Document11 pagesSis 05 5900Taha Zia50% (2)

- Iso 8501-1Document2 pagesIso 8501-1cheng_cheng12340% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Eng TELE-audiovision 1411Document164 pagesEng TELE-audiovision 1411Alexander WieseNo ratings yet

- Samyung BNW 50Document2 pagesSamyung BNW 50Aldrine Dela CruzNo ratings yet

- PDP-11/70 Processor Handbook (1977-1978)Document284 pagesPDP-11/70 Processor Handbook (1977-1978)TheAnonymousLugia100% (1)

- RS232 Serial Cable Pinout InformationDocument5 pagesRS232 Serial Cable Pinout InformationGrog Decimo RazielNo ratings yet

- CJ2MDocument28 pagesCJ2MkarthickbalaNo ratings yet

- Internet Access Via Cable TV NetworkDocument19 pagesInternet Access Via Cable TV Networkbest279100% (5)

- Design and Simulation of PFC Based CUK CDocument6 pagesDesign and Simulation of PFC Based CUK CSameer AnandNo ratings yet

- DSP SyllabusDocument2 pagesDSP SyllabuskumarNo ratings yet

- System Power Supplies 4-PPS-MDocument4 pagesSystem Power Supplies 4-PPS-Mtomjakson333No ratings yet

- Troubleshooting Guide - External Clock Reference AlarmDocument11 pagesTroubleshooting Guide - External Clock Reference AlarmAhmed Sharaf0% (1)

- f9222l 102 PDFDocument10 pagesf9222l 102 PDFfloriantudorNo ratings yet

- DX-790-960-65-17.5i-M: Electrical PropertiesDocument2 pagesDX-790-960-65-17.5i-M: Electrical PropertiesАлександрNo ratings yet

- Pioneer Deh p2550Document59 pagesPioneer Deh p2550Alberto DelgadoNo ratings yet

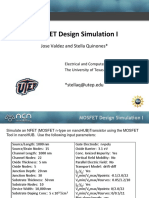

- EE 4350 MOSFET Design Simulation IDocument4 pagesEE 4350 MOSFET Design Simulation IalNo ratings yet

- EC09 506 Linear Integrated Circuits NOV 2015Document2 pagesEC09 506 Linear Integrated Circuits NOV 2015Sai DasNo ratings yet

- PLC Q&aDocument9 pagesPLC Q&aRendyAlf80% (5)

- 1T00918Document2 pages1T00918Clovis MachadoNo ratings yet

- High-Side Voltage-to-Current (V-I) Converter: TI Precision Designs: Verified DesignDocument21 pagesHigh-Side Voltage-to-Current (V-I) Converter: TI Precision Designs: Verified Designgeneric111No ratings yet

- Arc Welding MachineDocument34 pagesArc Welding Machinersgk75100% (1)

- 78M15G T60 KDocument10 pages78M15G T60 KMalek KamelNo ratings yet

- Sales Sheet Agile Airlink 1537518930Document2 pagesSales Sheet Agile Airlink 1537518930გიორგი მოდებაძეNo ratings yet

- Alternating Current Mcqs PDFDocument11 pagesAlternating Current Mcqs PDFPriNce Khatri0% (1)

- PLCDocument31 pagesPLCBilal ShahidNo ratings yet

- Chapter 15Document10 pagesChapter 15Yug VarshneyNo ratings yet

- PCB Layout DesignDocument74 pagesPCB Layout DesignMallappa Patil100% (1)

- H AMACHERDocument59 pagesH AMACHERPushpavalli Mohan0% (1)

- VSD PDFDocument20 pagesVSD PDFJovanny MarquezNo ratings yet

- System Verilog Basic Introduction && Assertions: Presenter - Suman HalderDocument18 pagesSystem Verilog Basic Introduction && Assertions: Presenter - Suman HalderSuman HalderNo ratings yet

- EE-103: Electrical Engineering: Chap:9 Sinusoids and PhasorsDocument33 pagesEE-103: Electrical Engineering: Chap:9 Sinusoids and PhasorsZarak KhanNo ratings yet

- Relay Operating Principles - Power System Relaying by Stanley, CH 2Document52 pagesRelay Operating Principles - Power System Relaying by Stanley, CH 2Muzammil NaeemNo ratings yet