Professional Documents

Culture Documents

Cig 2

Uploaded by

Senn OdrapmasdOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cig 2

Uploaded by

Senn OdrapmasdCopyright:

Available Formats

Department of Agriculture

PHILIPPINE COCONUT AUTHORITY

Research & Development, and Extension Branch

Elliptical Rd., Diliman, Quezon City 1101

Coconut Intercropping Guide No. 2

1. IMPORTANCE

Growing of intercrops in coconut lands produces more food and agricultural

products, ensuring food security of the people in rural and urban areas. At the same

time, the practice generates jobs and livelihood, enhancing farm incomes and the

purchasing power of people, thus alleviating poverty in farming communities. Moreover,

successful farmers serve as inspiration and enterprise leaders in their communities,

eventually treating coconut farming in an agribusiness way to create wealth and more

capital resources.

Banana, a popular, stable and marketable long-term fruit crop is widely planted

under and between stands of coconut trees. To be a compatible and productive

intercrop, banana plants is best planted not closer than 2 meters from the base of

coconut trees. Furthermore, where there is limited land for banana monocropping, the

inter-spaces of coconut lands (with 8-15 meters of spacing of coconut palms) are

amenable for several rows of banana crop. Also important, the bio-physical

environmental conditions, soil-wise, sunlight-wise and micro-climate variation within the

70-80% space between coconut trees in a farm has been known to be highly suitable for

a coconut-banana ecosystem. These are shown in Figure 1 and 2.

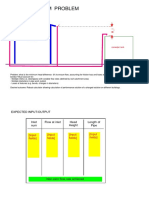

Figure 1. A farm layout of a coconut-banana cropping model under

square planting system of coconut 8-10 m)

Coconut-Fruit Crop (Banana) Cropping Model 1

Figure 2. A farm layout of a coconut-banana cropping model under

triangular planting system of coconut 8-10 m)

2. ADVANTAGES AND BENEFITS

Despite a low annual investment level (i.e., ranging from P 8,000 to P11,000) per

ha, Saba banana variety), the benefits derived at different levels (farm, community and

national ) from the coconut-banana cropping provide substantial advantages, impacting

on social, agro-economic and environmental dimensions. Meaning, the productive and

sustainable coconut-banana cropping commonly results in multifunction. It is a widely

grown fruit in the country, planted a s a component of different farming systems or as a

main crop in large farms in Mindanao.

For a 5-year cropping period, the average investment cost of P18,000 per

year/ha generates a total net income of P434,000 per ha. The benefit/cost

ratio increases from years 1 to 5, that is, year 1 = 0.5, year 2 = 4.0, year 3 =

5.7, year 4 = 6.5 and year 5 = 7.1 indicated in section 5.

The commercial banana cultivars grown popularly as intercrop of coconut are the

table bananas, mainly Latundan, Lakatan and Bungulan; and cooking bananas, Saba

and/or Cardaba.

Some of the key benefits of the coconut-banana cropping/ecosystem are as follow:

1) Banana can be intercropped in coconut palms as young as 1-3 years old and when

these palms reached 25 years (and beyond). Generally, banana and coconut do not

compete for soil resources, except when grown in dry zones.

2) Banana is fast-growing fruit crop that starts fruiting in 8 to 12 months from field-

planting. There is a stable and growing demand (locally and globally for different

varieties (cooking and non-cooking) for various uses, i.e., table or fresh banana,

chips, catsup, puree, flour and others.

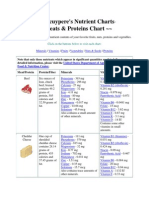

3) Its nutritive value and health benefits are well-known. Banana fruit is high

carbohydrates, potassium, calcium, vitamin C (ascorbic acid) and vitamin B6

Coconut-Fruit Crop (Banana) Cropping Model 2

(pyridoxine). Vitamin B6 is essential for maintaining healthy skin and nerves, in the

B

formation of red blood cells, in providing general disease-resistance, and stops the

human premature aging (Geddes & Grosset Ltd. 1998).

4) From the coconut trees, obtained are many basic food products from nuts (like

kernel/meat, coconut milk, coconut oil, coconut water/juice) and coconut sap (fresh

sap, vinegar, coconut nectar/honey and natural sap sugar); non-food raw materials

for various high value products (husked- based, shell-based). Many more products

are derived from other parts of the coconut trees.

2. MARKET DEMAND AND PRACTICES

About 66% of production is consumed locally (16.5% for processing; 45.5% as

table bananas; 4% as feeds/wastes for animal consumption), 34% exported (PCARRD

1999). Export earnings averaged about US$244 M/year, with 1.14 M tons of fresh

banana (mainly to Japan, Hongkong, Middle East countries). In 1997, 19.094 tons of

banana chips (from Saba banana) were exported.

Domestic market for fresh banana is dominated by middlemen and traders, the

export by multinational corporations. In small-scale farms bananas are sold on a finger

count basis; in commercial plantations by weight basis. Local prices fluctuate, mainly

due to the supply availability and fruit perishability which affects the quality.

3. GROWING CONDITIONS AND THE TECHNOLOGY

3.2 Environmental Requirements

To optimize the achievable yield of corn under the coconut-banana cropping

system, it is essential to provide the suitable conditions (climate and soils) for the two

crops. Moreover, the competition for light, soil and water resources usually results in

marginal economic returns from one of the component crops or in both.

Climatic Needs:

Factor Coconut Banana

Altitude (m above sealevel Less than 600 Less than 750

o

Temperature ( C) 24- 29 15-35

Light >2000 sunshine hours/year 3000-8000 ft-candles

Total annual rainfall (mm) 1500- 2500 (well distributed) >1000 (10-12 months

Typhoon frequency (%) < 20 </=10

Coconut-Fruit Crop (Banana) Cropping Model 3

Soil Requirements:

Soil Condition Coconut Banana

Soil Depth (cm) >75 >75

Drainage Moderate to well-drained Well-drained

Soil Acidity (pH) 5.5-7.5 6.0-7.5

Soil Texture Sandy, loamy, clayey (with Loamy, clayey (with good

good structure) structure)

Organic matter content Medium to High Medium to High

Major nutrients N, K, Cl, S, P, Ca, Mg, B N, P, K, Ca, Zn, B

4.2 Technology

It is very important to apply the best package of technologies (POT) or better

still, the site-specific technologies to achieve the maximum economic yield (MEY), highly

desirable to obtain the least production cost per unit product or per ha, and the

maximum returns to investment under the coconut-banana cropping production system.

As a detailed guide on the cultural practices of banana, the Philippines

Recommends for Banana (PCARRD 1987) is a popular reference-manual. For coconut,

two booklets were produced by the PCA as quick references: 1) Production Management

of Coconut (Magat 1999); and 2) Coconut-based Farming Systems (CBFS), Technology

Notes for Practicioners (Magat 1999).

Following are some salient recommended farming pointers or practices in a

coconut-banana cropping system:

BANANA

1) Land preparation - After clearing the interspaces of coconut, mark the required

spacing : 3 x 3 m , Lakatan and Latundan cultivars; 5 x 5 m, for Saba/ Cardaba.

2) Preparation of planting materials bole out corms with 1-3 live buds per sword

suckers/maiden suckers and cut all roots, leaving 1-2 cm long from the head; for

corms, treat with 50 g Dithane M45 + 30 ml Basudin 60 EC + 1.5 ml sticker in 20

liters water or soak in 50-55 oC hot water for 10 mins. For suckers, retain the 2

youngest leaves.

3) Field-Planting Dig holes depending on size of planting materials; plant corms in

slanting position with growing point on top. For suckers, plant in upright position and

cover with soil up to the collar and press gently.

4) Field Maintenance Fertilize banana with either one of the two options: 1) 100%

inorganic fertilizer (IF); 2) 75% IF + 25% organic fertilizers (OF). These are

indicated as follow:

Coconut-Fruit Crop (Banana) Cropping Model 4

Option 1: 100% inorganic (mineral) fertilizers

14-14-14 or

Urea a Solophos b KCl c

Age/Stage 14-5-20

(g/plant) (g/plant) (g/plant)

(g/plant)

Planting 70 50 80 -

3 months 100 65 105 -

6 months 115 80 125 -

9 months 115 80 125 -

Bearing (2x) - - - 500

a b c

46-0-0 0-20-0 0-0-60-44 (Cl)

Option 2: 75% Inorganic/mineral fertilizers + 25% Organic fertilizers

14-14-14 Chicken

Urea Solophos KCl

Age/Stage or 14-5-20 manure

(g/plant) (g/plant) (g/plant)

(g/plant) (g/plant)

Planting 50 40 60 - 300

3 months 75 50 80 - 475

6 months 85 60 100 - 525

9 months 85 60 100 - 525

Bearing (2x) - - - 375 700

Ringweed banana plants (within 1 m radius from pseudostem base); remove

dry leaves regularly (as practical); allow only one sucker per hill at a time. Do either

bud injection or pre-emergence bud spray and/ or bunch spray. Debud and plastic-

wrap developed the fruits. Wrap fruit bud with a sack and cut off when bunch are

fully-developed .

Saba or Cardaba cultivars and to some extent Latundan are affected by

Bugtok or Tibagnol disease. Infected fruits are discolored and exhibits hardness even

when ripe and/or cooked (Saba). It is caused by the bacterium Pseudomonas

solanacearum. A practical, effective and efficient way to control was formulated: pour

500 g of common salt (NaCl) by forming a hole on the harvested stump adjacent to

the one bearing the inflorescence and apply the salt and dissolve by water at least 10

days before or at 5 days after flower emergence. (Pava and Franje 1997).

5) Harvesting this is done at 10 to 15 months after planting or when the following are

observed: fruits are full, plum, round and light green in color; angles of fingers

rounded and leaves turn yellowish or yellowish orange.

Coconut-Fruit Crop (Banana) Cropping Model 5

COCONUT

With the coconut trees are already established and already at bearing stage, the

main farming practices are fertilization, underbrushing-weeding, mulching of the main

rootzone of coconut (also considered the fertilizing zone at trunk base of trees), and

harvesting. Post-harvest and primary processing practices (seasoning of partially

immature nuts for 710 days, dehusking and copra processing) are common in small to

medium scale farms. If sold to coconut desiccating plants, dehusked nuts are

immediately marketed. Coconut husks await decortication/defibering, while coconut

shells are converted to charcoal and sold to activated carbon processors.

A separate fertilization for the stands of coconut and the banana crop is

recommended. There are two average inorganic/mineral fertilizer recommendations for

coconut: 1) using the combination of single fertilizers (ammonium sulfate plus common

salt (for potassium-rich soils) or potassium chloride (0-0-60) for soils deficient in K; and

2) using ready-to-apply multinutrient fertilizers as the 14-5-20-0.02 (B), now

commercially available like COCOGROW (ATLAS Brand) in 25 kg. cpacity bags.

These two fertilizer recommendations are compatible with the application of

appropriate organic fertilizers (compost, cocopeat, commercial organic fertilizers). If

capital resources to purchase organic fertilizers is available, any of these organic

fertilizers ( total N, P and K of at least 5%) may be applied together with the mineral

fertilizers (options 1 and 2) indicated below at the rate of 3-4 times of the periodic

rates indicated. Organic fertilizers should be applied about a month ahead of the

appliation of the inorganic/mineral fertilizers. Organic fertilizers serve best as soil

conditioners and fertilizer supplements to the coconut-banana cropping system.

Option 1

Application of Single-Fertilizers (per tree):

a

Age/Stage Rate of Fertilizer Combination

Field-planting (FP) 150 g AS + 160 g SC or 200g KCl

6 months from FP 200 g AS + 200 g SC or 200 g KCl

1 year 500 g AS + 450 g SC or 600 g KCl

2 years 750 g AS + 750 g SC or 900 g KCl

3 years 1.0 kg AS + 1.25 kg SC or 1.5 kg KCl

4 years 1.25 kg AS + 1.35 kg SC or 1.70 kg KCl

5 years and onwards 1.50 kg AS + 1.70 kg SC or 2.00 kg KCl

a

AS Ammonium sulfate (21-0-0);

SC Sodium chloride (common salt);

KCl Potassium chloride (0-0-60)

Coconut-Fruit Crop (Banana) Cropping Model 6

Option 2

Application of ready-to-apply multinutrient

fertilizer (per tree):

Rate of 14-5-20

Age/Stage a

multi-nutrient Fertilizer

Field-planting (FP) 400 g

6 months from FP 600 g

1 year 1.25 kg

2 years 1.50 kg

3 years 2.00 kg

4 years 2.50 kg

5 years and onwards 3.00 kg

a

contains 14% N, 5% P2O5, 20% K2O plus 15% Cl , 4.5%S, 0.02% Boron, Ca.

5. INVESTMENT NEEDS: COSTS AND RETURNS

Simple Costs and Returns Analysis (P) of Coconut- Banana cropping (Saba or

Cardaba ), per ha (mainly adopted from Pava and Franje, 1997)

Item Year 1 Year 2 Year 3 Year 4 Year 5

BANANA:

A. Labor

1. Hauling 500 - - - -

(suckers)

2. Plowing 1,000 - - - -

3. Harrowing 800 - - - -

4. Staking (2md a @ 200 - - - -

P100

5. Digging holes, 6 md 600 - - - -

@ P 100

6. Planting, 5 md @ 500 - - - -

P100

7. Weeding, 2,400 2,400 2,400 4,800 4,800

Fertilizing &

Desuckering,

(4 x), 24 md @

P100

8. Harvesting - 900 1,800 1,800 1,800

9. 9 md @ P100

Subtotal 6,000 3,300 4,200 6,600 6,600

Coconut-Fruit Crop (Banana) Cropping Model 7

Continuation

Item Year 1 Year 2 Year 3 Year 4 Year 5

B. Supplies & Matls

1. Suckers (555 pcs 1,665 - - - -

@P3.00

2. lime, 75 bags @ 1,500 - - 1,500 -

P20.00

3. Fertilizers 1,800 1,800 3,600 3,600 3,600

(14-14-14), 4 bags

@ P 450

Subtotal 4,965 1,800 3,600 5,100 3,600

GrandTotal 10,965 5,100 7,800 11,700 10,200

C. Income

a) Yield (kg/ha) none 16,650 33,300 49,950 49,950

b) Gross value (P) none 41,625 83,250 124,875 124,875

c) Net Income (P) (-10,965) 36,525 75,450 113,175 114,675

COCONUT:

(Copra yield @ 2 t/ha,

@P15/kg

Nuts= 8,000/ha)

Cost of harvesting, 2,800 2,800 2,800 2,800 2,800

piling, hauling,

deshusking @

P0.35/nut

Copra making 960 960 960 960 960

@P0.12/kg

Transport/ 400 400 400 400 400

Handling, @ P0.20/kg

copra

Fertilizer application 360 360 360 360 360

Circle weeding, 4.5 2,430 2.430 2,430 2.430 2,430

md, 6x/yr

Fertilizer 2,000 2,000 2,000 2,000 2,000

cost b

Total Cost (P) 8,950 8,950 8,950 8,950 8,950

Yield (kg/ha) 2,000 2,000 2,000 2,000 2,000

Gross Income (P) 30,000 30,000 30,000 30,000 30,000

Net Income (P) 21,050 21,050 21,050 21,050 21, 050

Total Net income (P)

10,085 57,575 96,500 134,225 135,725

(coconut + banana)

Benefit/cost ratio 0.51 4.10 5.76 6.50 7.09

a

man-day

b

1.5 kg AS + 1.7 kg NaCl @ P5/kg and P4/kg, respectively, 135 trees/ha

Basis

2nd Year 555 hills x 2 harvest = 1,110 bunches @ 15 kg/bunch = 16,650 kg @ P2.50/kg

3rd Year 555 hills x 2 suckers x 2 harvest = 2,220 bunches @ 15 kg/bunch = 33,300 kg @ P2.50/kg

4th to 5th Year 555 x 3 suckers x 2 harvest = 3,330 bunches @ 15 kg/bunch = 49,450 kg @ P2.50/kg

Coconut-Fruit Crop (Banana) Cropping Model 8

6. POTENTIAL FINANCING SOURCES/CREDIT FACILITIES

Self or In-House Finance (Private)

Local Government Units (Municipal, Provincial, Congressional)

Government Banks & Lending Institutions

Private Banks and Lending Agencies

Cooperatives

Foundations

REFERENCES:

Agronomy and Soils Division, Davao Research Center.2003. Coconut- Banana

Intercropping. Davao City: Research & Development, and Extension Branch,

Philippine Coconut Authority. (Techno Guide No. 12, series 2003).

Pava, H.M. and Franje, N.S. 1997. Banana production technology. Musuan, Bukidnon:

Central Mindanao University. 56 p.

PCARRD-DOST. 1987. The Philippine Recommends for Banana. Los Baos, Laguna:

PCARRD.

PCARRD-DOST. 1999 (Revised). The Banana Industry. Los Baos, Laguna: Philippine

Council for Agriculture, Forestry and Natural Resources Research and

Development.

The Coconut Committee (1992). The Philippine Recommends for Coconut. Los Baos,

Laguna: PCARRD, PARRFI and PCRDF. (Phil. Recommends Series, No.2-b,

1993. 234 p.).

FOR MORE INFORMATION AND ASSISTANCE, YOU MAY CONTACT THE

FOLLOWING OFFICES SITUATED NEAR YOU:

Research & Development, and Extension Branch, PCA, Diliman,

Quezon City 1101

Telefax: 920-0415 Tel: 426-1398 Email: cbcarpio@mozcom.com or

ssmagat@pacific.net.ph

Field Services Branch, PCA, Diliman, Quezon City 1101

Telefax: 928-9488 Tel: 929-1590

Albay Research Center (ARC), PCA, Banao, Guinobatan Albay

Tel: (052) 484-6686 or 484-6685

Davao Research Center (DRC), PCA, Bago-Oshiro, Davao City, PO Box 80437

Tel: (082) 293-0115/0116/0119 Fax No. (082) 293-0571 Email: pcadrc@pldtdsl.net

Zamboanga Research Center (ZRC), PCA, San Ramon, Zamboanga City,

PO Box 356

Tel: (0917) 710-1820

Coconut-Fruit Crop (Banana) Cropping Model 9

PCA Region IV-B (MIMAROPA and rest of Luzon) Diliman, Quezon City

Telefax: 924-4761 Tel: 927-5227

PCA Region V (Bicol) , Sagpon, Legaspi City

Tel: (052) 245-5263 Fax: (052) 245-5263

PCA Region VI (Western Visayas), 12 Mabini St., Iloilo City

Tel: (033) 337-7514 Fax: (033) 335-0977

PCA Region VII (Central Visayas), DA7, Mandaue City (CEBU)

Tel: (032) 345-0009 Fax: (032) 345-8435

PCA Region VIII (Eastern Visayas), Govt Center, Candahug, Palo, Leyte

Tel: (053) 323-2698 Fax: (053) 323-2995

PCA Region IX (Western Mindanao), J.P. Rizal St., Zamboanga City

Tel: (062) 991-6369 Fax: (062) 992-1031

PCA Region X (Northern Mindanao), #30 Daumar St., Cagayan De Oro City

Tel: (088) 857-3707 Fax: (088) 272-2814 Email: pca10@sni.ph

PCA Region XI (Southern Mindanao), PCA Complex, Bago-Ohiro, Tugbok

District, Davao City

Tel: (082) 293-0384 Telefax: (082) 293-0049

PCA Region XII (Central Mindanao), 2nd Flr, AS Bldg. , Cor. JP Laurel and CM

Recto Sts, Gen. Santos City

Tel: (083) 544-6263 Telefax: (083) 553-9424 Email: pcar12@gsc.weblinq.com

PCA Region XIII (CARAGA), JC Aquino Ave., Pajera Subd., Butuan City

Tel: (085) 815-3232 Fax: (085) 226-4621

PCA-ARMM, Emilio Ong Bldg., Quezon Ave., Cotabato City

Telefax: (064) 421-2412.

Drafted by:

SS Magat

6 Dec. 2004/ PCA/RDEB-ARMD

c:\1-armd files\armd files (xp setup) november 2003\official\coco summit 2004 (intercrops)\coconut-banana v2.doc

Coconut-Fruit Crop (Banana) Cropping Model 10

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Water Demand CalcsDocument1 pageWater Demand CalcsSenn OdrapmasdNo ratings yet

- Sewage InfrastructureDocument5 pagesSewage InfrastructureSenn OdrapmasdNo ratings yet

- Mechanism For Supplying Real Estate Developers With Drinking Water and Sanitation ServicesDocument13 pagesMechanism For Supplying Real Estate Developers With Drinking Water and Sanitation ServicesSenn OdrapmasdNo ratings yet

- Vacuum Drainage System GuideDocument17 pagesVacuum Drainage System GuideSenn OdrapmasdNo ratings yet

- TFP1545 08 2018-ValveDocument12 pagesTFP1545 08 2018-ValveSenn OdrapmasdNo ratings yet

- CWC HP Xea 195 Z HDocument8 pagesCWC HP Xea 195 Z HSenn OdrapmasdNo ratings yet

- Charged System ProblemDocument1 pageCharged System ProblemSenn OdrapmasdNo ratings yet

- Guidelines For Greywater ReuseDocument12 pagesGuidelines For Greywater ReuseSenn OdrapmasdNo ratings yet

- HephworthsDocument48 pagesHephworthsSenn OdrapmasdNo ratings yet

- DM HSD - GU53 - LPGC2 - Technical Guideline On Safety of Liquefied Petroleum Gas Cylinders PDFDocument18 pagesDM HSD - GU53 - LPGC2 - Technical Guideline On Safety of Liquefied Petroleum Gas Cylinders PDFmasoodahmed74No ratings yet

- Design Guide For Wastewater Treatment Plants in Saudi ArabiaDocument182 pagesDesign Guide For Wastewater Treatment Plants in Saudi ArabiaSenn OdrapmasdNo ratings yet

- Abu Dhabi Food Control Authority (ADFCA) : Inspection Checklist - Fish MarketDocument1 pageAbu Dhabi Food Control Authority (ADFCA) : Inspection Checklist - Fish MarketSenn OdrapmasdNo ratings yet

- Heat TracingDocument12 pagesHeat TracingSenn OdrapmasdNo ratings yet

- 02 PDFDocument237 pages02 PDFmadantiwari200No ratings yet

- LCZ STEAM BOILER LCZ IFEN Nova Boiler FinalDocument2 pagesLCZ STEAM BOILER LCZ IFEN Nova Boiler FinalSenn OdrapmasdNo ratings yet

- Ksaconfcombinedpresentations PDFDocument215 pagesKsaconfcombinedpresentations PDFSenn OdrapmasdNo ratings yet

- Technical Information: N 10 - October 2010Document6 pagesTechnical Information: N 10 - October 2010Senn OdrapmasdNo ratings yet

- Basic Pump Theory - PrintDocument56 pagesBasic Pump Theory - PrintSenn OdrapmasdNo ratings yet

- Data Sheet: Wilo-Star-Z 25/6-3: Pump Curves Single-Phase CurrentDocument3 pagesData Sheet: Wilo-Star-Z 25/6-3: Pump Curves Single-Phase CurrentSenn OdrapmasdNo ratings yet

- Case Study: When HVAC Fire Protection Issues Inside Buildings Really MattersDocument3 pagesCase Study: When HVAC Fire Protection Issues Inside Buildings Really MattersSenn OdrapmasdNo ratings yet

- Design Considerations For Pools and Spas (Natatoriums) : John W. Lund Geo-Heat CenterDocument3 pagesDesign Considerations For Pools and Spas (Natatoriums) : John W. Lund Geo-Heat CenterНебојша РадићNo ratings yet

- Oryx Catalogue PDFDocument14 pagesOryx Catalogue PDFSenn OdrapmasdNo ratings yet

- LCZ STEAM BOILER TF - TFD Nova Boiler FinalDocument2 pagesLCZ STEAM BOILER TF - TFD Nova Boiler FinalSenn OdrapmasdNo ratings yet

- Data Sheet: Wilo-Star-ZD 25/6: Pump CurvesDocument7 pagesData Sheet: Wilo-Star-ZD 25/6: Pump CurvesSenn OdrapmasdNo ratings yet

- Good Practice Guide 300 - Lighting DesignDocument35 pagesGood Practice Guide 300 - Lighting DesignSenn OdrapmasdNo ratings yet

- ICEL 1006 2012 - Emergency Lighting Design GuideDocument32 pagesICEL 1006 2012 - Emergency Lighting Design GuideSenn OdrapmasdNo ratings yet

- Marley Trade Price List March 2020Document41 pagesMarley Trade Price List March 2020Senn OdrapmasdNo ratings yet

- Water Heaters General Catalogue: March 2007 EditionDocument68 pagesWater Heaters General Catalogue: March 2007 EditionknprajaramNo ratings yet

- CIBSE Lighting Guide LG3 - VDU (Addendum)Document8 pagesCIBSE Lighting Guide LG3 - VDU (Addendum)Senn OdrapmasdNo ratings yet

- CIE Emergency Lighting in Road TunnelsDocument17 pagesCIE Emergency Lighting in Road TunnelsSenn OdrapmasdNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Section C: Performance Activity Objective: To Provide You With An Opportunity To Demonstrate The Required Performance Elements For This UnitDocument9 pagesSection C: Performance Activity Objective: To Provide You With An Opportunity To Demonstrate The Required Performance Elements For This UnitNancy VermaNo ratings yet

- Making Sweet Potato Chips and FlourDocument8 pagesMaking Sweet Potato Chips and FlourErick Villacorta100% (1)

- Excel Project 1 Starter File F23Document11 pagesExcel Project 1 Starter File F23Mariola AlkuNo ratings yet

- DO - s2017 - 013 Policy and Guidelines On Healthy Food and Beverage Choices in Schools and in DepEd Offices PDFDocument32 pagesDO - s2017 - 013 Policy and Guidelines On Healthy Food and Beverage Choices in Schools and in DepEd Offices PDFargee_lovelessNo ratings yet

- SwedenDocument35 pagesSwedenapi-272537046No ratings yet

- Lembu Setata and Lembu SaktiDocument2 pagesLembu Setata and Lembu SaktiBagas P TyoNo ratings yet

- Basic Food I ReviewerDocument27 pagesBasic Food I ReviewerMaria Celina DumagcoNo ratings yet

- Grilled Chicken SaladDocument2 pagesGrilled Chicken SaladJapheth KariukiNo ratings yet

- Proposal Business PlanDocument13 pagesProposal Business PlanM Yusuf MaulanaNo ratings yet

- Crazy Cookie Dough Base Recipe 1 Baking 2020 2021Document3 pagesCrazy Cookie Dough Base Recipe 1 Baking 2020 2021Muñoz AnnafearlNo ratings yet

- Create A Colony 2 pdf-2Document7 pagesCreate A Colony 2 pdf-2api-295144385No ratings yet

- Before Empires and RoyaltyDocument2 pagesBefore Empires and RoyaltyNguyễn Xuân QuỳnhNo ratings yet

- 2 Restaurant Skills Part 2Document16 pages2 Restaurant Skills Part 2Samkeliso NkwanyaneNo ratings yet

- Meso Tabela - Proteini I Vitamini I Dr.Document17 pagesMeso Tabela - Proteini I Vitamini I Dr.Makedon MacedonianNo ratings yet

- Recipe Collection 61 PDFDocument2 pagesRecipe Collection 61 PDFSal LieNo ratings yet

- "©daffodil International University" IDocument29 pages"©daffodil International University" IOnly LaptopNo ratings yet

- FruitsDocument4 pagesFruitszohaymaNo ratings yet

- As Cookery-9 Q3 W3Document6 pagesAs Cookery-9 Q3 W3Lovely JavierNo ratings yet

- In A2 20 Ex Cto CRDocument4 pagesIn A2 20 Ex Cto CRAlejandra MartínNo ratings yet

- Quiz # 3 - Santos, Aira Kristelle M.Document4 pagesQuiz # 3 - Santos, Aira Kristelle M.Ai MendozaNo ratings yet

- Organic Linseed (Tisi) FarmingDocument4 pagesOrganic Linseed (Tisi) FarmingdonbosskissNo ratings yet

- Webinar Orientation On School-Based Feeding Program ImplementationDocument2 pagesWebinar Orientation On School-Based Feeding Program ImplementationGraciella Fae PuyaoanNo ratings yet

- Mass+In+A+Flash+2 0Document16 pagesMass+In+A+Flash+2 0rnastaseNo ratings yet

- Final DraftDocument11 pagesFinal Draftapi-534074414No ratings yet

- Which Food Am IDocument3 pagesWhich Food Am IDani Becerra100% (2)

- 1 Pick Out Malunggay Leaves From TheDocument9 pages1 Pick Out Malunggay Leaves From TheShiela Marie VergaraNo ratings yet

- Inquiries Investigation and ImmersionDocument61 pagesInquiries Investigation and Immersionmutsuko100% (4)

- High CholesterolDocument31 pagesHigh Cholesterolashoku2100% (1)

- Bypass Fat in Dairy Ration-A ReviewDocument17 pagesBypass Fat in Dairy Ration-A ReviewKadiwala Dairy FarmNo ratings yet

- IELTS Academic Reading Task: Tea TimesDocument4 pagesIELTS Academic Reading Task: Tea TimesThảo ThanhNo ratings yet