Professional Documents

Culture Documents

Fabrication of Portable Spot Welding Machine

Uploaded by

IJIRSTCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fabrication of Portable Spot Welding Machine

Uploaded by

IJIRSTCopyright:

Available Formats

IJIRST International Journal for Innovative Research in Science & Technology| Volume 3 | Issue 05 | October 2016

ISSN (online): 2349-6010

Fabrication of Portable Spot Welding Machine

Rishabh Sharma Vikas Kumar Jha

Department of Mechanical Engineering Department of Mechanical Engineering

Shri Mata Vaishno Devi University, Katra (Jammu & Shri Mata Vaishno Devi University, Katra (Jammu &

Kashmir), India Kashmir), India

Deepak Kumar Singh Ram Bhajan Kumar

Department of Mechanical Engineering Department of Mechanical Engineering

Shri Mata Vaishno Devi University, Katra (Jammu & Shri Mata Vaishno Devi University, Katra (Jammu &

Kashmir), India Kashmir), India

Rajiv Kumar

Department of Mechanical Engineering

Shri Mata Vaishno Devi University, Katra (Jammu & Kashmir), India

Abstract

This paper represents the portability of resistance spot welding machine and study of various factors like the thermo-effect of

nugget growing in single-phase AC resistance spot welding and heating of electrodes during spot resistance welding. The

designed welding machine is very less in weight with same strength of the regular spot welding machine with more degree of

freedom to work with. The first thing is the fabrication of the portable spot welding machine which is divided into two phases,

first is the formation of basic circuit of machine which includes small transformer of 1.2KVA with output voltage 0 to 2volt with

2-gauge wire & power switch and second is the formation of body and arm mechanism of the machine. Also the study is on

various the factors which come into light when process of spot welding takes place. One such factor is nugget formation. The

nugget formed in the work piece plays a crucial role in joining structure. Nugget forming process is not visible and also hard to

test.

Keywords: Fabrication of Portable Spot Welding Machine, Portable Spot Welding Machine

_______________________________________________________________________________________________________

I. INTRODUCTION

In earlier studies, researchers have found the possibility of nugget growth mechanism analysis and weld quality calculation by

various methods. Destructive test method was the commonly used method for spot weld quality, which was widely used in

macrostructure or microstructure observation and mechanical characteristic testing [13]. Because of its low efficiency and

results in the invalidation of product, the non destructive test is necessary in manufacture. Engineers toward quality evaluation of

spot welds have developed various non destructive test methods such as ultrasonic testing [4, 5] and ultrasonic C-scan detection

[6]. All these are off-line test methods and still problematic in test efficiency. Currently, weld quality test on the basis of on-line

technology are proposed, which can provide basis for technological development of non destructively test.

Heating of electrode is also a factor which has deep impact on the quality of the weld. During manufacturing of electrode

materials and their operation, one tries to have a long electrode life. The electrode life, i.e. the number of welds produced

depends on various factors which affects the behaviour of electrode material in not stabilised thermal conditions, with on-going

recrystallisation and ageing. The most important factors affecting electrode life include:

1) Chemical composition of an alloy used in the electrode and thermo- mechanical treatment affecting the structure, alloy

hardness, softening temperature and electric conductivity.

2) Settings of welding parameters (pressure force, value and time of welding current) depending on the type/grade and

thickness of a material being welded,

3) Shape and working diameter of an electrode, heating temperature of the working area, electrode cooling medium and its

flow rate, welding rate.

The impact of the above said factors on electrode life has been a subject of numerous researched works [2, 411].

Thus the electrodes are one of more important elements of a welding process, the impact of an electrode shape on the process

of welding has been a subject of research [12,13]. Many researchers mainly had focused on distribution of temperature in

welding area [15,16]. Researchers revealed that the use of numerical computational models could save time and reduce costs

while developing new welding technologies [14,17].

Also, weld nugget size and welding residual stresses are two important parameters determining the mechanical behaviour of

the spot weld joints. The residual stresses in welded parts could decrease fatigue and fracture strength of structures. This indicate

that through selection of appropriate parameters, desired nugget sizes and minimum welding residual stresses could be achieved

[18]. Also besides influencing the electrical resistance, electrode force imposes pressure on the weld zone during heating and

All rights reserved by www.ijirst.org 59

Fabrication of Portable Spot Welding Machine

(IJIRST/ Volume 3 / Issue 05/ 011)

cooling, and it affects the residual stresses, the welding time and current, electrode diameter, materials, pre- heating, post-heating

cycles, and work piece thickness are other effective parameters [19-20]. Moreover a systematic approach from safety point of

view was followed as per the research studies carried out by Irfan et al. [21].

II. FABRICATION OF PORTABLE SPOT WELDING MACHINE

Phase 1: Formation of Basic Circuit

The main circuit includes a transformer, 2-gauge copper wire, copper electrodes and connecting thimbles. Firstly, we have to

convert the step up trans former which is shown in fig. 1 into a step down transformer which is shown in Fig.2 with output

voltage of approx 2.1 volt & power 1.2 KW. For this purpose 2 gauge wires is required to make two turn winding which by

electromagnetic law of induction produces 1.2 volt. A pair of copper wire electrode is connected to secondary voltage circuit.

The created voltage is approx 2 volt giving a high current of 600 Amp.

Fig. 1: Basic Circuit Fig. 2: Basic Circuit

As shown in Fig.3 both the ends of 2 gauge copper wire are peeled out and attached with two thimbles which hold the copper

electrodes. These electrodes can be changed with time and also different diameters of electrodes can be used according to the

need.

Fig. 3: 2 Gauge copper wire

Now the basic circuit of the machine is formed which can spot weld two thin sheets.

Phase 2: Formation of basic body structure of machine

The body of the machine is simply made by wood which makes the machine light in weight. The wood used in the body of the

machine is plywood and soft wood. The arm mechanism includes a liver and a spring which provide correct amount of force

required to spot weld the metal sheets, fig.4 represents the basic structure of machine and fig. 5 shows the arm of machine on

which the electrode is fixed. The complete machine is shown in fig. 6 which is the complete working structure.

III. MEASUREMENTS

Wooden base = (65 x 13.7) cm

Covering box = (Length = 35cm); (Width = 16.2cm); (Height = 12.6cm)

Wooden Arm = (Length = 33cm); (Width = 3.9cm); (Height = 2cm)

Hinge Support = (Length = 7.5cm); (Height = 7.5cm)

Transformer = (Length = 9.6cm); (Height = 8.3cm)

All rights reserved by www.ijirst.org 60

Fabrication of Portable Spot Welding Machine

(IJIRST/ Volume 3 / Issue 05/ 011)

Fig. 4: Wooden base Fig. 5: Covering box

Fig. 6: Hinge Support

IV. COST OF THE MACHINE

Table 1

Cost of the machine

Item Cost (Rs.)

Transformer (LG microwave) 1100

Wood 300

Two gauge copper wire 600

Connecting wire 100

Spring 20

Two switches 45

Copper electrode (4 mm) 20

Extra (Nails, thimble) 50

Total 2,235

V. CONCLUSION

1) Portability of welding machine provide a crucial advantage to the user as it can be used at different places and working

conditions like overhead work.

2) The market cost of portable spot welding machines ranges between Rs 4,500 to Rs 9,000 and weighs between 14 kg to 16

kg, but as a development the machine we fabricated costs only Rs 2,235 and weighs 12 kg. From this we can clearly

conclude that the initial cost and weight of the machine is significantly reduced.

3) Due to absence of cooling system the life of the electrode is compromised.

REFERENCES

[1] F. Khodabakhshi, M. Kazeminezhad, A.H. Kokabi, Metallurgical characteristics and failure mode transition for dissimilar resistance spot welds between

ultra-fine grained and coarse-grained low carbon steel sheets, Mater. Sci. Eng. A 637 (2015) 1222.

[2] F. Khodabakhshi, M. Kazeminezhad, A.H. Kokabi, On the failure behaviour of highly cold worked low carbon steel resistance spot welds, Metall. Mater.

Trans. A 45 (2014) 13761389.

[3] F. Khodabakhshi, M. Kazeminezhad, A.H. Kokabi, Mechanical properties and microstructure of resistance spot welded severely deformed low carbon

steel, Mater. Sci. Eng. A 529 (2011) 237245.

[4] A.M. Safia, M.A. Salam Akandaa, Jafar Sadiqueb, Md. Saiful Alamb, Non-destructive evaluation of spot weld in stainless steel using ultrasonic

immersion method, Proc. Eng. 90 (2014) 110115.

[5] Z.H. Chen, Y.W. Shi, B.Q. Jiao, H.Y. Zhao, Ultrasonic non-destructive evaluation of spot welds for zinc-coated high strength steel sheet based on wavelet

packet analysis, J. Mater. Process. Technol. 209 (2009) 23292337.

[6] J. Liu, G.C. Xu, D.S. Xu, G.H. Zhou, Q.Y. Fan, Ultrasonic C-scan detection for stainless steel spot welding based on wavelet package analysis, J. Wuhan

Univ. Technol. 30 (2015) 580585.

All rights reserved by www.ijirst.org 61

Fabrication of Portable Spot Welding Machine

(IJIRST/ Volume 3 / Issue 05/ 011)

[7] F. Somczyski, Technology of production of forged and bent electrodes. Report from research work. No. 72/TL-05.1.3/417A/ 852/INOP/MPM Pozna,

1972.

[8] Z. Bartnik, W. Kaczmar, Z. Koralewicz, Influence of welding rate on heating of spot electrodes, Przegld Spawalnictwa 3 (1982).

[9] Z. Bartnik, L. Krynicki, Z. Koralewicz, Cooling of welding machine electrodes with low-temperature medium, Przegld Spawalnictwa 7 (1990).

[10] Z. Bartnik, W. Derlukiewicz, Factors affecting live of spot resistance welding electrodes, Przegld Spawalnictwa 7 (2006).

[11] M. Niemiec, Electral group of copper alloys for resistance welding. Spajanie 2/5/2004, 2004.

[12] K.S. Young, P.H. Thornton, Transient thermal analysis of spot welding electrodes, Welding Journal (January (Suppl.)) (1999).

[13] R.J. Bowers, C.D. Sorensen, T.W. Eager, Electrode in geometry in spot resistance welding, Welding Journal (February (Suppl.)) (1990).

[14] B.H. Chang, Y. Zhou, Numerical Study on the Effect of Electrode Force in Small-scale Resistance Spot Welding, Elsevier Science, 2003.

[15] H. Zhigang, I.S. Kim, J.S. Son, H.H. Kim, J.H. Seo, K.C. Jang, D.K. Lee, J.M. Kuk, A study on numerical analysis of the resistance spot welding

process, Journal of Achievements in Materials and Manufacturing Engineering 1 (January/February (1/2)) (2006).

[16] K.R. Chan, N. Scotchmer, J.C. Bohr, I. Khan, M.L. Kuntz, Y. Zhou, Effect of electrode geometry on resistance spot welding of AHSS, in: SMWC XII

Session 7-4, Livonia, MI, 2006.

[17] K.R. Chan, Save time and Money with resistance welding simulation software, Welding Journal (July) (2008).

[18] Anastassiou, M., Babbit, M., Lebrun, J.L., 1991. Residual stresses and microstructure distribution in spot-welded steel sheets relation with fatigue

behaviour. Mater.Sci. Eng. A 125, 141156.

[19] Khanna, K., Long, X., 2008. Residual stresses in resistance spot welded steel joints.Sci. Technol. Weld. Joi. 13, 278288.

[20] Lindh, V., Tocher, J.R., 1967. Heat generation and residual stress development in resistance spot welding. Weld. J. 46, 351360.

[21] Haq, M.I.U., Anand, A., Nasir, T. and Singh, D., Design Considerations for Safety in Automobiles: A System Approach. at International Journal of

Mechanical Engineering and Research, ISSN, pp.2249-0019.

All rights reserved by www.ijirst.org 62

You might also like

- An Overview of Pipeline Leak Detection TechnologiesDocument9 pagesAn Overview of Pipeline Leak Detection TechnologiesharmlesdragonNo ratings yet

- Bench Testing of Relief ValvesDocument1 pageBench Testing of Relief ValvesSARATH KRISHNAKUMARNo ratings yet

- Tender Document 1 PDFDocument184 pagesTender Document 1 PDFAdityaNo ratings yet

- Tube Removal Catalog Web ELLIOTDocument24 pagesTube Removal Catalog Web ELLIOTJose Luis RattiaNo ratings yet

- Howto-Recommended Guidelines For Testing of Heat ExchangersDocument1 pageHowto-Recommended Guidelines For Testing of Heat ExchangersSam_1_No ratings yet

- ME8595-Thermal Engineering-II Valliammai PDFDocument19 pagesME8595-Thermal Engineering-II Valliammai PDFSiva SubramaniamNo ratings yet

- AME 60646 Failure of Materials Fall 2012Document1 pageAME 60646 Failure of Materials Fall 2012thienmakbNo ratings yet

- Welding Eng Lab GuidenceDocument15 pagesWelding Eng Lab Guidencewan yusufNo ratings yet

- PC 2569 Apcomin Industrial Rozc PrimerDocument3 pagesPC 2569 Apcomin Industrial Rozc PrimerAshishKumar RavalNo ratings yet

- A. O. Univ.-Prof. Dipl.-Ing. Dr. Mont. Erich Folkhard (Auth.) - Welding Metallurgy of Stainless Steels-Springer-Verlag Wien (1988)Document288 pagesA. O. Univ.-Prof. Dipl.-Ing. Dr. Mont. Erich Folkhard (Auth.) - Welding Metallurgy of Stainless Steels-Springer-Verlag Wien (1988)Graylab Technologies100% (1)

- Fabrication of Tube Rolling MachineDocument6 pagesFabrication of Tube Rolling MachineSaravanan ViswakarmaNo ratings yet

- Tube Roller ExpansionDocument12 pagesTube Roller ExpansionTejaswiNo ratings yet

- PHE Manual 0109Document17 pagesPHE Manual 0109dirtylsuNo ratings yet

- Chapter 1 Oil Seal IntroductionDocument0 pagesChapter 1 Oil Seal IntroductionZMCONTROLNo ratings yet

- Bristle Blaster BrochureDocument6 pagesBristle Blaster BrochureDom BergeronNo ratings yet

- Asmi Code DescriptionDocument3 pagesAsmi Code DescriptionMilind GaikwadNo ratings yet

- Critical Observations During A Shut Down Audit of A PF BoilerDocument9 pagesCritical Observations During A Shut Down Audit of A PF Boilerparthi20065768No ratings yet

- Faisal Khan - CV PDFDocument4 pagesFaisal Khan - CV PDFHENRY LAPACANo ratings yet

- Inspection of Boiler & Heat Exchanger TubesDocument19 pagesInspection of Boiler & Heat Exchanger TubesAnsar Hayat100% (1)

- Fabrication and Analysis of Portable Spot Welding MachineDocument7 pagesFabrication and Analysis of Portable Spot Welding MachineCrispNo ratings yet

- Characteristics of St.37 Steel Materials With Temperature and Time On Heat Treatment Test Using FurnaceDocument5 pagesCharacteristics of St.37 Steel Materials With Temperature and Time On Heat Treatment Test Using FurnaceInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Digital Universal Hardness Tester BRV-187.5TDocument5 pagesDigital Universal Hardness Tester BRV-187.5T周记伟No ratings yet

- Exp-6 Creep TestDocument6 pagesExp-6 Creep TestHanamant HunashikattiNo ratings yet

- Heat Treatment: Dr. Mohamed Abd Elmonem DahaDocument23 pagesHeat Treatment: Dr. Mohamed Abd Elmonem DahashoroukNo ratings yet

- Process Industry Practices Fabrication/Installation Details Vessel Toleran (Elevation)Document1 pageProcess Industry Practices Fabrication/Installation Details Vessel Toleran (Elevation)Federico GonzálezNo ratings yet

- Defect Assessment of A Pressure Vessel Nozzle: Power & Pressure Systems Durability and Life Extension Jun-02Document27 pagesDefect Assessment of A Pressure Vessel Nozzle: Power & Pressure Systems Durability and Life Extension Jun-02venkatrangan2003No ratings yet

- Welding MidsemDocument100 pagesWelding Midsemamit kumarNo ratings yet

- Compression Test On MS and CI RevisedDocument7 pagesCompression Test On MS and CI Revisedafzal taiNo ratings yet

- Sem1WorkShop PDFDocument8 pagesSem1WorkShop PDFGuddu RajputNo ratings yet

- Fatigue Failure Resulting From Variable Loading 1-2Document24 pagesFatigue Failure Resulting From Variable Loading 1-2Rahul SinghNo ratings yet

- PWTH RequirementDocument2 pagesPWTH Requirementveeru290683_20976731No ratings yet

- ME8792 2marksDocument31 pagesME8792 2marksRajNo ratings yet

- R. Shankar Subramanian Department of Chemical and Biomolecular Engineering Clarkson UniversityDocument2 pagesR. Shankar Subramanian Department of Chemical and Biomolecular Engineering Clarkson UniversitynabskyNo ratings yet

- TCVN Water PipeDocument43 pagesTCVN Water PipeTuan DangNo ratings yet

- Tank Case StudyDocument2 pagesTank Case Studykaryantoherlambang100% (1)

- 07 Thermal StressDocument13 pages07 Thermal StressSundaravathanan ChellappanNo ratings yet

- Is 14539 - 1998Document11 pagesIs 14539 - 1998Sumit LakhotiaNo ratings yet

- To Investigate and Study The Process and Working of TIG Welding Its AdvantagesDocument5 pagesTo Investigate and Study The Process and Working of TIG Welding Its AdvantagesRao MaazNo ratings yet

- Corrosion PDFDocument22 pagesCorrosion PDFVishal ThakareNo ratings yet

- Uv-400 Series Superflood™: Our Most Powerful Uv-A Flood Lamps Designed Specifi Cally For NDTDocument1 pageUv-400 Series Superflood™: Our Most Powerful Uv-A Flood Lamps Designed Specifi Cally For NDTzaw lin ooNo ratings yet

- Cadet Boiler Installation ManualDocument92 pagesCadet Boiler Installation ManualAnonymous pkqcrsfmF100% (1)

- SecVIII Div1 UW40Document2 pagesSecVIII Div1 UW40arianaseriNo ratings yet

- Scope of Work - O&M of BTG at GKEL-2021-2022Document35 pagesScope of Work - O&M of BTG at GKEL-2021-2022Abzad HussainNo ratings yet

- Boiler Report ProjectDocument22 pagesBoiler Report ProjectAsad AyoubNo ratings yet

- Minimum Practical Wall ThicknessDocument5 pagesMinimum Practical Wall ThicknessDiana CarolinaNo ratings yet

- Heat ExchangersDocument66 pagesHeat ExchangersSaptarshi MandalNo ratings yet

- Hydraulic Bearing PullerDocument4 pagesHydraulic Bearing PullerRvenkatesan Venkatesan100% (1)

- Bright Annealing Process of Stainless S Teel TubeDocument2 pagesBright Annealing Process of Stainless S Teel TubeViraj ShiroleNo ratings yet

- Annealing (Metallurgy) WikiDocument4 pagesAnnealing (Metallurgy) WikiStephen MontelepreNo ratings yet

- Lab Report Metal FittingDocument3 pagesLab Report Metal FittingNurul Syafiqah67% (3)

- IbrDocument4 pagesIbrJayesh100% (1)

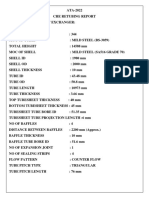

- CHE Retubing ReportDocument29 pagesCHE Retubing ReportRajesh KtrNo ratings yet

- Corrosion Behavior of Welded Stainless Steel PDFDocument20 pagesCorrosion Behavior of Welded Stainless Steel PDFLanang Dian NugrohoNo ratings yet

- Boiler Tube Repair PracticeDocument1 pageBoiler Tube Repair PracticejagyanduttaNo ratings yet

- Use & Care Guide: Precision Touch Control 800 Electric Slide-In SmoothtopDocument84 pagesUse & Care Guide: Precision Touch Control 800 Electric Slide-In Smoothtop@shline100% (2)

- Introduction To Arc Welding: Information Sheet - "Document14 pagesIntroduction To Arc Welding: Information Sheet - "Eahbm KaduNo ratings yet

- Record of Oil Flush - KPMOG PDFDocument1 pageRecord of Oil Flush - KPMOG PDFCokro YudhaNo ratings yet

- Heat Transfer Analysis During Friction Stir Welding of Al6061-T6 AlloyDocument8 pagesHeat Transfer Analysis During Friction Stir Welding of Al6061-T6 AlloySamsulNo ratings yet

- Kerf WidthDocument6 pagesKerf WidthlarryNo ratings yet

- Study of Process Parameter of Wire Electric Discharge Machining The ReviewDocument5 pagesStudy of Process Parameter of Wire Electric Discharge Machining The ReviewIAEME PublicationNo ratings yet

- Postprocessing of Compacted Images Through Consecutive DenoisingDocument4 pagesPostprocessing of Compacted Images Through Consecutive DenoisingIJIRSTNo ratings yet

- Vibration Analysis of Composite Leaf Spring by Finite Element MethodDocument7 pagesVibration Analysis of Composite Leaf Spring by Finite Element MethodIJIRSTNo ratings yet

- Patterns of Crop Concentration, Crop Diversification and Crop Combination in Thiruchirappalli District, Tamil NaduDocument10 pagesPatterns of Crop Concentration, Crop Diversification and Crop Combination in Thiruchirappalli District, Tamil NaduIJIRSTNo ratings yet

- Development of Satellite Data For Infrastructure Updation and Land Use/Land Cover Mapping - A Case Study From Kashipur & Chhatna Block, Bankura & Purulia District, West BengalDocument7 pagesDevelopment of Satellite Data For Infrastructure Updation and Land Use/Land Cover Mapping - A Case Study From Kashipur & Chhatna Block, Bankura & Purulia District, West BengalIJIRSTNo ratings yet

- Experimental Analysis of Friction Stir Processing of Tig Welded Aluminium Alloy 6061Document7 pagesExperimental Analysis of Friction Stir Processing of Tig Welded Aluminium Alloy 6061IJIRSTNo ratings yet

- The Effect of Diverse Recording Devices On Forensic Speaker Apperception SystemDocument9 pagesThe Effect of Diverse Recording Devices On Forensic Speaker Apperception SystemIJIRSTNo ratings yet

- Physico-Chemical Analysis of Selected Ground Water Samples in and Around Nagapattinam District, TamilnaduDocument3 pagesPhysico-Chemical Analysis of Selected Ground Water Samples in and Around Nagapattinam District, TamilnaduIJIRSTNo ratings yet

- Satellite Dish Positioning SystemDocument5 pagesSatellite Dish Positioning SystemIJIRST100% (1)

- Custom ROMDocument3 pagesCustom ROMIJIRSTNo ratings yet

- Multi-Physics Based Simulations of A Shock Absorber Sub-SystemDocument7 pagesMulti-Physics Based Simulations of A Shock Absorber Sub-SystemIJIRSTNo ratings yet

- Arduino-UNO Based Magnetic Field Strength MeasurementDocument4 pagesArduino-UNO Based Magnetic Field Strength MeasurementIJIRSTNo ratings yet

- Manganese: Affecting Our Environment (Water, Soil and Vegetables)Document7 pagesManganese: Affecting Our Environment (Water, Soil and Vegetables)IJIRSTNo ratings yet

- Study On Performance Evaluation of Forced Convection Solar Dryer For Turmeric (Curcuma Longa L.)Document10 pagesStudy On Performance Evaluation of Forced Convection Solar Dryer For Turmeric (Curcuma Longa L.)IJIRSTNo ratings yet

- Reconfigurable Manufacturing Systems Using The Analytical Hierarchical Process (AHP) - A ReviewDocument3 pagesReconfigurable Manufacturing Systems Using The Analytical Hierarchical Process (AHP) - A ReviewIJIRSTNo ratings yet

- Currency Recognition Blind Walking StickDocument3 pagesCurrency Recognition Blind Walking StickIJIRSTNo ratings yet

- Induction Motor Drive Using SPWM Fed Five Level NPC Inverter For Electric Vehicle ApplicationDocument7 pagesInduction Motor Drive Using SPWM Fed Five Level NPC Inverter For Electric Vehicle ApplicationIJIRSTNo ratings yet

- Development of Tourism Near Loktak Lake (Moirang) in Manipur Using Geographical Information and Management TechniquesDocument4 pagesDevelopment of Tourism Near Loktak Lake (Moirang) in Manipur Using Geographical Information and Management TechniquesIJIRSTNo ratings yet

- Rock Deformation by Extesometers For Underground Powerhouse of Sardar Sarovar Project (Gujarat)Document5 pagesRock Deformation by Extesometers For Underground Powerhouse of Sardar Sarovar Project (Gujarat)IJIRSTNo ratings yet

- Experimental Investigation On Concrete by Replacement of Sand by Silica Sand and Artificial SandDocument6 pagesExperimental Investigation On Concrete by Replacement of Sand by Silica Sand and Artificial SandIJIRSTNo ratings yet

- Performance Analysis of Organic Rankine Cycle (ORC) Working On Different Refrigerant Fluids Having Low Boiling PointDocument5 pagesPerformance Analysis of Organic Rankine Cycle (ORC) Working On Different Refrigerant Fluids Having Low Boiling PointIJIRSTNo ratings yet

- Efficient Revocation of Data Access in Cloud Storage Based On ABE-SchemeDocument6 pagesEfficient Revocation of Data Access in Cloud Storage Based On ABE-SchemeIJIRSTNo ratings yet

- Experimental Investigation On The Effect of Use of Bottom Ash As A Replacement of Fine AggregatesDocument7 pagesExperimental Investigation On The Effect of Use of Bottom Ash As A Replacement of Fine AggregatesIJIRSTNo ratings yet

- Impact of Different Soils and Seismic Zones On Varying Height of Framed StructuresDocument8 pagesImpact of Different Soils and Seismic Zones On Varying Height of Framed StructuresIJIRSTNo ratings yet

- Comparative Study of Inner Core, Peripheral and RC Shear Wall SystemDocument8 pagesComparative Study of Inner Core, Peripheral and RC Shear Wall SystemIJIRSTNo ratings yet

- Women Protection Mechanism With Emergency Communication Using Hand Waving PatternDocument5 pagesWomen Protection Mechanism With Emergency Communication Using Hand Waving PatternIJIRSTNo ratings yet

- Analysis of Agent Oriented Software EngineeringDocument5 pagesAnalysis of Agent Oriented Software EngineeringIJIRSTNo ratings yet

- Intelligent Irrigation SystemDocument5 pagesIntelligent Irrigation SystemIJIRSTNo ratings yet

- Literature Review For Designing of Portable CNC MachineDocument3 pagesLiterature Review For Designing of Portable CNC MachineIJIRSTNo ratings yet

- Infiltration, Permeability, Liquid Limit and Plastic Limit of SoilDocument12 pagesInfiltration, Permeability, Liquid Limit and Plastic Limit of SoilIJIRSTNo ratings yet

- Accounts Receivable Confirmation Letter: March 2014 Agrees With YourDocument10 pagesAccounts Receivable Confirmation Letter: March 2014 Agrees With Yourmj192No ratings yet

- Sanskritdocument029328mbp PDFDocument325 pagesSanskritdocument029328mbp PDFGirirajPurohitNo ratings yet

- Vajrayogni Long SadhanaDocument44 pagesVajrayogni Long SadhanaNilsonMarianoFilhoNo ratings yet

- AMFI Reports HubliDocument29 pagesAMFI Reports Hubliarbaz khanNo ratings yet

- Past Life and Pending Karmas Vedic Astrology Book For BeginnersDocument40 pagesPast Life and Pending Karmas Vedic Astrology Book For BeginnersJussa Mae Dajan100% (1)

- Swara GnyanaDocument4 pagesSwara Gnyanavizayrazu0% (1)

- Os and Ibntroduction To ProgramingDocument3 pagesOs and Ibntroduction To ProgramingHoney Ali100% (1)

- 09 - List of CasesDocument5 pages09 - List of Casesankita rokadiaNo ratings yet

- Hutatma Chowk and Flora FountainDocument3 pagesHutatma Chowk and Flora FountainANTHONY WRITERNo ratings yet

- ACK 019 502 HanumanDocument34 pagesACK 019 502 HanumanHarshal Shashikant NagleNo ratings yet

- Indian Knowledge SystemsDocument31 pagesIndian Knowledge Systemssaidaiah cheruvupallyNo ratings yet

- The Roots, Verb Forms, and Primary Derivatives of The Sanskrit Language - WhitneyDocument265 pagesThe Roots, Verb Forms, and Primary Derivatives of The Sanskrit Language - Whitneysktkoshas100% (2)

- Village SubCentre PHC MO Contact List SataraDocument271 pagesVillage SubCentre PHC MO Contact List SataraSanjay Bhagwat33% (3)

- Ethics ExercisesDocument2 pagesEthics ExercisesRica RebadomiaNo ratings yet

- Rahul Sankrityayan and The Buddhism of Nepal PDFDocument26 pagesRahul Sankrityayan and The Buddhism of Nepal PDFAmbrish (gYpr.in)No ratings yet

- Exhibitor List (Final)Document145 pagesExhibitor List (Final)ANILNo ratings yet

- The Path Vol 10 - William JudgeDocument466 pagesThe Path Vol 10 - William JudgeMark R. JaquaNo ratings yet

- Dadasaheb Phalke AwardDocument71 pagesDadasaheb Phalke AwardtinnymodiNo ratings yet

- SFGFVHHHGBNDocument4 pagesSFGFVHHHGBNSuresh ThanneruNo ratings yet

- Saptarishi Nadi Aries Lagna Chart 18Document27 pagesSaptarishi Nadi Aries Lagna Chart 18Олег КузнецовNo ratings yet

- Tin, Student's Pali DictionaryDocument272 pagesTin, Student's Pali Dictionarybyangsems100% (2)

- 5 Points of Yoga Wellness: 1. Proper Exercise (Asana)Document4 pages5 Points of Yoga Wellness: 1. Proper Exercise (Asana)tulikaNo ratings yet

- View Preview PDFDocument21 pagesView Preview PDFRaj TiwariNo ratings yet

- Common MeritDocument35 pagesCommon MeritVishvesh UpadhyayNo ratings yet

- EnglishDocument107 pagesEnglishSakthivel ThangamuthuNo ratings yet

- Detailed Strategy For Modern India - History Optional Part B - Tryst With Dholpur HouseDocument26 pagesDetailed Strategy For Modern India - History Optional Part B - Tryst With Dholpur Housenilabh007No ratings yet

- June 2014Document6 pagesJune 2014Gopal GopinathNo ratings yet

- Phonology of Punjabi - TextDocument242 pagesPhonology of Punjabi - TextHaroirum AfridiNo ratings yet

- Curriculum Vitae of VKADocument18 pagesCurriculum Vitae of VKAMohammad RehanNo ratings yet

- Lucknow Chapter - UP Architects AssociationDocument6 pagesLucknow Chapter - UP Architects AssociationluvsexordhokaNo ratings yet

- The Laws of Thermodynamics: A Very Short IntroductionFrom EverandThe Laws of Thermodynamics: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (10)

- Waste: One Woman’s Fight Against America’s Dirty SecretFrom EverandWaste: One Woman’s Fight Against America’s Dirty SecretRating: 5 out of 5 stars5/5 (1)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionFrom EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionRating: 3 out of 5 stars3/5 (1)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (51)

- Pilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CFrom EverandPilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CNo ratings yet

- Handbook of Mechanical and Materials EngineeringFrom EverandHandbook of Mechanical and Materials EngineeringRating: 5 out of 5 stars5/5 (4)

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsFrom EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsNo ratings yet

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 3.5 out of 5 stars3.5/5 (7)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchFrom EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchRating: 4 out of 5 stars4/5 (10)

- Introduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsFrom EverandIntroduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsNo ratings yet

- The Cyanide Canary: A True Story of InjusticeFrom EverandThe Cyanide Canary: A True Story of InjusticeRating: 4 out of 5 stars4/5 (52)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionFrom EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionRating: 4.5 out of 5 stars4.5/5 (3)

- The Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsFrom EverandThe Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsNo ratings yet

- Fuels, Furnaces and Refractories: International Series on Materials Science and TechnologyFrom EverandFuels, Furnaces and Refractories: International Series on Materials Science and TechnologyRating: 5 out of 5 stars5/5 (1)

- Rolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsFrom EverandRolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsNo ratings yet

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- Airplane Flying Handbook: FAA-H-8083-3C (2024)From EverandAirplane Flying Handbook: FAA-H-8083-3C (2024)Rating: 4 out of 5 stars4/5 (12)

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsFrom EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsNo ratings yet