Professional Documents

Culture Documents

Manual Material Handling Inspection Checklist

Uploaded by

awfahCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual Material Handling Inspection Checklist

Uploaded by

awfahCopyright:

Available Formats

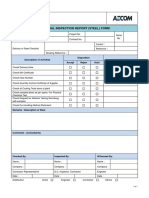

Manual Material Handling Inspection Checklist Clear Form

Department:

Location:

Inspector:

Date:

Corrected at

Date

N/A

INSPECTION ITEMS Y N Corrective Action time of

Complete

inspection

Job Design

1. When possible, jobs are designed to minimize

manual material handling.

2. When possible, mechanical lifting devices

(forklifts, hoists, cranes, and block and tackle)

are used.

3. Manual lifting and carrying devices (dollies,

hand trucks, pry bars, and hooks) are available

and in good condition.

4. Where possible, materials and equipment are

used that are easy to lift and carry (for

example, bricks with handholds or fiberglass

ladders).

5. Where possible, materials and equipment are

used that are easy to lift and carry (for

example, bricks with handholds or fiberglass

ladders).

6. Where possible, materials are ordered in

small, light quantities (for example, 3-foot

drywall or small packages of cement).

7. Lifting tasks are divided among workers to

reduce repetitive lifting.

8. Heavy materials which must be lifted manually

are stored off the ground, no lower than knee

height. (This limits the height of the lifting

required, and reduces pressure on the spine.)

9. Heavy materials are stored where there is

enough space to lift them safely, without

reaching or twisting.

10. When possible, jobs are designed to minimize

manual material handling.

Training

11. Workers have been trained about all identified

lifting hazards on the job

12. Workers have been trained in safe lifting

techniques

Work Practices

13. Materials are delivered as close as possible to

where they will be used.

14. Loads are split up to reduce weight.

15. Walkways are kept clear to allow use of

material handling devices like carts and dollies.

UCR Departmental IIPP Template http://www.ehs.ucr.edu/safety/IIPP/iipp.html Page 1 of 2

Manual Material Handling Inspection Checklist

Corrected at

Date

N/A

INSPECTION ITEMS Y N Corrective Action time of

Complete

inspection

Job Design

16. Mechanical devices or team lifting techniques

are used for heavy loads whenever possible.

17. Before lifting and carrying heavy objects,

workers plan the task, including resting points

if necessary.

18. Workers use the correct grip, test the load

before lifting and lift and hold the load close to

the body.

19. Loads are lifted and lowered gradually.

20. Mechanical devices or team lifting techniques

are used for heavy loads whenever possible.

21. Workers are encouraged to warm up at the

start of each shift, and to take regular stretch

breaks.

UCR Departmental IIPP Template http://www.ehs.ucr.edu/safety/IIPP/iipp.html Page 2 of 2

You might also like

- Quality Example 1 - ITP or QCP - Footer ApprovalDocument2 pagesQuality Example 1 - ITP or QCP - Footer ApprovalBea MokNo ratings yet

- Tool Box TalkDocument2 pagesTool Box TalkTwin BullsNo ratings yet

- Behavioral Based Safety Observation Checklist: ErgonomicsDocument2 pagesBehavioral Based Safety Observation Checklist: ErgonomicsRyan CyrillaNo ratings yet

- Confined Space Rescue Plan: Description of The WorkDocument2 pagesConfined Space Rescue Plan: Description of The Workidigiti100% (1)

- HSE 05-015a Ladder Inspection RegisterDocument1 pageHSE 05-015a Ladder Inspection RegisterQuentin KlynsmithNo ratings yet

- AE-QA-09 - Master List of Instrument Cum Calibration PlanDocument3 pagesAE-QA-09 - Master List of Instrument Cum Calibration PlanKarthi ThiyagarajanNo ratings yet

- Fire Water Tank (6monthly Inspection)Document2 pagesFire Water Tank (6monthly Inspection)Jet KimNo ratings yet

- Form-I-010 Welding Machine Inspection Form: Carry-In CertificateDocument1 pageForm-I-010 Welding Machine Inspection Form: Carry-In CertificateAdhy DarmawanNo ratings yet

- Smoke Detector ChecklistDocument1 pageSmoke Detector ChecklistTomin ThomasNo ratings yet

- Quality Assurance Plan For CRDi GensetDocument2 pagesQuality Assurance Plan For CRDi GensetnitinsomanathanNo ratings yet

- Hydrotest ProcedureDocument6 pagesHydrotest Procedurebagusu_6No ratings yet

- Non Conformance Report: Reg. Number DateDocument1 pageNon Conformance Report: Reg. Number DateAnnisa SeptyaniNo ratings yet

- AYC IC & ITP - GRP Shade InstallationDocument7 pagesAYC IC & ITP - GRP Shade Installationmoytabura96No ratings yet

- Pre-Mob Inspection Checklists 2 January 2016Document378 pagesPre-Mob Inspection Checklists 2 January 2016slamet4riadiNo ratings yet

- Diesel Generator Hour Meter & Fuel Consumption Daily ReportDocument2 pagesDiesel Generator Hour Meter & Fuel Consumption Daily ReportFreddy Elf100% (1)

- Conveyor Check ListDocument2 pagesConveyor Check Listh1549697100% (1)

- Welding Machine1Document1 pageWelding Machine1Projects DepartmentNo ratings yet

- ITP For Hydraulic BarrierDocument4 pagesITP For Hydraulic Barriermoytabura96No ratings yet

- QC-GF-002 - Material Inspection ReportDocument2 pagesQC-GF-002 - Material Inspection ReportDarrel Espino Aranas100% (1)

- SWP-06 ScaffoldDocument9 pagesSWP-06 ScaffoldShafiqNo ratings yet

- Confined Space Entry Permit Rev 01Document3 pagesConfined Space Entry Permit Rev 01Neel Vadera100% (1)

- SOP - 13 Loading & Unloading - Consummable From StoreDocument11 pagesSOP - 13 Loading & Unloading - Consummable From Storefaraz ahmed0% (1)

- Work Instruction - Welding MCDocument3 pagesWork Instruction - Welding MCManoj Kt100% (1)

- 39-98 - Safe Use of Lifting Machines and Lifting Tackle - 0Document59 pages39-98 - Safe Use of Lifting Machines and Lifting Tackle - 0JakesNo ratings yet

- Control Plan PQCT TableII PDFDocument1 pageControl Plan PQCT TableII PDFRehman LatifNo ratings yet

- Unit Gas Leak ChecklistDocument1 pageUnit Gas Leak Checklistfathul syaafNo ratings yet

- Material Handling SOPDocument1 pageMaterial Handling SOPRajesh Sharma100% (1)

- Final Inspection ChecklistDocument1 pageFinal Inspection ChecklistRonnel Leano100% (1)

- Part Name: Sample Size: Part No.: Date: Customer:: Verificatio NDocument25 pagesPart Name: Sample Size: Part No.: Date: Customer:: Verificatio Nsatrughana patraNo ratings yet

- A.9.02 - CPCL Itp For Utility Boiler PackageDocument3 pagesA.9.02 - CPCL Itp For Utility Boiler PackageGanesh EshwarNo ratings yet

- Welding Machine ChecklistDocument34 pagesWelding Machine ChecklistShahid BhattiNo ratings yet

- VL-HSE-008-R00 Compressed Gas Cylinder ChecklistDocument1 pageVL-HSE-008-R00 Compressed Gas Cylinder ChecklistRiju Scaria/EMD/QTRNo ratings yet

- 13-OM-QC-PL-MS-06 - MS FIXED TUBE TYPE EXCHANGER'S INSPECTION & CLEANING (Rev.00)Document7 pages13-OM-QC-PL-MS-06 - MS FIXED TUBE TYPE EXCHANGER'S INSPECTION & CLEANING (Rev.00)SANDEEP100% (1)

- SOP For Pneumatic Testing.Document2 pagesSOP For Pneumatic Testing.Ernst_SNo ratings yet

- Specialist Services: Preventive Maintenance ChecklistDocument2 pagesSpecialist Services: Preventive Maintenance ChecklistNakkolopNo ratings yet

- JSA Hot TapingDocument3 pagesJSA Hot TapingHeris Sitompul0% (1)

- Risk Assessment TSDocument5 pagesRisk Assessment TSMuhammad Reza GadranNo ratings yet

- Powder Coating ProcedureDocument1 pagePowder Coating Procedurenastyn-1No ratings yet

- LOG-563-03 Receiving Inspection Checklist Rev.1Document1 pageLOG-563-03 Receiving Inspection Checklist Rev.1Emy SumartiniNo ratings yet

- Form IA-002A (Audit Plan) (07-13-2012)Document2 pagesForm IA-002A (Audit Plan) (07-13-2012)granburyjohnstevens100% (1)

- Inspection Checklist For: Pipework InsulationDocument2 pagesInspection Checklist For: Pipework InsulationMuquequ@100% (1)

- Contractor Quality Control Plan For Painting WorkDocument2 pagesContractor Quality Control Plan For Painting WorkKalaiRazBalanNo ratings yet

- Incoming Inspection ReportDocument1 pageIncoming Inspection Reporttuan mai vanNo ratings yet

- Sample EHS Audit Check SheetDocument8 pagesSample EHS Audit Check SheetgovindNo ratings yet

- Method Statement Hot InsulationDocument14 pagesMethod Statement Hot InsulationSaleem AkhtarNo ratings yet

- Pre-Mobilisation Assurance Checklist BackupDocument7 pagesPre-Mobilisation Assurance Checklist BackupNazrin SHONo ratings yet

- Safety Daily Site Checklist Mastoura co-SA-1-12Document12 pagesSafety Daily Site Checklist Mastoura co-SA-1-12LawrenceNo ratings yet

- Roles Responsibility & Authority ProcedureDocument2 pagesRoles Responsibility & Authority ProcedureAyobami Blessing100% (2)

- Tank Lorry Safety & Security Check-Step 1Document3 pagesTank Lorry Safety & Security Check-Step 1fawad haider100% (1)

- HIRA FormatDocument2 pagesHIRA FormatSachin Yashwant kumbharNo ratings yet

- Material Inspection Report Steel FormDocument1 pageMaterial Inspection Report Steel FormMohamedGhanemNo ratings yet

- HSE MS Training Feb 2019Document17 pagesHSE MS Training Feb 2019Musalim Shaikh100% (1)

- Itp Installation of FcuDocument4 pagesItp Installation of FcuAkmaldeen AhamedNo ratings yet

- Fireproofing Check List Quality Control and Inspection Report FormDocument1 pageFireproofing Check List Quality Control and Inspection Report FormAnonymous 4e7GNjzGWNo ratings yet

- HIRA 013 Working Over Water.Document2 pagesHIRA 013 Working Over Water.srinibas mohapatra100% (1)

- Template-Post Shutdown ReportDocument3 pagesTemplate-Post Shutdown Reportarief bayuNo ratings yet

- Subcontractors EHS Audit TemplateDocument7 pagesSubcontractors EHS Audit TemplateDeepakNo ratings yet

- Shop Safety Checklist PDFDocument4 pagesShop Safety Checklist PDFjealousmistressNo ratings yet

- Office Safety Inspection Checklist: Inspection Items Y N Corrective ActionDocument3 pagesOffice Safety Inspection Checklist: Inspection Items Y N Corrective Actionanmec20No ratings yet

- Manual Handling WeightsDocument21 pagesManual Handling Weightsbatfink182100% (1)

- Annual Report 2006Document132 pagesAnnual Report 2006awfahNo ratings yet

- International Cement Review - Too Hot To Handle. Heat Resistant Belt ArticleDocument3 pagesInternational Cement Review - Too Hot To Handle. Heat Resistant Belt ArticleawfahNo ratings yet

- Fls Ball MillDocument8 pagesFls Ball Millrazen_inNo ratings yet

- 2 Hessen Equipment Testing DocumentDocument8 pages2 Hessen Equipment Testing DocumentawfahNo ratings yet

- Russia Coal Mining Sector ReportDocument39 pagesRussia Coal Mining Sector ReportawfahNo ratings yet

- 1060 4. Bathurst Coal Fact SheetDocument2 pages1060 4. Bathurst Coal Fact SheetawfahNo ratings yet

- Sustainable Development Health Safety UkDocument2 pagesSustainable Development Health Safety UkawfahNo ratings yet

- FEECO Complete OfferingsDocument8 pagesFEECO Complete OfferingsawfahNo ratings yet

- Burner Design and ResultsDocument5 pagesBurner Design and ResultsawfahNo ratings yet

- Phoenix S-Wall Technical-Manual enDocument44 pagesPhoenix S-Wall Technical-Manual enRavikanth Aluri100% (1)

- Steel Cord Belting BrochureDocument12 pagesSteel Cord Belting BrochureawfahNo ratings yet

- Lubrication Failure AnalysisDocument59 pagesLubrication Failure AnalysisMahaveer Singh100% (1)

- Codex Rohonc PDFDocument217 pagesCodex Rohonc PDFawfahNo ratings yet

- Dunlop Steelcord Leaflet en Aug2013Document2 pagesDunlop Steelcord Leaflet en Aug2013awfahNo ratings yet

- Conveyor Belt Manual PDFDocument74 pagesConveyor Belt Manual PDFawfahNo ratings yet

- 5.7 Insp and Sampling of Materials 03.22Document24 pages5.7 Insp and Sampling of Materials 03.22awfahNo ratings yet

- Common English IdiomsDocument13 pagesCommon English IdiomsLucia PopaNo ratings yet

- ContentDocument206 pagesContentawfahNo ratings yet

- Solid Alternative FuelsDocument12 pagesSolid Alternative FuelsawfahNo ratings yet

- PM Manual SMALL Rev June11 GATES Manual Tension CorreasDocument67 pagesPM Manual SMALL Rev June11 GATES Manual Tension CorreasDavid SaldarriagaNo ratings yet

- Elevator Belt and Splice Installation GuideDocument17 pagesElevator Belt and Splice Installation GuideawfahNo ratings yet

- Health ConsultDocument137 pagesHealth ConsultawfahNo ratings yet

- AP Pre Inspection Checklists For Nonmetallic Mineral Processing EquipmentDocument29 pagesAP Pre Inspection Checklists For Nonmetallic Mineral Processing EquipmentawfahNo ratings yet

- ChecklistDocument9 pagesChecklistawfahNo ratings yet

- Ppe Assessment Form ExamplesDocument18 pagesPpe Assessment Form Examplesawfah100% (1)

- Belt Position Monitoring System BCDocument2 pagesBelt Position Monitoring System BCawfah100% (1)

- "Fire Extinguishers": An Introduction ToDocument30 pages"Fire Extinguishers": An Introduction ToRafik RahmanNo ratings yet

- Concrete Services Standard SubcontractDocument21 pagesConcrete Services Standard SubcontractawfahNo ratings yet

- Nano-Metre Leather GloveDocument8 pagesNano-Metre Leather GloveawfahNo ratings yet

- Billy Elliot Stage NotesDocument29 pagesBilly Elliot Stage NotesHilly McChef100% (2)

- Engleski Jezik - Unit 4 & 5: Ime I Prezime: - RazredDocument4 pagesEngleski Jezik - Unit 4 & 5: Ime I Prezime: - RazredKatarina CrnkovićNo ratings yet

- Addition Five Minute Frenzy 0110 001 PDFDocument2 pagesAddition Five Minute Frenzy 0110 001 PDFSimone CarvalhoNo ratings yet

- Declaration of Conformity: According To FCC Part 15Document67 pagesDeclaration of Conformity: According To FCC Part 15ssenjoe100% (1)

- Single Brand SolutionDocument103 pagesSingle Brand Solutionamir6302No ratings yet

- Comics LectureDocument31 pagesComics Lectureandrew algarneNo ratings yet

- Repeater Details As Per Format. LatestDocument36 pagesRepeater Details As Per Format. LatestPoornima SinghNo ratings yet

- DC WBW Gc14 04 Final v2Document39 pagesDC WBW Gc14 04 Final v2snydererik555No ratings yet

- Go To Shortie SocksDocument2 pagesGo To Shortie SocksBritt Ney71% (24)

- BMW CD Changer E60Document14 pagesBMW CD Changer E60MOHSINNo ratings yet

- Pe1 ModuleDocument26 pagesPe1 ModulePamela Louise MercaderNo ratings yet

- KING 2011: Parand Software GroupDocument35 pagesKING 2011: Parand Software GroupOmid ZamaniNo ratings yet

- PastryClass CedricGroletDocument31 pagesPastryClass CedricGroletAsharualim Nebiru Agaku33% (27)

- DEVIALET ID PRICELIST 28062023Document2 pagesDEVIALET ID PRICELIST 28062023M farhan alfariziNo ratings yet

- Worksheet No.4 Quarter 1Document8 pagesWorksheet No.4 Quarter 1Claudia Zan100% (1)

- Spectra-FLEX Brochure 2022 enDocument12 pagesSpectra-FLEX Brochure 2022 enIvanNo ratings yet

- AppetizerDocument12 pagesAppetizerGrassLeaf StreamNo ratings yet

- How To Draw Manga Boys Step by - Studios, WaterDocument144 pagesHow To Draw Manga Boys Step by - Studios, WaterAsim RaoofNo ratings yet

- 116-122 Anandita SharmaDocument7 pages116-122 Anandita SharmazskwahNo ratings yet

- Mobile Banking - Modification - Form - 281021Document1 pageMobile Banking - Modification - Form - 281021NiiNo ratings yet

- Pick N Choose Non - VegetarianDocument2 pagesPick N Choose Non - VegetarianData PubNo ratings yet

- UntitledDocument782 pagesUntitledPaul ClarkeNo ratings yet

- How To Use Dforce - Creating A Blanket Draping Clothes On Furniture and Much More - Part 1Document91 pagesHow To Use Dforce - Creating A Blanket Draping Clothes On Furniture and Much More - Part 1Iman SaifulNo ratings yet

- 12.tehničke Karakteristike Bagera MH-5 (Engleski Jezik) PDFDocument16 pages12.tehničke Karakteristike Bagera MH-5 (Engleski Jezik) PDFadamajaks1985100% (2)

- Monthly MenuDocument4 pagesMonthly MenuMythbuster MomNo ratings yet

- U MDocument318 pagesU Minflorescence56No ratings yet

- A Bad Day Third Conditional 1bfs9l6Document1 pageA Bad Day Third Conditional 1bfs9l6gd cuentasNo ratings yet

- 4822797-Rujero y Paradetas From The Spanish Suite For Viola Guitar PDFDocument1 page4822797-Rujero y Paradetas From The Spanish Suite For Viola Guitar PDFFhomensNo ratings yet

- Chess Magazine Chess Mai3Document52 pagesChess Magazine Chess Mai3Francoise EithssenNo ratings yet

- Case Analysis of Tweeter Etc.: Marketing II AssignmentDocument4 pagesCase Analysis of Tweeter Etc.: Marketing II AssignmentAbinash BeheraNo ratings yet