Professional Documents

Culture Documents

3361701

Uploaded by

josephCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3361701

Uploaded by

josephCopyright:

Available Formats

Applied Instrumentation Course Code:3361701

GUJARAT TECHNOLOGICAL UNIVERSITY, GUJARAT

COURSE CURRICULUM

COURSE TITLE: APPLIED INSTRUMENTATION

(COURSE CODE: 3361701)

Diploma Programme in which this course is offered Semester in which offered

Instrumentation and Control Engineering Sixth

1. RATIONALE

The ultimate success of any plant control system rests on the ability of instrument experts to

make proper application of components and system and on the ability of maintenance people

to keep them calibrated and work safely. This course is essential in order to prepare future

instrumentation personals for these tasks.

2. COMPETENCIES

The course content should be taught and implemented with the aim to develop required skills

in the students so that they are able to acquire following competencies:

Operate and maintain different types of instrument air supply systems and

plant interlock system.

Select, install and maintain various instrumentation & control systems for

various process industries.

3. COURSE OUTCOMES

The theory should be taught and practical should be carried out in such a manner that students

are able to acquire required learning out comes in cognitive, psychomotor and affective

domain to demonstrate following course outcomes:

i Select appropriate instruments according to process application requirement.

ii Utilize instrument drawings during installation and commissioning of plant.

iii Design a plant interlock circuit.

iv Design an instrument air supply system for plant.

v Test and maintain major control loops of cement, textile and power plant.

vi Design, test and maintain major control loops for heat exchanger, chemical reactors

and distillation columns.

4. TEACHING AND EXAMINATION SCHEME

Teaching Scheme Total Examination Scheme

(Hours) Credits Theory Marks Practical Marks Total

(L+T+P) Marks

L T P C ESE PA ESE PA

200

3 0 4 7 70 30 40 60

Legends: L-Lecture; T Tutorial/Teacher Guided Theory Practice; P - Practical; C Credit

ESE - End Semester Examination; PA - Progressive Assessment.

GTU/NITTTR Bhopal/14 1 Gujarat State

Applied Instrumentation Course Code:3361701

5. COURSE CONTENT DETAILS

Unit Major Learning Outcomes Topics and Sub-topics

(in cognitive domain)

Unit I 1a Describe factors affecting for 1.1 Factors affecting for

Selection, selection of pressure instruments. selection of :

Installation 1b Describe factors affecting for 1.1.1 Pressure

and selection of flow instruments. Instruments

Commissioning 1c Describe factors affecting for 1.1.2 Flow Instruments

of Instruments. selection of level instruments. 1.1.3 Level Instruments

1d Describe factors affecting for 1.1.4 Temperature

selection of temperature Instruments

instruments. 1.1.5 Control Valve

1e Describe factors affecting for

selection of Control Valves.

1f Justify the need for instrumentation 1.2 Instrumentation related

related documents listed in topic documents :

1.2. Process flow sheets,

Mechanical flow sheets,

Instrument index sheet,

Loop wiring diagram, Panel

drawings and

specifications, Plot plans,

Installation details

1g State the checklist of good 1.3 Checklist of good

installation practices. installation practices

1h Describe typical checkout 1.4 Typical Check out

procedure for flow transmitter. procedure for:

1i Describe typical checkout - Flow transmitter

procedure for temperature - Temperature transmitter

transmitter. - Control valve

1j Describe typical checkout

procedure for control valve.

Unit-II 2a Describe sizing criteria and 2.1 Sizing criteria and pressure

Instrument Air pressure level for designing of air level for air supply system

Supply System supply system. 2.2 Supply System for low air

2b Draw and explain Air supply requirement

system for low air requirement. 2.3 Supply System for large air

2c Draw and explain Air supply requirement

system for large air requirement.

2d Explain construction and working 2.4 Compressor systems

of any one type of positive 2.4.1 Positive displacement

displacement type compressor. type

2e Describe Compressor controls. 2.4.2 Compressor controls

GTU/NITTTR Bhopal/14 2 Gujarat State

Applied Instrumentation Course Code:3361701

2f Justify the need for dryers.(State 2.5 Dryers

necessity of dryer) 2.5.1 Types of dryers-

2g Classify dryers. Explain desiccant Refrigeration and

dryers in detail. Desiccant(Heated and

2h Explain operation of heated type of Heatless)

desiccant dryers. 2.5.2 Necessity of dryers

2i Explain operation of heatless type

of desiccant dryers

Unit-III 3a Describe automatic stop motion 3.1 Textile industry

Industrial control in textile industry 3.1.1 Automatic stop

Control 3b Describe Humidity and moisture motion control

Schemes and control in textile industry. 3.1.2 Humidity and

Plant 3c Describe Stretch control in textile moisture control

Interlocks industry. 3.1.3 Stretch control

3d Explain kiln temperature control 3.2 Cement Industry - Kiln

system in cement industry temperature control

3e Explain single element Drum level 3.3 Thermal power plant

control in thermal power plant. 3.3.1 Drum level

3f Explain two element Drum level control-

controls in thermal power plant. single

3g Explain three element Drum level element, two

controls in thermal power plant. element and

three element.

3h Justify the need for plant 3.4 Need for plant interlocks

interlocks. 3.5 Simple plant interlock

3i Describe the working of any one circuit

plant interlock circuit with neat

diagram.

Unit-IV 4a State and explain heat exchanger 4.1 Heat Exchanger variables

Heat variables and draw its symbol. and symbol.

Exchanger & 4b Explain conventional heat 4.2 Conventional Heat

Chemical exchanger control scheme. Exchanger Control Scheme.

Reactors 4c Explain Temperature Pressure 4.3 Temperature-Pressure

cascade loop of heat exchanger. cascade loop in heat

4d Explain Temperature Flow exchanger.

cascade loop of steam reboiler. 4.4 Temperature-flow cascade

loop of steam reboilers.

GTU/NITTTR Bhopal/14 3 Gujarat State

Applied Instrumentation Course Code:3361701

4e Draw and Explain Temperature 4.5 Temperature control in a

control scheme for chemical chemical reactor.

reactor. 4.6 Cascade loop for

4f Explain cascade loop scheme for temperature control in a

temperature control in chemical reactor.

reactor. 4.7 Split range control of

4g Explain Split range control of multiple coolants in a

multiple coolants in chemical reactor.

reactor. 4.8 Reactor pressure control by

4h Explain Reactor pressure control vent throttling

by throttling flow of vent gas.

Unit-V 5a List out variables for distillation 5.1 Variables for distillation

Distillation column. column operation.

Column 5b Explain pressure control of 5.2 Distillation column pressure

Schemes Distillation column by throttling control by throttling

condenser water. condenser water.

5c Explain temperature control of 5.3 Distillation column

Distillation column by heat control temperature control by heat

to reboiler. control to reboiler.

5d Explain temperature control of 5.4 Distillation column

Distillation column by reflux flow temperature control by

control. reflux flow control.

5e Explain Feed flow control scheme 5.5 Feed flow control scheme of

of Distillation column. Distillation column.

5f Explain Cascade control of feed to 5.6 Cascade control of feed to

second column. second column.

6. SUGGESTED SPECIFICATION TABLE WITH HOURS AND MARKS(Theory)

Unit Unit Title Teaching Distribution Of Theory Marks

No. Hours R U A Total

Level Level Level Marks

I Selection, Installation and 12 2 5 11 18

Commissioning of Instruments.

II Instrument Air Supply System 7 2 4 6 12

III Industrial Control Schemes and 8 2 4 8 14

Plant Interlocks

IV Heat Exchanger & Chemical 8 2 4 8 14

Reactors

V Distillation Column Schemes 7 2 4 6 12

TOTAL 42 10 21 39 70

Legends: R = Remember; U = Understand; A = Apply and above levels (Blooms revised

taxonomy)

Note: This specification table shall be treated as a general guideline for students and teachers.

The actual distribution of marks in the question paper may vary slightly from above table.

GTU/NITTTR Bhopal/14 4 Gujarat State

Applied Instrumentation Course Code:3361701

7. SUGGESTED LIST OF EXERCISES/PRACTICALS

The practical should be properly designed and implemented with an attempt to develop

different types of skills (outcomes in psychomotor and affective domain) so that students

are able to acquire the competencies/programme outcomes. Following is the list of practical

exercises for guidance.

Note: Here only outcomes in psychomotor domain are listed as practical. However, if these

practical are completed appropriately, they would also lead to development of certain

outcomes in affective domain which would in turn lead to development of Course Outcomes

related to affective domain. Thus over all development of Programme Outcomes (as given in

a common list at the beginning of curriculum document for this programme) would be

assured.

Faculty should refer to that common list and should ensure that students also acquire

outcomes in affective domain which are required for overall achievement of Programme

Outcomes/Course Outcomes.

Approx.

S. Practical Exercise

Unit Hours

No. (Outcomes in psychomotor domain)

Required

1 I Select appropriate pressure instrument. 2

2 I Select appropriate flow instrument. 2

3 I Select appropriate level instrument. 2

4 I Select appropriate temperature instrument. 2

5 I Select appropriate type of control valve. 2

6 I Use the checklist of installation of a new instrument taking care 2

of all safety precautions.

7 I Check out a given flow transmitter prior to commissioning. 2

8 I Check out temperature transmitter. 2

9 I Check out control valve. 2

10 II Select proper pressure level and size of compressor for 2

instrument air supply system.

11 III Simulate automatic stop motion control process of textile 4

industry in a simulator.

12 III Simulate Humidity and moisture control of textile industry in a 4

simulator.

13 III Simulate Stretch control of textile industry in a simulator. 4

14 III Simulate kiln temperature control of cement industry in a 4

simulator.

15 III Simulate single element drum level control system in a 4

simulator.

16 III Simulate two element drum level control system in a simulator. 4

17 III Simulate three element drum level control system in a 4

simulator.

18 III Program interlocks circuit in plc simulator. 4

19 IV Simulate Conventional Heat Exchanger Control scheme in a 4

control simulator.

20 IV Simulate Temperature-Pressure cascade loop on steam heater in 4

GTU/NITTTR Bhopal/14 5 Gujarat State

Applied Instrumentation Course Code:3361701

Approx.

S. Practical Exercise

Unit Hours

No. (Outcomes in psychomotor domain)

Required

a control simulator.

21 IV Simulate Temperature-flow cascade loop on steam heater in a 4

control simulator.

22 IV Simulate Temperature control in a chemical reactor in a control 4

simulator.

23 IV Simulate Cascade loop for temperature control of reactor in a 4

control simulator.

24 IV Simulate Split range control of multiple coolants of reactor in a 4

control simulator.

25 IV Simulate Reactor pressure control by vent throttling in a control 4

simulator.

26 V Simulate Distillation column pressure control by throttling 4

condenser water in a control simulator.

27 V Simulate Distillation column temperature control by heat 4

control to reboiler in a control simulator.

28 V Simulate Distillation column temperature control by reflux flow 4

control in a control simulator.

29 V Simulate Feed flow control scheme of Distillation column in a 4

control simulator.

30 V Simulate Cascade control of feed to second column in a control 4

simulator.

31 V 4

Simulate column pressure control scheme in a control simulator.

Total Hours 104

Note: Perform any of the practical exercises from above list for total of minimum 56 hours

depending upon the availability of resources so that skills matching with the most of the

outcomes of every unit are included.

8. SUGGESTED LIST OF STUDENT ACTIVITIES:

i Present a seminar on any one technical topic.

ii Set up practical apparatus on their own during practical under the guidance of

faculty.

iii Debate on merits and demerits of current industrial control scheme.

iv Prepare a poster on any one topic from curriculum.

9. SPECIAL INSTRUCTIONAL STRATEGIES (If any):

i Display animation videos of industrial loops.

ii Arrange visit to nearby industry to observe real-time loops.

iii Facilitate the students to set up practical apparatus on their own.

iv Compliment student for his/her work done during the practical in order to

motivate him/her by student and Instruct him/her remedies to improve his work if

required.

v Arrange expert lectures of instrumentation engineers working in process

industries.

GTU/NITTTR Bhopal/14 6 Gujarat State

Applied Instrumentation Course Code:3361701

10. SUGGESTED LEARNING RESOURCES

A.) Books

Sr

Title of Book Author Publication

No.

1 Instrument Engineers Handbook Bela G Liptak Chilton book

company, Radnor,

Pennsylvania,3rd

edition

2 Applied Instrumentation in the W G Andrews, H B Gulf Publishing

process industries Williams Company.

3 Chemical Process Industries R N Shreeve McGraw-Hill, 3rd

edition

4 Chemical Engineering Dryden

B.) Major Equipment/Instruments:

i Control Valve

ii Compressor

iii Multimeter

iv Current Source

v Voltage Source,

vi Different types of pressure measuring instruments, Different types of flow

measuring instruments,Different types of temperature measuring instruments,

Different types of level measuring instruments,

vii Chemical reactor model,

viii distillation column model,

ix Heat exchanger model.

C.) Software/Learning Websites

i books.google.co.in

ii en.wikipedia.org

iii www.britannica.com

11. COURSE CURRICULUM DEVELOPMENT COMMITTEE

Faculty Members from Polytechnics

Prof. R J Dhruv, Sr. Lecturer (I/C HOD) in IC, AVPTI, Rajkot

Prof. R. P. Raiyani, I/C HOD, Christ Polytechnic Institute, Rajkot

Prof. (Smt.) S K Raval, Lecturer in IC, Government Polytechnic, Ahmedabad

Prof. M J Dehlvi, Lecturer in IC , Government Polytechnic, Gandhinagar

Coordinator and Faculty Member from NITTTR Bhopal

Dr. Joshua Earnest, Professor, Department of Electrical and Electronics

Engineering

Dr Shashi Kant Gupta, Professor and Coordinator for State of Gujarat

GTU/NITTTR Bhopal/14 7 Gujarat State

You might also like

- Instrumentation OverviewDocument70 pagesInstrumentation OverviewTalicni Tom100% (1)

- Introduction - Industrial InstrumentationDocument70 pagesIntroduction - Industrial InstrumentationEdu ParisNo ratings yet

- Course Title: Process Instrumentation-I: Instrumentation and Control Engineering 4 SemesterDocument7 pagesCourse Title: Process Instrumentation-I: Instrumentation and Control Engineering 4 SemesterAbarnaNo ratings yet

- 182113503NCS For Commercial HVAC Technician-2021Document24 pages182113503NCS For Commercial HVAC Technician-2021arjuntamangshangdenNo ratings yet

- Control Devices (CD) 3342001Document7 pagesControl Devices (CD) 3342001BHATT RONAK MT-04No ratings yet

- 5 Semester: I. Ii. Iii. Iv. VDocument9 pages5 Semester: I. Ii. Iii. Iv. VPATEL JAYNo ratings yet

- De ZG516 Course HandoutDocument18 pagesDe ZG516 Course HandoutpanyamnrNo ratings yet

- CI3600 WB1 ObjectivesDocument1 pageCI3600 WB1 Objectivesfreind bestNo ratings yet

- 3361701-Applied Instrumentation PDFDocument7 pages3361701-Applied Instrumentation PDFNitin PrajapatiNo ratings yet

- Es Zg511 Course HandoutDocument16 pagesEs Zg511 Course HandoutfenytepeNo ratings yet

- Course Code: 4360504Document9 pagesCourse Code: 4360504Abhishek ThummarNo ratings yet

- Process Control Unit 1Document44 pagesProcess Control Unit 1anshu4u06No ratings yet

- Part A: Content DesignDocument16 pagesPart A: Content DesignG C DODDA RANGAPPANo ratings yet

- Part A: Content DesignDocument16 pagesPart A: Content DesignAnuNo ratings yet

- Performance Monitoring Procedure - FinalDocument9 pagesPerformance Monitoring Procedure - FinalMuhammad Junaid KhanNo ratings yet

- Auto II WK 9-18Document7 pagesAuto II WK 9-18Anna Marie AbalajenNo ratings yet

- Instrument Configuration Practices Course Code: 3321704Document5 pagesInstrument Configuration Practices Course Code: 3321704Darshit KotadiyaNo ratings yet

- Preventative Maintenance Agreement: Extending Equipment LifeDocument8 pagesPreventative Maintenance Agreement: Extending Equipment LifeJo Ziza SugihartoNo ratings yet

- Guide 15997Document29 pagesGuide 15997djukalNo ratings yet

- Syllabus Analytical - InstrumenationDocument9 pagesSyllabus Analytical - Instrumenationurvish_soniNo ratings yet

- DIO 01.3. Tipno Odobrenje Proizvoda July 2020Document8 pagesDIO 01.3. Tipno Odobrenje Proizvoda July 2020Samo SpontanostNo ratings yet

- Process & Instrumentation Diagram (P&ID) : Dr. RameshDocument66 pagesProcess & Instrumentation Diagram (P&ID) : Dr. Rameshalejandro inostrozaNo ratings yet

- P&id PDFDocument66 pagesP&id PDFFarook MohideenNo ratings yet

- Process & Instrumentation Diagram (P&ID)Document66 pagesProcess & Instrumentation Diagram (P&ID)Syed HameedNo ratings yet

- Control & Inst - V-IDocument180 pagesControl & Inst - V-ISiva Kumar TutikaNo ratings yet

- Syllabus Modul GeothermalDocument6 pagesSyllabus Modul GeothermalAgastyo WahyuNo ratings yet

- Summary TABDocument8 pagesSummary TABFaizal AchmadNo ratings yet

- EE5462 Maintenance of Electrical EquipmentDocument9 pagesEE5462 Maintenance of Electrical Equipmentpruthvijkhonde7No ratings yet

- The Session Will Start at 13:05 and Will Be Recorded: Please Login To Socrative Student: Room Name: Weston3103Document21 pagesThe Session Will Start at 13:05 and Will Be Recorded: Please Login To Socrative Student: Room Name: Weston3103EMILY BLANDFORDNo ratings yet

- Mechatronics - de ZG516Document18 pagesMechatronics - de ZG516Umesh BhadaleNo ratings yet

- HVAC System Selection ReportDocument16 pagesHVAC System Selection ReportArman Ul Nasar100% (1)

- Vehicle Air Conditioning Course Code: 3360204Document6 pagesVehicle Air Conditioning Course Code: 3360204wolerosNo ratings yet

- Testo 315-4 CO Ambient Measuring Instrument: Instruction ManualDocument20 pagesTesto 315-4 CO Ambient Measuring Instrument: Instruction Manualliz angelicaNo ratings yet

- Chapter 01 PrintDocument8 pagesChapter 01 PrintErick OderoNo ratings yet

- Annex 2 Qualification of GC Equipment-1Document11 pagesAnnex 2 Qualification of GC Equipment-1BhargavaNo ratings yet

- CHAPTER 4 Process Control COMPLETEDocument42 pagesCHAPTER 4 Process Control COMPLETEkhairitajurusNo ratings yet

- SyllabusDocument9 pagesSyllabusbhattparthivNo ratings yet

- Amendment Sheet 1: Replacement TextDocument17 pagesAmendment Sheet 1: Replacement Textkapster KannourNo ratings yet

- Worldwide Engineering Standards: Procedures For High Humidity TestDocument3 pagesWorldwide Engineering Standards: Procedures For High Humidity TestAkmal NizametdinovNo ratings yet

- Instrumentation and ControlDocument2 pagesInstrumentation and ControlKrista JacksonNo ratings yet

- PCCGN002Document11 pagesPCCGN002Ittle1970100% (1)

- Annex 2 Qualification of GC EquipmentDocument11 pagesAnnex 2 Qualification of GC EquipmentBrian Williams100% (1)

- Read MeDocument22 pagesRead MeAkula VeerrajuNo ratings yet

- Iso 2314 1989Document11 pagesIso 2314 1989Midhun ThevalakkattumaliNo ratings yet

- Report On AutomationDocument37 pagesReport On AutomationSiddharth KUMAR SINGHNo ratings yet

- Unit 22 Instrumentation and Control Principles Learning Hours: 60 NQF Level 4: BTEC Higher National - H1Document6 pagesUnit 22 Instrumentation and Control Principles Learning Hours: 60 NQF Level 4: BTEC Higher National - H1jeevanNo ratings yet

- Mass Transfer SyllabusDocument7 pagesMass Transfer SyllabusMaandipsinh SolankiNo ratings yet

- Materials System SpecificationDocument7 pagesMaterials System SpecificationFlorante NoblezaNo ratings yet

- Syllabus 3361909Document8 pagesSyllabus 3361909Pavan PatelNo ratings yet

- Thermodynamics I Final Course PlanDocument2 pagesThermodynamics I Final Course PlanAkatew Haile MebrahtuNo ratings yet

- Mechanical Engineering: Department of DefenceDocument14 pagesMechanical Engineering: Department of DefenceTienNguyenNo ratings yet

- U R T System (I) : SER Equirements Emplate FOR A Nsert Your System Description HereDocument25 pagesU R T System (I) : SER Equirements Emplate FOR A Nsert Your System Description HereVinodh KumarNo ratings yet

- Automatic Controls for Heating and Air Conditioning: Principles and ApplicationsFrom EverandAutomatic Controls for Heating and Air Conditioning: Principles and ApplicationsRating: 4 out of 5 stars4/5 (2)

- Furuno CA 400Document345 pagesFuruno CA 400Димон100% (3)

- NBA - 1 - Syllabus Prescribed by WBSCTE - FinalDocument8 pagesNBA - 1 - Syllabus Prescribed by WBSCTE - FinalSo'ham DasNo ratings yet

- Works Masterspec 230594Document5 pagesWorks Masterspec 230594Joshua FernandezNo ratings yet

- Instrument Field Engineering: Prepared By: M.P.ALAMDocument99 pagesInstrument Field Engineering: Prepared By: M.P.ALAMsakendos torrosNo ratings yet

- GMN7152 2002Document16 pagesGMN7152 2002odiosmio8282201No ratings yet

- (A Govt. of India Enterprise) : Rites LimitedDocument3 pages(A Govt. of India Enterprise) : Rites LimitedjosephNo ratings yet

- Types of Ayurveda DoshasDocument4 pagesTypes of Ayurveda DoshasjosephNo ratings yet

- Tapeworm Drug ProtocolDocument10 pagesTapeworm Drug ProtocoljosephNo ratings yet

- Tapeworm Drug ProtocolDocument10 pagesTapeworm Drug ProtocoljosephNo ratings yet

- Register File Design Engineer - 630561Document33 pagesRegister File Design Engineer - 630561josephNo ratings yet

- Vin Poce TineDocument2 pagesVin Poce TinejosephNo ratings yet

- Jantri 2012-13Document12 pagesJantri 2012-13Bhajneet SinghNo ratings yet

- B R Ambedkar UniversityDocument2 pagesB R Ambedkar UniversityjosephNo ratings yet

- Hayagreeva: Hayagreeva (Hayavadhana or Hayagriva), The Lesser Known Vishnu Avatar, The Horse Faced GodDocument2 pagesHayagreeva: Hayagreeva (Hayavadhana or Hayagriva), The Lesser Known Vishnu Avatar, The Horse Faced GodjosephNo ratings yet

- Computer Training Under Empower Scheme: Microsoft ExaminationDocument4 pagesComputer Training Under Empower Scheme: Microsoft ExaminationjosephNo ratings yet

- Yoga Practical PaperDocument8 pagesYoga Practical PaperjosephNo ratings yet

- Palash TreeDocument1 pagePalash TreejosephNo ratings yet

- Dimostration in Metallic Alchemy: Veerbhadr Tantrokt Sarveshvari SadhnaDocument13 pagesDimostration in Metallic Alchemy: Veerbhadr Tantrokt Sarveshvari SadhnajosephNo ratings yet

- Identifying and Recognizing FishesDocument6 pagesIdentifying and Recognizing FishesjosephNo ratings yet

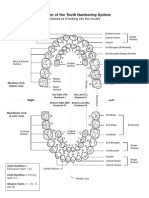

- Diagram of The Tooth Numbering SystemDocument1 pageDiagram of The Tooth Numbering Systemsaleh900No ratings yet

- Scheme For Certification of Silver Jewellery / Artefacts For Fineness Marking As Per Is 2112:2003Document4 pagesScheme For Certification of Silver Jewellery / Artefacts For Fineness Marking As Per Is 2112:2003josephNo ratings yet

- Multimodal Transport UNCTADDocument55 pagesMultimodal Transport UNCTADBhavini ModiNo ratings yet

- Identifying and Recognizing FishesDocument6 pagesIdentifying and Recognizing FishesjosephNo ratings yet

- GDB Quick GuideDocument7 pagesGDB Quick GuidejosephNo ratings yet

- Inna Phos Diammonium Phosphate MSDSDocument9 pagesInna Phos Diammonium Phosphate MSDSjosephNo ratings yet

- Scientech 4077: 30 V / 2 A, 5 V / 2 A, 15 V / 1 A Multiple Power SupplyDocument1 pageScientech 4077: 30 V / 2 A, 5 V / 2 A, 15 V / 1 A Multiple Power SupplyjosephNo ratings yet

- ElectronicsDocument16 pagesElectronicsjosephNo ratings yet

- The Pharmacy Act, 1948: Chapter Iii - State Pharmacy CouncilsDocument2 pagesThe Pharmacy Act, 1948: Chapter Iii - State Pharmacy CouncilsjosephNo ratings yet

- Gold - BisDocument4 pagesGold - BisjosephNo ratings yet

- Diagram of The Tooth Numbering SystemDocument1 pageDiagram of The Tooth Numbering Systemsaleh900No ratings yet

- BhairavDocument6 pagesBhairavmayurranjan100% (3)

- 1138 MetracidDocument2 pages1138 MetracidjosephNo ratings yet

- AllergyDocument1 pageAllergyjosephNo ratings yet

- Chandra Grahan PDFDocument3 pagesChandra Grahan PDFjoseph0% (1)

- Chandra Grahan PDFDocument3 pagesChandra Grahan PDFjoseph0% (1)

- Assignment 4: Chitresh KumarDocument7 pagesAssignment 4: Chitresh KumarChitreshKumarNo ratings yet

- SIL Working Method ReportDocument35 pagesSIL Working Method ReportEmzy Hussein90% (10)

- Things To Remember When Writing Your Conference Proposal AbstractDocument2 pagesThings To Remember When Writing Your Conference Proposal AbstractBalizkoa BadaezpadakoaNo ratings yet

- Synthesis of Isoamyl AcetateDocument3 pagesSynthesis of Isoamyl AcetateClaire TiongsonNo ratings yet

- BearingsDocument63 pagesBearingsYeabsraNo ratings yet

- Cerita BugisDocument14 pagesCerita BugisI'dris M11No ratings yet

- Water TableDocument5 pagesWater TableJay DoshiNo ratings yet

- Welspun One Logistics Parks: Hazard Risk AssessmentDocument2 pagesWelspun One Logistics Parks: Hazard Risk AssessmentR. Ayyanuperumal AyyanuperumalNo ratings yet

- A Dynamic Model For Automotive Engine Control AnalysisDocument7 pagesA Dynamic Model For Automotive Engine Control Analysisekitani6817No ratings yet

- PreliminaryDocument65 pagesPreliminarysame.pxtNo ratings yet

- SmartForm - Invoice TutorialDocument17 pagesSmartForm - Invoice TutorialShelly McRay100% (5)

- Tropical Rainforest Newsletter TemplateDocument92 pagesTropical Rainforest Newsletter TemplatedoyoungNo ratings yet

- Director Engineering in Detroit MI Resume Shashank KarnikDocument3 pagesDirector Engineering in Detroit MI Resume Shashank Karnikshashankkarnik100% (1)

- VMD-412 9 April 2014Document8 pagesVMD-412 9 April 2014ashish kumarNo ratings yet

- OM Version 1Document497 pagesOM Version 1Sushant SinghNo ratings yet

- Bus Depot Design Guidelines PDFDocument102 pagesBus Depot Design Guidelines PDFgregoblue100% (2)

- Rigstoreef Impact or Enhancement On Marine Biodiversity 2157 7625 1000187Document9 pagesRigstoreef Impact or Enhancement On Marine Biodiversity 2157 7625 1000187tavis80No ratings yet

- Uvod PDFDocument13 pagesUvod PDFbarbara5153No ratings yet

- MCQ in Engineering Economics Part 11 ECE Board ExamDocument19 pagesMCQ in Engineering Economics Part 11 ECE Board ExamDaryl GwapoNo ratings yet

- Exalted Signs Sun in AriesDocument6 pagesExalted Signs Sun in AriesGaurang PandyaNo ratings yet

- Permutation Vs CombinationDocument4 pagesPermutation Vs CombinationSaleh RehmanNo ratings yet

- Generalization of The Lavallée and Hidiroglou AlgorithmDocument11 pagesGeneralization of The Lavallée and Hidiroglou AlgorithmCristian MoisésNo ratings yet

- 2nd Announcement 13th InaSH Meeting 2019Document14 pages2nd Announcement 13th InaSH Meeting 2019adinda permataNo ratings yet

- Emergency Stop in PL E: SINUMERIK Safety IntegratedDocument10 pagesEmergency Stop in PL E: SINUMERIK Safety IntegratedVladimirAgeevNo ratings yet

- HSG11 V3+AnswersDocument10 pagesHSG11 V3+AnswershaNo ratings yet

- A Practical Guide To Geostatistical - HenglDocument165 pagesA Practical Guide To Geostatistical - HenglJorge D. MarquesNo ratings yet

- Ashley Skrinjar ResumeDocument2 pagesAshley Skrinjar Resumeapi-282513842No ratings yet

- Physics Sample Problems With SolutionsDocument10 pagesPhysics Sample Problems With SolutionsMichaelAnthonyNo ratings yet

- English 4 Realistic FictionDocument5 pagesEnglish 4 Realistic FictionRose Marie RebutaNo ratings yet