Professional Documents

Culture Documents

Se Nissan Sentra B16

Uploaded by

Alex HernandezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Se Nissan Sentra B16

Uploaded by

Alex HernandezCopyright:

Available Formats

BODY

SE

A

B

SECTION

SEAT C

E

CONTENTS

SERVICE INFORMATION ............................ 2 Diagnostic Worksheet ............................................... 9 F

PRECAUTIONS ................................................... 2 HEATED SEAT ................................................. 11

Precaution for Supplemental Restraint System Description ...............................................................11

G

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN- Wiring Diagram - HSEAT - ......................................12

SIONER" ................................................................... 2

Precaution Necessary for Steering Wheel Rota-

FRONT SEAT .................................................... 14

Driver Seat ...............................................................14 H

tion After Battery Disconnect ..................................... 2

Passenger Seat .......................................................15

Precaution for Work .................................................. 3

Removal and Installation .........................................15

Service Notice ........................................................... 3

Disassembly and Assembly .....................................16 SE

PREPARATION ................................................... 4

Special Service Tool ................................................. 4

REAR SEAT ...................................................... 19

Component Parts Drawing ......................................19

Commercial Service Tool .......................................... 4

Removal and Installation .........................................20 J

SQUEAK AND RATTLE TROUBLE DIAGNO- Disassembly and Assembly .....................................22

SIS ....................................................................... 5 Component Parts Drawing ......................................24

Work Flow ................................................................. 5 Removal and Installation .........................................24 K

Generic Squeak and Rattle Troubleshooting ............ 7

Revision: July 2010 SE-1 2011 Sentra

PRECAUTIONS

< SERVICE INFORMATION >

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0000000006151522

The Supplemental Restraint System such as AIR BAG and SEAT BELT PRE-TENSIONER, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly causing

serious injury.

When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000006151523

NOTE:

This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

Remove and install all control units after disconnecting both battery cables with the ignition knob in the

LOCK position.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ACC position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: July 2010 SE-2 2011 Sentra

PRECAUTIONS

< SERVICE INFORMATION >

5. When the repair work is completed, return the ignition switch to the LOCK position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.) A

6. Perform a self-diagnosis check of all control units using CONSULT-III.

Precaution for Work INFOID:0000000006487025

B

When removing or disassembling each component, be careful not to damage or deform it. If a component

may be subject to interference, be sure to protect it with a shop cloth.

When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component C

with a shop cloth or vinyl tape to protect it.

Protect the removed parts with a shop cloth and prevent them from being dropped.

Replace a deformed or damaged clip.

D

If a part is specified as a non-reusable part, always replace it with new one.

Be sure to tighten bolts and nuts securely to the specified torque.

After re-installation is completed, be sure to check that each part works normally.

Follow the steps below to clean components. E

- Water soluble dirt: Dip a soft cloth into lukewarm water, and wring the water out of the cloth to wipe the dirty

area.

Then rub with a soft and dry cloth.

F

- Oily dirt: Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%), and wipe

the dirty area.

Then dip a cloth into fresh water, and wring the water out of the cloth to wipe the detergent off. Then rub with

a soft and dry cloth. G

Do not use organic solvent such as thinner, benzene, alcohol, or gasoline.

For genuine leather seats, use a genuine leather seat cleaner.

Service Notice INFOID:0000000006151524

H

When removing or installing various parts, place a cloth or padding onto the vehicle body to prevent

scratches. SE

Handle trim, molding instruments, grille, etc. carefully during removing or installing. Be careful not to oil or

damage them.

Apply sealing compound where necessary when installing parts.

When applying sealing compound, be careful that the sealing compound does not protrude from parts. J

When replacing any metal parts (for example body outer panel, member, etc.), be sure to take rust preven-

tion measures.

K

Revision: July 2010 SE-3 2011 Sentra

PREPARATION

< SERVICE INFORMATION >

PREPARATION

Special Service Tool INFOID:0000000006151526

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.) Description

Tool name

Locating the noise

(J-39570)

Chassis ear

SIIA0993E

Repairing the cause of noise

(J-43980)

NISSAN Squeak and Rattle

Kit

SIIA0994E

For removing trim

( J-46534 )

Trim tool set

AWJIA0483ZZ

Commercial Service Tool INFOID:0000000006151527

(Kent-Moore No.)

Description

Tool name

(J-39565) Locating the noise

Engine ear

SIIA0995E

Revision: July 2010 SE-4 2011 Sentra

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

< SERVICE INFORMATION >

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

A

Work Flow INFOID:0000000006151528

SBT842

G

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interview to document the facts and conditions when the noise occurs and any H

customer's comments; refer to SE-9, "Diagnostic Worksheet". This information is necessary to duplicate the

conditions that exist when the noise occurs.

The customer may not be able to provide a detailed description or the location of the noise. Attempt to obtain

all the facts and conditions that exist when the noise occurs (or does not occur). SE

If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer is

concerned about. This can be accomplished by test driving the vehicle with the customer.

After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics J

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

Squeak (Like tennis shoes on a clean floor)

K

Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces

= higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping.

Creak(Like walking on an old wooden floor)

Creak characteristics include firm contact/slow movement/twisting with a rotational movement/pitch depen- L

dent on materials/often brought on by activity.

Rattle(Like shaking a baby rattle)

Rattle characteristics include the fast repeated contact/vibration or similar movement/loose parts/missing M

clip or fastener/incorrect clearance.

Knock (Like a knock on a door)

Knock characteristics include hollow sounding/sometimes repeating/often brought on by driver action.

Tick(Like a clock second hand) N

Tick characteristics include gentle contacting of light materials/loose components/can be caused by driver

action or road conditions.

Thump(Heavy, muffled knock noise) O

Thump characteristics include softer knock/dead sound often brought on by activity.

Buzz(Like a bumble bee)

Buzz characteristics include high frequency rattle/firm contact.

Often the degree of acceptable noise level will vary depending upon the person. A noise that you may judge P

as acceptable may be very irritating to the customer.

Weather conditions, especially humidity and temperature, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or location of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

Revision: July 2010 SE-5 2011 Sentra

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

< SERVICE INFORMATION >

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle twist.

5) At idle, apply engine load (electrical load, half-clutch on M/T model, drive position on CVT model).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

If it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, check ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follow the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area.To help pinpoint the source of the noise, use a listening tool

(Chassis Ear: J-39570, Engine Ear: J-39565 and mechanic's stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

removing the components in the area that you suspect the noise is coming from.

Do not use too much force when removing clips and fasteners, otherwise clips and fasteners can be broken

or lost during the repair, resulting in the creation of new noise.

tapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only tem-

porarily.

feeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the

noise.

placing a piece of paper between components that you suspect are causing the noise.

looking for loose components and contact marks.

Refer to SE-7, "Generic Squeak and Rattle Troubleshooting" .

REPAIR THE CAUSE

If the cause is a loose component, tighten the component securely.

If the cause is insufficient clearance between components:

- separate components by repositioning or loosening and retightening the component, if possible.

- insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or urethane

tape. A NISSAN Squeak and Rattle Kit (J-43980) is available through your authorized NISSAN Parts Depart-

ment.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

Always check with the Parts Department for the latest parts information.

The following materials are contained in the NISSAN Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100135 mm (3.945.31 in)/76884-71L01: 6085 mm (2.363.35 in)/76884-71L02: 1525

mm (0.590.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 5050 mm (1.971.97 in)/73982-50Y00: 10 mm (0.39 in) thick,

5050 mm (1.971.97 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 3050 mm (1.181.97 in)

FELT CLOTH TAPE

Used to insulate where movement does not occur. Ideal for instrument panel applications.

68370-4B000: 1525 mm (0.590.98 in) pad/68239-13E00: 5 mm (0.20 in) wide tape roll. The following

materials not found in the kit can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

Revision: July 2010 SE-6 2011 Sentra

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

< SERVICE INFORMATION >

SILICONE GREASE

Used instead of UHMW tape that will be visible or not fit. A

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

B

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR C

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle Troubleshooting INFOID:0000000006151529 D

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL E

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing F

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

G

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint H

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

SE

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the area with silicone, you will

not be able to recheck the repair. J

CENTER CONSOLE

Components to pay attention to include:

K

1. Shift selector cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit L

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the: M

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping N

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks from O

the NISSAN Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK P

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Revision: July 2010 SE-7 2011 Sentra

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

< SERVICE INFORMATION >

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the console panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the console at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lense loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Revision: July 2010 SE-8 2011 Sentra

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

< SERVICE INFORMATION >

Diagnostic Worksheet INFOID:0000000006151530

SE

LAIA0072E

P

Revision: July 2010 SE-9 2011 Sentra

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

< SERVICE INFORMATION >

LAIA0071E

Revision: July 2010 SE-10 2011 Sentra

HEATED SEAT

< SERVICE INFORMATION >

HEATED SEAT

A

Description INFOID:0000000006151531

When handling seat, be extremely careful not to scratch heating unit. B

Do not use any organic solvent, such as thinner, benzene, alcohol, etc. to clean trim.

G

WIIA0031E

SE

Revision: July 2010 SE-11 2011 Sentra

HEATED SEAT

< SERVICE INFORMATION >

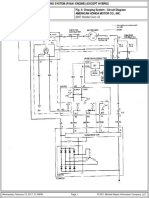

Wiring Diagram - HSEAT - INFOID:0000000006151532

ABJWA0204GB

Revision: July 2010 SE-12 2011 Sentra

HEATED SEAT

< SERVICE INFORMATION >

SE

ABJWA0203GB

Revision: July 2010 SE-13 2011 Sentra

FRONT SEAT

< SERVICE INFORMATION >

FRONT SEAT

Driver Seat INFOID:0000000006151533

AWJIA0535GB

1. Rear leg cover 2. Front mount washers 3. Seat assembly - SE-R

4. Seat cushion inner finisher 5. Seat cushion outer finisher 6. Seat belt buckle

7. Seat cushion trim 8. Seat cushion pad 9. Seat cushion heater

10. Seat cushion lower outer finisher 11. Seat cushion outer finisher 12. Lifter lever

13. Lifter lever cover 14. Reclining lever cover 15. Reclining lever

Revision: July 2010 SE-14 2011 Sentra

FRONT SEAT

< SERVICE INFORMATION >

16. Seat cushion outer finisher assembly 17. Seat cushion outer finisher 18. Reclining lever cover

with lift A

19. Reclining lever 20. Seat cushion outer finisher assembly 21. Seat assembly (except SE-R)

without lift

22. Headrest holder (lock) 23. Headrest holder (free) 24. Headrest B

A. Driver seat bolt - front B. Driver seat bolt - rear C. Retainers

Passenger Seat INFOID:0000000006151534

C

SE

O

AWJIA0536GB

1. Headrest assembly 2. Headrest holder (lock) 3. Headrest holder (free)

4. Seat assembly (except SE-R) 5. Seat cushion outer finisher 6. Reclining lever knob P

7. Lever cover 8. Seat belt buckle 9. Seat cushion inner finisher

10. Front mount washers 11. Seat assembly (SE-R)

Removal and Installation INFOID:0000000006151535

Removal

Revision: July 2010 SE-15 2011 Sentra

FRONT SEAT

< SERVICE INFORMATION >

WARNING:

When checking the seat circuit for continuity using a circuit tester, do not confuse its connector with

the side air bag module connector. Such an error may cause the air bag to deploy.

Before removing the front seat, turn the ignition switch off, disconnect both battery cables and wait

at lease three minutes.

CAUTION:

Do not drop, tilt, or bump the side air bag module while installing the seat. Always handle it with

care.

Front passenger seat is equipped with an Occupant Detection System sensor and control module.

Do not disassemble front passenger seat cushion assembly or remove the trim as this will affect the

Occupant Detection System calibration.

If the vehicle has been involved in a collision, the seat must be inspected for damage. Refer to SRS-

47, "For Frontal Collision".

When removing and installing the seat, use shop cloths to protect the vehicle from damage.

1. Disconnect the negative and the positive battery terminals and wait at least three minutes.

2. Disconnect the side air bag module harness connector.

3. Slide the seat until the four body mounting bolts are visible and a tool can be inserted.

4. Remove the four body mounting bolts.

5. Disconnect the seat harness connectors and remove the seat from the vehicle.

Installation

Installation in the reverse order of removal. Be careful of the following points.

Before the installation, confirm that the inside and outside slide rails are locked at the same positions.

Confirm that the slide rail location pin is set to the hole on the floor.

When installing the LH front seat tighten the bolts as shown.

LIIA2853E

When installing the RH front seat tighten the bolts as shown.

LIIA2854E

Disassembly and Assembly INFOID:0000000006151536

SEAT CUSHION TRIM AND PAD

Revision: July 2010 SE-16 2011 Sentra

FRONT SEAT

< SERVICE INFORMATION >

SE

BIIA0010E

1. LH seat 2. Seat cushion outer finisher 3. Lifter lever

J

4. Lifter lever cover 5. Reclining lever cover 6. Reclining lever

Clip C101

CAUTION: K

Front passenger seat is equipped with an Occupant Detection System sensor and control module.

Do not disassemble front passenger seat cushion assembly or remove the trim as this will affect the

Occupant Detection System calibration. L

During installation, the wire harness clips must be installed in the holes they were originally in. Do

not add additional clips.

When removing or installing the seat trim, handle it carefully to keep dirt out and avoid damage.

M

Disassembly

1. Remove seat. Refer to SE-15, "Removal and Installation" .

2. Remove the recliner lever and lifter level (if equipped). N

3. Remove the inner and outer front seat cushion finishers.

NOTE:

Remove the seat cushion lower outer finisher screw in order to remove the seat cushion lower outer finisher, if O

equipped.

Revision: July 2010 SE-17 2011 Sentra

FRONT SEAT

< SERVICE INFORMATION >

BIIA0009E

1. Seat cushion lower finisher screw Clip C101

4. Remove the air bag harness clips.

5. Remove the seat cushion retainers to separate the trim cover from the pad.

Assembly

Assembly is in the reverse order of disassembly.

Revision: July 2010 SE-18 2011 Sentra

REAR SEAT

< SERVICE INFORMATION >

REAR SEAT

A

Component Parts Drawing INFOID:0000000006151537

60:40 SPLIT FOLD DOWN SEAT B

SE

AWJIA0537GB

1. Headrest 2. Headrest holder (lock) 3. Headrest holder (free)

4. RH seatback frame 5. RH seat lock assembly 6. RH seatback trim

Revision: July 2010 SE-19 2011 Sentra

REAR SEAT

< SERVICE INFORMATION >

7. RH outer seat bracket 8. RH inner seat bracket 9. RH inner bracket cover

10. RH outer bracket cover 11. RH seatback trim 12. RH seat assembly

13. RH seat cushion assembly 14. RH seat cushion trim 15. RH seat cushion foam

16. RH seat cushion pad 17. RH seat cushion frame 18. Rear seat bracket assembly

19. LH seat cushion assembly 20. LH seat cushion trim 21. LH seat cushion foam

22. LH seat cushion pad 23. LH seat cushion frame 24. LH inner bracket cover

25. LH outer bracket cover 26. LH inner seat bracket 27. LH outer seat bracket

28. LH seatback pad 29. LH seat lock assembly 30. LH seatback frame

31. LH seatback trim 32. LH seat assembly 33. Cup holder

34. Armrest cover 35. Armrest

Removal and Installation INFOID:0000000006151538

CAUTION:

When removing and installing, use shop cloths to protect parts from damage.

60:40 SPLIT FOLD DOWN SEAT CUSHION

AWJIA0538GB

1. LH rear seat cushion 2. RH rear seat cushion

Removal

1. Lift up on the front of the LH and RH seat cushions and fold forward toward the front of the vehicle.

2. Push the cushion wires inward to disengage from the hinge brackets and remove the seat cushion.

Installation

Installation is in the reverse order of removal.

60:40 SPLIT FOLD DOWN RIGHT SEATBACK

Removal

Revision: July 2010 SE-20 2011 Sentra

REAR SEAT

< SERVICE INFORMATION >

1. Lift up on the front of the right seat cushion and fold forward toward the front of the vehicle.

A

AWJIA0539GB F

2. Remove the lower seatback mounting bolts from the right rear seat back brackets.

3. Slide rear seat back brackets toward the rear of the vehicle.

4. Lift the right seatback and remove from the vehicle. G

Installation

Installation is in the reverse order of removal.

H

60:40 SPLIT FOLD DOWN LEFT SEATBACK

Removal

1. Lift up on the front of the left seat cushion and fold forward toward the front of the vehicle. SE

AWJIA0540GB

2. Remove the lower seatback mounting bolts from the left rear seat back brackets.

3. Slide rear seat back brackets toward the rear of the vehicle.

4. Lift the left seatback and remove from the vehicle.

5.

Installation

Revision: July 2010 SE-21 2011 Sentra

REAR SEAT

< SERVICE INFORMATION >

Installation is in the reverse order of removal.

Disassembly and Assembly INFOID:0000000006151539

60:40 SPLIT FOLD DOWN SEAT ARMREST

AWJIA0541GB

1. RH rear seatback 2. Armrest cover

Disassembly of Armrest

1. Fold up the backside of the seatback and then remove the armrest cover.

2. Remove the armrest from the seatback.

Assembly of Armrest

Assembly is in the reverse order of disassembly.

Disassembly of Seatback Trim and Pad

1. Remove the headrest.

Revision: July 2010 SE-22 2011 Sentra

REAR SEAT

< SERVICE INFORMATION >

2. Remove the retainer under the back of seatback.

A

PIIB2486J

D

3.

4. Remove the headrest holder.

G

PIIB4084J

5. Remove the armrest. H

6. Remove the seatback trim.

7. Remove the seatback pad from the seatback frame.

Assembly of Seatback Trim and Pad SE

Assembly is in the reverse order of disassembly.

Before installing headrest holder, check its orientation (front/rear and right/left).

J

Disassembly of Seat Cushion Trim and Pad

Remove the hog rings to separate the trim and pad.

Assembly of Seat Cushion Trim and Pad

K

Assembly is in the reverse order of disassembly.

Revision: July 2010 SE-23 2011 Sentra

REAR SEAT

< SERVICE INFORMATION >

Component Parts Drawing INFOID:0000000006151540

FIXED BACK SEAT

WIIA1389E

1. Headrest 2. Headrest holder (lock) 3. Headrest holder (free)

4. Seatback frame 5. Seatback pad 6. Seatback trim

7. Seatback assembly 8. Seat cushion assembly 9. Rear seat cushion bracket assembly

10. Seat cushion trim 11. Seat cushion pad/frame A. Seatback frame bolts

Removal and Installation INFOID:0000000006151541

CAUTION:

When removing and installing, use shop cloths to protect parts from damage.

Revision: July 2010 SE-24 2011 Sentra

REAR SEAT

< SERVICE INFORMATION >

FIXED BACK SEAT CUSHION

A

Removal

1. Remove the rear seat cushion trim and pad.

Pull the lock at the front bottom of the seat cushion forward

B

(one for each side), and pull the seat cushion upward to

release the wire from the plastic hook, then pull the seat cush-

ion forward to remove.

C

SIIA0511E

E

Installation

Installation is in the reverse order of removal.

FIXED SEATBACK F

Removal

1. Remove the lower seatback bolts. G

2. Lift and remove fixed rear seatback from rear parcel shelf hanger.

Installation

Installation is in the reverse order of removal. H

SE

Revision: July 2010 SE-25 2011 Sentra

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Service Manual Common Rail System Isuzu 4HK1 6HK1Document48 pagesService Manual Common Rail System Isuzu 4HK1 6HK1vagpoul95% (148)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- ISUZU Truck Service Manual PDFDocument439 pagesISUZU Truck Service Manual PDFkaled ben abdallah67% (3)

- 4HK1 & 6HK1 ManualDocument352 pages4HK1 & 6HK1 Manuallionkinghd94% (104)

- Isuzu 6HK 1 Engine Fuel System CE Applications Rep Package 1 PDFDocument50 pagesIsuzu 6HK 1 Engine Fuel System CE Applications Rep Package 1 PDFVirgo100% (5)

- 4Hk1 6HK1 Engine Diagnostic and Drivability Student PDFDocument199 pages4Hk1 6HK1 Engine Diagnostic and Drivability Student PDFโจ้ สแปร์แร็ค92% (74)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- ISUZU 4HK1 6HK1 Type Engine PDFDocument48 pagesISUZU 4HK1 6HK1 Type Engine PDFЙОРДАН ГЕОРГИЕВ90% (21)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Nissan Rogue 2014 Service Repair ManualDocument4,971 pagesNissan Rogue 2014 Service Repair ManualAlex Hernandez100% (1)

- NPR MANUAL Y DIAGRAMA MOTOR ISUZU 729 - 4HK1 - Training PDFDocument121 pagesNPR MANUAL Y DIAGRAMA MOTOR ISUZU 729 - 4HK1 - Training PDFRoyert Salas96% (81)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- ISUZU N-Series 4HK1-manual-de-confianza-2Document34 pagesISUZU N-Series 4HK1-manual-de-confianza-2Alex Hernandez100% (6)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Body LOCK SECURITY SYSTEMDocument231 pagesBody LOCK SECURITY SYSTEMAlex HernandezNo ratings yet

- YD25 CR Fault Diagnosis PDFDocument101 pagesYD25 CR Fault Diagnosis PDFMaurihuaanaa Navarro Santana100% (6)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Nissan Patrol ZD30 Y61 Reference Document - ColourDocument129 pagesNissan Patrol ZD30 Y61 Reference Document - ColourIurie Maxim92% (12)

- Cooling System NISSAN B16Document56 pagesCooling System NISSAN B16Alex HernandezNo ratings yet

- DIAGNOSIS YD25ddtiDocument14 pagesDIAGNOSIS YD25ddtiAlex Hernandez100% (1)

- YD25 Engine MechDocument35 pagesYD25 Engine MechAlex Hernandez100% (2)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Emotional IntelligenceDocument5 pagesEmotional Intelligenceマリージョー 玄波楼No ratings yet

- Especificaciones Nissan ZD30 TD TERRANO II PDFDocument2 pagesEspecificaciones Nissan ZD30 TD TERRANO II PDFJefferson Humberto HerreraNo ratings yet

- ZD30 CRD 2008 1Document74 pagesZD30 CRD 2008 1powermanager96% (28)

- The AmazonsDocument18 pagesThe AmazonsJoan Grace Laguitan100% (1)

- Steering Control SystemDocument22 pagesSteering Control SystemAlex Hernandez100% (1)

- Nissan 2.4Document204 pagesNissan 2.4hectorgonzalezm100% (6)

- Blue Ocean Strategy: Case Study: Quick DeliveryDocument29 pagesBlue Ocean Strategy: Case Study: Quick DeliveryKathy V. Chua-GrimmeNo ratings yet

- 54 - Fuller FSO 6109A Transmission Service Manual PDFDocument134 pages54 - Fuller FSO 6109A Transmission Service Manual PDFJulio OrtegaNo ratings yet

- Denso CR - HP3 NissanDocument14 pagesDenso CR - HP3 NissanHerbert Sanchez75% (4)

- Digital Fabrication in Architecture PDFDocument192 pagesDigital Fabrication in Architecture PDFAndrada Iulia NeagNo ratings yet

- 3 - QMT425-T3 Linear Programming (29-74)Document46 pages3 - QMT425-T3 Linear Programming (29-74)Ashraf RadzaliNo ratings yet

- TestDocument21 pagesTestTri Arini TitisingtyasNo ratings yet

- Srs NISSAN SENTRA B16Document52 pagesSrs NISSAN SENTRA B16Alex HernandezNo ratings yet

- Introduction To The Philosophy of The Human PersonDocument21 pagesIntroduction To The Philosophy of The Human Personanon_254928515No ratings yet

- CASE ANALYSIS PretDocument4 pagesCASE ANALYSIS PretNate Dela CruzNo ratings yet

- Types of Communicative StrategyDocument46 pagesTypes of Communicative StrategyMyra Bolinas100% (1)

- Principles of Learning: FS2 Field StudyDocument8 pagesPrinciples of Learning: FS2 Field StudyKel Li0% (1)

- Fusileras Fuso 2012Document4 pagesFusileras Fuso 2012Alex HernandezNo ratings yet

- Wiper and Washer Nissan b16Document29 pagesWiper and Washer Nissan b16Alex HernandezNo ratings yet

- Service Manual: Group 14A CoolingDocument27 pagesService Manual: Group 14A CoolingAlex HernandezNo ratings yet

- Honda Civic LX 2007Document1 pageHonda Civic LX 2007Alex HernandezNo ratings yet

- Transfer Control UnitDocument6 pagesTransfer Control UnitAlex HernandezNo ratings yet

- 6M60 High Idle Test - EPA '07Document2 pages6M60 High Idle Test - EPA '07Alex HernandezNo ratings yet

- Brake System NISSAN B16Document51 pagesBrake System NISSAN B16Alex HernandezNo ratings yet

- Clutch NISSAN B16Document17 pagesClutch NISSAN B16Alex HernandezNo ratings yet

- Content 1. Knowing Oneself: Leyte National High SchoolDocument6 pagesContent 1. Knowing Oneself: Leyte National High SchoolMaria Theresa Deluna MacairanNo ratings yet

- Ratten V R (1974) HCA 35 (1974) 131 CLR 510 (25 September 1974)Document20 pagesRatten V R (1974) HCA 35 (1974) 131 CLR 510 (25 September 1974)Freya MehmeenNo ratings yet

- Tutorial-Midterm - CHEM 1020 General Chemistry - IB - AnsDocument71 pagesTutorial-Midterm - CHEM 1020 General Chemistry - IB - AnsWing Chi Rainbow TamNo ratings yet

- The Mind-Body ProblemDocument6 pagesThe Mind-Body ProblemCarlos Mendez PerezNo ratings yet

- Question Bank of Financial Management - 2markDocument16 pagesQuestion Bank of Financial Management - 2marklakkuMSNo ratings yet

- THE STUDY OF THE TESTIMONIES. - No. 1. A Series Presented at The 1893 General Conference Session by ELDER J. N. LOUGHBOROUGHDocument16 pagesTHE STUDY OF THE TESTIMONIES. - No. 1. A Series Presented at The 1893 General Conference Session by ELDER J. N. LOUGHBOROUGHKunedog1No ratings yet

- School Work - The Marriage CrisisDocument2 pagesSchool Work - The Marriage CrisisTreesy NgoNo ratings yet

- Lantolf Concept Based InstructionDocument16 pagesLantolf Concept Based Instructionphdreadings39No ratings yet

- The PowerDocument13 pagesThe PowerCamila PisaniNo ratings yet

- MMW SyllabusDocument13 pagesMMW SyllabusBien TecsonNo ratings yet

- Dwnload Full Social Psychology 4th Edition Gilovich Test Bank PDFDocument35 pagesDwnload Full Social Psychology 4th Edition Gilovich Test Bank PDFalilonghidotardlyq71i7f100% (8)

- Safety Awareness TrainingDocument20 pagesSafety Awareness TrainingPl nagappanNo ratings yet

- Simplified Analysis of 'Out, Out' - Robert FrostDocument3 pagesSimplified Analysis of 'Out, Out' - Robert FrostSANDREA RUTHNo ratings yet

- Presentation 1Document7 pagesPresentation 1Funio KhanNo ratings yet

- 03 9609 12 MS Prov Rma 08022023111718Document18 pages03 9609 12 MS Prov Rma 08022023111718Kalsoom SoniNo ratings yet

- TIFR Pamphlet On Homological MethodsDocument105 pagesTIFR Pamphlet On Homological MethodsRAMJANNo ratings yet

- AP Macroeconomics: About The Advanced Placement Program (AP)Document2 pagesAP Macroeconomics: About The Advanced Placement Program (AP)Adam NowickiNo ratings yet

- 2020-08-17 WITS - MECN 5005A - Systems MGMT - Lecture 2 of 8 - SharedDocument73 pages2020-08-17 WITS - MECN 5005A - Systems MGMT - Lecture 2 of 8 - SharedUnarine MutshinyaloNo ratings yet

- 308 MSR Folktale Sir CedricDocument3 pages308 MSR Folktale Sir Cedricapi-242415607No ratings yet

- Evaluation Sheet For RankingDocument6 pagesEvaluation Sheet For RankingSonny MatiasNo ratings yet