Professional Documents

Culture Documents

BMTS-CP-031 - Asphalt Compaction Mould

Uploaded by

virajCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BMTS-CP-031 - Asphalt Compaction Mould

Uploaded by

virajCopyright:

Available Formats

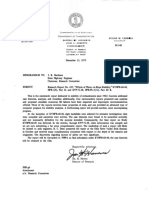

INTERNAL CALIBRATION PROCEDURE

Approved by: H. Woodyat Date:2004

BMTS-CP-031, Issue 1, January 2004

INTERNAL CALIBRATION PROCEDURE AND RESULTS

Asphalt Cylinder Moulds to BS 598 Part 107 :1990

ITEM DETAILS

Bodycote Reference Serial Number Description Range

Asphalt Cylinder Moulds N/A

Procedure

1. Equipment required

REFERENCE EQUIPMENT REQUIRED/USED

Description Bodycote Reference Date of Last Calibration Stated

Uncertainty

Vernier Calipers to 0.01 mm

Steel Rule to 1/16th of an inch

Balance to 1 g

Thermometer to 1oC, min.

2 Method ( Refer figure 2 of BS 598 part 107:1990 for details)

Extension/Extraction Collar

2.1 Measure the outer diameter at two diametrically opposite positions to the nearest 0.01mm. (a)

2.2 Measure inner diameter at two diametrically opposite positions to the nearest 0.01mm.(b)

2.3 Measure height at approximately four equidistant positions to the nearest 0.01 mm.(c)

2.4 Measure the height of the groove at approximately four different positions to the nearest 0.01mm.(d)

Mould Cylinder

2.5 Measure the outer diameter of the mould top rim at two diametrically opposite positions to the nearest 0.01mm.

(e)

2.6 Measure the inner diameter at two diametrically opposite positions to the nearest 0.01mm. (f)

2.7 Measure the height of the groove at approximately four equidistant positions to the nearest 0.01mm. (g)

2.8 Measure the height of the mould at approximately four equidistant positions to the nearest 0.01mm.(h)

2.9 Measure the outer diameter of the mould at two diametrically opposite positions to the nearest 0.01mm.(i)

Mould Base

2.10 Measure the diameter of the inner protruded portion at two diametrically opposite positions to the nearest 0.01

mm.(j)

2.11 Measure the height of the inner protruded portion at four approximately equidistant positions to the nearest

0.01mm. (k)

2.12 Measure the thickness of the base plate at four approximately equidistant positions to the nearest 0.01mm.(l)

2.13 Measure the outer diameter of the base plate at two diametrically opposite positions to the nearest 0.01mm.(m)

Results of Calibration

Page 1 of 2 BMTS- CP- 031

INTERNAL CALIBRATION PROCEDURE

Approved by: H. Woodyat Date:2004

Mass or Dimension Measured Reading Number Specification

1 2 3 4 Mean

Extension/Extraction Collar

Outer diameter, mm (0.01) a 113.5 114.5

Inner diameter , mm (0.01) b 104.7 104.9

Height, mm (0.01) c 69.9 70.1

Height of groove, mm (0.01) d 7.00 7.10

Mould Cylinder

Outer diameter of top rim, mm (0.01) e 108.6 108.8

Inner mould diameter, mm (0.01) f 101.5 101.7

Height of groove, mm (0.01 ) g 6.40 6.50

Height of mould, mm (0.01) h 87.3 87.5

Outer diameter of mould, mm (0.01) i 113.5 114.5

Mould Base

Inner protruded portion diameter, mm ( 0.01 ) j 100.7 101.3

Inner protruded portion Height, mm (0.01) k 11.00 11.10

Thickness of base plate, mm (0.01) l 2.95 3.05

Outer diameter of base plate, mm (0.01) m 120.5 121.5

Note: Essential Dimensions: f & j.

This design has been found satisfactory. Alternative designs are acceptable providing the essential dimensions are complied

with and the mould does not distort during compaction (Page 5 of BS 598: Part 207:1990).

Date of Calibration Ambient Temperature (C)

Suitability for Use/Restrictions on Use

Name of Operator Signature of Operator Checked by, Name Checked by, Signature

Page 2 of 2 BMTS- CP- 031

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- MS For Sheet Piling InstallationDocument35 pagesMS For Sheet Piling InstallationvirajNo ratings yet

- MS For Sheet Piling InstallationDocument35 pagesMS For Sheet Piling InstallationvirajNo ratings yet

- French Revolution ChoiceDocument3 pagesFrench Revolution Choiceapi-483679267No ratings yet

- Spec 828 11 June 2010.u - 2788646r - 2n - D1023132817Document13 pagesSpec 828 11 June 2010.u - 2788646r - 2n - D1023132817virajNo ratings yet

- Chich The ChickenDocument23 pagesChich The ChickenSil100% (4)

- Steel Pipe Piles 1999Document84 pagesSteel Pipe Piles 1999vothephuong100% (3)

- Attachment 1Document2 pagesAttachment 1virajNo ratings yet

- Spec 814 CFA Piles May 6 2015.RCN-D1523246311Document18 pagesSpec 814 CFA Piles May 6 2015.RCN-D1523246311K H V V MADUSHANKANo ratings yet

- Specification 835 4 April 13.RCN-D1323122512Document20 pagesSpecification 835 4 April 13.RCN-D1323122512K H V V MADUSHANKANo ratings yet

- Spec 813 11 June 2010.u - 2788224r - 1n - D1023132324Document23 pagesSpec 813 11 June 2010.u - 2788224r - 1n - D1023132324virajNo ratings yet

- Spec 821 11 June 2010.u - 2788528r - 1n - D1023132656Document13 pagesSpec 821 11 June 2010.u - 2788528r - 1n - D1023132656virajNo ratings yet

- Specification 833 Bridge Balustrades 3 August 2012.U - 3886768r - 1n - D1223236353Document15 pagesSpecification 833 Bridge Balustrades 3 August 2012.U - 3886768r - 1n - D1223236353virajNo ratings yet

- Specification 8142C 18 Jan 2011.u - 3050520r - 1n - D112314197Document14 pagesSpecification 8142C 18 Jan 2011.u - 3050520r - 1n - D112314197virajNo ratings yet

- Spec 820 Concrete 24 Nov 2016.RCN-D1623749976Document30 pagesSpec 820 Concrete 24 Nov 2016.RCN-D1623749976virajNo ratings yet

- Spec 819 11 June 2010.u - 2790253r - 1n - D1023134404Document12 pagesSpec 819 11 June 2010.u - 2790253r - 1n - D1023134404virajNo ratings yet

- Specification 831 03 Sep 2015.RCN-D1523516807Document14 pagesSpecification 831 03 Sep 2015.RCN-D1523516807K H V V MADUSHANKANo ratings yet

- Specification 822 Steel Reinforcement 02feb 2016.RCN-D162363735Document17 pagesSpecification 822 Steel Reinforcement 02feb 2016.RCN-D162363735virajNo ratings yet

- Specification 824 Prestressing of Concrete.u - 4073942r - 1n - D1223350066Document20 pagesSpecification 824 Prestressing of Concrete.u - 4073942r - 1n - D1223350066virajNo ratings yet

- Specification 803 24nov 2016.RCN-D1623750166Document13 pagesSpecification 803 24nov 2016.RCN-D1623750166virajNo ratings yet

- Spec 812 Bored Piles 17 March 2015.RCN-D1523144916Document19 pagesSpec 812 Bored Piles 17 March 2015.RCN-D1523144916virajNo ratings yet

- Specification 830 Structural Steelwork 02 Feb 2016.RCN-D162364100Document35 pagesSpecification 830 Structural Steelwork 02 Feb 2016.RCN-D162364100virajNo ratings yet

- Spec 870 11 June 2010.u - 2795475r - 1n - D1023137018Document9 pagesSpec 870 11 June 2010.u - 2795475r - 1n - D1023137018K H V V MADUSHANKANo ratings yet

- Specification 801 Excavation 26amp3b Backfill For Structures 10 Nov 2016.RCN-D1623714787Document16 pagesSpecification 801 Excavation 26amp3b Backfill For Structures 10 Nov 2016.RCN-D1623714787GEO MSc Group-2016No ratings yet

- Specification 802 Mechanically Stabilised Earth Walls 7 Aug 15.RCN-D1523454210Document13 pagesSpecification 802 Mechanically Stabilised Earth Walls 7 Aug 15.RCN-D1523454210K H V V MADUSHANKANo ratings yet

- Effects of Water On Slope Stability - 3 PDFDocument44 pagesEffects of Water On Slope Stability - 3 PDFreem.ranoom.moonNo ratings yet

- Spec 875 - 3 Nov 16.RCN-D1623700158Document12 pagesSpec 875 - 3 Nov 16.RCN-D1623700158GEO MSc Group-2016No ratings yet

- Spec 860 11 June 2010.u - 2792564r - 1n - D1023135589Document16 pagesSpec 860 11 June 2010.u - 2792564r - 1n - D1023135589K H V V MADUSHANKANo ratings yet

- Spec 825 11 June 2010.u - 2791921r - 1n - D1023135429Document8 pagesSpec 825 11 June 2010.u - 2791921r - 1n - D1023135429virajNo ratings yet

- Spec 871 11 June 2010.u - 2795637r - 1n - D1023137200Document9 pagesSpec 871 11 June 2010.u - 2795637r - 1n - D1023137200GEO MSc Group-2016No ratings yet

- Contribution of The Root To Slope StabilityDocument12 pagesContribution of The Root To Slope StabilityvirajNo ratings yet

- Specification 201 Quality Systems 14 April 2016.RCN-D1623234100Document59 pagesSpecification 201 Quality Systems 14 April 2016.RCN-D1623234100virajNo ratings yet

- Catalogue PDFDocument4 pagesCatalogue PDFShivam GuptaNo ratings yet

- Chapter 4Document19 pagesChapter 4EyadNo ratings yet

- IRC-114-2013 Use of Silica Fume in Rigid PavementDocument14 pagesIRC-114-2013 Use of Silica Fume in Rigid PavementZakee MohamedNo ratings yet

- Important instructions on judicial procedure from Narada SmritiDocument6 pagesImportant instructions on judicial procedure from Narada SmritirohitNo ratings yet

- Land Equivalent Ratio, Growth, Yield and Yield Components Response of Mono-Cropped vs. Inter-Cropped Common Bean and Maize With and Without Compost ApplicationDocument10 pagesLand Equivalent Ratio, Growth, Yield and Yield Components Response of Mono-Cropped vs. Inter-Cropped Common Bean and Maize With and Without Compost ApplicationsardinetaNo ratings yet

- Viscosity IA - CHEMDocument4 pagesViscosity IA - CHEMMatthew Cole50% (2)

- Silyzer 300 - Next Generation PEM ElectrolysisDocument2 pagesSilyzer 300 - Next Generation PEM ElectrolysisSaul Villalba100% (1)

- User Manual: C43J890DK C43J892DK C49J890DK C49J892DKDocument58 pagesUser Manual: C43J890DK C43J892DK C49J890DK C49J892DKGeorge FiruțăNo ratings yet

- Enbrighten Scoring Rubric - Five ScoresDocument1 pageEnbrighten Scoring Rubric - Five Scoresapi-256301743No ratings yet

- Participatory Assessment of Ragay Gulf Resources and SocioeconomicsDocument167 pagesParticipatory Assessment of Ragay Gulf Resources and SocioeconomicsCres Dan Jr. BangoyNo ratings yet

- Captive Screws - Cap Head: Hex. SocketDocument5 pagesCaptive Screws - Cap Head: Hex. SocketvikeshmNo ratings yet

- Main: Exploded ViewDocument30 pagesMain: Exploded ViewamokssantiagoNo ratings yet

- Comandos HuaweiDocument3 pagesComandos Huaweicgottoli0% (1)

- ARTS 9 Q4 Week 1Document3 pagesARTS 9 Q4 Week 1Elaissa MaglanqueNo ratings yet

- Modul English For Study SkillsDocument9 pagesModul English For Study SkillsRazan Nuhad Dzulfaqor razannuhad.2020No ratings yet

- Eco 301 Final Exam ReviewDocument14 pagesEco 301 Final Exam ReviewCảnh DươngNo ratings yet

- Camp ApplianceDocument1 pageCamp ApplianceflyzalNo ratings yet

- Split Plot Design GuideDocument25 pagesSplit Plot Design GuidefrawatNo ratings yet

- Beuys Begleitheft en ScreenDocument18 pagesBeuys Begleitheft en Screensofijawt0% (1)

- Goldenberg and Reddy (2017)Document10 pagesGoldenberg and Reddy (2017)Mariana ToniniNo ratings yet

- V Bhebhe PDFDocument63 pagesV Bhebhe PDFVusi BhebheNo ratings yet

- Demo TeachingDocument22 pagesDemo TeachingCrissy Alison NonNo ratings yet

- NotesTransl 108 (1985) Larsen, Who Is This GenerationDocument20 pagesNotesTransl 108 (1985) Larsen, Who Is This GenerationluzuNo ratings yet

- Rigor Mortis and Lividity in Estimating Time of DeathDocument2 pagesRigor Mortis and Lividity in Estimating Time of DeathfunnyrokstarNo ratings yet

- Rise of NationalismDocument19 pagesRise of NationalismlolaNo ratings yet

- Delhi Police ResultDocument26 pagesDelhi Police ResultExam Aspirant100% (1)

- Hall Design For SpeechDocument1 pageHall Design For SpeechSarovar SaroNo ratings yet