Professional Documents

Culture Documents

Biodiesel Lab7

Uploaded by

Karla LopezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Biodiesel Lab7

Uploaded by

Karla LopezCopyright:

Available Formats

Green Chemistry Workshop Mission College 2010

Biodiesel: Renewable Resources for Energy Production

Summary:

This experiment demonstrates the use of vegetable oil as an alternative, renewable

feedstock. The reaction incorporates NaOH (or KOH) as a catalyst in order to

achieve high yield and minimize waste. In addition, the glycerol by-product can be

reused in order to make glycerine soap.

In this experiment you will synthesize diesel fuel from a triester of glycerol (a

triacylglycerol or triglyceride). This reaction is known as a transesterification reaction.

Transesterification is the process of transforming one type of ester into another type of

ester. This reaction incorporates the use of the strong base in a base- catalyzed

nucleophilic addition-elimination reaction at the carbonyl carbon of the triglyceride.

Audience:

There are multiple lesson plans and laboratory activities in this unit. Portions can be used

as appropriate within the general or organic chemistry laboratory or classroom.

Chemical Concepts:

Reactions of carbonyl compounds, nucleophilic substitution and elimination reactions;

transesterification; saponification; use of IR spectroscopy; use of a catalyst; properties of

matter, titration

Green Chemistry Concepts:

Pollution Prevention; Safer Chemical Products; Renewable Resources; Design for

Degradation

Contents:

Synthesis and Analysis of Biodiesel, Hand-Out Page Page 2

Activity 1: Determining the physical properties of vegetable oils Page 4

Activity 2: Titration of Waste Vegetable Oil (WVO) Page 8

Activity 3: Synthesis of Biodiesel from WVO Page 11

Activity 4: Analysis of biodiesel Page 16

Source: Beyond Benign; Ed Brush, Bridgewater State College; John Thompson, 1

Lane Community College

Green Chemistry Workshop Mission College 2010

Biodiesel: Renewable Resources for Energy Production

HAND-OUT PAGE

Note: The following procedure is for synthesizing a biodiesel mini-batch from 100% pure

unused vegetable oil. This method can easily be modified for using recycled, used

vegetable oil.

1. Add 0.35 g of finely ground anhydrous NaOH into 20 mL of pure (99% or higher

purity) methanol in a 250 mL Erlenmeyer flask containing a magnetic stir bar in a well-

ventilated location (hood). Put the flask on a magnetic stir plate, and stir vigorously until

all of the NaOH is dissolved. This flask now contains sodium methoxide. Note: Sodium

methoxide is an extremely strong base and should be handled with care.

2. When all of the NaOH is dissolved, pour 100 mL of oil into the methoxide solution

while continually stirring. At first the mixture will become cloudy, but should soon

separate into two layers. Let the reaction continue.

3. Note that under normal laboratory conditions this reaction is done using warmed

vegetable oil ( ~40C) and the reaction is stirred for about 15 minutes. The reaction

mixture is then (a) transferred to a separatory funnel or (b) centrifuged to speed the

separation of the biodiesel from the glycerine. The separation should be done at least one

hour after the trans-esterification reaction was initiated.

3. The mixture will have separated into two different layers. The glycerol is denser than

the biodiesel. Open the stopcock of the separatory funnel and allow the glycerol to drain

into a small beaker.

6. Note that IR spectroscopy can be used to identify your products. Print out the spectras

and compare with known spectra. The biodiesel may be hard to compare, since most oils

are comprised of different length carbon chains. Comparing to known spectra can easily

identify the glycerol. The presence of glycerol indicates a successful reaction.

Source: Beyond Benign; Ed Brush, Bridgewater State College; John Thompson, 2

Lane Community College

Green Chemistry Workshop Mission College 2010

Determining the physical properties of vegetable oils.

In this experiment, you will be given 4 different kinds of vegetable oils to evaluate. The

four vegetable oils have different melting points and densities, which are listed in the

table below. If you have been given the following information, determine which is which:

Type of Oil Melting Point Melting Point (C) Density (g/mL),

(F) 25C

Peanut Oil 37.4 3 0.917

Soybean Oil 3.2 -16 0.920 0.925

Coconut Oil 70 21 0.9 0.915

Canola Oil 14 -10 0.920 0.925

Procedure:

1. Develop an experiment (test) to determine the relative melting points of the four

unknown oils. Record your results and verify your answers with your instructor.

Test (please describe):

Unknown Oil # Observations Melting Point

1

2. Develop an experiment (test) to determine the density of the unknown oils. Record you

results and verify your answers with your instructor.

Test (please describe):

Unknown Oil # Observations Density

1

Source: Beyond Benign; Ed Brush, Bridgewater State College; John Thompson, 3

Lane Community College

Green Chemistry Workshop Mission College 2010

Biodiesel: Renewable Resources for Energy Production

Activity 1: Determining the physical properties of vegetable oils

Instructor Guide

This is a simple way of visualizing physical changes of matter by investigating the

difference in vegetable oils. Students are given 4 unknown oils, which are available at the

supermarket and are asked to perform a test on the oils to determine the identity of the

unknown. The coconut oil has a melting point close to room temperature and will solidify

upon cooling slightly. Upon cooling all 4 oils over ice, the coconut oil will solidify first,

followed by the peanut oil. The canola oil and soybean oil should both not solidify due to

their melting points being below the freezing point of water. The density of each oil can

also be determined by doing a simple volume to weight calculation, or by using a

hydrometer. The concept of other distinguishing properties of the oils can then be

discussed (viscosity, color, etc.).

Required time: 45 60 minutes

Supplies needed:

Coconut Oil

Peanut Oil*

Rapeseed Oil

Soybean Oil

25 mL Erlenmeyer flask (4/student)

250 mL Beakers (4/student)

Ice

Thermometers (1/student)

Graduated cylinders (10 mL volume)

Plastic pipettes (4/student)

Balance

* Be aware of peanut allergies and substitute oils as appropriate. Do not use if there is a

peanut allergy in your classroom.

Preparation:

All oils are available from the supermarket.

Place oils in containers and label each with a number (make a note as to which oil

refers to which number).

Place all 4 oils in warm water bath so that the coconut oil remains warm and

therefore liquid (by placing all in the bath, the students will not know which is the

coconut oil)

Give each student (or student group) a set of 25mL Erlenmeyer Flasks (4), 250 mL

beakers (4) (for ice), Thermometer, Graduated cylinder, Plastic pipettes for

transferring oil

Source: Beyond Benign; Ed Brush, Bridgewater State College; John Thompson, 4

Lane Community College

Green Chemistry Workshop Mission College 2010

Source: Beyond Benign; Ed Brush, Bridgewater State College; John Thompson, 5

Lane Community College

Green Chemistry Workshop Mission College 2010

Biodiesel: Renewable Resources for Energy Production

Activity 1: Determining the physical properties of vegetable oils

Student Worksheets

Introduction:

A major source of energy for our society is the burning of fossil fuels such as coal,

petroleum and natural gas. These sources of energy have been found to have limited

amounts available, and therefore are said to be depleting resources. Scientists are

continuously looking to find alternatives to fossil fuels. One such alternative is using

vegetable oils to make fuel. Vegetable oils, such as those from corn, soy beans and canola

have been found to be suitable alternatives to diesel fuel, which has traditionally come

from petroleum.

Biodiesel is a fuel made from renewable resources such as vegetable oils that is used in

diesel engines. Rudolf Diesel developed the diesel engine in 1893. He developed the

engine to first run on peanut oil and he demonstrated this at the World Fair in Paris,

France in 1900. Later on, the Diesel engine was modified to use a fraction of petroleum,

obtained from fossil fuels. Today, many vehicles use the diesel engine, including many

large vehicles such as trucks and buses. And, today more and more diesel engines are

being modified to use biodiesel, which was the original intent of Ruldof Diesel when he

developed the engine.

Biodiesel can be used directly in unmodified diesel engines, or blended with regular

diesel fuel. When burned, biodiesel smells like french fries or popcorn.

Which vegetable oils are the best for use as biodiesel? What properties do you think a

vegetable oil should have in order to operate properly in a diesel engine? To think about

this, we will first take a closer look at vegetable oils that we find in the kitchen. These

oils are similar to those that are used as biodiesel. Please note that the oils, although

similar in properties, are not the same oils that are used as biodiesel fuel. The oils can be

converted quite easily to biodiesel fuel as you will find in a later lesson when we perform

a chemical reaction.

Determining the physical properties of vegetable oils.

In this experiment, you will be given 4 different kinds of vegetable oils to evaluate. The

four vegetable oils have different melting points and densities, which are listed in the

table below. If you have been given the following information, determine which is which:

Type of Oil Melting Point Melting Point (C) Density (g/mL),

(F) 25C

Peanut Oil 37.4 3 0.917

Soybean Oil 3.2 -16 0.920 0.925

Coconut Oil 70 21 0.9 0.915

Canola Oil 14 -10 0.920 0.925

Source: Beyond Benign; Ed Brush, Bridgewater State College; John Thompson, 6

Lane Community College

Green Chemistry Workshop Mission College 2010

Procedure:

1. Develop an experiment (test) to determine the relative melting points of the four

unknown oils. Record your results and verify your answers with your instructor.

Test (please describe):

Unknown Oil Observations Melting Point

#

1

2. Develop an experiment (test) to determine the density of the unknown oils. Record you

results and verify your answers with your instructor.

Test (please describe):

Unknown Oil Observations Density

#

1

Source: Beyond Benign; Ed Brush, Bridgewater State College; John Thompson, 7

Lane Community College

Green Chemistry Workshop Mission College 2010

Student Questions

1. Based on your experiments, identify the unknown oils:

Unknown Oil Oil Name

#

1

2. Are you able to distinguish between the oils by using density and melting point alone?

If not, what other tests would you propose to determine which oil is which?

3. If you are investigating the use of these four vegetable oils for the use in a biodiesel

engine, which one(s) would you recommend? Why?

4. What benefits do you think using biodiesel has compared to using traditional diesel

fuel?

Source: Beyond Benign; Ed Brush, Bridgewater State College; John Thompson, 8

Lane Community College

Green Chemistry Workshop Mission College 2010

Biodiesel: Renewable Resources for Energy Production

Activity 2: Titration of Waste Vegetable Oil (WVO)

Instructor Guide

Note: The preparation of biodiesel is a multi-step process that includes 3 activities.

Activity 2 can be done by the instructor ahead of time OR if waste vegetable oil is NOT

used, then this step can be skipped and 100% pure unused vegetable oil can be used.

The first activity for making Biodiesel is a titration exercise, which can be used to teach

students about the concept of concentrations and molarity.

Waste vegetable oil (WVO) can be obtained from the cafeteria or a local restaurant that

serves fried food if asked! Be sure to filter the solids from the vegetable oil before using.

Due to the breakdown of the triglycerides during the frying process, it is necessary to first

determine the content of free fatty acids in the WVO. You are able to do this ahead of

time to save time in class. Or, alternatively, you can use this as a lesson with your

students to learn titration techniques. Be sure to check student answers before moving on

to Activity 3.

Helpful Tips:

Vegetable oil purchased from the store can be used instead of waste vegetable oil.

In this case, there are no free fatty acids and the amount of base required to

hydrolyze the triglyceride can be calculated easily from the Activity 2 Worksheet.

NaOH or KOH can be used as the base catalyst. Adjust the student sheet as

needed to reflect the base used.

Required Class time: 45 60 minutes.

Supplies needed:

Buret, 10 mL

Ring Stand

Buret Clamp

0.01M NaOH (5-7 mL/student)

Graduated cylinder, 10mL

Isopropanol

Erlenmeyer flask, 25 mL

Autopipet (1 mL volume)

Pipet tips

Phenolphthalein indicator

Distilled water

Source: Beyond Benign; Ed Brush, Bridgewater State College; John Thompson, 9

Lane Community College

Green Chemistry Workshop Mission College 2010

Biodiesel: Renewable Resources for Energy Production

Activity 2: Titration of Waste Vegetable Oil (WVO)

Student Worksheets

Your raw material for making biodiesel will be the Waste Vegetable Oil (WVO) from

the cafeteria. When heated at high temperatures in the presence of water from food, the

fatty acid esters in vegetable oil begin to break down by a chemical reaction called

hydrolysis, producing free fatty acids and glycerol. The fatty acids can inhibit the

transesterification reaction by reacting with the base (KOH) catalyst used in the

transesterification. For this reason, it is very important that we determine the exact

concentration of free fatty acids by titrating the WVO with a known concentration of

sodium hydroxide (NaOH). You can then calculate the amount of additional KOH

catalyst you will need in the transesterification reaction.

Your WVO was collected from the cafeteria and was filtered to remove food particles.

Experimental Procedure:

1. Clamp a 10.0 mL clean, dry buret to a ring stand. Check that the buret is dry. Using a

graduated cylinder obtain about 5-7 mL of 0.0100 M NaOH. Make sure that the stopcock

is closed, and pour the NaOH solution into the dry buret.

2. Using a graduated cylinder measure obtain 10 mL of 2-propanol (isopropanol) and

pour into a 25 mL Erlenmeyer flask. Using an automatic pipet add exactly 1.00 mL of

WVO to the isopropanol and swirl to dissolve. Add 2-3 drops of phenolphthalein.

3. Record the exact volume of NaOH in the buret to two decimal places. Place the flask

containing the WVO under the buret and begin adding the NaOH dropwise, while

swirling the flask. If drops of the NaOH fall on the sides of the flask you will need to

rinse them down with a few drops of distilled water. The solution in the flask may turn

milky; this is normal. Continue adding the NaOH dropwise to the swirling flask until you

get a light pink color that persists at least 15 seconds. If the solution turns bright pink

you need to start over. RECORD the final volume of NaOH in the buret to two decimal

places.

4. Before continuing to PART II, you and your lab partner must complete the PART I

Worksheet on the next page to determine the moles of fatty acids present in the WVO

sample, and the total amount of KOH catalyst you will need for the transesterification

reaction.

5. Rinse your buret with distilled water and clamp upside down with the stopcock open.

Source: Beyond Benign; Ed Brush, Bridgewater State College; John Thompson, 10

Lane Community College

Green Chemistry Workshop Mission College 2010

Name:_____________________________________

1) Complete the following reaction for the titration of a carboxylic acid with NaOH

(acid/base reaction):

R C OH + NaOH

2) Volume of 0.0100 M NaOH used in the WVO titration _________________________

3) Moles of NaOH needed to neutralize the free fatty acids in 1.00 mL of

WVO________________________

4) Moles of KOH you will need to neutralize the free fatty acids in 10.0 mL of

WVO_____________________

The amount of base needed as a catalyst for the transesterification reaction is equal to 3.5

grams of NaOH per 1000 mL of PURE veggie oil.

5) How many grams and moles of NaOH will be needed as catalyst for 10.0 mL of

PURE veggie oil?

_____________________________grams ____________________________moles

6) We are using KOH as catalyst. How many moles of KOH will be needed for 10.0 mL

of PURE veggie oil?

___________________________moles KOH catalyst for 10.0 mL pure veggie oil

7) NOW, how many TOTAL moles of KOH will be needed for the transesterification

reaction:

moles KOH to neutralize fatty acids + moles KOH as reaction catalyst =

___________________total moles

8) The KOH for transesterification is provided as a 10.0 M aqueous solution. How many

mL and mL of 10.0 M KOH will be needed?

______________________________mL _____________________________mL

Source: Beyond Benign; Ed Brush, Bridgewater State College; John Thompson, 11

Lane Community College

Green Chemistry Workshop Mission College 2010

Biodiesel: Renewable Resources for Energy Production

Activity 3: Synthesis of Biodiesel from WVO

Instructor Guide

This activity can be used for discussing synthesis and synthetic transformations. The

process involves the use of a catalyst and therefore catalysis can be discussed. The nature

of vegetable oil and diesel allows for many discussions when introducing organic

chemistry concepts including hydrocarbons, functional groups (esters), fatty acids, etc.

The synthesis of biodiesel is fairly straightforward and can be done in one laboratory

session. The first step of the synthesis involves the transesterification and will require

about on hour for the reaction to occur. The prepared biodiesel can be stored for a week

between class periods (if needed). The washing step is essential to purify the biodiesel

and to ensure it will function properly in Activity 4. Alternatively, the instructor can

perform the washing and extraction steps outside of class to save class time.

Helpful tips:

While heating the reaction, the reaction will turn clear. The reaction will be done

when it turns cloudy and it will begin to turn opaque. The cloudy look will be due

to two layers being formed (the top, biodiesel layer and the bottom glycerol

layer).

If you do not have a centrifuge, then the separation can be performed by allowing

the biodiesel and glycerol layers to settle (let them sit overnight). The two layers

will separate easily and the top layer can be poured off. A separatory funnel can

be used to help separate the two layers and this will help when washing with

water.

Ethanol or methanol can be used in this reaction. However, ethanol will require

more time to react, where methanol will be a quicker reaction (both you will be

able to see when they are done by the cloudiness). Both alcohols should be

handled carefully. However, methanol poses more of a risk in terms of the hazard

and should be used carefully with supervision of the students.

Be sure to use 200 proof Ethanol, which is dry and water-free. Water in the

ethanol can interrupt the reaction. Ethanol is flammable and hazardous by

ingestion. Please be sure to take the appropriate safety precautions before using

either alcohol. Keep careful watch over students using the alcohol and if needed,

dispense the alcohol into the reaction vessel for the students.

NaOH can be used instead of KOH. Be sure to adjust the student worksheets as

needed based on the base used.

Required time: ~2-3 hours

Supplies needed:

Erlenmeyer flask, 25 mL (2)

WVO, 10mL/student

Stir bar

Source: Beyond Benign; Ed Brush, Bridgewater State College; John Thompson, 12

Lane Community College

Green Chemistry Workshop Mission College 2010

Ethanol, 200 proof

KOH* (10 N)

Stir/hot plate

Centrifuge tubes w/ caps

Centrifuge

Pipettes

Acetic acid, 0.1 M

Distilled water

Balance

*KOH is corrosive and can cause burns on the skin. If contact with skin is made, wash

with copious amounts of water immediately. Be sure to read safety information regarding

this chemical and to take the appropriate safety precautions before using in the

classroom.

Source: Beyond Benign; Ed Brush, Bridgewater State College; John Thompson, 13

Lane Community College

Green Chemistry Workshop Mission College 2010

Biodiesel: Renewable Resources for Energy Production

Activity 3: Synthesis of Biodiesel from WVO

Student Worksheets

Plant vegetable oils are made of what are called triglycerides; which are composed of

three fatty acids that are linked to a glycerol molecule by an ester bond. Fatty acids are

long, straight chains of carbon atoms with hydrogen atoms attached (hydrocarbons) with

a carboxylic acid group (COOH) at one end and a methyl group (CH3) at the other end.

These long, straight chains combine with the glycerol molecule to form a triglyceride

(oil).

Note that three fatty acids are used to form the triglyceride. Depending on the oil or fat,

the lengths of the fatty acid chains will vary and the three fatty acids that make up the

triglyceride can be three different fatty acids. Because they can be three different fatty

acids, the term R is used to represent the carbon chain. R, R1 and R2 all represent

different lengths of carbon chains. These oils and fats are commonly found in plants and

in our bodies.

In order to make biodiesel the triglyceride molecules can be converted into a simpler

form through what is called a transesterification reaction. This reaction converts one type

of ester group to another. In the reaction scheme below you can see that the ester groups

Source: Beyond Benign; Ed Brush, Bridgewater State College; John Thompson, 14

Lane Community College

Green Chemistry Workshop Mission College 2010

that are attached to the glycerol portion of the molecule are broken and converted to a

different type of ester.

The reaction scheme above shows that we use an alcohol, such as ethanol (CH3CH2OH)

and a catalyst (potassium hydroxide, KOH) to convert the vegetable oil into biodiesel and

glycerol, a by-product of the reaction. You can see that since the starting material on the

left side of the equation had three fatty acid hanging off the glycerol that we needed 3

ethanol molecules to produce 3 biodiesel molecules.

Keep in mind that since biodiesel is actually a mixture of esters, different types of

vegetable oils can produce fuels with different properties.

You are now ready to make your own biodiesel fuel from WVO.

Experimental Procedure:

1) Determine the mass of a clean, dry 25 mL Erlenmeyer flask. Add to this flask 10.0

mL of WVO using the bottle dispenser, and record the exact mass of the WVO. Add a

stir bar to the WVO, 2.0 mL of ethanol, and the appropriate volume of 10.0 M KOH

calculated in PART I. Stir the reaction mixture vigorously (setting of 8-9) at 50oC for 60

minutes. Record all observed changes during the reaction.

2. Transfer the reaction mixture to two centrifuge tubes, and centrifuge for 5 minutes.

You should end up with two layers, with the biodiesel on top. Using a pipet, discard the

lower layer which contains glycerol and KOH catalyst into the labeled waste container.

3. Combine the crude biodiesel into one centrifuge tube. Add 1 mL of 0.1M acetic acid

to the biodiesel, cap the tube, invert gently five times (do not shake), then centrifuge for 5

minutes. Discard the bottom, aqueous layer into the labeled waste container. Repeat the

extraction step using 1 mL of distilled water.

The extraction or washing in step 3 removes flammable ethanol, glycerol byproduct,

catalyst, and fatty acid salts (soaps) from your biodiesel. If the water wash is not done

properly, contaminating ethanol could create a fire hazard, and contaminating glycerol,

catalyst, and soaps will negatively affect combustion and engine performance.

Furthermore, mixtures of biodiesel and water will form an emulsion if shaken. Fuel

Source: Beyond Benign; Ed Brush, Bridgewater State College; John Thompson, 15

Lane Community College

Green Chemistry Workshop Mission College 2010

emulsions with water would be disastrous in a diesel engine. Finally, all traces of water

must be removed from the washed biodiesel before use in a diesel engine is possible.

4. Using a pipet transfer the washed biodiesel to a pre-weighed 25 or 50 mL Erlenmeyer

flask. Heat this sample at 70-80oC for 10-15 minutes to evaporate residual water. Obtain

the mass of your dry biodiesel.

Source: Beyond Benign; Ed Brush, Bridgewater State College; John Thompson, 16

Lane Community College

Green Chemistry Workshop Mission College 2010

Biodiesel: Renewable Resources for Energy Production

Activity 4: Analysis of Biodiesel

Instructor Guide

This activity consists of three tests the students can perform on the biodiesel they have

prepared in order to test the properties. They will test the pH of the biodiesel, allowing

for a discussion of acids and bases and pH. They can also test the combustion of the

product they made.

Helpful Tips:

The combustion test should be performed by the instructor and performed in a well-

ventilated area such as a fume hood or outside. The biodiesel prepared should

combust easily, while the starting material (canola oil) should not burn.

The melting point test can be done by placing the sample in a freezer or by using ice

to cool the sample.

Required class time: 45-60 minutes

Supplies needed:

Distilled water

pH paper

test tubes (small)

glass spatula

wad of cotton

test tube rack

sample vial, 3 mL

thermometer

Source: Beyond Benign; Ed Brush, Bridgewater State College; John Thompson, 17

Lane Community College

Green Chemistry Workshop Mission College 2010

Biodiesel: Renewable Resources for Energy Production

Activity 4: Analysis of Biodiesel

Student Worksheet

You will now test your biodiesel sample to determine the properties of the fuel. You will

perform some simple tests to test the properties. Record your results on the worksheet on

the following page.

Determining the pH: add 5 drops of your biodiesel to 1 mL of distilled water and mix

thoroughly. Using pH paper, estimate the aqueous pH of your biodiesel.

Combustion Test: Obtain a small wad of cotton and roll this tightly onto the end of a

glass spatula to form a torch. Dip this into your biodiesel and stand up in a beaker or

test tube rack. Now, take your torch to your instructor and they will try lighting the

sample with a match. Time how long your sample burns, the color of the flame, and

whether any smoke or soot is observed. Was the torch easy to light? Is there an odor?

Freezing Point: Biodiesel will gel at low temperatures. Transfer your biodiesel to a 3

mL reaction vial, and place in the test tube rack in the freezer for 15-20 minutes. Your

biodiesel should gel in this time. If your biodiesel does not gel, repeat the drying

step.

Remove the sample from the freezer and immediately add a digital thermometer and

record the temperature. Holding the vial near its top, stir the gel with the thermometer

and record the temperature when the sample has completely melted or clarified. BE

SURE TO CLEAN THE THERMOMETER WHEN DONE!

Disposal: When you are done, pipette your biodiesel sample into the labeled collection

container.

Source: Beyond Benign; Ed Brush, Bridgewater State College; John Thompson, 18

Lane Community College

Green Chemistry Workshop Mission College 2010

Name:_____________________________________

Actual mass of the 10.0 mL of WVO used ___________________________(g)

Mass of dry, purified biodiesel _____________________________(g)

%Yield of biodiesel based on mass _____________________________

Color of purified

biodiesel________________________________________________________________

_

Estimated aqueous pH of your biodiesel_________________________

Time (minutes) that your biodiesel sample

burned_________________________________

Temperature at which your gelled biodiesel melted or

clarified_______________________

Source: Beyond Benign; Ed Brush, Bridgewater State College; John Thompson, 19

Lane Community College

Green Chemistry Workshop Mission College 2010

Supplemental Student Questions:

1. List four advantages of using biodiesel as a fuel.

2. Explain the difference between renewable and non-renewable resources.

3. Based on the aqueous pH of your biodiesel, comment on its corrosive properties.

4. Explain the purpose of the acid wash in step #3. Write a balanced chemical equation

as part of your explanation.

5. At what temperature did your gelled biodiesel melt or clarify? Is biodiesel a

practical fuel for the northeastern U.S.? What options are possible to improve the

freezing point characteristics of biodiesel?

6. In the commercial production of biodiesel, 1.20 x 103 kg of vegetable oil produces 1.10

x 103 kg of biodiesel. How does your yield compare to this

7. One argument against biodiesel being a green fuel is that combustion produces CO2,

which is a greenhouse gas. Is it possible to counter this argument from the standpoint of

using renewable resources?

Source: Beyond Benign; Ed Brush, Bridgewater State College; John Thompson, 20

Lane Community College

You might also like

- Synthesis of Biodiesel in A High School Lab by Richard L. SnyderDocument16 pagesSynthesis of Biodiesel in A High School Lab by Richard L. SnyderKM_147No ratings yet

- Preparation of BiodieselDocument6 pagesPreparation of Biodieselpranjal JaiswalNo ratings yet

- Bio DieselDocument15 pagesBio DieselAvnish BhasinNo ratings yet

- Ip ProjectDocument19 pagesIp ProjectSoham JadhavNo ratings yet

- BiodieselDocument3 pagesBiodieselapi-276659279No ratings yet

- Green Lab 4 RuppDocument4 pagesGreen Lab 4 RuppTEN CHEANGNo ratings yet

- Sedimentation Method Used in Purifying Cooking OilDocument9 pagesSedimentation Method Used in Purifying Cooking OilaliacensisNo ratings yet

- Selection of An Efficient Method of Biodiesel Production From Vegetable Oil Based On Fuel PropertiesDocument5 pagesSelection of An Efficient Method of Biodiesel Production From Vegetable Oil Based On Fuel PropertiesseventhsensegroupNo ratings yet

- Experiment 9 - Fats and OilsDocument7 pagesExperiment 9 - Fats and OilsWerlyn Mae GonzagaNo ratings yet

- To Study The Production of Biodiesel Future FuelDocument12 pagesTo Study The Production of Biodiesel Future FuelAditya MishraNo ratings yet

- Stoichiometry Making Biodiesel (Single Phase)Document6 pagesStoichiometry Making Biodiesel (Single Phase)Ahmed MustafaNo ratings yet

- Lab 8 - Biodiesel PDFDocument3 pagesLab 8 - Biodiesel PDFAmal ..No ratings yet

- Lab Workshop BIODIESELmicroscale 07Document7 pagesLab Workshop BIODIESELmicroscale 07atz KusainNo ratings yet

- 095 104Document10 pages095 104hongduc6No ratings yet

- Biodiseal Cooked OilDocument4 pagesBiodiseal Cooked OildineshlathiaNo ratings yet

- Biodiesel Synthesis from Vegetable OilDocument3 pagesBiodiesel Synthesis from Vegetable OilGuilherme FriasNo ratings yet

- Lipid Extraction Lab ReportDocument5 pagesLipid Extraction Lab ReportClarice CatorceNo ratings yet

- Seminar On: Preparation of Biodiesel From Waste Cooking Oil and Study Its Effects On Performance of Diesel EngineDocument19 pagesSeminar On: Preparation of Biodiesel From Waste Cooking Oil and Study Its Effects On Performance of Diesel EngineSourabh Makham0% (1)

- Green Chemistry Lab ReportDocument36 pagesGreen Chemistry Lab ReportAmal ManojNo ratings yet

- Custard Apple Seed To FuelDocument6 pagesCustard Apple Seed To FuelAsif Akhtar100% (1)

- Biodiesel From Seeds: An Experiment For Organic Chemistry: Steven W. GoldsteinDocument4 pagesBiodiesel From Seeds: An Experiment For Organic Chemistry: Steven W. GoldsteinnestorNo ratings yet

- Lab 6 - 022-023Document5 pagesLab 6 - 022-023Noor JanahiNo ratings yet

- ObjectiveDocument24 pagesObjectiveAryan SawlaniNo ratings yet

- Acid-Catalyzed Preparation of Biodiesel From Waste Vegetable OilDocument3 pagesAcid-Catalyzed Preparation of Biodiesel From Waste Vegetable OilRommelGalvanNo ratings yet

- How To Make Bio Diesel - 11 Steps (With Pictures)Document5 pagesHow To Make Bio Diesel - 11 Steps (With Pictures)Sumit KumarNo ratings yet

- Chem ResearchDocument5 pagesChem ResearchRitika SunilNo ratings yet

- 931-Article Text-1480-1-10-20160816Document6 pages931-Article Text-1480-1-10-20160816TB Didi SupriadiNo ratings yet

- UntitledDocument8 pagesUntitledMeena JeerhNo ratings yet

- Biodiesel chp1Document5 pagesBiodiesel chp1Alvaro Jasmine KateNo ratings yet

- Bio DiselDocument15 pagesBio DiselAmritansh JaiswalNo ratings yet

- Eco-friendly BiodieselDocument13 pagesEco-friendly BiodieselSanjeev NehruNo ratings yet

- Balleza and MadredanoDocument7 pagesBalleza and MadredanoMerelle Paulino MadredanoNo ratings yet

- Biodiesel Lab Kim Kozloff, Logan Owen, Samantha Wardell, Andrew Keating, Katherine Yeacker, and Sara Heines 3 Hour March 25, 2015Document3 pagesBiodiesel Lab Kim Kozloff, Logan Owen, Samantha Wardell, Andrew Keating, Katherine Yeacker, and Sara Heines 3 Hour March 25, 2015api-276389806No ratings yet

- Production of Biodiesel From Used Vegetable OilDocument4 pagesProduction of Biodiesel From Used Vegetable OilEmmanuelNo ratings yet

- 2009 Tint Tint Kywe - Production of Biodiesel From Jatropha Oil. - IntroducciionDocument7 pages2009 Tint Tint Kywe - Production of Biodiesel From Jatropha Oil. - IntroducciionArceo A HenryNo ratings yet

- Investigating Biodiesel Concoction ProcessDocument7 pagesInvestigating Biodiesel Concoction ProcessJosh Aldrin SarioNo ratings yet

- Green Chemistry Bio Diesel ProjectDocument21 pagesGreen Chemistry Bio Diesel Projectjazz fernsNo ratings yet

- Exp. 4 Lipid Extraction and Lipid TestsDocument5 pagesExp. 4 Lipid Extraction and Lipid TestsEMELIE GRACE E CACHERONo ratings yet

- Green ChemistryDocument10 pagesGreen Chemistryvijiramraj786No ratings yet

- Optimization of Biodiesel Production From Bakul OilDocument5 pagesOptimization of Biodiesel Production From Bakul Oilsukanta60No ratings yet

- Preparation of Biodiesel From Cooking OilDocument10 pagesPreparation of Biodiesel From Cooking Oiliminathi955No ratings yet

- Lab Exercise 6Document3 pagesLab Exercise 6clarence manegdegNo ratings yet

- Experiment 10 Properties of Lipids Fats and OilsDocument8 pagesExperiment 10 Properties of Lipids Fats and OilsMark JNo ratings yet

- Exprement 9:synthesis of Biodiesel: ObjectiveDocument5 pagesExprement 9:synthesis of Biodiesel: ObjectiveMoontarij JahanNo ratings yet

- Introduction To Green ChemistyDocument21 pagesIntroduction To Green ChemistyHeartykingnkNo ratings yet

- Chemistry ProjectDocument56 pagesChemistry Projectpradeep bijarniaNo ratings yet

- PRODUCTION OF BIODEISEL FROM WASTE PALM OIL USING (Autosaved)Document17 pagesPRODUCTION OF BIODEISEL FROM WASTE PALM OIL USING (Autosaved)ockiyacliffcNo ratings yet

- Investigating Green Chemistry: Bio-diesels and Bio-PetrolDocument13 pagesInvestigating Green Chemistry: Bio-diesels and Bio-PetrolsayanNo ratings yet

- IJETR022982Document4 pagesIJETR022982erpublicationNo ratings yet

- The Synthesis of Biodiesel From Waste Vegetable OilDocument7 pagesThe Synthesis of Biodiesel From Waste Vegetable OilMxokzah CmohNo ratings yet

- Exp 5 (Peroxide Value)Document7 pagesExp 5 (Peroxide Value)eizat abasNo ratings yet

- Chemical Modification of Triglyceride Oils and Their Industrial ApplicationsDocument28 pagesChemical Modification of Triglyceride Oils and Their Industrial ApplicationsDavis BeautiesNo ratings yet

- Green Chemistry Biofuel Extraction ProcessDocument5 pagesGreen Chemistry Biofuel Extraction ProcessSuriyavelu M. S.No ratings yet

- Making Biodiesel (Single-Phase Reaction) : StoichiometryDocument7 pagesMaking Biodiesel (Single-Phase Reaction) : StoichiometrymuradNo ratings yet

- Characterization of LipidsDocument4 pagesCharacterization of LipidsEzraela Neriah AmodoNo ratings yet

- 7 - Spectral Properties Biodiesel, V.28, n.1, 2011Document5 pages7 - Spectral Properties Biodiesel, V.28, n.1, 2011Bolivian Journal of ChemistryNo ratings yet

- Experiment 9 - Synthesis & Analysis of Biodiesel From Vegetable Oil Via TransesterificationDocument3 pagesExperiment 9 - Synthesis & Analysis of Biodiesel From Vegetable Oil Via TransesterificationLindelwa MthembuNo ratings yet

- Chemistry Investigatory - BiodieselDocument21 pagesChemistry Investigatory - BiodieselRakshith RajaramNo ratings yet

- Deep Frying: Chemistry, Nutrition, and Practical ApplicationsFrom EverandDeep Frying: Chemistry, Nutrition, and Practical ApplicationsMichael D. EricksonRating: 5 out of 5 stars5/5 (1)

- Single Cell Oils: Microbial and Algal OilsFrom EverandSingle Cell Oils: Microbial and Algal OilsZvi CohenNo ratings yet

- Managing Your Cholesterol Harvard HealthDocument56 pagesManaging Your Cholesterol Harvard Healtholly fernandezNo ratings yet

- Master Your Macros Ebook 041421Document220 pagesMaster Your Macros Ebook 041421Michael Clapham100% (3)

- The Skinny On Omega 3 FatsixbsxDocument1 pageThe Skinny On Omega 3 FatsixbsxContrerasOneal22No ratings yet

- Lipids: Types, Structures and FunctionsDocument47 pagesLipids: Types, Structures and FunctionsMarialNo ratings yet

- Nutrition Exam 2 Review 2015Document3 pagesNutrition Exam 2 Review 2015WesleyNo ratings yet

- Pediatric Nutrition GuideDocument6 pagesPediatric Nutrition GuideJoher Bolante Mendez Jr.No ratings yet

- Profoundly Raw EbookDocument118 pagesProfoundly Raw Ebookapi-27873786No ratings yet

- Preparation of Ice Cream Mix: Dairy Technology B.K.Singh, Dairy TechnologyDocument19 pagesPreparation of Ice Cream Mix: Dairy Technology B.K.Singh, Dairy TechnologyRnav rnavNo ratings yet

- The Metabolism of Sorbitan Monostearate PDFDocument6 pagesThe Metabolism of Sorbitan Monostearate PDFCamilo Ernesto Moreno CristanchoNo ratings yet

- PFAD Factsheet 20200605 RDocument4 pagesPFAD Factsheet 20200605 RFina Mustika SimanjuntakNo ratings yet

- BSc. Ag 8th Sem Applied Human NutritionDocument187 pagesBSc. Ag 8th Sem Applied Human Nutritionkaladhar timilsinaNo ratings yet

- 40k+rf Cavitation Ultrasound RF Lipo Laser Lypolysis LLLT 160mw 8 Big+4 SmallDocument4 pages40k+rf Cavitation Ultrasound RF Lipo Laser Lypolysis LLLT 160mw 8 Big+4 SmallErvin AmannNo ratings yet

- A Teenager's Nutritional Needs (14 To 17 Years Old)Document4 pagesA Teenager's Nutritional Needs (14 To 17 Years Old)SeharNo ratings yet

- Simply Orange Juice Redesign BookDocument10 pagesSimply Orange Juice Redesign Bookcinyp15No ratings yet

- The nutritional benefits of almonds for heart health and weight controlDocument13 pagesThe nutritional benefits of almonds for heart health and weight controlSyaddan ShopNo ratings yet

- Nutritional Biology Final Exam ReviewDocument9 pagesNutritional Biology Final Exam Reviewjenm1228No ratings yet

- Nutritional Quality and Safety of Organic Food A Review PDFDocument10 pagesNutritional Quality and Safety of Organic Food A Review PDFHoàng Hạnh PhươngNo ratings yet

- Fats and Fixed OilsDocument17 pagesFats and Fixed OilsMikay Barroga50% (2)

- Low FODMAP Food PlanDocument2 pagesLow FODMAP Food PlanEllice O. MonizNo ratings yet

- Sample Case StudyDocument10 pagesSample Case Studyapi-702059884No ratings yet

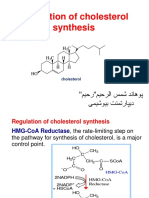

- Regulation of Cholesterol SynthesisDocument20 pagesRegulation of Cholesterol SynthesisHusnaNo ratings yet

- Adult Nutrition Plan for Managing Obesity, Diabetes and HypertensionDocument7 pagesAdult Nutrition Plan for Managing Obesity, Diabetes and HypertensionAISHA ZAFARNo ratings yet

- Test Bank For Nutritional Foundations and Clinical Applications 7th Edition by GrodnerDocument12 pagesTest Bank For Nutritional Foundations and Clinical Applications 7th Edition by GrodnerMartin Courser100% (35)

- Biochemistry (Prelim) ReviewerDocument20 pagesBiochemistry (Prelim) ReviewerKeyla PedrosaNo ratings yet

- Q2 Grade 7 HEALTH DLL Week 1Document10 pagesQ2 Grade 7 HEALTH DLL Week 1Jet Arcangel Laroco LarocoNo ratings yet

- Gym Plan 2014Document10 pagesGym Plan 2014adNo ratings yet

- Contemporary Nutrition 9th Edition by Wardlaw and Smith ISBN 125933208X Solution ManualDocument10 pagesContemporary Nutrition 9th Edition by Wardlaw and Smith ISBN 125933208X Solution Manualcharles100% (20)

- (VIP 90 - Tuần Số 13) Ngày 31.5 - Luyện Tập Bài Đọc Điền (Buổi 2)Document2 pages(VIP 90 - Tuần Số 13) Ngày 31.5 - Luyện Tập Bài Đọc Điền (Buổi 2)Nhân NguyễnNo ratings yet

- Panjab University BHMCT 2semestersyllabusDocument134 pagesPanjab University BHMCT 2semestersyllabusMourya AnkurNo ratings yet

- Maimonides - Metabolism - Intermittent Fasting - Rabbi Yonason HerschlagDocument322 pagesMaimonides - Metabolism - Intermittent Fasting - Rabbi Yonason Herschlagemily turnerNo ratings yet