Professional Documents

Culture Documents

Comparative Design and Analysis of Self Supporting and Guyed Steel Chimney

Uploaded by

IJIRSTCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Comparative Design and Analysis of Self Supporting and Guyed Steel Chimney

Uploaded by

IJIRSTCopyright:

Available Formats

IJIRST International Journal for Innovative Research in Science & Technology| Volume 3 | Issue 07 | December 2016

ISSN (online): 2349-6010

Comparative Design and Analysis of Self

Supporting and Guyed Steel Chimney

R. Boopathiraja K. Kayalvizhi

Assistant Professor Assistant Professor

Department of Civil Engineering Department of Civil Engineering

The Kavery College of Engineering, India The Kavery College of Engineering, India

R. Vanathi

Assistant Professor

Department of Civil Engineering

The Kavery College of Engineering, India

Abstract

The area proposed for the construction of this chimney is at an industry in Metter. They have already provided 43m self-supporting

steel chimney. In addition to that, analysis and design of 72m steel chimney (Self-supporting Vs Guyed) for eco-friendly purpose.

Here we design and analysis a steel chimney having a height of 72m steel chimney and structural elements of the chimney such as

foundation are designed. By comparing the moments of self-supporting steel chimney and guyed steel chimney from manual

design. The base moment of guyed steel chimney is less than the self-supporting steel chimney and hence Guyed Steel Chimney

is safe at that site.

Keywords: Auto CADD, STAAD pro, guy ropes, cylindrical shell

_______________________________________________________________________________________________________

I. INTRODUCTION

Our project deals with the design of a steel structure. The type of chimney that we have taken for our project is industrial chimney

with steel. Here design of loads and the design of self weight and foundation were carried out manually. The various drawings

were drafted by AutoCAD 2013.And the analysis is done by STAAD pro 2007. Usually the design of the structural elements

carried out manually and it takes more time but we can learn more things. If the structure is small than the calculation will be

simpler and can also be completed quickly. But for the chimney, the calculation for the design of the structural elements will be

tedious and time consuming. Chimneys are used to emit the exhaust gases, higher up in the atmosphere, so that diffusion of gases

takes place. There are mainly three types of chimney structures: - R.C.C chimney, Steel chimney, Brick chimney. For project,

considered steel chimney structure.

II. DESIGN OF SELF-SUPPORTING STEEL CHIMNEY

Basic Dimensions of Chimney:

Total height of chimney = 72m

Height of flare = H = 1/3(72) = 24 m

Diameter of the flare =1.6x3 = 4.8m.

Computation of wind pressure:

The design wind speed at any height z is given by

Vz=Vb.k1.k2.k3

Where, Vb = basic wind speed at the site =47m/s for salem.

k1=probability factor (risk coefficient) =1.0for general buildings and structures.

k3=topography factor =1.0 for flat topography

k2=terrain, height and structure size factor

Vz= 47 x 1 x 1 x k2

Now design wind pressure Pz= 0.6Vz2N/m2

Pz=0.6(47k2) x10-3 kN/m2= 1.3254k22 KN/m2

For chimney, adopting a shape factor of 0.7

Pz= (pz.D.z)0.7

All rights reserved by www.ijirst.org 13

Comparative Design and Analysis of Self Supporting and Guyed Steel Chimney

(IJIRST/ Volume 3 / Issue 07/ 003)

Table 1

Moment at each section

Section H (m) D (m) k2 p=1.3245 k22 P=pxDxhxSF (kN) h MW=Pxh1 (kNm) Mwxx

1 72 3 1.201 1.910 32.096 68 2182.510 128.383

2 64 3 1.19 1.876 31.510 60 1890.629 511.191

3 56 3 1.178 1.838 30.878 52 1605.666 1143.553

4 48 3 1.165 1.798 30.200 44 1328.819 2020.230

5 40 3 1.145 1.736 29.172 36 1050.207 3134.399

6 32 3 1.125 1.676 28.162 28 788.541 4477.905

7 24 3.3 1.09 1.574 29.081 20 581.617 6050.384

8 16 3.9 1.054 1.471 32.136 12 385.627 7867.728

9 8 4.5 1 1.325 33.377 4 133.510 9947.124

TOTAL 9947.124

Where

H = Height from bottom

D = Diameter of section

h1 = P acts at a height from above the base

Mw = overturning moments at the base

h' = Height difference between two station (H1 H2)

Design of Chimney Shell:

Stress due to chimney weight, fs=0.0785ht N/mm2

Stress due to weight of lining, fl=0.002ht/t N/mm2

Stress due to wind, f w=(0.004Mwxx)/(D^2 t) N/mm2

Minimum thickness of shell from stability point of view=D/500=3000/500=6mm.

It is assumed that the design life of steel chimney shell will be 20 years and coal is used for boiler. Hence add additional 4mm

Thickness to account for corrosion. Hence total minimum thickness of plate=6+4=10mm.

Effective thickness =10-4=6mm

Table - 2

Determination of stress

Section D (m) t (m) ht fs Fl Fw fc max ft max fc max < cx1 D/t ht/D c (From IS 6533)

1 3 0.006 8 0.63 2.67 3.03 6.32 0.36 58 500 2.67 58

2 3 0.006 16 1.26 5.33 12.06 18.65 6.73 58 500 5.33 58

3 3 0.006 24 1.88 8.00 26.98 36.86 18.98 58 500 8.00 58

4 3 0.006 32 2.51 10.67 47.66 60.84 36.99 58 500 10.67 58

5 3 0.008 40 3.14 10.00 55.46 68.60 45.46 75.6 375 13.33 75.6

6 3 0.008 48 3.77 12.00 79.23 94.99 67.23 75.6 375 16.00 75.6

7 3.6 0.008 56 4.40 14.00 74.34 92.74 60.34 64 450 15.56 64

8 4.2 0.008 64 5.02 16.00 71.02 92.05 55.02 58 525 15.24 58

9 4.8 0.008 72 5.65 18.00 68.75 92.40 50.75 58 600 15.00 58

Computation of Actual Weight:

Self Weight of chimney Ws = Density of steel (78.5kN/m3) x Volume of steel in chimney

Ws = (4xx3x8x0.01x78.5) + (2xx3x8x0.012x78.5) +3xx ((3+4.8)/2) x8x0.012x78.5

= 236.75 + 142.05 + 277 = 656.25 kN

Wl = (48xx2.90x0.1x20) + (24xx ((2.9+4.7)/2)x0.1x20 =1447.646 KN

Total W=656.25+1447.646=2103.896 KN

Increase the weight by 5% to account for lap, stiffeners, platforms, ladder etc.

Total W= (2103.896 +105.195) =2209.091 KN

Check for Earthquake Forces:

Area of cross-section at the base =x4.8x0.016 =0.241m2

72

Factor 2 = 2 = 42.43

2.4

CT 78.2 and Cv 1.45

T=CT

233072

T=78.2

2108 0.2419.81

T=1.473 sec

Hence for 2% damping, = 0.1

All rights reserved by www.ijirst.org 14

Comparative Design and Analysis of Self Supporting and Guyed Steel Chimney

(IJIRST/ Volume 3 / Issue 07/ 003)

For medium soil, with isolated footing, =1.2

Importance factor I=1.Seismic zone factor for zone IV,

F=0.25

h= F I=0.1x1.2x0.25x1=0.03

Mx=h W [0.6( )0.5 + 0.4( )4 ]

At the base, x=4

1

Also = [236.75(72.16)+71.025(72-36)+94.7(72-44) +369.331x12 +874.619x48+573.027x12]

2219.452

=32.33 m

Mbase =0.03x2330x32.33(0.6+0.4)

=2259.867 KN-m

Moment at top of flared portion (x=48m)

48 48

MX=48=2259.867[0.6( )0.5 +0.4( )4 ]

72 72

=2259.867(0.4899+0.079)

=1285.662 KN-m

Comparing these moments with the corresponding moments due to wind, it found that wind governs the design. Hence the

thicknesses found on the basis of wind loads are OK, and further detail may be worked out for wind force and not for earthquake

force.

Design of Joint:

Up to top 32m height:

Thickness of plates =10mm. Use 18mm dia. rivets.

Strength in single shear= (18+1.5)2x100x10-3 =29.865 KN

4

Strength in bearing = (18+1.5)x10x300x10-3=58.5 KN

Rivet value =29.865KN

Required strength of plate= 2 =150x0.7=105N/mm2

Strength per unit length=105x10=1050N/mm

Using double rivets lap, joint,

29.86521000

Pitch of rivet= =56.89 mm.

1050

Maximum pitch=10t=10x10=100 mm.

However, provide double riveted lap joint, joint, using 18 mm dia. rivets at a pitch of 55 mm c/c.

For Lower Portion

Thickness of plate =16 mm, use 22 mm dia. rivets.

Strength in single shear = (18 + 1.5)2 x100x10-3=43.374 KN

4

Strength in bearing =23.5x16x300x10-3 =112.8 KN

= 43.374 .

Required strength of plate=105 N/mm2

Strength for unit length =105x16=1680N/mm

Using triple riveted lap joint,

43.37431000

Pitch of rivets = = 77.45

1680

Maximum pitch =10t=10x16=160 mm

However, provide triple lap joint, using 22 mm dia. rivets at a pitch of 75 mm c/c.

Design of the Flue Opening:

Area of cross-section of chimney = (32)=7.069 m2

4

Area of breech opening = 1.2x7.069=8.483 m2

2

Max. Width of opening = 3 = 2

3

Keep 1.8 m wide 4.6 m high opening.

Actual area provided=1.8x4.6=8.282 which is about 17% greater than the area of cross section of chimney.

Area of stack plates removed=16x1800=288002

Length of chord=R+R cos (or)

L=R (1+cos )

0.9

= tan1 =30.934

1.5

cos = 0.8575

L=1.5(1+0.8575)=2.786 m

All rights reserved by www.ijirst.org 15

Comparative Design and Analysis of Self Supporting and Guyed Steel Chimney

(IJIRST/ Volume 3 / Issue 07/ 003)

Dia 3

= =1.0767

L 2.786

Area of reinforcement =28800x1.0767 31000 mm2

1

Reinforcement of each vertical side = x31000=15500mm2

2

Provide 2L 150x150x18 @ 5780 x2 =11560 mm2

1plate 300x16 =4800 mm2

2

Total =16360 mm

The same reinforcement is provided at top and bottom of breech opening.

Tensile stress in stack plates = t 2 =150x0.7=105 N/mm2

1

Force in each vertical side = x31000x104x10-3=1627.5 KN

2

Strength of 22 mm dia rivet in double shear =2x43.374

=1627.5 KN

Rivet value of 22 mm dia. rivets (bearing on mm plates)

=112.8 KN

Rivets value =86.748 KN

NO. Of rivets =18.76

Provided two rows of 10 rivets on each vertical side at a pitch of 80 mm in each of the extended portion of vertical

reinforcement. Thus, the vertical reinforcement will extent above and below the opening by a distance of a 10x80=800mm. in the

vertical and horizontal reinforcement, use 22 mm dia. Rivets at a pitch of 10x16=160 mm c/c.

Design of Base Plate:

The maximum compressive force per unit length

Ws+Wl 4Mw

Fc= + KN/m

dc d2c

2330 48757.93

= +

4.8 (4.82 )

=154.51+483.98

=638.48KN/m =638.48N/mm2

Allowable bearing pressure, c =4N/mm2

F 638.49

m= c = = 159.6 mm

c 4

Provide 160mm wide base plate. Use two 70x70x10mm angle for connecting the stack to the base. Using 22mm dia, rivets for

connection, strength of rivet in double shear = 2x43.37 = 86.748KN which strength of rivet in bearing against 16mm plate is

112.8KN. Hence rivet value = 86.748KN.

Rivet value 86.748103

Pitch of rivet = = = 135.86mm

Fc 638.49

Maximum permissible pitch = 10t = 10x16 =160mm

Hence provide 22mm dia. rivets @ 130mm c/c.

160

Projection c = - (10+8) = 62mm.

2

638.49

Actual bearing pressure = = 3.99N/mm2

160

3c 33.99

tb = xc = x62 = 15.77mm

bs 185

Provide 16mm thick base plate.

Design of Anchor Bolts:

Maximum uplift force per unit length of circumference

4M Ws

Ft = w 2 -

dc dc

As per IS 6533 (part 2): 1989, the overturning moment Mw should be increased to 1.5 times from stability consideration

4(8757.931.5) 771.806

Ft = = 674.8KN/m

4.82 4.8

Let us provide 39mm dia. ISO fine threaded bolts having effective area = 1028mm2 , at root of thread. Taking permissible tensile

strength of 120N/mm2 at the root of thread.

Strength of each bolt = 1028x120x103 =123.36KN.

No increase in stress is recommended since wind is the major load in the case of chimneys.

123.36

Spacing of bolts = x1000 = 182.8mm

674.8

4.81000

No. of bolts =82.5

182.8

However, provide 85 bolts of 39mm nominal diameter on a circle diameter

4.8+0.7 4.87m

All rights reserved by www.ijirst.org 16

Comparative Design and Analysis of Self Supporting and Guyed Steel Chimney

(IJIRST/ Volume 3 / Issue 07/ 003)

4.871000

Actual spacing of bolts = =180mm

85

Alternatively use HTFG bolts M 30(10K) having proof load of 392.7KN

392.71000

Spacing of bolts = = 582mm

674.8

4.81000

No. of bolts = 25.9

582

However, provide 30 HTFG bolts of dia. of 10K grade, on a bolt-circle diameter of 4.87m

4.871000

Actual spacing = = 510mm.

30

Design of Foundation Block:

Let us provide solid foundation in the form of frustum of a cone. Let the upper diameter be 6m. Keeping a slope of 45 (equal to

maximum permissible value for plain concrete),and a depth of 3m, the diameter at base = 6+2x3=12m

Volume of pedestal = (12 + 22 + 1 2 )

12

3

= (62 + 122 + 6 12) = 197.92m3

12

Weight of pedestal = 197.92x24 = 4750.09 KN

Volume of earth fill = (12)2 3.0 197.92 = 141.373

4

Taking unit weight of earth fill as 17KN/3

Weight of earth backfill = 141.37x17= 2403.32 KN

Weight of foundation plus stack = 771.81+4750.09+2403.32 = 7925.22KN

Total wind force =28.473+27.911+27.356+26.65+25.493+24.362+

25.283+27.574+28.888= 24.99

Wind moment at base = 8757.93+241.99x3.0 = 9483.9KN-m

9483.9 1

e= = 1.197< 12

7925.22 8

= foundation + (stack + lining) = 4750.09 + 2330 = 7080.09KN

7080.09 9483.9

Max base pressure = 2 + 3 = 62.60+55.90 = 118.5KN/2

4 (12) 32(12)

Factors of Safety Against Overturning:

Overturning moment M0 = 9483.9KN-m

Restoring moment = (4750.09+771.81)6

=33131.4KN-m

Factor of safety = 33131.4/9483.9 = 3.49>1.5 Hence safe.

Check Against Sliding:

Let =0.35

Friction force = (4750.09+771.81)0.35 = 5521.9>241.99 . Hence safe.

III. DESIGN OF GUYED STEEL CHIMNEY

Data:

Height of chimney =72m

Diameter of chimney =4m

Provide one set of three guy-ropes

For one set of three guy ropes, the collar is attached at a depth one-third from the top that is (72/3)=24m .

1 =72-24=48m

H-1 =72-48=24m

Horizontal Wind Pressure:

Assumed intensity of horizontal wind is 1kN/m2 .

Total horizontal wind force

=1x72x4

=228 KN/m2

Bending Moment at the Level of Collar:

1

M= ( (H-1 )2)

2

1 228

= ( ) (2424)

2 72

All rights reserved by www.ijirst.org 17

Comparative Design and Analysis of Self Supporting and Guyed Steel Chimney

(IJIRST/ Volume 3 / Issue 07/ 003)

=912KN-m

Reaction at the level of collar:

= 3 /4

=3x228 /4 = 171 KN

Reaction at the base:

= - = 228- 171

= 57KN

Position of Zero Shear Force:

Let 1 be the depth from top where the shear force is zero.

- *1 =0

( * H)- ( *1 ) =0

2

2

1 =

21

7272

1 =

248

1 = 54m

Bending Moment at Base:

M=( * H) (1- )2

2 21

22872 72

=( )(1- )2

2 248

=513 KN-m

Pull in the Guy Rope:

Angle between the guy rope and horizontal may be kept 45 . Angle with the vertical shall also be45 .

= ( ) ( )

21

22872

=( )

45 248

= 214.83 KN

The base moment of guyed steel chimney is less than the self-supporting steel chimney and hence Guyed Steel Chimney is safe at

that site.

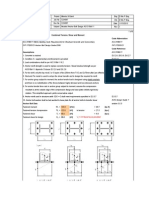

Fig. 1: Auto CADD Drawing of Guyed Steel Chimney

All rights reserved by www.ijirst.org 18

Comparative Design and Analysis of Self Supporting and Guyed Steel Chimney

(IJIRST/ Volume 3 / Issue 07/ 003)

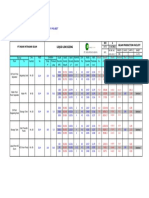

Fig. 2: 2D View of guyed steel chimney

Fig. 3: Displacement Diagram

All rights reserved by www.ijirst.org 19

Comparative Design and Analysis of Self Supporting and Guyed Steel Chimney

(IJIRST/ Volume 3 / Issue 07/ 003)

Mz(kip-in)

60 49.6 60

40 40

20 20

21 11

20 5 10 15 20 24 20

40 40

60 -51.5 60

Fy(kN)

0.60 0.60

0.40 0.40

0.20 0.20

21 11

0.20 5 10 15 20 24 0.20

0.40 0.40

0.60 -0.476 -0.476 0.60

Fx(kN)

30 26.6 30

20 20

10 1.03 10

21 11

10 5 10 15 20 24 10

20 20

30 30

Fig. 4: Shear Force and Bending Moment Diagram

All rights reserved by www.ijirst.org 20

Comparative Design and Analysis of Self Supporting and Guyed Steel Chimney

(IJIRST/ Volume 3 / Issue 07/ 003)

IV. CONCLUSION

The planning and design of the self-supported steel chimney and guyed steel chimney have been completed effectively in this

project. By comparing the moments of both chimneys, the base moment of guyed steel chimney is less than the self-supporting

steel chimney and hence GUYED STEEL CHIMNEY is safe at that site. And the displacement of guyed steel chimney is very less

in this project and hence it is safe. As it is a height of 72m it doesnt affect the surrounding atmosphere. All the drawings were

drafted by using Auto CAD 2013 software. And analysis of guyed steel chimney is done by STAAD.Pro 2007.

REFERENCES

[1] IS 6533 Part 1; 1989, Design and Construction of Steel Chimney, Bureau of Indian Standards, New Delhi (2002).

[2] IS 6533 Part 2; 1989, Design and Construction of Steel Chimney, Bureau of Indian Standards, New Delhi (2005).

[3] IS 800 2000 Basic structural design.

[4] Comprehensive Design of steel structures Dr. B.C.Punmia, ashok Kumar jain.

[5] Canadian Journal on Environmental, Construction and Civil Engineering Vol. 3, No. 2, February 2012.

[6] G. Murali, B. Mohan, P. Sitara and P. Jayasree/ International Journal of Engineering Research and Applications (IJERA) ISSN: 2248-9622 www.ijera.com

Vol. 2, Issue 2, Mar-Apr 2012, pp.490-498.

All rights reserved by www.ijirst.org 21

You might also like

- Slope Stability Analysis Input Data: Project SettingsDocument5 pagesSlope Stability Analysis Input Data: Project SettingsanonimusazNo ratings yet

- Sheeting Structure Verification Input DataDocument26 pagesSheeting Structure Verification Input DataanonimusazNo ratings yet

- Thermal Stresses Beams and Frames Detailed Exposition PDFDocument17 pagesThermal Stresses Beams and Frames Detailed Exposition PDFatankasalaNo ratings yet

- Analysis On Laterally Loaded Group PilesDocument5 pagesAnalysis On Laterally Loaded Group PileschenNo ratings yet

- Response Spectrum Curves (ASCE)Document6 pagesResponse Spectrum Curves (ASCE)Hannah EsmaelNo ratings yet

- LRFD Compression Member DesignDocument236 pagesLRFD Compression Member DesignWayne Alegria JumawanNo ratings yet

- All Page PDFDocument24 pagesAll Page PDFsskamalakannanNo ratings yet

- Abstract of Cost: Name of Work: CDocument14 pagesAbstract of Cost: Name of Work: Cmail2rahulgargNo ratings yet

- Research Report On Single Plate Shear Connections: North Carolina State UniversityDocument51 pagesResearch Report On Single Plate Shear Connections: North Carolina State UniversityHarshaVeeragandhamNo ratings yet

- Add any change made in the sheet with new revision NoDocument16 pagesAdd any change made in the sheet with new revision Nochenfs27531No ratings yet

- 2007 Steel Tanks, Seismic Design of Ground Supported Liquid Storage Welded Steel TanksDocument5 pages2007 Steel Tanks, Seismic Design of Ground Supported Liquid Storage Welded Steel Tanksmmoeini412002No ratings yet

- Case-1 (Actual Load+tension With Anchor Bar)Document16 pagesCase-1 (Actual Load+tension With Anchor Bar)userhieNo ratings yet

- 4.3 Design of Base Plate W STIFFENER (Feb 21 2015)Document27 pages4.3 Design of Base Plate W STIFFENER (Feb 21 2015)Jair llacuachaqui villalvaNo ratings yet

- ACI Detailing Manual-2004: Reported by ACI Committee 315Document1 pageACI Detailing Manual-2004: Reported by ACI Committee 315vacamia2No ratings yet

- Anchor Design HILTIDocument14 pagesAnchor Design HILTIRohit GadekarNo ratings yet

- Fabricator Doc 19-8-2021Document39 pagesFabricator Doc 19-8-2021accountsNo ratings yet

- Basics of Tank Seismic OCRDocument35 pagesBasics of Tank Seismic OCRmario_gNo ratings yet

- IES MASTER Digital Online ClassesDocument5 pagesIES MASTER Digital Online ClassesSumanNo ratings yet

- Bottom LugDocument7 pagesBottom LugAjiri IvoviNo ratings yet

- Aci 303.1-97Document10 pagesAci 303.1-97Carlos BernabeNo ratings yet

- Mathcad - Tank Foundation Design Actions - 2611-501 & 502 - Rougher WMS Feed Tank 1 & 2Document15 pagesMathcad - Tank Foundation Design Actions - 2611-501 & 502 - Rougher WMS Feed Tank 1 & 2shashank sharmaNo ratings yet

- RCC32 Ribbed Slabs (A & D) GFDGDocument26 pagesRCC32 Ribbed Slabs (A & D) GFDGLove SemsemNo ratings yet

- Geodesic Analysis SampleDocument22 pagesGeodesic Analysis SampleSeaShell_6No ratings yet

- 1997 - Veletsos Et Al - Dynamics of Solid Containing TanksDocument93 pages1997 - Veletsos Et Al - Dynamics of Solid Containing TanksmahdiebNo ratings yet

- Shear Lug DesignDocument19 pagesShear Lug DesignariyaNo ratings yet

- Chapter 7 Snow LoadsDocument14 pagesChapter 7 Snow LoadsGhaedan HameedNo ratings yet

- TIA 222G wind load parametersDocument29 pagesTIA 222G wind load parametersboypardede3552No ratings yet

- 9 Design of Flat Slab Column Connections As Per Aci 352-4-R89 23052014 5Document2 pages9 Design of Flat Slab Column Connections As Per Aci 352-4-R89 23052014 5Ahmad Badsha QuadriNo ratings yet

- AISC Member Dimensions ViewerDocument1 pageAISC Member Dimensions ViewerAulia MirzaNo ratings yet

- Simplified Buckling-Strength Determination of Pultruded FRP Structural BeamsDocument17 pagesSimplified Buckling-Strength Determination of Pultruded FRP Structural BeamswalaywanNo ratings yet

- Design Example of Pipe Rack StructureDocument16 pagesDesign Example of Pipe Rack StructureJimit PayNo ratings yet

- Fatigue Analysis and Repair of A High Mast Light Pole: SynopsisDocument14 pagesFatigue Analysis and Repair of A High Mast Light Pole: SynopsisjaffliangNo ratings yet

- Single Bolt Embedment Design - Aci 349Document1 pageSingle Bolt Embedment Design - Aci 349Akhtar BahramNo ratings yet

- Design of Steel BeamDocument19 pagesDesign of Steel BeamAnonymous tBhJoH5wgMNo ratings yet

- CivilBay Engineering XXX Design Project Shear Connection Shear-1 PDFDocument9 pagesCivilBay Engineering XXX Design Project Shear Connection Shear-1 PDFhemantcabhaleNo ratings yet

- Sap2000 Egitim 2 GKTDocument32 pagesSap2000 Egitim 2 GKTAlp KuzubasiogluNo ratings yet

- Crack Mitigation of Post Tensioned Floors TN454Document40 pagesCrack Mitigation of Post Tensioned Floors TN454kiranNo ratings yet

- Seismic design loads and combinationsDocument15 pagesSeismic design loads and combinationsAmey Gudigar100% (1)

- Component Testing, Seismic Evaluation and Characterization of Buckling-Restrained BracesDocument15 pagesComponent Testing, Seismic Evaluation and Characterization of Buckling-Restrained BracesDiego Matias Burgos FuentesNo ratings yet

- BIA - Steel Lintel DesignDocument7 pagesBIA - Steel Lintel Designgpax42No ratings yet

- Calculating Wind Load on a Dish AntennaDocument1 pageCalculating Wind Load on a Dish AntennadovermanNo ratings yet

- W14x43 To HSS6x6x1 - 2 Moment ConnDocument21 pagesW14x43 To HSS6x6x1 - 2 Moment ConnrajedmaglinteNo ratings yet

- Bond, Anchor and ShearDocument15 pagesBond, Anchor and ShearBatepola BacNo ratings yet

- Fillet Welding On Gussets and LugsDocument1 pageFillet Welding On Gussets and LugsSeungmin PaekNo ratings yet

- Vol 3 No 1 WebDocument4 pagesVol 3 No 1 WebVikas PatelNo ratings yet

- Example II.C-5 HSS Chevron Brace Connection: F F F FDocument5 pagesExample II.C-5 HSS Chevron Brace Connection: F F F FVasilica BarbarasaNo ratings yet

- Spreadsheets To BS 8110Document11 pagesSpreadsheets To BS 8110NitinShepurNo ratings yet

- Ibc 16Document114 pagesIbc 16Luis Fernando BaqueNo ratings yet

- E Hconsulting CC: Civil and Structural DesignDocument4 pagesE Hconsulting CC: Civil and Structural DesignGaurav MalyaNo ratings yet

- Paper 118 Guidelines For Prequalification and Design of Post-Installed and Cast-In Anchors in Australia - 2Document11 pagesPaper 118 Guidelines For Prequalification and Design of Post-Installed and Cast-In Anchors in Australia - 2Tarek AbulailNo ratings yet

- Calculating crack width and capacity of a reinforced concrete slabDocument3 pagesCalculating crack width and capacity of a reinforced concrete slabOmar MokhtarNo ratings yet

- İsrail Deprem Yönetmeliği EkiDocument18 pagesİsrail Deprem Yönetmeliği EkiErol Eylemci KaplanNo ratings yet

- Highlights of New ASCE Standard On Composite SlabsDocument21 pagesHighlights of New ASCE Standard On Composite SlabsGuilhermino BrittoNo ratings yet

- Unistrut CalcDocument12 pagesUnistrut Calcjacs127No ratings yet

- Seepage Flow Net FDMDocument68 pagesSeepage Flow Net FDMRenalyn AndradeNo ratings yet

- Appendix - Ii: Principles of Construction, Material and Design of Ferrocement TankDocument5 pagesAppendix - Ii: Principles of Construction, Material and Design of Ferrocement TankbenzzenhdNo ratings yet

- Cali Marine Oil Terminal Engineering and Maintenance Eskijian Paper - 2ADocument10 pagesCali Marine Oil Terminal Engineering and Maintenance Eskijian Paper - 2AvuongNo ratings yet

- Smart Design of RC Column Subjected To Earthquake Load: Dr. A. S. Pant, B.G. Birajdar, A.R. ToraseDocument8 pagesSmart Design of RC Column Subjected To Earthquake Load: Dr. A. S. Pant, B.G. Birajdar, A.R. ToraseAnand.5No ratings yet

- Oel Report Mos-1Document14 pagesOel Report Mos-1Muhammad Hassan Syed BSCVE2021No ratings yet

- The Effect of Diverse Recording Devices On Forensic Speaker Apperception SystemDocument9 pagesThe Effect of Diverse Recording Devices On Forensic Speaker Apperception SystemIJIRSTNo ratings yet

- Postprocessing of Compacted Images Through Consecutive DenoisingDocument4 pagesPostprocessing of Compacted Images Through Consecutive DenoisingIJIRSTNo ratings yet

- Physico-Chemical Analysis of Selected Ground Water Samples in and Around Nagapattinam District, TamilnaduDocument3 pagesPhysico-Chemical Analysis of Selected Ground Water Samples in and Around Nagapattinam District, TamilnaduIJIRSTNo ratings yet

- Satellite Dish Positioning SystemDocument5 pagesSatellite Dish Positioning SystemIJIRST100% (1)

- Patterns of Crop Concentration, Crop Diversification and Crop Combination in Thiruchirappalli District, Tamil NaduDocument10 pagesPatterns of Crop Concentration, Crop Diversification and Crop Combination in Thiruchirappalli District, Tamil NaduIJIRSTNo ratings yet

- Custom ROMDocument3 pagesCustom ROMIJIRSTNo ratings yet

- Development of Satellite Data For Infrastructure Updation and Land Use/Land Cover Mapping - A Case Study From Kashipur & Chhatna Block, Bankura & Purulia District, West BengalDocument7 pagesDevelopment of Satellite Data For Infrastructure Updation and Land Use/Land Cover Mapping - A Case Study From Kashipur & Chhatna Block, Bankura & Purulia District, West BengalIJIRSTNo ratings yet

- Experimental Analysis of Friction Stir Processing of Tig Welded Aluminium Alloy 6061Document7 pagesExperimental Analysis of Friction Stir Processing of Tig Welded Aluminium Alloy 6061IJIRSTNo ratings yet

- Vibration Analysis of Composite Leaf Spring by Finite Element MethodDocument7 pagesVibration Analysis of Composite Leaf Spring by Finite Element MethodIJIRSTNo ratings yet

- Manganese: Affecting Our Environment (Water, Soil and Vegetables)Document7 pagesManganese: Affecting Our Environment (Water, Soil and Vegetables)IJIRSTNo ratings yet

- Multi-Physics Based Simulations of A Shock Absorber Sub-SystemDocument7 pagesMulti-Physics Based Simulations of A Shock Absorber Sub-SystemIJIRSTNo ratings yet

- Currency Recognition Blind Walking StickDocument3 pagesCurrency Recognition Blind Walking StickIJIRSTNo ratings yet

- Arduino-UNO Based Magnetic Field Strength MeasurementDocument4 pagesArduino-UNO Based Magnetic Field Strength MeasurementIJIRSTNo ratings yet

- Induction Motor Drive Using SPWM Fed Five Level NPC Inverter For Electric Vehicle ApplicationDocument7 pagesInduction Motor Drive Using SPWM Fed Five Level NPC Inverter For Electric Vehicle ApplicationIJIRSTNo ratings yet

- Experimental Investigation On Concrete by Replacement of Sand by Silica Sand and Artificial SandDocument6 pagesExperimental Investigation On Concrete by Replacement of Sand by Silica Sand and Artificial SandIJIRSTNo ratings yet

- Development of Tourism Near Loktak Lake (Moirang) in Manipur Using Geographical Information and Management TechniquesDocument4 pagesDevelopment of Tourism Near Loktak Lake (Moirang) in Manipur Using Geographical Information and Management TechniquesIJIRSTNo ratings yet

- Study On Performance Evaluation of Forced Convection Solar Dryer For Turmeric (Curcuma Longa L.)Document10 pagesStudy On Performance Evaluation of Forced Convection Solar Dryer For Turmeric (Curcuma Longa L.)IJIRSTNo ratings yet

- Performance Analysis of Organic Rankine Cycle (ORC) Working On Different Refrigerant Fluids Having Low Boiling PointDocument5 pagesPerformance Analysis of Organic Rankine Cycle (ORC) Working On Different Refrigerant Fluids Having Low Boiling PointIJIRSTNo ratings yet

- Experimental Investigation On The Effect of Use of Bottom Ash As A Replacement of Fine AggregatesDocument7 pagesExperimental Investigation On The Effect of Use of Bottom Ash As A Replacement of Fine AggregatesIJIRSTNo ratings yet

- Rock Deformation by Extesometers For Underground Powerhouse of Sardar Sarovar Project (Gujarat)Document5 pagesRock Deformation by Extesometers For Underground Powerhouse of Sardar Sarovar Project (Gujarat)IJIRSTNo ratings yet

- Reconfigurable Manufacturing Systems Using The Analytical Hierarchical Process (AHP) - A ReviewDocument3 pagesReconfigurable Manufacturing Systems Using The Analytical Hierarchical Process (AHP) - A ReviewIJIRSTNo ratings yet

- Comparative Study of Inner Core, Peripheral and RC Shear Wall SystemDocument8 pagesComparative Study of Inner Core, Peripheral and RC Shear Wall SystemIJIRSTNo ratings yet

- Efficient Revocation of Data Access in Cloud Storage Based On ABE-SchemeDocument6 pagesEfficient Revocation of Data Access in Cloud Storage Based On ABE-SchemeIJIRSTNo ratings yet

- Intelligent Irrigation SystemDocument5 pagesIntelligent Irrigation SystemIJIRSTNo ratings yet

- Infiltration, Permeability, Liquid Limit and Plastic Limit of SoilDocument12 pagesInfiltration, Permeability, Liquid Limit and Plastic Limit of SoilIJIRSTNo ratings yet

- Impact of Different Soils and Seismic Zones On Varying Height of Framed StructuresDocument8 pagesImpact of Different Soils and Seismic Zones On Varying Height of Framed StructuresIJIRSTNo ratings yet

- Analysis of Agent Oriented Software EngineeringDocument5 pagesAnalysis of Agent Oriented Software EngineeringIJIRSTNo ratings yet

- Literature Review For Designing of Portable CNC MachineDocument3 pagesLiterature Review For Designing of Portable CNC MachineIJIRSTNo ratings yet

- Women Protection Mechanism With Emergency Communication Using Hand Waving PatternDocument5 pagesWomen Protection Mechanism With Emergency Communication Using Hand Waving PatternIJIRSTNo ratings yet

- Problem 826 - Continuous Beam by Three-Moment Equation - Strength of Materials ReviewDocument4 pagesProblem 826 - Continuous Beam by Three-Moment Equation - Strength of Materials ReviewJhundel Factor PajarillagaNo ratings yet

- Anna University - Department of Civil - Structural Engineering DivisionDocument2 pagesAnna University - Department of Civil - Structural Engineering Divisiondhaval2011No ratings yet

- Artech Cooling Towers ManufacturerDocument19 pagesArtech Cooling Towers ManufacturerRaouia MaalemNo ratings yet

- Trenton: 20u 40u Stratagraph On Location at 5:00 PM Waiting On Rig To Trip Back To Bottom With Tri-ConeDocument24 pagesTrenton: 20u 40u Stratagraph On Location at 5:00 PM Waiting On Rig To Trip Back To Bottom With Tri-ConeFrancico Javier Ondo BitegueNo ratings yet

- BS 4346-1 Joints and FittingsDocument13 pagesBS 4346-1 Joints and FittingsPD AWSSIESPNo ratings yet

- IMG - 0020 PSME Code 2012 18Document1 pageIMG - 0020 PSME Code 2012 18Bugoy2023No ratings yet

- Design of Two Way Slabs Location Reference: Slab-4: B/W Grid 11 To 13 & A To BDocument13 pagesDesign of Two Way Slabs Location Reference: Slab-4: B/W Grid 11 To 13 & A To BAwais HameedNo ratings yet

- AXIS (Updated)Document27 pagesAXIS (Updated)joone M. gutierrezNo ratings yet

- Septic Tank Design ConceptDocument20 pagesSeptic Tank Design Conceptsatya prakash goudaNo ratings yet

- Katalog - HagoDeck BVH Maxi PoklopciDocument1 pageKatalog - HagoDeck BVH Maxi PoklopciJovo BozovicNo ratings yet

- Transport Engineering Exam QuestionsDocument8 pagesTransport Engineering Exam QuestionssreenathNo ratings yet

- Analysis and Design of Profiled Blast Walls Prepared by ImperialDocument63 pagesAnalysis and Design of Profiled Blast Walls Prepared by ImperialRicardoNo ratings yet

- Prokon - CF1 For Column 450x450Document5 pagesProkon - CF1 For Column 450x450archetype designNo ratings yet

- Uttarakhand PWD Estimation for Road Improvement WorksDocument21 pagesUttarakhand PWD Estimation for Road Improvement WorksdaisyNo ratings yet

- Cavitation Analysis of Kaplan Series Propeller Effect of Pitch Ratio and Nprop Using CFDDocument11 pagesCavitation Analysis of Kaplan Series Propeller Effect of Pitch Ratio and Nprop Using CFDAgung BosqueNo ratings yet

- Structural ReportDocument13 pagesStructural ReportDan SantosNo ratings yet

- FEA 2016 Release NotesDocument12 pagesFEA 2016 Release NotesKlLeeNo ratings yet

- CanalDocument24 pagesCanalMuhammad UmarNo ratings yet

- Evolution of Highway Failures and Their Maintenance: I R J E T (Irjet)Document11 pagesEvolution of Highway Failures and Their Maintenance: I R J E T (Irjet)Faraz hasan KhanNo ratings yet

- Design Rigid Haryati 2018 PDFDocument196 pagesDesign Rigid Haryati 2018 PDFlsatchithananthanNo ratings yet

- ACCROPODE™ BrochureDocument4 pagesACCROPODE™ BrochureberdhondNo ratings yet

- Material Co EfficientDocument2 pagesMaterial Co Efficientpravin2185No ratings yet

- Unit 1 Background To RC Design - NotesDocument40 pagesUnit 1 Background To RC Design - NotesNico Dela RamaNo ratings yet

- The Concrete Centre: Spreadsheets To BS 8110 EtcDocument1 pageThe Concrete Centre: Spreadsheets To BS 8110 EtcmayphyoNo ratings yet

- Gyprock 513 Party Wall 201205Document28 pagesGyprock 513 Party Wall 201205duckeNo ratings yet

- Client: PT Insani Mitrasani Gelam Project: Gelam Production Facility Project Subject: Liquid Line Sizing Ref.: API 14E, GPSA Sec .17Document1 pageClient: PT Insani Mitrasani Gelam Project: Gelam Production Facility Project Subject: Liquid Line Sizing Ref.: API 14E, GPSA Sec .17Elias EliasNo ratings yet

- White Paper: Dismount and ReuseDocument16 pagesWhite Paper: Dismount and ReuseSoifern K.No ratings yet

- Building Construction Department (BCD) Edmac Engineering Consultant (I) Pvt. LTDDocument20 pagesBuilding Construction Department (BCD) Edmac Engineering Consultant (I) Pvt. LTDIrfan Khan100% (1)

- Chapter 5Document28 pagesChapter 5Jaswinder KaurNo ratings yet

- HTL Ispat PVT LTD: 428 5.100 TotalDocument1 pageHTL Ispat PVT LTD: 428 5.100 Totalmadhav jadhavNo ratings yet