Professional Documents

Culture Documents

TDJ240-0 NG SRT Clarifier PDF

Uploaded by

Hery GunawanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TDJ240-0 NG SRT Clarifier PDF

Uploaded by

Hery GunawanCopyright:

Available Formats

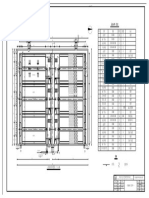

TDJ240-0

9500

10

6740

6080

4020

a DN500

325 b DN400

426

c DN150

d ()

A-A e DN800

2620

f DN200

g DN150

Pipe size table

Form of connection

Symbol Nominal size surfaces Usage

10

5

a DN500 Butt weld Juice inlet

A A b DN400 Juice outlet

Butt weld

890

c DN150 Butt weld Liquidation pipe (for shutdown)

Liquid level d Checking window (sight glass)

e DN800 Butt weld Quick open manhole for clarifier

f DN200 Butt weld Mud outlet

b

g DN150 Butt weld Vessel drain

4000

a

1

32512 d

C 1

2

b

12

a

3

Nominal mad level

4Q/TJ/Z140

c

Technical explanation

885

225

2400 1The equipment will be dispatched in bulk,assemblied and welded at sife.all pipe on

10685

14 the equpment body will be opened and welded at site.

800

10000

2The bottom of clarifier is the clarified juice storage tank.It is also the support of

200

the clarifier bottom.The cone part of clarifer is the upper cover of clarified juice

1010

storage tank.

800

3After the clarifer and clarified juice storage tank are welded together,the stairs

will be welded at the benchmark of the bottom of clarified juice storage tank

according to the drawing.

4The heat preservation of clarifier is according to the regulations of Q/TJ/Z140.

1280

6000

285

T012 CLARIFIED JUICE STORAGE TANK

f

g

6000

4000

D

54

d

e

c

800

C

1:10

600

600

600

2500

b

a

700

400

450

00

0

PROJECT AREA EQUIP. REF. SERIAL REV.

R1

DRG No.

F010

2000

4

APPROVED

d KUNMING LIGHT INDUSTRY MACHINARY

INVESTIGATED COMPANY LTD.

e 3

200

c KLIM Co.

EXAMINED DISCIPLINE

EQUIPMENT

2 LPI-BATURAJA SUGAR FACTORY PROJECT

CHECKED STAGE

50 1 JUICE CLARIFICATION STATION

DESIGNED SCALE

NG SRT(SRI) DRAWING No.

1500 0 1:35

F010

REV. D/M/Y DRAWN BY WEIGHT TDJ240-0

NG SRTCLARIFIER (SRI)

You might also like

- 6-1 廢水收集處理系統規劃練習題 PDFDocument14 pages6-1 廢水收集處理系統規劃練習題 PDFFlora LinNo ratings yet

- UF Manual 2012 (1) - 16461215029Document78 pagesUF Manual 2012 (1) - 16461215029WendyNo ratings yet

- 太陽熱能利用與製冷 Solar Thermal Heating and CoolingDocument31 pages太陽熱能利用與製冷 Solar Thermal Heating and CoolingSTM Works0% (1)

- 高效低耗碱性电解水制氢装置的结构设计及性能研究 王玉杰Document70 pages高效低耗碱性电解水制氢装置的结构设计及性能研究 王玉杰irisqu2No ratings yet

- 基于HTRI的冷凝器优化设计最终版 PDFDocument70 pages基于HTRI的冷凝器优化设计最终版 PDFaaa100% (1)

- 電氣施工規範 (FPCC) 920617Document14 pages電氣施工規範 (FPCC) 920617Yang WuNo ratings yet

- 臭氧催化氧化计算书Document7 pages臭氧催化氧化计算书WendyNo ratings yet

- 儀器工程規範3Document98 pages儀器工程規範3Yang WuNo ratings yet

- 京鼎 石油化工装置布置设计導則Document49 pages京鼎 石油化工装置布置设计導則Yang WuNo ratings yet

- 京鼎 加热炉配管设计导则Document47 pages京鼎 加热炉配管设计导则Yang WuNo ratings yet

- 京鼎 管廊配管设计导则Document36 pages京鼎 管廊配管设计导则Yang WuNo ratings yet

- 半導體及光電廢水處理技術概論Document44 pages半導體及光電廢水處理技術概論bill100% (2)

- 能源損失耗能計算公式 PDFDocument9 pages能源損失耗能計算公式 PDF黃冠旗No ratings yet

- 几乎所有食物的英文!!Document5 pages几乎所有食物的英文!!Rongrong Fu100% (1)

- NB-HM3810微電腦電烤箱 使用說明書 PDFDocument28 pagesNB-HM3810微電腦電烤箱 使用說明書 PDFAurora ChangNo ratings yet

- NB-HM3810微電腦電烤箱 使用說明書 PDFDocument28 pagesNB-HM3810微電腦電烤箱 使用說明書 PDFAurora Chang100% (2)

- 公共工程製圖手冊製圖標準圖例Document160 pages公共工程製圖手冊製圖標準圖例9 onNo ratings yet

- 08第八章 鍋爐維修作業程序 (v2.2)Document18 pages08第八章 鍋爐維修作業程序 (v2.2)yen691028No ratings yet

- 阀门知识简介完全版 - (上)Document43 pages阀门知识简介完全版 - (上)ZangNo ratings yet

- 電子級異丙醇純化技術介紹 簡報資料 PDFDocument46 pages電子級異丙醇純化技術介紹 簡報資料 PDF小菜包100% (1)

- API & ISO Certified 1 0Document12 pagesAPI & ISO Certified 1 0GeorgeNo ratings yet

- Centum VP 操作手册Document122 pagesCentum VP 操作手册qiang gaoNo ratings yet

- February 2018 (Chemical Engineering Issue) PDFDocument34 pagesFebruary 2018 (Chemical Engineering Issue) PDFelfelixNo ratings yet

- C19 L型基座式分電箱詳圖Document1 pageC19 L型基座式分電箱詳圖chaoyiv2No ratings yet

- 溜冰場標準圖Document1 page溜冰場標準圖chaoyiv2No ratings yet

- 编 号 图 别 Discipline Number Designed Class Des no. Discipline 图 别 比 例 日 期 advisor Scale Date Academic School of Environment Harbin Institute of TechnologyDocument1 page编 号 图 别 Discipline Number Designed Class Des no. Discipline 图 别 比 例 日 期 advisor Scale Date Academic School of Environment Harbin Institute of Technology阙绮东No ratings yet

- 413E63-02-07-01R1~04R1 交通洞结构布置修改图(中英对照版)20181116-001Document1 page413E63-02-07-01R1~04R1 交通洞结构布置修改图(中英对照版)20181116-001Elvis Sandro Montesinos chNo ratings yet

- Drawing 2Document1 pageDrawing 2andreas pranotoNo ratings yet

- BG BG G01.020.3 FLK - BDocument2 pagesBG BG G01.020.3 FLK - BbuziNo ratings yet

- Arrangement of Boiler NozzleDocument1 pageArrangement of Boiler NozzleMaritime MineNo ratings yet

- Drawing 1Document1 pageDrawing 1andreas pranotoNo ratings yet

- Osnova Garaže BedemDocument1 pageOsnova Garaže BedemPredrag KrsmanovićNo ratings yet

- CH TU 00Document4 pagesCH TU 00Roke LlamocaNo ratings yet

- Drawing 4Document1 pageDrawing 4andreas pranotoNo ratings yet

- 3rd QDJE519N0 RearRoofSpoiler 20141015Document9 pages3rd QDJE519N0 RearRoofSpoiler 20141015ivanNo ratings yet

- Planos de Gobi/RullDocument8 pagesPlanos de Gobi/Rullhelen diazNo ratings yet

- XRZ-500 Outline DrawingDocument1 pageXRZ-500 Outline Drawingsaberma tecnical officeNo ratings yet

- 20J333建筑防腐蚀构造 (高清带书签)Document184 pages20J333建筑防腐蚀构造 (高清带书签)chengNo ratings yet

- 剑桥雅思真题16Document1 page剑桥雅思真题16Maoyuan GaoNo ratings yet

- HA Columba (Crate)Document4 pagesHA Columba (Crate)mfarrukhkNo ratings yet

- FFB Scraper Conveyor No. 1ADocument1 pageFFB Scraper Conveyor No. 1ABuditama ChandranegaraNo ratings yet

- A3-03 立面及大樣詳圖 (一)Document1 pageA3-03 立面及大樣詳圖 (一)Campus HsuNo ratings yet

- A14 型鋼護欄及槽鋼護欄詳圖 V2.0 2022.04-A3Document1 pageA14 型鋼護欄及槽鋼護欄詳圖 V2.0 2022.04-A3chaoyiv2No ratings yet

- 2011 rabbit year - Zhaocaijingbao 招财进宝。 fengshui fortune forecast for 2011Document188 pages2011 rabbit year - Zhaocaijingbao 招财进宝。 fengshui fortune forecast for 2011Didadi KohNo ratings yet

- CPC 100T RC P 001 01Document1 pageCPC 100T RC P 001 01crack1943No ratings yet

- SRN Flange SketchDocument1 pageSRN Flange SketchSACHIN PATELNo ratings yet

- SXJ - Gear Box Assembly DrawingDocument1 pageSXJ - Gear Box Assembly DrawingnagarajangopiNo ratings yet

- BerimbauDocument1 pageBerimbauMylena FelipeNo ratings yet

- Gbr. Plat DeukerDocument1 pageGbr. Plat DeukerBiltsar BardaNo ratings yet

- Red Sea Jeddah Mall DirectoryDocument6 pagesRed Sea Jeddah Mall DirectoryAbi Faiq100% (1)

- C32 橢圓形基座式分電箱詳圖Document1 pageC32 橢圓形基座式分電箱詳圖chaoyiv2No ratings yet

- 加重钻杆的耐磨带焊接实例解析Document3 pages加重钻杆的耐磨带焊接实例解析xiong hanNo ratings yet

- ANHELODocument11 pagesANHELOEddie Irizarry100% (2)

- LN CN DMSFDocument8 pagesLN CN DMSFsf wNo ratings yet

- (Wiring Listrik) B00836 P5026 Patriot DFBB PDFDocument56 pages(Wiring Listrik) B00836 P5026 Patriot DFBB PDFabdulwahid lesmanaNo ratings yet

- BABA - Tumulte Des Flots - SHIOSAIDocument13 pagesBABA - Tumulte Des Flots - SHIOSAIBaptiste Le PageNo ratings yet

- 181203 LGA-4100 現場接管接線圖Document10 pages181203 LGA-4100 現場接管接線圖manh hoNo ratings yet

- GND GND: Sheet - 1Document1 pageGND GND: Sheet - 1Daniel OfoeNo ratings yet

- No Smoking SignageDocument1 pageNo Smoking SignageEason YUNo ratings yet

- 2542αδειαDocument1 page2542αδειαtama0924No ratings yet