Professional Documents

Culture Documents

MSDS

Uploaded by

ramod100%(1)100% found this document useful (1 vote)

1K views26 pagesSDS

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSDS

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

100%(1)100% found this document useful (1 vote)

1K views26 pagesMSDS

Uploaded by

ramodSDS

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 26

Material Safety Data Sheet

DIESEL FUEL No. 2

Product Use: Fuel

Product Number(s): CPS203410 [See Section 16 for Addtional Product Numbers]

Descl Oreo tel Fuel 2, Altemative Low Aromatic Diesel (ALAD), Caleo LS Diesel 2, Calco ULS DF2, Caleo ULS

Company Identification

Chevron Products Company

Marketing, MSDS Coordinator

6001 Bollinger Canyon Road

‘San Ramon, CA 94583,

United States of America

‘Transportation Emergency Response

CHEMTREC: (600) 424-9900 or (703) 527-3887

Health Emergency

Sor cse ne*aeney Information Center; Located inthe USA. Intemational collect cals accepted. (200) 231-0629 or (610)

231-0623

Product Information

MSDS Requests: (800) 689-2998

Technical information: (510) 242-5357

Tan oom oes: his MOS covers all Chevron and Calco non-CARB Diesel No. 2Fuels. The sulfur content less

than 0.5% (mass), Red dye is added to nor-taxable fuel. (MSOS 6864)

[sections conPasionrmronwaTion on NoREDENTS

64742-80-9

| COMPONENTS

Kerosine

Kerosine, hydrodesulturized

Distilates (petroleum), ight catalytic cracked

Naphthalene

Total sultur None

{[seorions HazaRos menTiricaTion

EMERGENCY OVERVIEW

- COMBUSTIBLE LiQUID AND VAPOR

- HARMFUL OR FATAL IF SWALLOWED - MAY CAUSE LUNG DAMAGE IF SWALLOWED

- CAUSES SKIN IRRITATION

= MAY CAUSE CANCER BASED ON ANIMAL DATA

IMMEDIATE HEALTH EFFECTS

Eye: Not expected to cause prolonged or significant eye irritation

aac onract wrth the skin causes iritation. Skin contact may cause crying or defating of the skin. Symptoms may

include pain, itching, discoloration, sweling and bistering. Contact with the skin is not expected to cause an alergie skin

Fesponse. Not expecied to be harrnful to internal organs if absorbed through the skin.

Oaeston: Because ofits low viscosty, this material can directly enter the lungs, if swalloned, or if subsequently vomited.

Qice inthe lungs its very diffcut to remove and can cause severe injury or death. May be irritating to mouth, throat, and

stomach, Symptoms may inciude pain, nausea, vomiting, and diarthea

tnataon: MBs ofthis material may cause respiratory imtation. Symptoms of respiratory eration may include coughing

and difficulty breathing,

DELAYED OR OTHER HEALTH EFFECTS:

yy Cause cancer. Whole diesel engine exhaust has been

classified as @ Group 2A carcinogen (probably carcinogenic to humans) by the Intemational Agency for Research oh

Cancer (IARC). Diesel exhaust particulate has been classified as reasonably anticipated to be a human carcinogen inthe

National Toxicology Program's Ninth Report on Carcinogers. The National Institute of Occupational Safely snd Health

(NIOSH) has recommended that whole diesel exhaust be regarded as potentially causing cancer. Diesel engine exhaust

) fs known to the State of Calfornia to cause cancer. Contains naphthalene, which has been classified as a Group 2B

carcinogen (possibly carcinogenic to humans) bythe Intemational Agency for Research on Cancer (IARC),

See Section 11 for additional information. Risk depends on duration and level of exposure.

SECTION 4 FIRST AID MEASURES ]

Eye: No specific first aid measures are required. Asa precaution, remove contact lenses, if wom, and flch eyes with

water

Sidr: Wash skin vith water immediately and remove contaminated eiothing and shoes. Get medical attention i ny

sympioms develop. To remove the material rom skin, use soap and water, Discard contaminated elothing and chess or

thoroughly clean before reuse.

Ingestion: if swallowed, get immediate medical attention, Do not induce vornting. Never give anything by mouth to an

unconscious person.

{nhalation: Move the exposed person to fresh at. not breathing, give artical respiration. Ifbreathing is diffcuk, give

oxygen. Get medical attention if breathing difficulties continue,

Tots fo Physicians: Ingestion ofthis preduct or subsequent vomiting may result in aspiration of ight hydrocarbon quid,

which may cause pneumonitis,

SECTION SRE Flo}TiNe REASURES l

‘See Section 7 for proper handling and storage.

FIRE CLASSIFICATION:

OSHA Classification (29 CFR 1910, 1200): Combustible liquid

NFPA RATINGS: Health: 0 Flammability: 2 Reactivity: 0

FLAMMABLE PROPERTIES:

Flashpoint: (Pensky-Martens Closed Cup) 52°C (125 °F) (Min)

Autoignition: 257 °C (494 °F)

Flammability (Explosive) Limits (% by volume in air): Lower: 0.6 Upper: 4.7

EXTINGUISHING MEDIA: Use water fog, foam, dry chemical or carbon dioxide (CO2) to extinguish ames

PROTECTION OF FIRE FIGHTERS:

Fite Fighting Instructions: For fires involving tis material, do not enter any enclosed or confined fre space without |

proper protective equipment, including self-contained breathing apparatus,

Combustion Products: Highyy dependent on combustion conditions. A complex mixture of airbome solids, liquids, and

gases including carbon monoxide, carbon dioxide, and unidentified organic compounds will be evolved when nis rate al

Protective Measures: Eliminate all sources of ignition in the vicinly of the spill or released vapor. If this material is

{eleased into the work area, evacuate the area immediately, Monitor area with combustible gas incicator,

vath applicable regulations,

Roporing: Report spils to local authorities andiorthe U.S. Coast Guard's National Response Center at (800) 424-8002

238 appropriate or required.

SECTION 7 HANDLING AND STORAGE ]

Fprecattionary Measures: Liquid evaporates and forms vapor (furies) which can catch fre and bara wil Siplosve force

CGE vapor Spreads easily and can be set on fre by many sources such as pilet lights, welding equipment ana

electrical motors and switches. Fire hazard is greater as liquid temperature rise above 200 (8579

Pac, Betin eyes, on skin, or on clothing. Do not taste or swallow. Do not breathe vapor or fumes, Do not breathe mist

‘Wash thoroughly after handling. Keep out of the reach of children,

gsuay Handling Hazards: WARNING! Do not use as portable heater or appliance fue. Toxic umes may accumulate

and cause death.

Serer flandling Information: Avoid contaminating sell o releasing this material nto sewage and crainage systems

and bodies of water.

Static Hazard: Eleciostatc charge may accumulate and create a hazardous conkition when handling this material. To

Inininize this hazard, bonding and grounding may be necessaty but may not, by themselves, be sulfiient, Revs al

erations which have the potential of generating and accumulating an electrostatic charge andlor 2 flarmnotie

aanleg mare lie tank and container ling, spash fling, tank cleaning, samping, gauging, suftch loading, tering,

Beige Gatation, and vacuum truck operations) and use appropriate mitgating procedures. Fat more informon velo io

Recor Peck 1210.166, Flammatie and Combustible Liquids’, Nalicnal Fire Protection Assocation (NFPA 77,

erommenced Practice on Sialic Electricity, andor the American Petroleum Institute (API) Recommended Prectice

2003, Protection Against Ignitions Arising Out of Static, Lightning, and Stray Currents.

Say at alae Information: DO NOT USE OR STORE near hest, sparks, lames, or hot surfaces . USE AND STORE

ONLY IN WELL VENTILATED AREA, Keep container closed when not in use.

raphe ath regs: Container is nt designed to contain pressure. Do nat tse pressure to empty container ori may

Bene ih explosive force. Empty containers retain product residue (soi, Iquid, and/or vapor) ad can be dangers

Do net pressurize, ut, weld, braze, solder, dil grind, or expose such containers to heat, lame, sparke, state electricity,

oF other sources of ignton. They may expiode and cause injury or death. Empty containers chould be completely hero

lo and promptly retumed to a drum reconditioner or disposed of properiy,

SEcTONs EXPOSURE CONTROL PERSONAL PROTECTION j

GENERAL CONSIDERATIONS:

Consider the potential hazards ofthis material (see Section 3), applicable exposure limits, job activities, and other

Substances in the work place When desigring engineering controls and selecting personal protective ecuipmnert If

engineering controls or work practices are not adequate to prevent exposure to harmful levels of this meter the

oreanal pretecive equipment listed below is recommended. The user should read and understand all insttuctons and

limitatons supplied with the equipment since protection is usually provided for a limited time or under ceriain

circumstances.

ENGINEERING CONTROLS:

Use Process enclosures, ooal exhaust ventilation, or other engineering controls to control airborne levels below the

ecommended exposure limits.

PERSONAL PROTECTIVE EQUIPMENT

mieraeee, Protection: No special eye protections normally required. Where splashing is possible, wear safely glasses

with side shields as a goad safety practice.

Soro toe On; Wea pictecve clothing to prevent skin contact. Selection of protective clothing may Include gloves,

apron, bodte. and complete facial protection depending on operations conducted. Suggested materals fr polcane

loves clude: Viton, Chlorinated Polyethylene (or Chiorosulfonated Polyethylene), Nile Rubber, Polyuretrone

a peson Protection: Determine if airzome concentrations are below the recommended occupctional exposcre its

fot jurediction of use. if airborne concentrations are above the acceptable limits, wear an approved resprates har

Provides adequate protection from this material, such as: Air-Purilying Respirator for Organie Vapors

When used as a fuel. this material can preduce carbon monoxice in the exhaust. Determine if airborne concentrations are

below the occupational expesure limit for carbon monoxide. Ifnot, wear an approved positive-pressure si-suppiying

respirator.

ss 2 postive pressure alt-supplying respirator in circumstances where air-purifying respirators mey not provide adequate

protection.

Occupational Exposure Limits:

Component gency TWA sree [ealing —JNowaton

Dios Fuel Naz cs fioomgmd E Skin AS wil

ycrocaroon

Giese Fusl Ne ix C fooomgrns Ee

Kercsne jaca! froomams F Ista AS Tour

scrocabon

Veecare [eux E fooomarns = E

stone, pyaedesatrsed accnt Tom Stn Tor

vetocabon

apo

Raresin,Fycrosenased our fcoo mgs -

Naprrsions — So pom weg |S ppm weigh Ben

Napihelene Pesta Zoo main E E

SECTION 9 PHYSICAL AND CHEMICAL PROPERTIES :

Attention: the data below are typical values and do not constitute a specification.

Color: Varies depending cn specification

Physical State: Liquid

Odor: Petroleum odor

pH: Not Applicable

Vapor Pressure: 0.04 kPa (Approximate) @ 40°C (104 °F)

Vapor Density (Air =): >1

Boiling Point: 175.6°C (S48"F) - 370°C (66°F)

‘Solubility: Soluble in hydrocarbons; insoluble in water

Freezing Point: Not Applicable

Melting Point: Not Applicable

Specific Gravity: 0.8 - 0.88 @ 15.6°C (60.1°F) (Typical)

Viscosity: 1.9 cSt 4.1 cSt @ 40°C (104*F)

SECTION 0 STABILITY AND REACTHTTY ]

Chemical Stability: This meteralis considered stable under normal amblent and antoipated storage and hancling

cconditions of temperature and pressure.

Incompatibility With Other Materials: May react wth strong acids or strong oxidizing agents, such as chlorates, nitrates,

peroxides, etc!

Hazardous Decomposition Products: None known (None expected)

za Peyaaton, aces smctenin lao oe

IMMEDIATE HEALTH EFFECTS

Eye Irritation: The eye iration hazard is based on evaluation of data for similar materials or product components

‘Skin Ititation: The skin lation hazard is based on evaluation of deta for similar materials of product componente,

‘Skin Sensitization: This material cid not cause skin sensitization reactions in a Buehler guinea pig tose

Acute Dermal Toxicity: LD50: >SmVkg (rabbit)

Acute Oral Toxicity: LD50: > 5 mi/kg (rat)

Acute Inhalation Toxicity: 4 hour(s) LC50: > Srl (rat).

ADDITIONAL TOXICOLOGY INFORMATION:

This product contains gas ois.

CONCAIWE (product dossier 95/107) has summarized current healt, safety anc environmental deta avaliable for a

‘umber of gas ois, tyeically hycrodesuifurized middle dstilates, CAS 64742-80-9, straight-1un middle distllates, CAS

£t741-44-2, andlor light catcracked distilate CAS 64741-59-9. CARCINOGENICITY: All materials tested have caused

{he development of skin tumors in mice, but all estured severe skin initation and sometimes a long latency period befere

lumers developed, Straight-run and cracked gas oil samples were studied to determine the influence of dermal initaisn

on ihe carcinogenic acivty of middle cstilates. At non-irrtant doses the straight-run gas oil was nat carcinogenic, but at

ete ease eieak actly was demonstrated, Cracked gas oils, wtien diluted with mineral oll demonstrated carcinogenic

activity inespective of the occurrence of skin initalion. Gas ols were tested on male mice to study tumor

initlating/promoting activity, The results demonstrated that while a straight-run gas oll sample was nelther an initiator ot

Promotor, a blend of straight~run and FCC stock was both a tumor initiator and a promoter

GENOTOXICITY: Hydrotrected & hydrodesulfurzed gas olls range in actvty trom inactive to weakly positive in in-vitro

bacterial mutagenicity assays. Mouse lymphoma assays on straightrun gas oils without subsequent

fGredesulphurzetion gave posiive results inthe presence of S@ metabolic activation. In-vivo Bone marrow cytogenetics

and sister chromatic exchange assay exhibited no activity for straight-tun components with or without

‘This product contains naphthalene,

GENERAL TOXICITY: Exposure to naphthalene has been reported to cause methemoglobinemia and/or hemolytic

arma. eepecialy in humans defcient inthe enzyme glucose-6-phosphate dehydrogenase. Laboratory animale given

‘epeated oral doses of naphthalene have developed cataracts. REPRODUCTIVE TOXICITY AND BIRTH DEFECTS

eae oa-Tot cause bith defects when administered orally to rabbits, rats, anc mice during pregnancy, but sightly

{euiced Iter size in mice at dose levels that were lethal to the pregnant females. Naphthalene has been reported to oes

‘the human placenta,

GENETIC TOXICITY: Naphthalene caused chromosome aberrations and sister chromatid exchanges in Chinese hamster

‘ovary ces, but was not a mutagen in several other in-vitro tests,

CARCINOGENICITY: In a study conducted by the National Toxicology Program (NTP), mice exposed to 10 or 20 ppm of

paphihalene by inhalation daily fortwo years had chronic inflammation of the nose and lunge and increased inckderocs of

inctaplasia in those tissues. The incidence of benign lung tumors (alveolarforonchiolar adenomas) was significa ty

{pezeased in the high-dose femate group but not inthe male groups. In another two-year inhalation study cancer by

[ecehing naphthalene at 41 mg/kg/day. This product may contain significant amounts of Polynucleer Aromatic

Hycrecatbone (PAHs) which have been shown to cause skin cance’ after prolonged and frequent contact with the ekin of

{est animals. Brief or intermittent skin contact with this product is not expected to have serious effects iit ie washed from,

crease le skin cancer is unlikely to occur in human beings following use ofthis produc, skin contact and breathing,

Of mists, vapors or dusts should be reduced to a minimum.

[[seenow 2 ecovosicaL nFORMATION ]

EcoToxiciry

48 how's) EC50: 20-210 mgfl (Daphnia magna)

98 hour(s) LC50: 21-210 mgil (Salmo gairdneri)

72 hour(s) EC90: 2.6.25 mg/l (Raphidocellus subeapitata)

ENVIRONMENTAL FATE

On release to the environment the lighter components of diesel fuel wil generally evaporate but depending on local

fnionmental conditions (temperature, wind, mixing or wave action, sol ype, etc) the remainder may beoome dispersed

in the water colurm or absorbed to soll or sediment. Diesel fuel would not be expected to be readlly biodegradable in

Fe Dean emt CECO method 3018} appromataly 4% bladearadation was teccided over 28 days. Hovever

Se oer, mown that most hyerocarbon comporents of diesel fuel are degraded in sollin ihe precence cf oxygen, Under

jiaefobic condtions. such as in anoxic sediments, rates of biodegradation are negligible.

[section 13 oisrosaL consipeRaTions ‘J

fe material fois intended purpose or recycle i posse, This maori, it must be dscarded, may meet he orteria of

2 fazatcous waste as defined by US EPA under RCRA (40 CFR 261) rater State an ecal agus at

cera physical properties and analysis for regulated components may be necessary to makes coroner

foe nett lasses as ahazarcous wat, federal aw requten depos at loeroed ezarioes sess

facility. He

[ection 7a TRANSPORT INFORMATION

‘Fhe gesctption shown may not apply to al shipping situations. Consutt 49CFR, or appropriate Dangerous Goods

Regulations, for acktional description requirements (e.g, technical name) and mode speci ‘or quantity-specific shipping

requirements,

DOT Shipping Description: UN1202, GAS OIL, COMBUSTIBLE LIQUID, It

IMO/MDG Shipping Description: UN1202, GAS OIL, 3, II, FLASH POINT SEE SECTION 5

ICAOIATA Shipping Description: UN1202, GAS OIL, 3, Ill

[SECTION 15 REGULATORY INFORMATION J

EPCRA 311/312 CATEGORIES: 1. Immediate (Acute) Health Etfects: YES

2. Delayed (Chronic) Health Effects: YES

3. Fire Hazard: YES

4, Sudden Release of Pressure Hazard: NO

5. Reactivity Hazard: NO

REGULATORY LISTS SEARCHED:

OT-I=IARC Group 1 O3-EPORA 313

O1-2A=IARC Groun 24 ‘CA Proposition 65

01-28-IARC Group 28 O52MA RTK_

(O2=NTP Carcinogen OB=NU RTK.

O7=PA RTK.

‘The following components of this material are found on the regulatoy lists indicated.

Diesel Fus! No. 2 07

Distilates, straight run middle (gas oil light) 08

Kerosine 05, 06, 07

Naphthalene 01-28, 02, 03, 04, 05, 06, 07

THRESHOLD PLANNING quaNTITEs(rPq):

[eengenenttea —Yeroduct na —]

[ess56 ks

CHEMICAL nwveNToRIES:

(eucomponents comply withthe folowing chemical inventory requirements: AICS (Austrata}, DSL (Canada), EINECS

(European Union), IECSC (China), KECI (Korea), PICCS (Phippines), TSCA (Lite States)

CERCLA REPORTABLE Qual

[Naptinatene

NEW JERSEY RTK CLASSIFICATION:

Refer o components listed in Section 2. Under the New Jersey Righto-Know Act L. 1963 Chapter 318 Nu SA. 34584

et. Seq, the produc is to be identified as follows: DIESEL FUEL

WHMIS CLASSIFICATION:

Class 8, Division 3: Combustible Liquids

Class D, Division 2, Subdivision A: Very Toxic Material -

Carcinogenicity

Cass 0, Division 2, Subdivision 8: Toxic Material -

‘Skin or Eye Irritation

[atone omen nronmation j

NFPA RATINGS: Health: 0 Flammability. 2 Reactivity: 0 a

{Greact 1 Slight, 2 Moderate, 3 High, 4-Extreme, PPE:~ Personal Protection Equipment index recommendation, *

Nate Sted! Indicator), These values are obtained using the guidelines or published evaluations prepared bythe

NNatlenal Fire Protection Association (NFPA) or the National Paint and Coating Association (fr HMIS ratings)

esr oduct Number(s): CPS209413, CPS203417, CPS220122, CPS225114, CPS225115, 0PS225150,

GP S275008, Seen 0009. CPS270008, CPSZ7E094, CPS370095, CPS270056, CPS27 1006, CPS372000, CPS272007,

Seer ange Soee 2008, CPS272010, CPS272011, CPS272012, CPS272013, CPS272083, CPS2/2102, CPS2/O126,

CP Sa alan Sosa gtBs. CPS272190, CPS272195, CPS272593, CPS272601, CPS272603, CPS2/2793, CPS27 3008,

(CPS273030, CPS273053, CPS275000

REVISION STATEMENT: This revision updates the following sections ofthis Material Safety Data Sheet: 4,2, 16

Revision Date: March 21, 2008

ABBREVIATIONS THAT MAY HAVE BEEN USED IN THIS DOCUMENT:

Ly Threshold Limit Value VA Time Weighted Avera

[STEL- Short-term Exposure Limit [PEL - Permissible Exposure Limit

(8 = Chemical Abstact Service Number

NFPA — National Fire Protedion Association (USA)

OT _Dopariment of Transportaten (USA) INTP — National Toxicology Program (USA

PARC eeratonal Agency for Resear on Cancer [OSHA = Ocmupatonal Safely ane Heath AGrincraton

Pgpared according to the OSHA Hazard Communication Standard (29 CFR 1910.1200) and the ANSI

MSDS Standard (2400.1) by the Chevron Energy Technology Company, 100 Chevron Way, Richmond,

California 94802,

The above information is based on the data of which we are aware and is believed to be correct as

Of the date hereot. Since this information may be applied under conditions beyond our control and

i athich wa may be unfamiliar and since data made available subsequent tothe date hereo! may

Cuggest modifications of the information, we do not assume any responsibilty for the results of he

MATERIAL SAFETY DATA SHEET

COMMERCIAL NAME : BITUBOARD

1, PRODUCT AND COMPANY IDENTIFICATION

Produced / Distributed by: Henkel Polybit Industries Led,

P.0.Box; 293, Umm Al Quwain.

United Arab Emirates,

Tel: 1971 6 7670777, Fax: +971 6 7670197

e-mail: pol pit.e

ww he it

COMPOSITION / INFORMATION ON INGREDIENTS

Chemical Composition WI % CAS No.

Bitumen 65-70 64742-93.4

Polymer 3-12 95751

Calcium carbonate 22.27 1317-65.

Fibre glass mat <2 65997-17-3

Polyethylene film <1 N/A

3. POTENTIAL HAZARDS

Inhalation In ease of extreme exposure to fumes, irritation of upper respiratory tract,

coughing and congestion may occur.

Skin ‘Temporary itching or redness may oceur.

Absorption NA.

Ingestion ingested, irritation of the gastrointestinal tract may occur.

‘Medical conditions ENA,

Aggravated by exposure

FIRST AID MEASURES

Bye contact Do not rub or scratch. Dust particles may cause the eye to be scratched

‘Wash eyes with copious amount of water for several minuten if intitaton

persists, seek medical attention,

Skin contact + Remove contaminated clothes immediately. Wash affected arca with soap &

plenty of water. If irritation occurs, obtain medical attention.

Inhalation Remove affected person to fresh air. Drink water to clear throat and blow nose

to remove dust. If symptoms persist obtain medical attention,

Ingestion : If swallowed obtain medical attention immediately,

FIRE FIGHTING MEASURES

Fight Fire With DOP/Foam/COz

Emits CO, CO2, Carbon Particles,

Further information ‘Burning of this material will produce thick black smoke. Use respiratory

protection for fire fightin

‘ACCIDENTAL RELEASE MEASURES

Containment Procedures Pick up large pieces. Vacuum dust. Ifsweeping is necessary, use dust

Suppressant such as water. Do not dry sweep dust accumulation,

Environmental Precautions _: Wastes are not hazardous as defined by the resource conserwanney and

recovery act

7, HANDLING & STORAGE

Storage ‘Store in shaded areas and away from direct sunlight. Protect from extremes of

temperature. Keep containers tightly closed and dry.

Handling ‘There is no health hazards associated with normal Usage. Use protective tools

such as gloves and goggles with side shields while handling to avold anjusy,

‘3. EXPOSURE CONTROLS / PERSONAL PROTECTION

Personal Protective equipment

Respiratory protection Use Ori-nasal respirator ifproduet required in confined spaces,

Bye protection : Safety goggles with side shields,

‘Skin protection : Impervious gloves.

Industrial Hygiene Wash hands before breaks and after finishing work,

ST ATIATTLA

3.

MATERIAL SAFETY DATA SHEET BITUBOARD

PHYSICAL AND CHEMICAL PROPERTIES

Form + Solid

Color Dark Mat surfaced with PE film.

Odour Typical.

Bolling point, °C > 300

Melting point, °C 15105

Freezing Point, °C NA

Flash Point, °C NA,

Autoflamibility, °C None.

To.

Rate of Burning

Specific Gravity at 25°C

Not Determined,

LI2-1.14

Vapour Pressure, KPa at 20°C: N/A

Ph value Na,

Solubility in water Nil.

Voc < 50g/L,

‘STABILITY AND REACTIVITY

Stability : Stable.

Chemical stability Avoid direct exposure to very high heat or flame or solvents,

Incompatibility Strong oxidizing agents, reducing agents, strong solvents, strong acids & alkalis.

Hazardous decomposition Decomposition mainly derived from ageing or burning of the prockicts, Thess

INFORMATION ON TOXICITY

decomposition products may inelude carbon monoxide, carbon dionide,

carbon particles and hydrocarbons,

in

‘This product is Non-toxic

‘2, INFORMATION ON ECOLOGICAL EFFECTS ——————————————————___

Mobility

Bio-accumulative Potential

Non mobile solic,

Data not available.

Bco-toxicity : Date not available.

Acute Toxicity : Data not available

13. DISPOSAL

Disposal Use licensed waste disposal contractors ard consult local authority when

disposing of this product.

14 TRANSPORT

“This product is classified as non hazardous for transport,

18 REGULATIONS

Labeling, According to EEC directives concerning preparation. ~ N/A

Symbol Non Flammable

RPhrase(s)

S Phrase (s]__$36/37/39_: Wear suitable protective clothing, gloves and eye/ face protection,

16. FURTHER INFORMATION; Please contact

PRODUCT MANAGER

Tel: +971 6 7670777

Fax: +971 6 7670197

Specie prods gre based on our present imowidge. However, they shall not constitute a guarantee for any

‘specific product features and shell not establish a legally valid comtractual relationship

Date: 22/01/2012

MATERIAL SAFETY DATA SHEET

COMMERCIAL NAME

Produced / Distributed by

: BITUSTICK

PRODUCT AND COMPANY IDENTIFICATION

Henkel Polybit industries Ltd,

P.O.Box: 293, Umm Al Quwain,

United Arab Emirates.

‘Tel: +971 6 7670777, Fax: +971 6 7670197

e-mail: polvbit@henicelpovbitcom

sexy hencepolybit come

COMPOSITION / INFORMATION ON INGREDIENTS

Chemical Composition Wr % CAS No.

Bitumen 65-70 8052-42.4

Styrene Butadiene Styrene B11 ‘9003-55-8

Mineral Oil 10-12, 6474.96-4

Resin 35 64742-16-1

Anti-Oxidants <1 00128-37-0

HDPE film 8.18 N/A

3. POTENTIAL HAZARDS.

Inhalation + In case of extreme exposure to fumes, irritation of upper respiratory tract,

coughing & congestion may occur.

Skin ‘Temporary itching or redness may occur,

Absorption NA.

Ingestion : If ingested, iritation of the gastrointestinal tract may occur.

Medical conditions NA,

@&___ FIRST AID MEASURES

Bye contact :Do not rub or scratch. Dust particles may cause the eye to be scratched.

Wash eyes with copious amount of water for several minutes. Ifiritation

persists, seek medical attention,

‘Skin contact + Remove contaminated clothes immediately. Wash affected area with soap &

plenty of water. If critation occurs, obtain medical attention,

Inhalation : Remove affected person to fresh air. Drink water to clear throat é blow nose to

remove dust. If symptoms persist obtain medical attention,

Ingestion + If swallowed obtain medical attention immediately. Induce vomiting only on the

advice of physician,

5. IN EVENT OF FIRE

Fight Fire With DCP/Foam/Cos

Bmits # CO, COs, Carbon Particles,

Further information

Use respiratory protective equipment for fighting fire

&.___ ACCIDENTAL RELEASE MEASURES

Containment Procedures

Environmental Precautions

HANDLING & STORAGE

“Technical Protective Measures

Handling

ick up large pieces. Vacuum dust. If sweeping is necessary, use dust

suppressant such as water, Do not dry sweep dust accumulation,

+ Wastes are not hazardous as defined by the resource conservation & |

recovery act.

+ Store in shaded areas & away from direct sunlight. Protect from extremes of

temperature. Keep containers tightly closed and dry.

‘There is no health hazards associated with normal usage. Use protective tools

such as gloves & goggles with side shields while handling to avoid injury.

‘8. EXPOSURE CONTROLS / PERSONAL PROTECTION

Personal Protective equipment

Respiratory protection

Eye protection

Skin protection

Industrial Hygiene

i Wash hands before breaks end after finishing work,

+: Use Ori-nasal respirator if product required in confined spaces.

# Safety goggles with side shields,

Impervious gloves.

Sa

MATERIAL SAFETY DATA SHEET BITUSTICK

9. PHYSICAL AND CHEMICAL PROPERTIES

Form Solic

Color Dark.

Odor : Characteristic.

Boiling point, °C £5300

Melting point, °C 2> 105

Flash Point, °C NA

‘Autoflamibility, °C : None.

Rate of Burning, : Not Determined,

Vapor Density NA.

Specific Gravity at 25°C 1.02-1.03

Vapor Pressure, KPa at 20°: N/A

Ph value NAL

Solubility in water Nil.

voc < 50g/L.

10. STABILITY AND REACTIVITY

Stability : Stable.

Chemical stability Avoid direct exposure to very high heat or flame or solvents,

Incompatibility : Strong oxidizing egents, reducing agents, strong solvents, strong acids & alkalis,

Hazardous decomposition + Decomposition mainly derived from ageing or burning of the products. ‘Thess

decomposition products may include carbon monoxide, carbon dioxide, carbon

Particles & hydrocarbons.

Ti. INFORMATION ON TOXICITY

‘This product is Non-toxic.

12. INFORMATION ON ECOLOGICAL EFFECTS

Mobility Non mobile solid

Bio-accumulative Potential _: Non Bio degradable

Eco-toxioity Not eco-friendly.

Acute Toxicity Not Toxic.

3. DISPOSAL

Disposal + Use licensed waste disposal contractors and consult local authority when

disposing.

14 TRANSPORT

‘This product is classified as non hazardous for transport.

15 REGULATIONS

Labeling Non Hazardous

‘Symbol Non Flammable

RPhrase(s)

S Phrase (s|__$96/37/39_: Wear suitable protective clothing, gloves and cye/face protection.

16. FURTHER INFORMATION: Please contact

PRODUCT MANAGER

‘Tel: +971 6 7670777

Fax: +971 6 7670197

The above data are based on our present Imowledge, However, they shall not constitute a guarantee for any

specific product features and shall not establish a legally valid contractual relationship,

Date: 22/01/2012

MATERIAL SAFETY DATA SHEET

COMMERCIAL NAME : BITUBOND N

L PRODUCT AND COMPANY IDENTIFICATION

Produced / Distributed by Henkel Polybit Industies Li.

P.O.Box: 293, Umm Al Quwain,

United Arab Emirates,

‘Tek +971 6 7610777, Fax: +971 6 7670197

e-mail polybitemiratenetae

seu henna

2 COMPOSITION / INFORMATION ON INGREDIENTS

Chemical charactezation etic robber with mineral extender, somatic solvent, aliphatic solvent

CASNo. + 108-883 Aromatic Solvent

141-78-6 Aliphatic Solvent

Synthetic Rubber Not Required

Hazardous ingredients Contain,

3. POTENTIAL HAZARDS

Hazards Information Cosrosive, Causes burns. Harmful by inhalation in contact with skin and if swallowed

4 FIRST AID MEASURES

Bye contact ‘Wath ees with copious amount of water for several inate. [fission pes, seek

sedical ateation

Skin contact Remove contaminated clothes immediatly. Wash affected aren with soap & plenty of

vate. Ifinitacon occurs, obtain medical attention.

Inhalation + Remove affected person to fesh ai. If symptoms persist obtain medical attenon,

Ingestion : Do not induce vomiting. Obtzin medical atention immediately.

5.__ FIRE FIGHTING MEASURES

Soitable Extinguishing media Carbon dioxide, dey powder, foam and water.

Not to be used

Combustion pzoduets

Further information

© ACCIDENTAL RELEASE MEASURES

‘Af spillage leakage + Absocb with suiable matecl lke sand, eat, Seal in plastic bag & bug in land, Flash

Contaminated ares with plenty of water.

Ta adeition please ef to local regulations for dispose.

7. HANDLING & STORAGE

Storage Keep contuiness tightly closed and dey. Store between +5° C to 425°C. Storein

conformity with lal fie cegulstons

Handling Mainsin god standards of pesonal hygiene. Use in well ventilated sree to avid vapour

ames, Suitable respiatony equipment should be worn when working in cloves

Provection aginst fice & explosion _: No particular measuses cequiced,

8 _-EXPOSURE CONTROLS / PERSONAL PROTECTION

Exposure limits: MAK (DRG, 1997)

Pecional Protective equpment —_: Use Osi-nasalrespntor if products used in confined spaces,

Eye protection Safery goggles

Sian protection Impervious gloves

Tus Fygiene ‘Wash hands before bresks and aftr finishing work, Do not eat, denk or smoke at

-workphce

Engineering Control Use loci exhaust venation. Use fameproot equipment and measures [slate al potctial

sources of ignition,

9. PHYSICAL AND CHEMICAL PROPERTIES

Form Viscous Liquid.

Coloe Black

Odiae Strong Solvent.

Boiling poiat,'C NA

Molin pois,C NA

Flask Pot, (Closee)’C > 4c

Autoflanibiliy,‘C Na

Explosive Properties (4) Na

LANEY

MATERIAL SAFETY DATA SHEET BITUBOND N’

“Thermal Decomposition Na

Specific Gravity at 25°C 209-100

Vapor Pressure, KPa at 206 PNA,

Viscosity 25°C) £8000 ep

Ph value Na.

Solubility in waree Insoluble

10. STABILITY AND REACTIVITY

Natard Decompostion Poduct : Hazardous decomposion product are aot expected to form duting nosmal storage, When

rs

exposed to high temperature may produce obnoxious or ieitation vapors le carbon

‘monoxide and dioxide, ammonia, corrosive gases.

Hazardous reactions -Exothetmic reaction with isocyanates and epoxy cesn, Reaction with acids possible

INFORMATION ON TOXICITY

The following toxicological assessment is based on knowledge ofthe toxic ofthe product's components,

Oral LD50, at + Product not toxicologically tested.

(On Eyes/kkin (Causes skin corcosion and tecious eyes damage.

Other Information

INFORMATION ON ECOLOGICAL EFFECTS

Becological effec information Do not discharge product in drains & sewer.

‘mpaitment of sludge activity

Other information

B DISPOSAL

Disposal + Mix sepaate product components in ratio and ss supplied in suitable metal containe

Bay ia lind. Use licensed waste disposal contactors and consul loalauthouy sen

disposing.

14 TRANSPORT

UN/SINo, 2735,

IMO Clase :

Packing Geoup Hi

‘Masine Politant

TATA/ICAO Clase Class 8

ADR Chas :

Ot: information Protec epinst moistuce. Clos contsners hermetically and protect aginst heating >50°C.

5 REGULATIONS

Labeling + According to EEC dicetves concerning preparations

Symbol C, Comosive

Phrases) R 20/21/22 “Hlarmfal by inhalation, in contact with skin and if swallowed

B4 Causes barns

SPhaase ). $26 Avoid contact with eyes. Rinse immediately with plenty of water and seek medical advice

S28 + Avoid contact wth skin wash immediately with plenty wate and soup

$36/31/39 + Wear suitable protective clothing, gloves and ey face protection Use in well venated

$45 In ease of accident or if feeling unvel, sek medical advice immediately Show the label

‘here posible)

$51 2 Use ony in well ventilated areas.

16. FURTHER INFORMATION

Approved MK

Relsed 2M

{Dis above data ace based on ou present knowledge. However, they shall not constitute a goacatee foc any specific product features

and stall not establish a legally valid contractual relationship.

Date: 01/12/2012

[Polybit

MATERIAL SAFETY DATA SHEET

COMMERCIAL NAME : POLYBOARD

1, PRODUCT AND COMPANY IDENTIFICATION

Produced / Distributed by Henkel Polybit industries Ltd,

P.O.Box: 293, Umm Al Quwain.

United Arab Bmirates.

Tel: +971 6 7670777, Fax: +971 6 7670197

e-mail: polvbiv@emirate net.ae

ynmw.henkelpolybit.com,

INFORMATION ON INGREDIENTS

Chemical characterization N/A

Description : Wood fibre board of pipe fibre with waterproofing agent without dye

Hazardous contents N/A

‘SU HAZARD IDENTIFICATION

Identification of hazards N/A

Specific hazards for people and the environment: N/A

@. FIRST AID MEASURES

General information No specific measures necessary

After skin contact

“After eye contact

‘After inhalation

5. FIRE FIGHTING MEASURES

Suitable extinguishing media Water, Foam, CO, extinguishing powder

Special protective equipment No specific measures necessary

6 ACCIDENTAL RELEASE MEASURES

Personal Precaution Keep sources of ignition away

Environmental Precaution N/A

Methods for cleaning/picking up _: Pick the material up mechanically

7, HANDLING & STORAGE

Handling N/A

Information on safe handling N/A

Information on fire and explosion protection: General company regulation on fire protection must he observed

Storage : Dry at room temperature

8. EXPOSURE CONTROLS & PERSONAL PROTECTION EQUIPMENT

Ingredients with occupational limit values that require monitoring: Dust

Personal Protection equipment + Not required

General protection and hygiene measure: Not required

‘9. PHYSICAL & CHEMICAL PROPERTIES

Form’ Solid

Colour : Natural

Odour Weak characteristic inherent odour

Change of state EN/A

Melting point NA

Flashpoint N/A

‘Water content 182%

Explosion hazard N/A

‘Thermal decomposition condition to avoid: No decomposition if handled as specified

MATERIAL SAFETY DATA SHEET POLYBOARD

10. STABILITY AND REACTIVITY

Hazardous Reaction None

Hazardous decomposition product None

Ti. INFORMATION ON TOXICITY

‘Acute toxicity

Primary irvitant effect

On the skin No Irritant effect

On the eye No Irritant effect

Sensitization No sensitizing effect known

‘Additional toxicological information + Ihandlled correctly & used as specified the product causes no health

Hazards. The substance does not need to be labelled on the basis of the

‘mast recent version of EC list.

12, INFORMATION ON ECOLOGICAL EFFECTS

Ecological Information

General information As a pure natural substance, the product ecologically safe

13, DISPOSAL

Disposal considerations ‘The product may be sent to a composting or an incineration plant,

provided that the local regulations are observed and if necessary,

following consultation with the disposer or the local regulating authority

14. TRANSPORT

‘Transport on Lend, ADR/RID and GGVS/GGVE (intemational/ domestic)

ADR/RID-GGVS/E class Not hazardous goods

Number / letter # Not hazardous goods

15. REGULATIONS

Labeling in accordance with EWC guidelines : Labeling not required

National regulations

Water hazard class Not a water hazard

16, FORTHER INFORMATION Please contact

PRODUCT MANAGER

Tek: +971 6 5722282

Fax: +971 6 5722289

Approved : MN

Released, HIM

‘The above data are based on our present knowledge. However, they shall not constitute a guarantee for any specific

product features and shall not establish a legally valid contractual relationship,

Date: 12/01/2012

LENCHy

MATERIAL SAFETY DATA SHEET

COMMERCIAL NAME, POLYGLOW

PRODUCT AND COMPANY IDENTIFICATION

Produced / Distributed by: Henkel Polybit Industries Le.

P.0.Box: 293, Umm Al Quwain,

United Arab Emirates,

‘Tek +971 67670777, Fax: 4971 67670197

e-mail: polybit@emirate.net.oe

ww henkelpolbit.com

2. COMPOSITION 7 INFORMATION ON INGREDIENTS

‘Chemical Composition wre CAS No.

Bitumen 42-87 64742-53-4

Hydrocarbon Solvent 47-53 98751-29-4

Hazardous ingredients Contain

‘3. POTENTIAL HAZARDS

Flammable, Harmful: possible risk of irreversible effects in contact with skin,

HIRST AD MEASURES

Bye contact ‘Wash eyes with copious amount of water for several minutes. If iritation

persists, seek medical attention.

‘Skin contact Remove contaminated clothes immediately. Wash affected area with soap &

plenty of water. if irritation occurs, obtain medical attention,

Tnhalation Remove affected person to fresh air. If symptoms persist obtain medical

attention,

Ingestion + If swallowed wash out mouth. Do not induce vorniting. Obtain medical

attention immediately.

EVENT OF FIRE

Fight ire With : DCP/Foam/ COs (Small Fire).

Fight fire with plenty of water (ange fre)

Baits It emits tonic/CO/Suiphur di-cxide fumes,

Further information : Use protective equipment while fighting fre

‘C—aecWwanTat RELEASE WEASURES ee

Personal Precautions Wear suitable clothing, gloves and eye/face protection. Immediately issue NO

‘SMOKING & NO NAKED FLAMES warnings,

Environmental Precautions _ : Avoid entry into drains, sewers and water courses,

Decontamination Procedures: Absorb with suitable material ice sand, earth, Seal in plastic bag & bury in

JanaSil.

‘WANDEING & STORAGE

Storage Keep containers tightly closed and dry. Store between 45° C to +25°C. Store in

conformity with Iocal fire regulations

Handling Maintain good standards of personal hygiene, Use in well ventilated areas to

‘avoid vapor fumes. Suitable respiratory equipment should be wore when

working in closed environments,

‘5. EXPOSURE CONTROLS / PERSONAL PROTECTION

Personal Protective equipment: Use Ori-nasal respirator if product is used in confined spaces.

Bye protection Safety goggles

Slan protection Impervious gloves

Industrial Hygiene + Wash hands before breaks and after finishing work Do not eat, drink or smoke

at workplace,

ise local exhaust ventilation. Use flameproof equipment and measures, [solate

all potential sources of ignition,

9. PHYSICAL AND CHEMICAL PROPERTIES

Engineering Control

Ferm Liquid.

Color Blacke

Odor ‘Typical

Boiling point, °C 140

eling point, NA

Flash Point, (Closed)“C 40

‘Autotlamibility, > 200

Explosive Properties (%) Lower Level: 0.9% Upper Level 8%

Relative Density at 20°C tor

Vapor Pressure, KPa at 20°C 3.6.5,

Ph value NA. (non aqueous)

Solubility in water, Insoluble

LENE

MATERIAL SAFETY DATA SHEET. PoLYeLow.

30. STABILITY AND REACTIVITY

‘Stability + Stable. Containe volatile solvent,

Conditions to avoie # Any source of ignition. Temperatures above 40°C.

Incompatibility : Strong acids, strong alkalis, strong oxidizing agents.

Hazardous decomposition _: Thermal decomposition: Oxides of carbon, suiphur compounds, nitrogen

compounds,

TL, INFORMATION ON TOXICITY

‘The following toxicological assessment is based on knowledge of the toxicity of the produet’s components,

(Oral LDSO, rat>2gm/ keg.

On Byes ‘Severe iritation,

On Skin larmful by absorption through skin, Iritating, especially in presence of

sunlight.

Inbalation ‘Vapors may cause headaches, dizziness and central nervous system

depression.

Ingestion ‘May cause nausea, vomiting end diarrhea.

Chronic Bifects Bitumen presents no known chronic health hazards, However, when mixed

With diluents iis believed that the product becomes bio-available: Repeated

‘and proionged contact, aid poor personal hygiene practices may result in

sin cancer,

12, INFORMATION OW BCOLOGICAL EFFECTS

Mobility ‘Mobile liquid, insoluble in water

Persistence & Degratability _: Expected not ta be readily biodegradable.

Bio-accumulative Potential _: Non bio degradable,

Eco-toxicity Not evo friendly. Toxic.

Acute Toxicity Moderate

TS. DISPOSAL

Disposal Use licensed waste disposal contractors and consult local authority when

disposing

14 TRANSPORT

UN/SI No. 21999

IMO Class a3

Packing Group ot

Marine Pollutant Yes

IATAJICAO Class 3

ADR Class 3

TS REGULATIONS

Labeling + Dangerous substances directives, 67/548 /EEC.

Dangerous preparations directive, 88/379/EEC

Safety Data Sheets directives, 91/155/EEC

Carcinogens directives, 90/398 BEC.

Symbot xa

R Phrases(s) Flammable. Harmful possible tisk of irreversible effects in contact with skin

S Phrase (s). $25 ‘Avoid contact with eyes

S28 Avoid contact with skin, wash immediately with plenty water

36/37/39: Wear suitable protective clothing, gloves and eye/face protection. Use in well

ventilated areas.

‘Statutory Instruments ‘Chemicals (Hazard information and pack) Regs, 1993 {St 1746)

Control of substances hazardous to health Regs. 1988 (St 1651)

Highly flammable liquids 6 Liquefied Petroleum Gases Regs. 1972 (SI 917)

Codes of Practice ‘Waste management. The duty of eare. The control of substances hazarows to

health & conirol of carcinogenic substances (5).

Guidance Notes Occupational exposure imits (E1140)

‘The storage of highly flammable liquids (CS 2)

16. FURTHER INFORMATION: Please contact

PRODUCT MANAGER

‘Tel: +971 6 7670777

Fax: 1971 6 7670197

The above data are based on our present knowiedge. However, they shall not constitute @ guarantee for any

‘specitic product features and shall not establish a legally valid contractual relationship,

22/1/2012

TDS Polycoat_GCC_1012

Ley

POLYCOAT

Bitumen emulsion paint

Powycouris on emulsified thixotropic bitumen protective coating. The coating dries to form « block flexible

protective film. The finished film forms a tough barrier to vapor transmission.

CHARACTERISTICS

> esas the attock of sls Ike chlorides and sul

phates that are present in the sol

> Easy to opply

> Cold applied

> Adheres to concrete, metal, wood, cork, etc.

> Can be applied in closed or confined spaces

> Water-based

> Non: flammable

» Versatile

> Economical

FIELDS OF APPLICATION

Potrcoar is used for providing damproofing for

below ground concrete structures which are above

the water table, This can also be used os the

protective coating for buill-up roofing systems and

other exposed surfoces. The cooting is also used

{8 a moisture vapor barrier on block works and

‘concrete surfaces prior to cladding,

APPLICATION INSTRUCTIONS

The opplication temperature should be between

5°C fo 55°C. Application procedures may vary

slightly depending upon site conditions. The

general recommended guidelines for the

pplication of the bitumen coating isos follows:

Sudoce preparation

The surface sholl be cleoned thoroughly of all

coniaminanis like dust, traces of curing

compound, oil and grease. All surface

imperfections ond protrusions ore to be removed

cond repaired. Structurally unsound and friable

concrete must be removed and repaired with a

suitable PoUckeTe* concrete repair mortar.

Priming

Primer is clways recommended prior to coating as

it not only penetrates into the concrete pores and

seals the substrate. It clso acts os an adhesion

promoter for further cootings. The primer coat con

be made in the sile by diluting the same bitumen

emulsion with 20% water. The primer may be

applied by a brush, roller or airless spray. Allow

the primer to dry before any further coats ore

cpplied. However, fthe primer afer opplicalion

left open for more then 24 hours after it becomes

dry clean the suroce of any setled dust and epply

© fresh coat of ho primer.

Apzlication

Stir the contents of the drum thoroughly prior to

application to remove ony sediment. The

pplication can be done with a roller, brush oF

cirless spray. Apply the coating at a coverage rate

of 1-4 m2/k/coat, depending on the dry flim

thickness required. When applied at 4m*/lt./coo!,

the dty film thickness achieved will be 125

‘microns. Further coats shall be applied only afer

the previous coat dries off completely. However,

the coverage depends on the smoothness and

porosity ofthe substrate and the requited thickness

of the coating,

Protection

The coating shall be protected from ongoing site

cctivties and during backfiling from getting

damaged by © 150 micron polyethylene sheet

[COVERAGE

Moisture vapor barrier cooting: 4 m®/h/coat will

‘ive dry film thickness of 125 microns.

STORAGE & SHELF LIFE

The drums and poils must be stored in o covered

areo, away from direct sunlight, UV and other

sources of heat. The shelf lfe is up to 12 months

when stored os per recommendations. Excessive

exposure to sunlight, UV and ether sources of heat

will result in considerable deterioration of the

product and reduce its shelf ie.

yeoat_GCC_1012

TOS Pol

BSNS ae eye ee aise fe NILSSON

Protective clothing such os gloves and goggles PROPERTIES vawues | TEST

should be wom when handling the product. Treat STANDARDS

‘any splashes to the skin or eyes with fresh water Foam Thick |

immediately. Should any of the products be Viscous

‘occidental swallowed, do nol induce vomiting, but lisuid

call for medical assistance immediately. Ensure

thot the container is evailable for medical Color trom |

attendant fo examine any relevant instructions and

content detoils. Density [a/ee] 1.02 =0.02 | ASTM D 2939

PSuPPLY 0

Firm set [hrs} 24 ASTM D 2939

Pocom 15k pail 200m

Seat a 200 Rl ecko | SES |

* Refer to website for TDS re)

Service emp, FC] | -5t075 |

All valves given are subject to 5-10% tolerance

‘etanercept rare ene ed oe ptr oe on or

‘Gere fhe weraned ths Eemaon shot gure our yan ceneonon A cae penoos obra Woe moe eam th

Fan 805 tS ar hoy as pct her. Moa nt ht dar aha ie oe

‘pl a ee mee etn en a tr inten integer

Sea rc pia ee cae oedema

ick Gv vis eis ae ofl conduct rg rape onan se he Nene cae hee nae eee am wa

on on ok rowel enpennce

ising bv ccloced dao

Mondocued in GCE.

Hon Poi nde i Hook hpi adi Us

Inemet vonhelabohbit com ma pbk Denes coe

d

20s 298 Un owas UME 10's Zin, alot 3984, eo

Sel Tt 4970 87670777, Fou 4971 81670197 ahs 96688994100, Fow' 9668 8895913,

memcema, Fosnye 971 6TO7O/HT, Fon 49% 6 767689

Cea iaaeat el ey

MATERIAL SAFETY DATA SHEET

|Polybit 4

. ————_ eer coe,

COMMERCIAL NAME :POLYPOXY CT PART A

1. PRODUCT AND COMPANY IDENTIFICATION

Produce / Ditbuted by Heakel Polybit Indus ad.

P.0.Box: 298, Umm Al Quvain,

United Arab Eris

‘Tels +971 6 7670777, Fax +971 6 7670197

ema

epalyliteam

COMPOSITION 7 INFORMATION ON INGREDIENTS

Chemica cheneterzation Blend of bitumen, amine wth atl rand solvent,

CASNO. 2455-13-2

ws224

10838

Hard ingress + contins solvents which we fama end haf,

3POTENTIAL HAZARDS: used infomation The mail cons ben whichis back soso Eaponie fe an gute tse

mee

RST AD MEASURES

ye contact Wash pe with copious amount of wats for sever aut. I isation pits, eck

rede stention

Skin contac -Remore contaminated clothes meres, Wa affected area with soap & plenty of

‘miter [fiaton oer ob medi enti nates

Inhulasion Remon affered pron ofesh a. Espen pei brain media tention.

Iegestion Do sat inde vomit Oban medi atenton meat.

HIRE FIGHTING MEASURES

Suiuble Eingishing medi, Carton ded dey powces and foun, ter payor fg,

Notto be wed Warerina je

Connon procs 2

‘@ ACCIDENTAL RELEASE MEASURES

‘Aer silage leakage Aloe with site mate Hk end cath, Sn pltic ig & busy Dan. lsh

Contained aea wi pny of wate

Tn acdrion plese rele to local relations for dips

7. HANDLING STORAGE

Stonge Keep contests closed an dey. Store berween 45°C to 428" C. Store in

‘anfoenty with eal Sze eulationa

Handling Minin good standards of pecsoalingere. Use in wel vena aeas to avoid vip

fame. Sarai espeoryepment shold be worn when working clea pane

Prteson aint fie eexplovion __: Avid wen conned sc vous non ao

EXPOSURE CONTROLS / PERSONAL PROTECTION

Expo inst: MAK DFG, 197)

Petsonal Proteate agupment Ute Oren espintrif producti uted in confined spaces

ye peoteeson Safety goggles

Skin protection Imperion love

nti Hygiene Wash hands before breaks and afer fining wok. Do aot a chick o smoke at

sworkpice

nyneeing Conta Us oes venaion Use aeproo gst a mascot pen |

surces of rion |

5 PHYSICAL AND CHEMICAL PROPERTIES |

Foam Opa pid, |

Color Bhek |

sous Chance

Boling poi C NA

Meking point NA. |

Flash Ping, (Clsed)'C Appeos. 30°C |

Autofamibiy,"C Nik |

Explosive Properite (2) NA |

‘Theemal Decompsiion Docs not oceur ar ambien empeat |

Speaiie Gravy 25°C 120

Vapour Pree, KPa at 206 NAL

Vscony @°0) 12tTepe

Soll i water Incl

|Polybit 4

SS Sie

MATERIAL SAFETY DATA SHEET. POLYPOXY CT PART A.

1 STABILITY AND REACTIVITY

Mazaed Decomposion Product Hazardous decomposition prodet ar not expected to form ducing oemal korg. When

‘expoted to high temperate may produce fame, smokes eben done

Hiardous eacions NA,

IE INFORMATION ON TOXIC

‘The flowing toxclogealaseesment based on kaowizdge ofthe toxic ofthe product’ components

Ge LD50 es No Dats Arable

OnE yes

On Skin

(eke Tnfrmation

1, "INFORMATION ON ECOLOGICAL EFFECTS

[eolgal efecinformation ‘Do not discharge podetin dein 8 ewer,

Impaizmen of sdge sei,

3B. DISPOSAL

Disposal Mix separate proietcommponsotsn ato and ae spl in suitable mets continee,

‘Buy anil. Use Eoesed waste disposal conactos al consult loa aunty when

epoang

TRANSPORT

UNAINe m0

INO Csr

Peeking Goup Mt

DMasne Pole

IATA/ICAO Cee Chass 1

ADR Clas

Other inrmaton

B REGULATIONS

Labeling According o EEC dienes concemning peepctions

Symbo C Contre

RPhase(@) 20/21 ‘af by sbalation andi contact with skin

B36 Cao burs

XB May ensesrenszation by kin contact

R52/33 Hirmfl to aquatic organs ay eae long tem adres ets in agutc envionment

SPhase(). $24/25 Avi onze with skin aes

2 = Avoid contst wih je. Rinse amen wit plenty of wate sn ce medic! advice

25 Avoid contact with skin, wash zmmedtely with plenty water and soap,

536/37/39 ‘Wear suitable protective dthing, lores and ee face protecion. Use ia wel vented

ssi Ure onlin well vented aca.

16. FORTHER INFORMATION Please contact

PRODUCT MANAGER

Tel: +971 6 767077

Fax: +971 6 7670197

Approved MIN

Released JM

‘The above dat ate based on ou present knowledge. However, they shall ot constvte a guarantee for any specific product featres and

shall noc establish legally valid contractual relationship.

Date: 29/1/2012

MATERIAL SAFETY DATA SHEET

COMMERCIAL NAME

| Polybit f

—— am

POLYPOXY CT PART B

PRODUCT AND COMPANY IDENTIFICATION

Produced / Disibued by

Henkel lpi indie Led

P.0.Box: 293, Umm Al Quwain,

nated Amb Emits

‘Tek: +971 6 1670777, Pax: #971 6 7670197

mad pivhit@imiorenetse

ssowhanlepalyh

COMPOSITION 7 INFORMATION ON INGREDIENTS

Chemical ezeteiation| ‘Blend of Modified Epoxy Resine with stable ddtves

CAS 25058586

3. POTENTIAL. HAZARDS

Hiacde Information Product contaminates wats Toxic to agua organisms. May cause long erm advene

effecsn the aquatic cavtomment Caves skin sensizaton, Skin etsy repented contact

an inesease dhs ffreIntatig o ees and sen

HIRST ADD MEASURES

Bye conuct, Wath eres with copious smount of wets foc ever mintes. If intion persis, sek

redial tention

Skin contact Remove conmiated lotes ined, Wash fect aces with soxp & plenty of

‘eter. Fiaton occu, cain medal atenon,

Inhalation Remove affected person to fecha. IFemplome pest obtain madi stenton

Ingestion Do sotindace Clas medial atenon ene

Fins FIGHTING MEASURES

Sible Estngushing meds (Catbon donde, dey powder ane fam water pray o: fog,

Notto bewsed Water in jet

Combuston products

ther infomation

‘ACCIDENTAL RELEASE MEASURES

‘Ae sige esage -Absc with suitable material Hie snd ut, Sealin plac bag bury in end. Fish

Contaiated area wth lay of wate

Tn dion pease ster tll relations for disposal

HANDLING © STORAGE

Stomge Keep contains phy closed snd dey. Stor Between 45® Ct 425°C. Stor in

confoenty wis eal fie epltions,

Harding Monin good stundac of personal iygene. Use in wel venisted ares o avid vapout

Protection asin fre & elation

Fumes. Sutablerexpistryegupaent shuld be wora when woskigmclose ace,

Avoid usin contin paces 8 ous fon

"EXPOSURE CONTROLS / PERSONAL PROTECTION

Exponzelimis: MAK DFG, 1997)

Personal Provete emapment

Eye protetion|

‘Ska protection

Indust ygene

ngineeing Cont)

Use Orinal respite ipod ie wd in confined epaces

Suter evens

Impervious gloves

Was hands before bresks and ater finishing work Do no est, sk or smoke at

workplace

‘Use loa exh venation. Use fameprcofeqipment and measures fobs ll pend

sous of ion.

‘PYSICAL AND CHEMICAL PROPERTIES

For

Color

sour

Boiing pent

Meking point, 'C

‘Opsque Viscous ii,

Sigh yell

Charteris

: | Polybit 4

—S Savor

MATERIAL SAFETY DATA SHEET POLYPOXY CT PART B

‘lash Point, (Cosed)"C > 150°C

Autoflambilty, C 300"

Explosive Poperics (4) NA

‘Thermal Decomposition Doesnot occur at ambient temperature

Density g/l 25°C 16

‘Vapour Presse, KPa at 29°C S<001PA AT 20°C

‘Viseosiy °C) U0-180Paixe

Phralue 1,

Soluhiiny in water Insole

WW STABILITY AND REACTIVITY

Hara Decomposition Produce Hezasdous decomposition rode are not expected to fon dng normal storage When,

‘exposed thigh temperate may produce exrbon monoxide and diowsle,

‘Hazardous restions ENA.

iy INFORMATION ON TOXICITY

‘The following toxicological assessments based on knowiee ofthe toxicity ofthe produc’ components

rat LDS0, sax

On Eyes Imitation.

On Skin Irraion.

Other Information Toko squat orniss. May nue long tem aver effets in agua envionment

12, "INFORMATION ON ECOLOGICAL EFFECTS

Reologcl fect information Do not dichargeproductin dine & sewers.

Impairment of ge acvity

ther infration

DISPOSAL

Dispos + Mix apurate prodvetcompenents in ratio and a supplied in nutable metal consner.

Bury is nd. Use licensed waste disposal coouactors and consult loa asocty when

Spore,

TRANSPORT

UN/SI No. +3082

IMO Class

Packing Group aL

‘Manne Pllasat Vee

TATA/ICAO Css Class 9

ADR Chass

‘Other infocmaion Environmentally hazardous ssbstance, quid, NO.S. (Contains epary resin)

15 REGULATIONS

Labding Accoating to EEC directives concerning prepares

Symbol Xi Int

RPheasesl) 236/38 ‘satng to eyes and skin.

4S ‘May cause shin sensitization by skin contact

51/53 Toxic to agua organisms, may cane long teem sess effet inthe aquatic envionment.

‘SPhase(). $24/25 Avoid contact with skin and eyes.

26 Avoid conte with jes. Rinse immediately with plenty of water and seck medical advice,

528 Avoid contact wich skin, wash mediately with plenty water and wosp,

$36/30/39 Weue suitable protective ciothing, gloves and eye face protetion. Use in well venta

sot Avoid edease tothe envierment. Refer special insractions fey data sheers

16. FURTHER INFORMATION Please contact

PRODUCT MANAGER

‘Tel: +971 6 7670777

Fax: +971 6 7670197

Approved MN

Released 2M

‘The above data ae based on our present knowlege However, they shall aot constitute a guarante for any specie product fentres and

shall aot establish a legally valid contracaal relationship.

Date: 22/1/2012

|Polybit 4

MATERIAL SAFETY DATA SHEET ee ——e como

COMMERCIAL NAME : POLYPRIME SB

1. PRODUCT AND COMPANY IDENTIFICATION

Prediced / Distributed by ‘Henkel PolybitIadusties Led

P.0.Box: 293, Umm Al Quwain,

United Arab Emirtes

Tel 4971 6 1610777, Pax: 4971 67670197

e-mail polybit@emirate.neuae

ww henkelpalybtcom

2 COMPOSITION] INFORMATION ON INGREDIENTS

Chemical Composition wr CAS No.

Bitumen 40-45 64742-5934

Hydrocarbon Solvent 55-60 64742-82-1

Hazardous ingrdiens Contain.

3. POTENTIAL HAZARDS + Flammable, Maemful: possible dskof exeverable effects a contact with

skin,

<__HIRSTAIDMEASURES

ye contact ‘Wash eyes with copious emount of water for several minutes. IFietation petits, sock

‘medical attention,

Skin contact Remove contaminated clothes immediately, Wash affected atea with soap & pleny of water If

inritation oceuts, obtain medial attention,

Tkastion Remove affected person to fresh ai. I symptoms persist obtain medical attention,

Ingestion 1 swallowed wash out mouth Bo not induce vomiting Obtain radial attention inimedatly

INVENT OF IRE

Fight Fite With DEP/Foam/COs Small Fit)

Fight fre with plenty of water (ere fi).

Enis = tems texic/CO/Suiphur diode Fumes

Furhee information Use protective equipment while Gghtng fe

© ACCIDENTAL RELEASE MEASURES

Personal Precastons Wear suitable clothing, gloves and eye/ face protection, Immediately sue NO

SMOKING & NO NAKED FLAMES warnings

avizonmeatal Precastions Avoid entzy into drains, sewers and watercourses,

Decontesnination Procedures Absorb with suitable material ike sand, cath Sal in peste bag & busy in

landfil,

7 HANDLING & STORAGE

Storage Keep containers ight closed ani dy, Store between +5°C to 425°C. Store in

conformity with loeal fie segulations

Hanlin, ‘Maiatin good sandards of pessonal hygiene. Use in wel vented areas to

avoid vapor fumes. Suitable respzatry equipment should be worn when

‘working in eloted envizonments

5. EXPOSURE CONTROLS / PERSONAL PROTECTION

Pemoml Protective equipment: Use Orinasal respirator if products used in confined spaces,

Bye proton Safer goeeles|

Skin protection Impervious gloves

TnehstialFygiene Wath hands before breaks and ater Snishing work. Do nt et, dink or smoke at workplace

Engineering Control Use local exhaust venslaion. Use fameproo! equipment and measures, Isle all poral

sources of

5. PHYSICAL AND CHEMICAL PROPERTIES

Fom Tiguid.

Color Black

Oder = Typical

Boiling poins °C > 140

Nekking post, © NAL

Flas Point, (Closed)"C 0

Avto-fammabiiy > 200

wore) 485 g/t

Lower Level 0.9%, Upper Level:

Relive Density at 20 101

|Polybit 4

SS Sanu

MATERIAL SAFETY DATA SHEET POLYPRIME SB

‘Vapor Pressure, KPa at 20 03.05,

Solabiity in water Jmmsiseble

1. STABILITY AND REACTIVITY

Subilty Stable Contin volatile solvent.

Conditions to avoid ‘Any source of ignition. Temperatures above 40'C.

Incompastalisy Strong acids stiong alkalis, strong oxidizing agents

Hazardous decomporiton ‘Thermal decomposition; Oxide of carbon, sulphur compounds attogen

compounds.

iL ___INFORMATION ON TOXICITY

‘The folowing toxicelgical assessment i based on knowledge ofthe toxicity ofthe product’ eomponcas

(Oral LD50, ra>2pm/k

On Eyes Sever itton,

On Skin Hama by absompeion through skin, Iain, especially in presence of sunlight.

Inhalation Vapors may cause headaches, diziness and central nervous system depression

Ingestion May cause nasa, vomiting sind diarten,

Chronie Etfecs ‘Bitumen presents ao known chronic health hazards, However, when mixed with diluents itis

believed thatthe product become bio-aradable. Repeated and prolonged contac, alied poor

personal hygiene practices may result in shin cancer,

12, _"INFORNATION ON ECOLOGICAL EFFECTS

Mobility ‘Mobile liquid, nvolube in wats

Persistence & Degradabity Expected not be ready biodegradable

Bio-accumulative Potenial [Noo bio degradable

eo-toxiciy = Not ec frienly. Tie

Acute Toxicity Moderate

i DIsPosaL

Disposal se cened waste depo contactors ae cont oe authori when disposing.

7 TRANSPORT

UN/SINo. 1999

IMO Chse 33

Packing Group. m1

Nasine Pollut Yes

IATA/ICAO Chase 3

ADR Chass 3

5 REGULATIONS

Labeling Dangerous substances directives, 67/548/EEC.

Dangerous preparation directive, 88/379/BEC

Safety Data Sheets dretves, 91/155/EEC

Carcinogens ditetves, 90/394/RC.

Symbol Xo

RPhnses() Flameable Ham possible sk of irevensible effect in contact with ski,

SPhrase(@). S25 + Avoid contact with ee,

8 Avoid contact with skin, wash immediatly with plenty water.

5836/37/39 ‘Wear suitable protective clothing, gloves and eye/face protection, Use in well ventilated azea.

Saatucogy Instruments (Chemicals (Hazacd information and pack) Reps, 1993 (1 1746).

Control of substances hazardous to haleh Reg. 1988 (St 1657)

Highy Dammable liquids & Liquefied Peroleom Gates Regs. 1972 I 917).

Coées of Practice ‘Waste management. The duty of cae. The control of substances azazdous to heath e

contol of carcinogenic substances (3)

(Guidance Nores ‘Occupational exposure limits (EH 40)

‘The storage of highly lamsnableigids (CS 2)

16 FURTHER INFORMATION 7 Pleare contact

PRODUCT MANAGER

Tek +9716 760777

Fax +9716 7670197

‘The abore dit ate based on our present knowledge, However, they shall not constitute a guarantee for any specific product features and shall

not establish a legally valid contsctual relationship.

Date 22/1/2012

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Safety in Heat Memo 2022Document2 pagesSafety in Heat Memo 2022ramodNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Personal Protective Equipment ListDocument1 pagePersonal Protective Equipment ListramodNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- 5S-Lean Audit Checklist - ManufacturingDocument4 pages5S-Lean Audit Checklist - ManufacturingkajalNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- To Do List With People Assigned To TasksDocument4 pagesTo Do List With People Assigned To TasksramodNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Safety in Heat CampaignDocument17 pagesSafety in Heat CampaignramodNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Good PracticesDocument3 pagesGood PracticesramodNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- HSE Audit Checklist: Emergency Equipment Safety Inspection Checklist ItemDocument3 pagesHSE Audit Checklist: Emergency Equipment Safety Inspection Checklist Itemramod100% (2)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- SM203 HSE Observations ChecklistDocument5 pagesSM203 HSE Observations ChecklistramodNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Emergency Contact FormDocument1 pageEmergency Contact Formluis_leon_121No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- 201918Document1 page201918ramodNo ratings yet

- 201918Document1 page201918ramodNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Work Improvement Notice MUS-C1-HSE-CWIN-098Document19 pagesWork Improvement Notice MUS-C1-HSE-CWIN-098ramodNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Al Jaber - 34 CertificatesDocument11 pagesAl Jaber - 34 CertificatesramodNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 3824 001Document1 page3824 001ramodNo ratings yet

- Contents List: Home InventoryDocument2 pagesContents List: Home InventoryunameNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Contents List: AGP HSE InventoryDocument3 pagesContents List: AGP HSE InventoryramodNo ratings yet

- HSE Observation Card LogDocument1 pageHSE Observation Card Logramod100% (1)

- Corona Info in Simple PDFDocument15 pagesCorona Info in Simple PDFramodNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Toolbox Talk - Corona PDFDocument1 pageToolbox Talk - Corona PDFramodNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Interview QuestionsDocument1 pageInterview QuestionsramodNo ratings yet

- Work at HightDocument32 pagesWork at HightMY TEC SUPPORTNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Q A For Hse Manager PositionDocument5 pagesQ A For Hse Manager PositionramodNo ratings yet

- Ministerial Decree No 401 of 2015 - EnglishDocument3 pagesMinisterial Decree No 401 of 2015 - EnglishramodNo ratings yet

- HSE Weekly Attendance Report - J253Document1 pageHSE Weekly Attendance Report - J253ramodNo ratings yet

- Safety Moment CsDocument1 pageSafety Moment Csramod100% (1)

- Agp Tipper Truck Ins Dated 02-03-2019Document1 pageAgp Tipper Truck Ins Dated 02-03-2019ramodNo ratings yet

- TyreDocument1 pageTyreramodNo ratings yet

- Think Before You Tip Induction Record: You Must Not You Must AlwaysDocument2 pagesThink Before You Tip Induction Record: You Must Not You Must Alwaysramod100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Bulletin Apr 16-2Document1 pageBulletin Apr 16-2ramodNo ratings yet

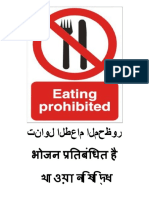

- No EatingDocument1 pageNo EatingramodNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)