Professional Documents

Culture Documents

Risk Ass - TK-4742-WELDING ACTVITIES FOR REST AREA PREPARATION

Uploaded by

nsadnanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Ass - TK-4742-WELDING ACTVITIES FOR REST AREA PREPARATION

Uploaded by

nsadnanCopyright:

Available Formats

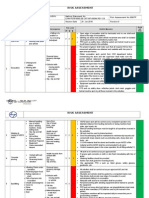

EHS RISK ASSESSMENT

ACTIVITY: WELDING ACTVITIES FOR REST AREA PREPARATION

PACKAGE NUMBER: TK-4742

Current Risk Final Risk

Task (Steps) Potential Hazard Existing Control Additional Control Prob

Cons. Prob. Risk Cons. Risk

.

Supervisor to ensure all applicable

PTW to be available prior to

commencement of the task.

Proper coordination with client.

Unauthorized Toolbox talks to be held at site, this

6.1 workers at working shall cover the method statement

area may injure and job safety analysis. 3 4 12

due to moving of Only competent and authorized

construction personnel to be deployed,

supervisor to ensure all workers

equipments.

involve in the activity received EHS

induction of EMAL/SLII.

Work check list has to be

completed.

All personnel involve in the activity

must be aware of heat stress,

Hot environment supervisor to ensure drinking cold

4 3 12

water is available all the time.

Provide rest shed with air

conditions.

All personnel involve in the activities

must wear the required PPEs at all

times (hard hat safety glass for gas

Working without cutting /welding safety shoe 3 2 6

P.P.E.s ,welding apron,hand gloves

,coverall)

Note: This is applicable to all

activities.

503406-AD0000-68AF-12303_R01 (2012-01-30) Page 1 of 6

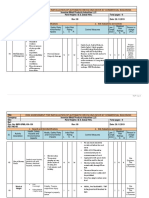

EHS RISK ASSESSMENT

ACTIVITY: WELDING ACTVITIES FOR REST AREA PREPARATION

PACKAGE NUMBER: TK-4742

Welding and gas cutting work should

be done only by competent and

authorized personnel

Incompetent

Toolbox talk to be given to all 3 3 9

6.3 welder

personnel involve in the activity.

Supervisor to ensure all hand tools

are in good condition

Manual handling Supervisor to conduct daily crew

Injury to workers meeting prior to start work 4 2 8

(back,hands,foot) Use proper PPEs.

Obstacles on area Supervisor to conduct daily crew

may cause tripping meeting prior to start work

3 2 6

and slipping Carry out good housekeeping and

hazards stacking of materials accordingly.

503406-AD0000-68AF-12303_R01 (2012-01-30) Page 2 of 6

EHS RISK ASSESSMENT

ACTIVITY: WELDING ACTVITIES FOR REST AREA PREPARATION

PACKAGE NUMBER: TK-4742

Welding machine and its

components (cable, electrode,

handle, etc) should be inspected

daily before operation.

Welding set must be earthed.

Welding machine should be

inspected and approved by

EMAL/SLII.

Provide proper sign boards such as

DANGER WELDING/GAS

CUTTING WORKS IN

Use of welding

OPERATION

machine 4 3 12

Competent and trained individual

should set the voltage of welding

machine.

Cables must be kept neat and free

from anything that cause stress

and damage.

A drip tray must be located under

each welding set where diesel is

the power source.

Power source / generator must be

switch off before leaving the work

area

503406-AD0000-68AF-12303_R01 (2012-01-30) Page 3 of 6

EHS RISK ASSESSMENT

ACTIVITY: WELDING ACTVITIES FOR REST AREA PREPARATION

PACKAGE NUMBER: TK-4742

Obtain a hot work permit prior to

start the welding/gas cutting job

The hot work area must be provided

with adequate ventilation to protect

persons against atmospheric

contaminants.

Take necessary precautions as

mentioned on the hot work permit

Fire watchman equipped with

Flammable

sufficient fire extinguisher to be

materials & other 4 3 12

made available during the

fire hazards

welding/gas cutting activities

Erect screens and fire blanket to

control welding sparks and protect

general public from burns and

exposure to UV-rays.

Improve and practice proper

housekeeping.

Cover flammable materials with fire

blanket if not possible to relocate.

Supervisor to conduct daily crew

meeting prior to start work

Erect screens and fire blanket to

Burns 3 3 9

control welding sparks and protect

general public from burns and

exposure to UV-rays

NOTE: All Current Risk ranked above C-15 must have additional control measures: Risk = Consequence x Probability (R = C x P)

Tolerable Risk (Low) = 1-6, Medium = 8 -12, (Methods statement), Intolerable Risks (High) = 15 25 (Method Statement plus additional Control Measures in place)

503406-AD0000-68AF-12303_R01 (2012-01-30) Page 4 of 6

EHS RISK ASSESSMENT

ACTIVITY: WELDING ACTVITIES FOR REST AREA PREPARATION

PACKAGE NUMBER: TK-4742

Consequence

Consequence ( Severity) Rating Factors (5) Probability Rating Factors (5) Frequency/Probability

(Severity)

No Safety Health Environ. Financial No Frequency A B C D E

1 First Aid Immediate Minor <AED 1k <1 hr A (1) Practically impossible or Once in 10 years 5 5 10 15 20 25

2 Medical Temporary Short term <AED50K 1-2 hrs B (2) Not likely or Once per year 4 4 8 12 16 20

3 Lost Time Short term Long term >AED300k 2-4 hrs C (3) Could happen or Monthly 3 3 6 9 12 15

4 Disability Long term Serious >AED500k 4-8 hrs D (4) Has happened or Weekly 2 2 4 6 8 10

5 Fatality Fatal Catastrophic >AED1m >1 shift E (5) Common or Daily 1 1 2 3 4 5

Risk assessment compiled by :

Risk Assessor:

SACHIN BABU EHS ADVISOR 25-06-2012

Name Designation Signature Date

Risk assessment approved by :

EHS Department:

Name Designation Signature Date

503406-AD0000-68AF-12303_R01 (2012-01-30) Page 5 of 6

EHS RISK ASSESSMENT

ACTIVITY: WELDING ACTVITIES FOR REST AREA PREPARATION

PACKAGE NUMBER: TK-4742

Construction:

Name Designation Signature Date

Management:

Name Designation Signature Date

503406-AD0000-68AF-12303_R01 (2012-01-30) Page 6 of 6

You might also like

- Hyundai Engineering & Construction Co., Ltd. HAMAD MEDICAL CITY Construction Package CP-300B Hospital Fit Out ProjectDocument4 pagesHyundai Engineering & Construction Co., Ltd. HAMAD MEDICAL CITY Construction Package CP-300B Hospital Fit Out ProjectYounis Khan100% (1)

- Risk AssessmentDocument10 pagesRisk AssessmentKyaw Kyaw Aung89% (9)

- Welding, Cutting and GrindingDocument6 pagesWelding, Cutting and GrindingMohammed MinhajNo ratings yet

- 3-REV.1 - Hot Work - Risk Assessment JHADocument16 pages3-REV.1 - Hot Work - Risk Assessment JHAnaiyar100% (1)

- 2.risk Assessment of Working at HeightDocument7 pages2.risk Assessment of Working at HeightRisal Sinu50% (2)

- ConfinedSpace RiskAssessmentDocument9 pagesConfinedSpace RiskAssessmentrashid zaman100% (5)

- Risk Assessment Welding & Radiography of Chilled Water PipeDocument11 pagesRisk Assessment Welding & Radiography of Chilled Water PipeAldrin75% (8)

- Risk Assesment 16 - Pre - Assembly and Erection ofDocument7 pagesRisk Assesment 16 - Pre - Assembly and Erection ofRochdi BahiriNo ratings yet

- Risk Assessment - Installation of Ventilation FanDocument6 pagesRisk Assessment - Installation of Ventilation Fannsadnan100% (5)

- Hot Work Risk Assessment and PermitDocument3 pagesHot Work Risk Assessment and Permitstitchvn75% (12)

- Risk Assessment For Cable InstallationDocument15 pagesRisk Assessment For Cable InstallationKaruppu Samy86% (7)

- Risk Assessment For Installation of Water Supply PipeDocument18 pagesRisk Assessment For Installation of Water Supply PipeAnandu Ashokan89% (27)

- Hse Risk Assessment - 006 Ra - Hdpe Duct LayingDocument7 pagesHse Risk Assessment - 006 Ra - Hdpe Duct Layingbinunalukandam83% (12)

- RA 020 Risk Assessment - Risk Assessment - Installation of Cables in Ducts & TrenchesDocument11 pagesRA 020 Risk Assessment - Risk Assessment - Installation of Cables in Ducts & Trenchesthomson100% (1)

- Aboveground Piping Installation Works 2016Document7 pagesAboveground Piping Installation Works 2016Aldrin75% (4)

- DDC Systems2Document28 pagesDDC Systems2nsadnan100% (1)

- 002 Working at Height Risk AssessmentDocument3 pages002 Working at Height Risk Assessmentmyo lwin75% (4)

- Risk Assessment - Confined Space Entry - Labours Work Inside The Pipe08122011-1Document4 pagesRisk Assessment - Confined Space Entry - Labours Work Inside The Pipe08122011-1nayakya40% (5)

- Site Activities Risk AssessmentDocument50 pagesSite Activities Risk Assessmentjamie542393% (41)

- 002 Working at Height Risk AssessmentDocument4 pages002 Working at Height Risk Assessmentgangadharan000100% (14)

- Risk Assessment For Scaffolding PDFDocument13 pagesRisk Assessment For Scaffolding PDFطارق رضوانNo ratings yet

- Checklist For Access Control System InstallationDocument6 pagesChecklist For Access Control System Installationnsadnan71% (7)

- Working at Height Risk AssessmentDocument9 pagesWorking at Height Risk AssessmentNebosh Diploma Assignment83% (6)

- Generic Risk AssessmentDocument8 pagesGeneric Risk Assessmentmorgojoyo100% (3)

- Risk Assessment - House and BuildingDocument1 pageRisk Assessment - House and Buildingnayanahari0% (1)

- Risk Ass - CE - 0994 - GAS CUTTING, WELDING, GRINDING, LOADING AND UNLOADING OF ANODE PALETTEDocument12 pagesRisk Ass - CE - 0994 - GAS CUTTING, WELDING, GRINDING, LOADING AND UNLOADING OF ANODE PALETTEnsadnan100% (4)

- Risk Assessment For CanopyDocument5 pagesRisk Assessment For CanopyJSN179100% (7)

- Portable Power Tools - Risk Assessment2Document3 pagesPortable Power Tools - Risk Assessment2Basit Nawaz100% (1)

- Scaffolding Risk AssessmentDocument3 pagesScaffolding Risk AssessmentAlexandru Ghigea100% (1)

- Jsa-Jha For Using of Hand ToolsDocument2 pagesJsa-Jha For Using of Hand ToolsKamran Khan50% (2)

- Risk Assessment in A Welding and Construction SiteDocument3 pagesRisk Assessment in A Welding and Construction SiteFad Tobi75% (8)

- Risk Assessment - Installation and Testing of Motorized Fire & Smoke DamperDocument10 pagesRisk Assessment - Installation and Testing of Motorized Fire & Smoke Dampernsadnan50% (2)

- Example Risk Assessment For ExcavationsDocument3 pagesExample Risk Assessment For ExcavationsYaser A. Al-Bustanji72% (18)

- Working at Heights Rescue ProcedureDocument4 pagesWorking at Heights Rescue ProcedureAizat Hanem100% (1)

- Grinding Equipment Risk AssessmentDocument3 pagesGrinding Equipment Risk Assessmentdroffilcz270% (1)

- JHA Manual HandlingDocument5 pagesJHA Manual HandlingFatin Zulkifli100% (1)

- Use of Hand ToolsDocument2 pagesUse of Hand Toolsvictor100% (1)

- RA - 018 01 Scaffolding Erection and DismantlingDocument14 pagesRA - 018 01 Scaffolding Erection and DismantlingVuong Bui95% (63)

- RISK ASSESSMENT - TK-4742-Operation Training For Overhead CraneDocument6 pagesRISK ASSESSMENT - TK-4742-Operation Training For Overhead CranensadnanNo ratings yet

- RISK ASSESSMENT - TK-4742-Operation Training For Overhead CraneDocument6 pagesRISK ASSESSMENT - TK-4742-Operation Training For Overhead CranensadnanNo ratings yet

- Risk Assessment of Scaffolding Works - Rev. 1Document20 pagesRisk Assessment of Scaffolding Works - Rev. 1Jayson Escamillan67% (3)

- Risk Assessment - Pre-Internal Wiring of Patch PanelDocument3 pagesRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- Risk Assessment - Pre-Internal Wiring of Patch PanelDocument3 pagesRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- Risk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)Document3 pagesRisk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)nsadnan100% (2)

- Risk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)Document3 pagesRisk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)nsadnan100% (2)

- Working at Height: Activity-Based Risk Assessment FormDocument7 pagesWorking at Height: Activity-Based Risk Assessment Formfredo100% (4)

- RISK ASSES-97-Erection of Steel Structure BuildingDocument8 pagesRISK ASSES-97-Erection of Steel Structure BuildingRochdi BahiriNo ratings yet

- Risk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3Document4 pagesRisk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3nsadnanNo ratings yet

- Working at Height Risk AssessmentDocument7 pagesWorking at Height Risk AssessmentAshish100% (3)

- Risk Assessment For Installation of Automatic Revolving Door InstallationDocument8 pagesRisk Assessment For Installation of Automatic Revolving Door Installationsabirbdk100% (1)

- 007 - Risk Ass. - CE-0994-MEP WorksDocument9 pages007 - Risk Ass. - CE-0994-MEP Worksnsadnan50% (2)

- Risk Assessment For HDB (14.12.12)Document9 pagesRisk Assessment For HDB (14.12.12)Saravanan SKNo ratings yet

- Risk Assessment For Tank BaseDocument5 pagesRisk Assessment For Tank Baseramod100% (2)

- RISK ASSESSMENT - CG-4706-offloading The 40 Feet Container and Offloading The MaterialsDocument6 pagesRISK ASSESSMENT - CG-4706-offloading The 40 Feet Container and Offloading The Materialsnsadnan100% (5)

- Electric Hand Drill Risk AssessmentDocument4 pagesElectric Hand Drill Risk AssessmentTariq AkhtarNo ratings yet

- JSA of Pipe Unloading.Document2 pagesJSA of Pipe Unloading.vijay kumar singh100% (1)

- Risk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and TestingDocument12 pagesRisk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and Testingnsadnan100% (1)

- Risk Assessment For Piping ErectionDocument6 pagesRisk Assessment For Piping ErectionAzhar MushtaqNo ratings yet

- JSA For BM - To Dry Up at Site, Remove Motor To Workshop For Repair, Re-Install & Perform Run Test-CRMDocument10 pagesJSA For BM - To Dry Up at Site, Remove Motor To Workshop For Repair, Re-Install & Perform Run Test-CRMChung TrịnhNo ratings yet

- Confined SpaceDocument23 pagesConfined Spacemujahid11370% (1)

- Fire Extinguisher Inspection ProcedureDocument1 pageFire Extinguisher Inspection ProcedureRavi KannanNo ratings yet

- Barangay DRRMC Checklist 2017Document9 pagesBarangay DRRMC Checklist 2017San Isidro LabradorNo ratings yet

- Contractor Risk Assessment FormDocument5 pagesContractor Risk Assessment FormRoger Simbhoo100% (1)

- Checklist For Commissioning of CCTV SystemDocument2 pagesChecklist For Commissioning of CCTV Systemnsadnan70% (10)

- Risk AssessmentDocument6 pagesRisk Assessmentkaruppusamymari100% (1)

- 6-Steel Work Risk Assessment ReportDocument7 pages6-Steel Work Risk Assessment ReportSyed Ali Hassan67% (3)

- RISK ASSESSMENT - Hydro Pressure TestDocument44 pagesRISK ASSESSMENT - Hydro Pressure Testloveson709No ratings yet

- ADDC Electricity Wiring Regulations - Mar.2014Document276 pagesADDC Electricity Wiring Regulations - Mar.2014hajimak89% (18)

- CCTV Testing and Commissioning Pre-Check List (ID 1506)Document1 pageCCTV Testing and Commissioning Pre-Check List (ID 1506)nsadnan67% (3)

- Risk Ass. - PM - 1009 - INSTALLATION OF CABLE TRAY AND CABLE BETWWEN PCM SUBSTATION AND NEW STAIR CASE DBDocument13 pagesRisk Ass. - PM - 1009 - INSTALLATION OF CABLE TRAY AND CABLE BETWWEN PCM SUBSTATION AND NEW STAIR CASE DBnsadnanNo ratings yet

- 13.2.4 RA SWP For Cable Installation Glanding Terminating Testing To Site Cabins at DCLDocument13 pages13.2.4 RA SWP For Cable Installation Glanding Terminating Testing To Site Cabins at DCLMARIAN100% (1)

- Karl Jaspers Tragedy Is Not EnoughDocument119 pagesKarl Jaspers Tragedy Is Not EnoughJuracy Oliveira100% (2)

- 109 Installation CCTV Systems PDFDocument60 pages109 Installation CCTV Systems PDFRodelDavidNo ratings yet

- Risk Assessments For ACTIVITY BASEDDocument4 pagesRisk Assessments For ACTIVITY BASEDhello3232No ratings yet

- Supervisor's Investigative Report Form and InsructionsDocument2 pagesSupervisor's Investigative Report Form and InsructionsRyan FlemingNo ratings yet

- Municipal DRRM ChecksDocument11 pagesMunicipal DRRM ChecksPrincess TantaoNo ratings yet

- CONTINGENCY PLAN TYPHOON SantolDocument15 pagesCONTINGENCY PLAN TYPHOON SantolRey Mark Collado100% (7)

- Checklist For Pre Commissioning of CCTV SystemDocument1 pageChecklist For Pre Commissioning of CCTV Systemnsadnan67% (6)

- Testing and Commissioning Pre-Check List (ID 1506)Document1 pageTesting and Commissioning Pre-Check List (ID 1506)nsadnan0% (2)

- 2008 Fire Protection GuideDocument50 pages2008 Fire Protection GuideDan PascaruNo ratings yet

- ONVIF Profile T Specification v1-0Document77 pagesONVIF Profile T Specification v1-0nsadnanNo ratings yet

- 1 45Document3 pages1 45nsadnan0% (1)

- ONVIF Profile - S Specification v1-2Document42 pagesONVIF Profile - S Specification v1-2nsadnan0% (1)

- ONVIF Profile Feature Overview v2-2Document6 pagesONVIF Profile Feature Overview v2-2nsadnanNo ratings yet

- Peer Communications Protocol Communications Media: Twisted Pair Copper Conductors Ranging From 16 To 24 GageDocument5 pagesPeer Communications Protocol Communications Media: Twisted Pair Copper Conductors Ranging From 16 To 24 GagensadnanNo ratings yet

- BSIA Cyber Secure It January 2019Document16 pagesBSIA Cyber Secure It January 2019nsadnanNo ratings yet

- HVAC ManualDocument107 pagesHVAC ManualWissam JarmakNo ratings yet

- Exc Fibre Installation GuideDocument38 pagesExc Fibre Installation GuidensadnanNo ratings yet

- Excel Intelligent PduDocument21 pagesExcel Intelligent PdunsadnanNo ratings yet

- Exc Fibre Installation GuideDocument16 pagesExc Fibre Installation GuideMohamad FaifNo ratings yet

- Excel Intelligent Pdu User InstructionsDocument2 pagesExcel Intelligent Pdu User InstructionsnsadnanNo ratings yet

- Exc Installation GuideDocument1 pageExc Installation GuidensadnanNo ratings yet

- Sensor Line Cable InstallationDocument6 pagesSensor Line Cable InstallationnsadnanNo ratings yet

- Risk Assessment - Tk-4741-Removal Works For Site Office FacilitiesDocument14 pagesRisk Assessment - Tk-4741-Removal Works For Site Office FacilitiesnsadnanNo ratings yet

- RISK ASSESSMENT - Load Current Measurement and Cleaning of Oil CoolerDocument5 pagesRISK ASSESSMENT - Load Current Measurement and Cleaning of Oil CoolernsadnanNo ratings yet

- PlachimadaDocument63 pagesPlachimadaSridhar AnanthaNo ratings yet

- Site Emergency Evacuationl Plan JEC Aramco Phase-01Document4 pagesSite Emergency Evacuationl Plan JEC Aramco Phase-01Shah MuzzamilNo ratings yet

- Indonesia Disaster Management Reference HandbookDocument90 pagesIndonesia Disaster Management Reference HandbookMohamad YunusNo ratings yet

- Cbse Ugc Net Paper 1 June 2014Document16 pagesCbse Ugc Net Paper 1 June 2014Anju SharmaNo ratings yet

- Fourth Science TestDocument6 pagesFourth Science Testsnaira ebanNo ratings yet

- Patricia Kenady - ch04 News Release 1Document2 pagesPatricia Kenady - ch04 News Release 1api-432657565No ratings yet

- Criteria Selection and Site CategoryDocument11 pagesCriteria Selection and Site CategoryDona NofiesNo ratings yet

- The Role of Social Worker-Post Disaster SituationDocument4 pagesThe Role of Social Worker-Post Disaster SituationDenver John Tacderas SolivenNo ratings yet

- Tos DRRDocument2 pagesTos DRRRyan San Luis100% (2)

- Anushree Gupta 19216012 - VIETNAM PDFDocument12 pagesAnushree Gupta 19216012 - VIETNAM PDFAnushree GuptaNo ratings yet

- NEA A Year Review 2015-16Document156 pagesNEA A Year Review 2015-16Avik PoudelNo ratings yet

- Ship/Platform Collision Risk in The UKCS - The Regulator's PerspectiveDocument19 pagesShip/Platform Collision Risk in The UKCS - The Regulator's Perspectiveuserscribd2011No ratings yet

- Quiz 1 - Mohd Khairul Fathy - 55222121157Document3 pagesQuiz 1 - Mohd Khairul Fathy - 55222121157M Asrar SidonNo ratings yet

- Volume 1-Policy 2014: AASHTO Drainage ManualDocument73 pagesVolume 1-Policy 2014: AASHTO Drainage ManualVicenteRocabadoNo ratings yet

- Volcanic Eruptions: Sneha Sara Varghese 36Document12 pagesVolcanic Eruptions: Sneha Sara Varghese 36snehasara10No ratings yet

- Beckett, Benjamin and Modern Crisis in CommunicationDocument14 pagesBeckett, Benjamin and Modern Crisis in CommunicationwillosisblessedNo ratings yet

- Earthquake Drill 2022Document42 pagesEarthquake Drill 2022Joyce CarreonNo ratings yet

- 2011 Sikkim EarthquakeDocument5 pages2011 Sikkim Earthquakedaniyal rasheedNo ratings yet

- Causes of TsunamiDocument2 pagesCauses of TsunamiAnanth SrinivasanNo ratings yet

- Science-9 Module-1 Version-3.docx NEWDocument14 pagesScience-9 Module-1 Version-3.docx NEWLINDSY MAE SULA-SULANo ratings yet

- The 2010 Earthquake in HaitiDocument14 pagesThe 2010 Earthquake in Haitiنزار خيرNo ratings yet

- 2010 SHMP FinalDocument748 pages2010 SHMP FinalMauro CaccavaleNo ratings yet

- CasestudyDocument2 pagesCasestudyAjmal AhammedNo ratings yet

- NEAP Narrative Report - March (Quarterly)Document11 pagesNEAP Narrative Report - March (Quarterly)Richa ShahiNo ratings yet

- Raworth Eternal SectionsDocument32 pagesRaworth Eternal SectionsKevin ThompsonNo ratings yet