Professional Documents

Culture Documents

JHA Welding & Grinding Work Rev 001

Uploaded by

Jeremia SamosirOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JHA Welding & Grinding Work Rev 001

Uploaded by

Jeremia SamosirCopyright:

Available Formats

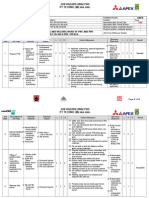

Job Hazard Analysis (JHA) DATE: 12 / 10 / 2013

REGISTERED No.

ENTITY: Direct Hire / SUBCONTRACTOR NAME__SMOE__________

PROJECT: Australia Pacific LNG Module Yard Project

ADDRESS: Jln. Hang Kesturi VI lot 5 -1 Kabil

LOCATION: APLNG Mod Yard PHONE:

JOB DESCRIPTION: Welding & Grinding Work. (Rev001)

EMERGENCY ACTION PLAN: As per site Emergency Response and Preparedness Plan (25509-100-GPP-GHX-00003) and site specific emergency response plans.

SMOE - Medical Clinic : 07788074112, Pisa ES&H : 08127027441

PLANNED HIGH RISK ACTIVITY:

Excavation entry Explosives use Confined space entry Hazardous substance use Work at heights

Roof work Tilt Up/Precast use Structural alterations Mobile plant operations Work in/over water

Road/Rail work Gas/Chemical/Fuel line work Energised electrical work Temperature extremes Flammable/contaminated

Demolition work Marine activities Asbestos removal atmosphere

Demolition Cert. No. Asbestos Removal Cert. No.

DEVELOPED BY: REVIEWED BY:

Certificate

No Name Signature Position No Name Signature Position Date.

No.

1 Pahala Sirait Welding Supervisor 1 Joko Priono ES&H Supervisor 14 October 2013

2 Fred Seale Propane Area Mgr. 2 Koko Biantoro ES&H Supervisor 14 October 2013

3 Mike Murphy Cryo Area Mgr. 3

4 Waylon Johnson OSBL Area Mgr. 4

Welding

5 Billy Moor

Superintendent 5

6 Damsen Welding Supervisor 05.09.2013 6

APPROVAL BY:

Name: Mike Dorris Signature: Position: General Superintendent Date: 14 October 2013

REVIEW: (NOTE: Work SHALL NOT proceed until the JHA is signed and dated by the HSE Manager or nominee and Construction Superintendent or nominee)

Name: Beng Kee Tan Signature: Position: ES&H Manager Date: 14 October 2013

HSE-FORM-012 5 July 2012 1

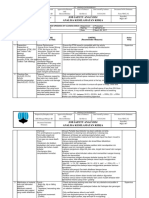

P.P.E REQUIREMENTS PLANT, EQUIPMENT & TOOLS FOR JOB TAGGING & SIGNS PERMITS &

INSTRUCTION

Check Check Check Check

Electrical power Welding

Hard hat Long pants Barrier mesh Confined Space

tools machine

Clear safety

Sock/Boot protectors Fans Winch Flagging Excavation

Glasses

Tinted safety

Safety Boots Fire controls Information tags Floor/Roof Opening

glasses

Face shield/ welding Out of Service High Pressure /

Hearing protection First aid kit

hood tags Abrasive Blasting

Long sleeve HiVis Personal Danger

Particulate dust mask Hand tools Hot Work

shirt Tags

Gloves -leather Ladder Personal locks HV Access

Gloves Hyflex Persons working

Mobile plant Instruction Manual

(Nitrile) above

Gloves - PVC Scaffold Road cones Isolation

Sunscreen Shovel Cofined Space MSDSs

Suspended

Insect repellent Spill kit

Personnel Platform

Skills/Competencies/Authorisations

Check

Integrated Tool

Asbestos Removalist Dozer Rigger Intermediate Skid Steer

Carrier

Backhoe EWP Light Vehicle Roller Spreader

Compactor Excavator Marine craft Scaffolder Advanced Other

Concrete Placing boom Front end loader Materials hoist Scaffolder Basic

Crane type and

Forklift Personnel hoist Scaffolder Intermediate

capacity:

Demolisher Grader Rigger Advanced Scraper

Dogger Heavy vehicle Rigger Basic Skidder

HSE-FORM-012 5 July 2012 2

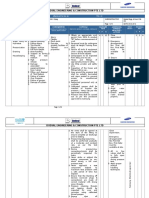

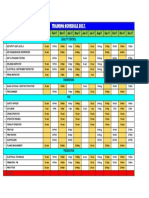

RISK SCORE CALCULATOR

Use the Risk Score Calculator to determine the level of risk of each hazard

What would the What is the LIKELIHOOD of an occurrence? Hierarchy of Controls

CONSEQUENCE of an Can the hazard be Eliminated or removed from

occurrence be? Unlikely Rare Possible Likely Almost Certain

the work place?

Minor Can the product or process be Substituted for

Low Low Low Low Medium

First aid treatment a less hazardous alternative?

Medium Can the hazard be Engineered away with

Low Low Medium Medium High

Medical treatment guards or barriers?

Serious Can Administration Controls be adopted

Low Medium Medium High High

Lost time incident ie procedures, job rotation etc

Major Low Medium High High High

Fatality or permanent impairment Can Personal Protective Equipment & Clothing

Catastrophic be worn to safe guard against hazards?

Medium High High High High

Multiple fatalities or permanent impairment

Control Methods & Monitoring Residual

Step Hazard Risk Risk

What are the hazards of each What control measures will be used? Action By

Describe the job step by step? Score Score

step? How will the effectiveness of the controls be determined?

(Inspection & ongoing monitoring)

Watch your hands/body before placing in between two

objects (specifically one has potential to move)

Pinch point

M Wear leather gloves when carrying materials. L Work crew

Always keep the body parts away from potential pinch

point or moving objects.

Assess weight of tools, equipment, materials youre

going to move (25 kg maximum per person).

Keep your back straight when lifting/pulling tools or

Preapare welding & grinding tools Back injury M material. L Work crew

Use lifting aid or other people to help when lifting

heavy materail (eg welding machine).

Adopt proper manual lifting technique when lifting.

Clear all access path free from cables,

hoses,materials or arrange them properly with warning

Tripping hazard M sign. L Work crew

Maintain good cable / hose management.

Maintain good housekeeping in the workplace.

HSE-FORM-012 5 July 2012 3

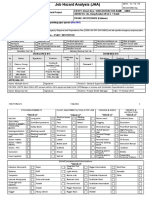

Control Methods & Monitoring Residual

Step Hazard Risk Risk

What are the hazards of each What control measures will be used? Action By

Describe the job step by step? Score Score

step? How will the effectiveness of the controls be determined?

(Inspection & ongoing monitoring)

Wear Particulate dust mask. Supervisor /

Dust & toxic gases H Only trained worker will be involved for welding & L ES&H / Work

grinding activity. crew

Check inspection sticker on the electrical tools and

visual check conditon of the tools and cables.

Ensure that all electrical equipment connected with

Electrical shock H L Work crew

ELCB.

Ensure that grounding is in place prior to start using

any electrical tools.

Using welding apron.

Spark/burn M L Welder

Use fire blanket to control the slag / spark.

Wear leather gloves while carry out welding or

grinding work.

Stay away from line of fire when using grinding

Cutting Hazard M L Welder

machine.

Correct type of disc for the material.

Correct Disc speed (rpm) rating for the Grinder

Welding & grinding works Vibration M Handle must be fitted and used while grinding work L Welder

Obtain Hot Work Permit prior to start the work

(especially for confined space & work over water)

Remove all flammable substances prior to start hot

Work crew /

Fire/explosion M work L

ES&H

No synthetic cloth.

Use fire blanket to control the slag / spark.

Fire extinguisher shall be put in place.

Noise M Wear ear protection. L Welder

Wear welding visor with correct shaded lens

Wear double eye protection. E.g. welding hood and

safety glasses.

UV exposures/eye irritation M L Welder

Before remove eye protection equipment, close your

eyes and brush the dust away from your face and

eyes prior to open eyes again.

Provide elevated platform (if needed) to ease to

Limited access L L Work crew

access.

HSE-FORM-012 5 July 2012 4

Control Methods & Monitoring Residual

Step Hazard Risk Risk

What are the hazards of each What control measures will be used? Action By

Describe the job step by step? Score Score

step? How will the effectiveness of the controls be determined?

(Inspection & ongoing monitoring)

Hot surface / Burn M Wait until the welded joint cool down prior to leave.. L Work crew

Sharp edges M Wear leather gloves and maintain long sleeves shirt. L Welder

Work finished & house Keeping

Body injury from crawling (knees, Wear leather gloves, maintain long sleeves shirt and

M L Welder

elbow and head) pants.

Hazardous waste from welding

M Dispose of welding rod waste in proper container. L Supervisor

rod waste

HSE-FORM-012 5 July 2012 5

Job Hazard Analysis (JHA)

SIGN OFF SHEET

All persons performing any activity covered by this JHA MUST sign off prior to commencement of this task as recognition of having read and understood the work steps and

preventative actions required to reduce the risk of harm, and ensure safe work practices are maintained.

I, the undersigned, declare that I have read and understand the requirements of this JHA and will work in accordance with the prescribed controls.

Name Signature Position Date Name Signature Position Date

HSE-FORM-012 5 July 2012 6

You might also like

- JSA For Cutting, Grinding and WeldingDocument4 pagesJSA For Cutting, Grinding and Weldingyc safety100% (3)

- JSA For Hydrotesting PDFDocument6 pagesJSA For Hydrotesting PDFMohammed Minhaj100% (1)

- JSA Cable Laying PDFDocument2 pagesJSA Cable Laying PDFManoj WaskelNo ratings yet

- Job Hazard Analysis FOR Grinding WorkDocument6 pagesJob Hazard Analysis FOR Grinding WorkMAHA LINGAMNo ratings yet

- JSA For Fabrication WorksDocument11 pagesJSA For Fabrication Workssurendra behera100% (3)

- JSA Installation of Equipment For Electrical and InstrumentDocument3 pagesJSA Installation of Equipment For Electrical and InstrumentHong Hai Pham75% (4)

- Jsa For Civil WorkDocument6 pagesJsa For Civil WorkMuhammad Umar GondalNo ratings yet

- JSA E&I 10.electrical Instrument Panels RemovalDocument3 pagesJSA E&I 10.electrical Instrument Panels RemovalAmyNo ratings yet

- Job Safety Analysis:: RTR DRAIN LINE REPLACEMENT (Excavation and Backfilling)Document5 pagesJob Safety Analysis:: RTR DRAIN LINE REPLACEMENT (Excavation and Backfilling)Madhan KannanNo ratings yet

- Jsa-Jha For Using of Hand ToolsDocument2 pagesJsa-Jha For Using of Hand ToolsKamran Khan50% (2)

- JSA For DuctDocument13 pagesJSA For DuctRakeshkasarlaNo ratings yet

- Job Hazard Analysis Welding Operations: Job Title: Work Place LocationDocument18 pagesJob Hazard Analysis Welding Operations: Job Title: Work Place Locationmuhammad imtiaz100% (1)

- TEIPL-JSA-021 Working at Height, Scaffolding R1Document5 pagesTEIPL-JSA-021 Working at Height, Scaffolding R1ba ratnaparkheNo ratings yet

- Jsa For Piping and Erection RevisedDocument1 pageJsa For Piping and Erection RevisedAlvin Smith77% (26)

- Jsa Pipe Cutting at Fire PumpDocument5 pagesJsa Pipe Cutting at Fire PumpHow Chin Engineering Sdn BhdNo ratings yet

- JSA Fitting and Welding Work For Pipe Trench InstalationDocument6 pagesJSA Fitting and Welding Work For Pipe Trench InstalationAzmi Fauzi78% (9)

- Jha Piping Insulation Installation and Dismantle Work p28Document12 pagesJha Piping Insulation Installation and Dismantle Work p28AmirHakimRusli100% (1)

- How Chin Engineering: Job Safety AnalysisDocument5 pagesHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdNo ratings yet

- Jsa For Pipe Fabrication ErrectionDocument8 pagesJsa For Pipe Fabrication Errectionjithin shankarNo ratings yet

- Ast Jsa - Piping FabricationDocument3 pagesAst Jsa - Piping Fabricationmd_rehan_2No ratings yet

- Jsa Loading and Unloading of Pile PipesDocument4 pagesJsa Loading and Unloading of Pile PipesOsiobe Ewomazino100% (1)

- Electrical InstallationDocument3 pagesElectrical InstallationWalid KhelfaNo ratings yet

- JSA Cable LayingDocument2 pagesJSA Cable Layingnishanth100% (2)

- JHA Arc WeldingDocument2 pagesJHA Arc WeldingechaNo ratings yet

- Jsa - Electrical WorksDocument2 pagesJsa - Electrical WorksaneshseNo ratings yet

- PCSB JHA Troubleshooting SMRGDocument4 pagesPCSB JHA Troubleshooting SMRGMohamad JazlanNo ratings yet

- Jsa For Weld and GrindingDocument6 pagesJsa For Weld and GrindingTanzeel LiaqatNo ratings yet

- Mie Hse Jha 002 - Welding, Cutting, Fabrication WorkDocument4 pagesMie Hse Jha 002 - Welding, Cutting, Fabrication WorkLuqman Osman100% (1)

- Copy (2) of JSA For Removal of MS Sheet For E&P ShedDocument12 pagesCopy (2) of JSA For Removal of MS Sheet For E&P Shedmidozoty50% (2)

- Jsa Welding Cutting and Grinding at Closing AreaDocument7 pagesJsa Welding Cutting and Grinding at Closing AreaDedy Kurniawan100% (2)

- Jsa Cable TerminationDocument4 pagesJsa Cable TerminationSyed Yousuf Ali100% (1)

- Hydrotest & Pneumatic Test - TRADocument6 pagesHydrotest & Pneumatic Test - TRAOws Anish100% (3)

- JSA #19 Grinding, Welding, Gas CuttingDocument2 pagesJSA #19 Grinding, Welding, Gas CuttingSubham Sohal100% (1)

- Jsa For Painting Operation: S.N o Scope of Activity Hazard Control Measures Requested byDocument3 pagesJsa For Painting Operation: S.N o Scope of Activity Hazard Control Measures Requested bywahyu nugroho100% (2)

- JSA Confined Sapce EntryDocument1 pageJSA Confined Sapce EntryprasongNo ratings yet

- JSA PaintingDocument1 pageJSA PaintingjonesNo ratings yet

- Hard Hat, Safety Glasses, Safety Boots Compulsory: PowerDocument9 pagesHard Hat, Safety Glasses, Safety Boots Compulsory: PowerEbeneshwar Anthony71% (7)

- Confined Space JSADocument1 pageConfined Space JSADILAL B P100% (16)

- Jsa Grinding Welding Gas CuttingDocument3 pagesJsa Grinding Welding Gas CuttingRana Waseem Khan82% (79)

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7Document4 pagesThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7abhijit janaNo ratings yet

- Jsa For Arc WeldingDocument3 pagesJsa For Arc Weldingtnssbhaskar100% (5)

- JSA Earthpit Construction GeneralDocument4 pagesJSA Earthpit Construction Generalmukka88No ratings yet

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSDocument2 pagesProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSJohn100% (1)

- 008 JSA - Manual BoringDocument3 pages008 JSA - Manual BoringMohammed MinhajNo ratings yet

- PTW JHA Electrical Wiring Installation Work at Air Dryer RoomDocument4 pagesPTW JHA Electrical Wiring Installation Work at Air Dryer RoomPHH9834No ratings yet

- 0017 JS A Hot Job (Welding, Grinding & Cutting)Document4 pages0017 JS A Hot Job (Welding, Grinding & Cutting)Positivesolution100% (2)

- Jsa For Lifting Crane 016Document6 pagesJsa For Lifting Crane 016kiran kumar100% (1)

- JSA Machinal PipingDocument7 pagesJSA Machinal PipingNaitik Desai48100% (1)

- JSA WeldingDocument4 pagesJSA Weldingyc safetyNo ratings yet

- Copy (4) of JSA For HDPE Liner Fusion Welding Includes Night WorksDocument7 pagesCopy (4) of JSA For HDPE Liner Fusion Welding Includes Night WorksMohammed Minhaj80% (5)

- Manual Tig Welding (RRC) - Job ProcedureDocument3 pagesManual Tig Welding (RRC) - Job Proceduretitto84886100% (1)

- JHA Civil WorksDocument2 pagesJHA Civil Worksethelchudi100% (11)

- JSA Template 2017-05-31 Cable Tray InstallationDocument19 pagesJSA Template 2017-05-31 Cable Tray InstallationJayvee Baradas ValdezNo ratings yet

- Job Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityDocument2 pagesJob Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityJayendra PatelNo ratings yet

- JSA For Chimney Works 17.09.2021Document2 pagesJSA For Chimney Works 17.09.2021Brenden PalanithangamNo ratings yet

- Gas Cutting JsaDocument4 pagesGas Cutting JsaMohammed Minhaj100% (1)

- Blasting & Painting JHADocument8 pagesBlasting & Painting JHADedy Kurniawan100% (1)

- Civil & Piping Work at Cast HouseDocument8 pagesCivil & Piping Work at Cast HouseVinayaga MoorthiNo ratings yet

- Sepcoii II: Job Safety Analysis (J S A)Document8 pagesSepcoii II: Job Safety Analysis (J S A)Abdus SamadNo ratings yet

- Jsa MV Cable Pulling, Termination and TestingDocument11 pagesJsa MV Cable Pulling, Termination and TestingMohammad AqilNo ratings yet

- Total Monthly Worked Hours Drainage System at Phosphate Line PT Nihon Global TechDocument2 pagesTotal Monthly Worked Hours Drainage System at Phosphate Line PT Nihon Global TechJeremia SamosirNo ratings yet

- Inspection Mobile Elevating Work Platform (Aerial Lift)Document6 pagesInspection Mobile Elevating Work Platform (Aerial Lift)Jeremia SamosirNo ratings yet

- Job Safety Analysis: Protective Equipment Required To Perform This JobDocument2 pagesJob Safety Analysis: Protective Equipment Required To Perform This JobJeremia SamosirNo ratings yet

- Laporan Tindakan Perbaikan Dan Peningkatan Hse: PT Nihon Global TechDocument1 pageLaporan Tindakan Perbaikan Dan Peningkatan Hse: PT Nihon Global TechJeremia SamosirNo ratings yet

- Weekly HSE ReportDocument4 pagesWeekly HSE ReportJeremia Samosir100% (4)

- Daily Inspection NewDocument1 pageDaily Inspection NewJeremia Samosir100% (1)

- PT Nihon Global Tech: First Aid Box ChecklistDocument2 pagesPT Nihon Global Tech: First Aid Box ChecklistJeremia SamosirNo ratings yet

- Peraturan Umum ScaffoldingDocument5 pagesPeraturan Umum ScaffoldingDhany IraoneNo ratings yet

- Schedule 2017Document1 pageSchedule 2017Jeremia SamosirNo ratings yet

- Biology Q PDFDocument9 pagesBiology Q PDFsumon chowdhuryNo ratings yet

- Family Stress TheoryDocument10 pagesFamily Stress TheoryKarina Megasari WinahyuNo ratings yet

- Prof. Madhavan - Ancient Wisdom of HealthDocument25 pagesProf. Madhavan - Ancient Wisdom of HealthProf. Madhavan100% (2)

- Assignment On Inservice Education Sub: Community Health NursingDocument17 pagesAssignment On Inservice Education Sub: Community Health NursingPrity DeviNo ratings yet

- Jurnal SOL MeningiomaDocument6 pagesJurnal SOL MeningiomaConnie SianiparNo ratings yet

- Proposed Child Right's Policy FrameworkDocument2 pagesProposed Child Right's Policy FrameworkCrisDBNo ratings yet

- Library PDFDocument74 pagesLibrary PDFfumiNo ratings yet

- Thorley Amended Complaint (Signed)Document13 pagesThorley Amended Complaint (Signed)Heather ClemenceauNo ratings yet

- Olivares VsDocument2 pagesOlivares VsDebbie YrreverreNo ratings yet

- Essay 31 - Permissive ParentingDocument2 pagesEssay 31 - Permissive Parentingqbich37No ratings yet

- Mdp36 The EndDocument42 pagesMdp36 The Endnanog36No ratings yet

- 3 Ways To Take Isabgol - WikiHowDocument6 pages3 Ways To Take Isabgol - WikiHownasirNo ratings yet

- Unknown Facts About Physicians Email List - AverickMediaDocument13 pagesUnknown Facts About Physicians Email List - AverickMediaJames AndersonNo ratings yet

- Lecture 8 - ThermodynamicsDocument65 pagesLecture 8 - ThermodynamicsHasmaye PintoNo ratings yet

- 10.1.polendo (Additional Patent)Document11 pages10.1.polendo (Additional Patent)Rima AmaliaNo ratings yet

- BV DSG eDocument18 pagesBV DSG eIulianIonutRaduNo ratings yet

- Safety Tips in Playing ArnisDocument2 pagesSafety Tips in Playing ArnisDensyo De MensyoNo ratings yet

- Geography - Development (Rural - Urban Settlement)Document32 pagesGeography - Development (Rural - Urban Settlement)jasmine le rouxNo ratings yet

- Postoperative Care in Thoracic Surgery A Comprehensive GuideDocument397 pagesPostoperative Care in Thoracic Surgery A Comprehensive GuideΑΘΑΝΑΣΙΟΣ ΚΟΥΤΟΥΚΤΣΗΣ100% (1)

- Chap 6 - Karen HorneyDocument95 pagesChap 6 - Karen HorneyDiana San JuanNo ratings yet

- Sebaran Populasi Dan Klasifikasi Resistensi Eleusine Indica Terhadap Glifosat Pada Perkebunan Kelapa Sawit Di Kabupaten Deli SerdangDocument7 pagesSebaran Populasi Dan Klasifikasi Resistensi Eleusine Indica Terhadap Glifosat Pada Perkebunan Kelapa Sawit Di Kabupaten Deli SerdangRiyo RiyoNo ratings yet

- Dryer Regenerative Blower Purge DBP 02250195 405 R00 PDFDocument84 pagesDryer Regenerative Blower Purge DBP 02250195 405 R00 PDFjennyNo ratings yet

- Chapter 7 Unemployment, Inflation, and Long-Run GrowthDocument21 pagesChapter 7 Unemployment, Inflation, and Long-Run GrowthNataly FarahNo ratings yet

- Sol. Mock Test CBSE BiologyDocument3 pagesSol. Mock Test CBSE BiologysbarathiNo ratings yet

- Datasheet MEC MPS200 v1 2018Document4 pagesDatasheet MEC MPS200 v1 2018Cepi Sindang KamulanNo ratings yet

- Cleaning of Contact Points and Wiring HarnessesDocument3 pagesCleaning of Contact Points and Wiring HarnessesRafa Montes MOralesNo ratings yet

- B1 Pendent SprinklerDocument2 pagesB1 Pendent SprinklerDave BrownNo ratings yet

- Electric Field Summary NotesDocument11 pagesElectric Field Summary NotesVoyce Xavier PehNo ratings yet

- Butt Weld Cap Dimension - Penn MachineDocument1 pageButt Weld Cap Dimension - Penn MachineEHT pipeNo ratings yet

- Power Divider and Combiner: EE403-Microwave Engineering MTC, EE Dep., Electromagnetic Waves GroupDocument52 pagesPower Divider and Combiner: EE403-Microwave Engineering MTC, EE Dep., Electromagnetic Waves GroupHabibat El Rahman AshrafNo ratings yet