Professional Documents

Culture Documents

Testing Direct Digital Controls (DDC)

Uploaded by

efasaravananOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Testing Direct Digital Controls (DDC)

Uploaded by

efasaravananCopyright:

Available Formats

Testing Direct Digital Controls

(DDC)

Document Number EN-MPS-713

Revision 0

Approved by Ric Morris

Stations

November 29, 2004

Active Divisions/Departments

FEMC

Raytheon Polar Services Company

Facilities Engineering, Maintenance, and Construction (FEMC)

Contract No. OPP 0000373

Hard Copy Not ControlledControlled Copy Available On-line

Raytheon Polar Services Company EN-MPS-713

Testing Direct Digital Controls Revision 0

Stations

Table of Contents

Table of Contents ................................................................................................................. i

Purpose................................................................................................................................ 1

Scope/Applicability............................................................................................................. 1

Responsibilities ................................................................................................................... 1

FEMC .............................................................................................................................. 1

Project Engineer or Designee....................................................................................... 1

Certified Technician ..................................................................................................... 1

NSF.................................................................................................................................. 2

Title II Inspector........................................................................................................... 2

DDC System Check Out ..................................................................................................... 2

Hardware Control Panel Check ....................................................................................... 2

Software Check................................................................................................................ 3

Systems Check................................................................................................................. 4

Engine Jacket Water Heat Recovery and Cooling System........................................... 4

Waste Heat Hydronic System....................................................................................... 4

Exhaust Gas Heat Recovery......................................................................................... 5

Building Heating Hydronic System ............................................................................. 6

Heating Water System .................................................................................................. 7

Hot Water Single Zone Air Handling Units ................................................................. 7

Exhaust Fans ................................................................................................................ 8

Blower Coil Unit .......................................................................................................... 8

References........................................................................................................................... 9

Records ............................................................................................................................... 9

Facilities Engineering, Maintenance, and Construction (FEMC) i

Contract No. OPP 0000373

Raytheon Polar Services Company EN-MPS-713

Testing Direct Digital Controls Revision 0

Stations

Purpose

Procedure to standardize the testing of the Direct Digital Control (DDC)

systems for construction projects.

Scope/Applicability

The DDC system for each project must be thoroughly checked out to ensure

functionality.

Responsibilities

FEMC

P r o jec t E ng i ne er or D e s ig nee

Coordinates the Final Inspection with appropriate parties.

Oversees/Partcipates in the Start-up, Test, and Inspection Process to ensure

the Specifications and Procedures are followed.

C e rt if i ed Te ch n ic ia n

Performs any testing, start-up, or inspection as dictated to ensure the warranty

maintains its integrity; codes are followed; and procedures are followed as

required.

Facilities Engineering, Maintenance, and Construction (FEMC) Page 1 of 9 total pages

Contract No. OPP 0000373

Raytheon Polar Services Company EN-MPS-713

Testing Direct Digital Controls Revision 0

Stations

NSF

T it le II In sp ect or

Independent Inspector for the NSF, who witnesses the testing, start-up, and

conducts his required inspections for the NSF.

DDC System Check Out

Since each system for every project varies, the DDC contractor will need to

develop his or her own format to test the system. Below is the basic process,

which needs to be detailed by the contractor.

Hardware Control Panel Check

Each control panel has a fixed number of digital inputs/outputs and analog

inputs/outputs. Every condition should be checked against its intended

functionality.

First, check the wiring. Perform all loop checks. Confirm all circuits

terminate at the device shown on the drawings using wire type specified.

Confirm shields are properly terminated and loop resistance is within proper

limits.

Second, check each input and verify the desired output occurs. This includes

verifying the control valves, actuators, dampers, and other devices function as

intended for the desired resolution as a reaction to the input from the level

sensors, flow sensors, and other input devices. The Sequence of Operation

shall be verified, as well.

For example, if the Inside Air Temperature sensor sends an input signal of a

temperature two (2) degrees lower than the setpoint or the desired temperature

range, then the appropriate heating functions should occur to increase the

inside air temperature.

Facilities Engineering, Maintenance, and Construction (FEMC) Page 2 of 9 total pages

Contract No. OPP 0000373

Raytheon Polar Services Company EN-MPS-713

Testing Direct Digital Controls Revision 0

Stations

See the following samples of checklists:

Control Panel Date:

Location/Name:

Input/Output Wiring Functions Comments

Input A#

Input D#

Output A#

Output D#

Device Instance

Device Address

Temperature Control Panel #

Card #

Object System Tested Verify Wiring Tech

Object Descr. Reading Reading Units / Installation Initials Comments

Software Check

The software operation confirmation is required as well. The software shall

be loaded into the equipment, and tests shall be run. For instance, change the

set point, and confirm the reactions denoted occur. The signal is sent out

through the software, and the information on the screen reflects what is

actually happening with the equipment. This must be documented. The

vendor (or RPSC, if self performing) shall supply the form to document the

test results, and prove the software functions.

Facilities Engineering, Maintenance, and Construction (FEMC) Page 3 of 9 total pages

Contract No. OPP 0000373

Raytheon Polar Services Company EN-MPS-713

Testing Direct Digital Controls Revision 0

Stations

Systems Check

Below is a list of systems and equipment point check out, which must be

completed in order to confirm the DDC system operates as intended. These

systems may not apply to all projects, and some projects could have additional

systems. The vendor (or RPSC, if self-performing) will submit a project

specific systems checklist.

En g in e Jac ket W ate r He at Re co ve ry a nd Co o lin g Sy ste m

The commissioning technician will verify the normal operating conditions

while a generator engine is running and verify the functionality of each

component and it respective inputs and outputs to the DDC system to include

the following:

9 Engine Run Status

9 Engine Jacket Leaving Temperature

9 Engine Jacket Entering Temperature

9 Engine Jacket Motor Operated Valve Modulation

9 Engine Jacket Motor Operated Valve Position

9 Heat Exchanger Entering Temperature

9 Heat Exchanger Leaving Temperature

9 Heat Exchanger Flow

9 Radiator Entering Temperature

9 Radiator Leaving Temperature

9 Radiator Fan Start/Stop

9 Radiator Fan Status

9 Radiator Fan Variable Frequency Drive Modulation

9 Radiator Fan Speed

9 Radiator Room Space Temperature

9 Radiator Room Outside Air Damper Operation

9 Radiator Room Return Air Damper Operation

9 Radiator Room Exhaust Air Damper Operation

9 All Alarms Reporting

Wa ste H eat H yd ron ic Sy ste m

The commissioning technician will simulate the normal operating conditions

for each piece of equipment and verify the functionality of each component

Facilities Engineering, Maintenance, and Construction (FEMC) Page 4 of 9 total pages

Contract No. OPP 0000373

Raytheon Polar Services Company EN-MPS-713

Testing Direct Digital Controls Revision 0

Stations

and its respective inputs and outputs to the DDC system to include the

following:

9 Pumps Start/Stop

9 Pump Status

9 Pump Lead/Lag

9 Pump Switch

9 Differential Pressure Switch

9 Variable Frequency Drives Modulation

9 Variable Frequency Drives Speed

9 Differential Pressure Sensor (System Loop pressure)

9 End of the Line Differential Pressure

9 Loop Hot Water Supply Temperature

9 Loop Hot Water Return Temperature

9 Loop Flow Transmitter

9 Heat Exchanger Entering Temperature

9 Heat Exchanger Leaving Temperature

9 Heat Exchanger Flow Transmitter

9 Heat Exchanger Motor Operated Valve Operation

9 Heat Exchanger Motor Operated Valve Position

9 All Alarms Reporting

E x hau st Ga s H ea t R ec ov ery

The commissioning technician will simulate the normal operating conditions

for each piece of equipment and verify the functionality of each component

and its respective inputs and outputs to the DDC system to include the

following:

9 Pumps Start/Stop

9 Pump Status

9 Pump Lead/Lag

9 Pump Switch

9 Differential Pressure Switch

9 Variable Frequency Drives Modulation

9 Variable Frequency Drives Speed

9 Differential Pressure Sensor (System Loop pressure)

9 Exhaust Gas Heat Exchanger Entering Temperature

9 Exhaust Gas Heat Exchanger Leaving Temperature

9 Exhaust Gas Heat Exchanger Flow

9 Exhaust Gas Heat Exchanger Motor Operated Valve Open/ Close

9 Exhaust Gas Heat Exchanger Motor Operated Valve Position

Facilities Engineering, Maintenance, and Construction (FEMC) Page 5 of 9 total pages

Contract No. OPP 0000373

Raytheon Polar Services Company EN-MPS-713

Testing Direct Digital Controls Revision 0

Stations

9 Waste Heat Exchanger Entering Temperature

9 Waste Heat Exchanger Leaving Temperature

9 Waste Heat Exchanger Flow

9 All Alarms Reporting

B u i l d in g H e at in g H y dr on i c Syste m

The commissioning technician will simulate the normal operating conditions

for each piece of equipment and verify the functionality of each component

and its respective inputs and outputs to the DDC system to include the

following:

9 Waste Heat HX Entering Temperature

9 Waste Heat HX Leaving Temperature

9 Waste Heat HX Flow

9 Building Primary Loop WH HX Entering Temperature

9 Building Primary Loop WH HX Leaving Temperature

9 Building Primary Loop WH HX Flow

9 Waste Heat Available Yes/No

9 Primary Heating Loop Pump Start/Stop

9 Primary Heating Loop Pump Status

9 Primary Heating Loop Pump Lead/Lag

9 Primary Heating Loop Pump Switch

9 Primary Heating Loop Differential Pressure Switch

9 Primary Loop System Differential Pressure

9 Boiler Enable/Disable

9 Boiler Status

9 Boiler Heating Stage Low Fire

9 Boiler Heating Stage High Fire

9 Boiler Lead/Lag

9 Boiler Switch

9 Boiler Anti-shock

9 Boiler Low Water Cutoff

9 Boiler High Limit

9 Boiler Hot Water Entering Temperature

9 Boiler Hot Water Leaving Temperature

9 Boiler Flow

9 Outside Air Temperature

9 Boiler Reset Schedule

9 Primary/Secondary Loop Hot Water Mixing Motor Operated Valve

Modulation

Facilities Engineering, Maintenance, and Construction (FEMC) Page 6 of 9 total pages

Contract No. OPP 0000373

Raytheon Polar Services Company EN-MPS-713

Testing Direct Digital Controls Revision 0

Stations

9 Primary/Secondary Loop Hot Water Mixing Motor Operated Valve

Position

9 Secondary Loop (Building Loop) Heating Water Supply Temperature

9 Secondary Loop (Building Loop) Heating Water Return Temperature

9 Building Loop Pump Start/Stop

9 Building Loop Pump Status

9 Building Loop Pump Lead/ Lag

9 Building Loop Pump Switch

9 Building Loop Pump Differential Pressure Switch

9 Building Loop System Differential Pressure

9 Building Loop End of Line Differential Pressure

9 All Alarms Reporting

He at in g Wa ter System

The temperature control contractor will simulate the normal operating

conditions for the local heating water system and verify the functionality of

each component and its respective input and output to the DDC control system

to include the following items:

9 Space Temperature

9 Reheat Coil Valve Open/Closed

9 Reheat Valve Position

9 Fin tube Radiation Valve Open/Closed

9 Fin tube Radiation Valve Position

9 All Alarms Reporting

H o t W at e r S i n g le Z one A i r H a ndl i n g U n it s

The commissioning technician will simulate the normal operating conditions

for each air-handling unit and verify the functionality of each component and

its respective input or output to the DDC control system to include the

following items:

9 Economizer Dampers

9 Outside Air Damper

9 Return Air Damper

9 Relief damper

9 Building Static Pressure

9 Heating Coil Motor Operated Valve

9 Supply Fan Start/Stop

9 Supply Fan Status

Facilities Engineering, Maintenance, and Construction (FEMC) Page 7 of 9 total pages

Contract No. OPP 0000373

Raytheon Polar Services Company EN-MPS-713

Testing Direct Digital Controls Revision 0

Stations

9 Variable Frequency Drive Modulation

9 Variable Frequency Drive Speed

9 Duct Static Pressure

9 Space Temperature

9 Duct Smoke Detector

9 Discharge Air Temperature

9 Filter Status

9 Door Switch

9 Mixed Air Temperature

9 Return Air Temperature

9 CO2 Sensor

9 Freeze stat (Low Limit Thermostat)

9 All Alarms Reporting

The differential pressure switch provided for filter status will be appropriately

configured so as to close a contact to the DDC system if the pressure drop

across the filter bank exceeds the manufacturers recommended limit.

The low limit thermostat will be set at 35F (adjustable).

Ex hau st Fa ns

The commissioning technician will simulate the normal operating conditions

for the exhaust fans and verify the functionality of each component and its

respective input or output to the DDC control system to include the following

items:

9 Exhaust Fan Start/Stop

9 Exhaust Fan Status

9 Exhaust Fan Damper Open/Close

9 Exhaust Fan Damper Position

9 Building Static Pressure

9 Variable Frequency Drive Modulation

9 Variable Frequency Drive Speed

B lo w e r C o i l U n i t

The commissioning technician will simulate the normal operating conditions

for the blower coil unit and verify the functionality of each component and its

respective input or output to the DDC control system to include the following

items:

Facilities Engineering, Maintenance, and Construction (FEMC) Page 8 of 9 total pages

Contract No. OPP 0000373

Raytheon Polar Services Company EN-MPS-713

Testing Direct Digital Controls Revision 0

Stations

9 Heating coil HW valve

9 Supply Fan Start/Stop

9 Supply Fan Status

9 Space Temperature

9 Discharge Air Temperature

9 Filter Status

9 Freeze stat (Low Limit Thermostat)

9 All Alarms Reporting

The differential pressure switch provided for filter status will be appropriately

configured so as to close a contact to the DDC system if the pressure drop

across the filter bank exceeds the manufacturers recommended limit.

The low limit thermostat will be set at 35F (adjustable).

References

See project plans, specifications, and submittals.

Records

Hardcopies of completed test results are maintained within FEMC Document

Control in project specific files, and electronic copies are available on station.

Facilities Engineering, Maintenance, and Construction (FEMC) Page 9 of 9 total pages

Contract No. OPP 0000373

You might also like

- FAT ChecklistDocument17 pagesFAT ChecklistNoe Jimenez100% (2)

- Diagnostic Trouble Code (DTC) Charts and Descriptions: Procedure Revision Date: 03/29/2006Document147 pagesDiagnostic Trouble Code (DTC) Charts and Descriptions: Procedure Revision Date: 03/29/2006efasaravananNo ratings yet

- Instrumentation and ControlDocument126 pagesInstrumentation and ControlMira AlvarezNo ratings yet

- MOS - MV SwitchgearDocument59 pagesMOS - MV SwitchgearOsman AbdoutNo ratings yet

- Auxiliary Relay Test Report: Sheet 1 of 1Document1 pageAuxiliary Relay Test Report: Sheet 1 of 1TariqMalikNo ratings yet

- ITP - Installation of Fiber Optic CablesDocument5 pagesITP - Installation of Fiber Optic CablesVasilica Barbarasa60% (5)

- Pre-Com. Procedure For Tertiray - 415V SWGRDocument13 pagesPre-Com. Procedure For Tertiray - 415V SWGRBalamurugan SelvarajNo ratings yet

- Itp Installation of Fiber Optic CablesDocument4 pagesItp Installation of Fiber Optic Cablesqasim078100% (2)

- Grounding Installation Inspection and Test Plan ITPDocument2 pagesGrounding Installation Inspection and Test Plan ITPtristan guarinoNo ratings yet

- Loop Check PresentationDocument39 pagesLoop Check Presentationsaqib javaid100% (5)

- Commissioning Documents For Instrumentation EngineersDocument7 pagesCommissioning Documents For Instrumentation EngineersVraja Kisori100% (1)

- 3rd Quarter ExamDocument2 pages3rd Quarter ExamPhiw Tabuzo33% (3)

- Check List For Pre Commissioning of MV SwitchgearDocument2 pagesCheck List For Pre Commissioning of MV Switchgeararuna100% (9)

- ElectricianDocument3 pagesElectricianefasaravanan50% (2)

- Testing and Commissioning Procedure For Building Management SystemDocument8 pagesTesting and Commissioning Procedure For Building Management SystemJane NixonNo ratings yet

- Sabp Z 019Document29 pagesSabp Z 019Hassan MokhtarNo ratings yet

- DCS Commisioning StepsDocument7 pagesDCS Commisioning StepsJoven BabieraNo ratings yet

- Practical Data Acquisition for Instrumentation and Control SystemsFrom EverandPractical Data Acquisition for Instrumentation and Control SystemsNo ratings yet

- Tubing Leak TestDocument3 pagesTubing Leak TestOwais MalikNo ratings yet

- Draft - Sat Procedure For Access Control SystemDocument11 pagesDraft - Sat Procedure For Access Control SystemVenkataramanan SNo ratings yet

- PC-J-94 Instrument Loop Check (Analogue Inputs)Document1 pagePC-J-94 Instrument Loop Check (Analogue Inputs)Memyhu MahmudahNo ratings yet

- IEC 61850 Testing - Equipment Requirements and ToolsDocument50 pagesIEC 61850 Testing - Equipment Requirements and ToolsIDI Energy100% (1)

- DCS Commissioning StepsDocument14 pagesDCS Commissioning StepsElton Hove100% (1)

- AEi Reliability Report Example PDFDocument18 pagesAEi Reliability Report Example PDFT/ROXNo ratings yet

- DCS Specification PDFDocument31 pagesDCS Specification PDFIsagani MadridNo ratings yet

- Measurement Systems - E. O. Doebelin and D. N. ManikDocument54 pagesMeasurement Systems - E. O. Doebelin and D. N. Manikefasaravanan50% (2)

- CommissioningDocument22 pagesCommissioningMary Grace D. Almiranez100% (1)

- Four-Stroke, Four Cylinder Diesel Engine: BY Shubham Kulshrestha Atul Yadav Irfan KhanDocument27 pagesFour-Stroke, Four Cylinder Diesel Engine: BY Shubham Kulshrestha Atul Yadav Irfan KhanShubham Kulshrestha100% (1)

- API RP 2A Platform Inspection Procedure REV 0Document21 pagesAPI RP 2A Platform Inspection Procedure REV 0Putu Yusna Armita100% (3)

- 01 CCTV Sat-Sakaka-NewDocument20 pages01 CCTV Sat-Sakaka-NewVenkataramanan S67% (3)

- Service General Specification: Applicable SystemsDocument2 pagesService General Specification: Applicable SystemsRizky MuhammadNo ratings yet

- Modbus Check Sheet ExampleDocument2 pagesModbus Check Sheet ExampleGuston SupriyadiNo ratings yet

- DCS Commissioning StepsDocument10 pagesDCS Commissioning StepsNGASSAKI ATONGUI Christ HubertNo ratings yet

- Smart Grid Testing: ApplicationDocument3 pagesSmart Grid Testing: ApplicationTayyab ZubairNo ratings yet

- Sensation: System Maintenance Protocol SystemDocument14 pagesSensation: System Maintenance Protocol SystemJairo ManzanedaNo ratings yet

- Siremobil Iso-C: System WartungsprotokollDocument12 pagesSiremobil Iso-C: System WartungsprotokollVlady Lopez CastroNo ratings yet

- Electrical Commissioning Procedure: Document Number Version Number AuthorDocument16 pagesElectrical Commissioning Procedure: Document Number Version Number Authorizzy umandalNo ratings yet

- Tooo': oOO OO.Document28 pagesTooo': oOO OO.ediasianagriNo ratings yet

- Commissioning SOP TemplateDocument12 pagesCommissioning SOP TemplatePK KNo ratings yet

- SPNZ 227 ADocument37 pagesSPNZ 227 Amasruba.public.serviceNo ratings yet

- C-54 NocDocument41 pagesC-54 NocRochdi SahliNo ratings yet

- Acceptance Testing - ELT - 201!2!2Document6 pagesAcceptance Testing - ELT - 201!2!2castrojpNo ratings yet

- In-Line Eddy Current Testing of Wire Rod: Technical InformationDocument7 pagesIn-Line Eddy Current Testing of Wire Rod: Technical InformationBK ICTNo ratings yet

- Project Name System Verification Document: Company LogoDocument11 pagesProject Name System Verification Document: Company LogoFahad RustamNo ratings yet

- Bacnet Verification System Pre-Functional Checklist: Statement of ReadinessDocument10 pagesBacnet Verification System Pre-Functional Checklist: Statement of Readinessnitroxx7No ratings yet

- Maintenance Protocol Siemens Iconos R200Document21 pagesMaintenance Protocol Siemens Iconos R200cankutayhotmail.comNo ratings yet

- PC-JX-XX E&I Interface Function Test - TemplateDocument2 pagesPC-JX-XX E&I Interface Function Test - TemplatePipin AripinNo ratings yet

- 1.mechanical - Electrical Completion Inspection Checklist - E20812Document3 pages1.mechanical - Electrical Completion Inspection Checklist - E20812Lulu ChaniagoNo ratings yet

- Client - MDDDocument66 pagesClient - MDDSam lopezNo ratings yet

- Commissioning Requirements 03/02 01810 - 1 OF 20 D:/DOCS/DIV1/03-02/01810Document20 pagesCommissioning Requirements 03/02 01810 - 1 OF 20 D:/DOCS/DIV1/03-02/01810Venkataramanan SNo ratings yet

- 1.itp Sur 0001Document2 pages1.itp Sur 0001Doni TriatmojoNo ratings yet

- Automated Analysis of Circuit Breaker Operation - CIRED 2003Document8 pagesAutomated Analysis of Circuit Breaker Operation - CIRED 2003Karunia Fajar Yoga SaktiNo ratings yet

- Laser Receiver Control Panel (LRCP) Software User Manual EN USDocument61 pagesLaser Receiver Control Panel (LRCP) Software User Manual EN USbejanNo ratings yet

- Pressure Measurement (Project Standards and Specifications) : KLM Technology GroupDocument6 pagesPressure Measurement (Project Standards and Specifications) : KLM Technology GroupTolera WorkuNo ratings yet

- Steering Gear Control System: Standard For CertificationDocument7 pagesSteering Gear Control System: Standard For CertificationsimonNo ratings yet

- Tillit Tivva Sow 2.2.1Document10 pagesTillit Tivva Sow 2.2.1steve-gilNo ratings yet

- Company Profile Global Twin StarDocument6 pagesCompany Profile Global Twin StarJane Junita WorangNo ratings yet

- Checklist For Testing IED's Rev00Document4 pagesChecklist For Testing IED's Rev00Santhosh Kumar VinayagamNo ratings yet

- DVCon Europe 2015 T07 PresentationDocument98 pagesDVCon Europe 2015 T07 PresentationJon DCNo ratings yet

- Lecture 01 - Introduction To VLSI TestingDocument44 pagesLecture 01 - Introduction To VLSI Testingmayank pNo ratings yet

- Ilovepdf MergedDocument509 pagesIlovepdf Mergedvinu43No ratings yet

- Method Statement-Main-28139Document10 pagesMethod Statement-Main-28139rajaram shettyNo ratings yet

- E-003B Rev C2-MIPS Distribution BoardDocument2 pagesE-003B Rev C2-MIPS Distribution BoardMusab ShabbirNo ratings yet

- Distributed Control SystemDocument6 pagesDistributed Control SystemslowdogNo ratings yet

- Technical Proposal For Retrofit of Batch Centrifugal Machines AutomationDocument6 pagesTechnical Proposal For Retrofit of Batch Centrifugal Machines AutomationmichaelNo ratings yet

- ThanjavurDocument21 pagesThanjavurefasaravananNo ratings yet

- Eurotherm 3200series Controllers Datasheet PDFDocument6 pagesEurotherm 3200series Controllers Datasheet PDFefasaravananNo ratings yet

- Thanjore: July 30Document21 pagesThanjore: July 30efasaravananNo ratings yet

- AvadiDocument3 pagesAvadiefasaravananNo ratings yet

- Chennai: July 27Document5 pagesChennai: July 27efasaravananNo ratings yet

- RASNE Software ManualDocument15 pagesRASNE Software ManualefasaravananNo ratings yet

- What Does This Block Diagram Mean?: Process ControlDocument20 pagesWhat Does This Block Diagram Mean?: Process ControlefasaravananNo ratings yet

- Type K Calibration EquationDocument1 pageType K Calibration EquationefasaravananNo ratings yet

- Tamil Nadu Teacher Eligibility Test 2017: Attestation by The Gazetted Officer With Seal and DateDocument1 pageTamil Nadu Teacher Eligibility Test 2017: Attestation by The Gazetted Officer With Seal and DateefasaravananNo ratings yet

- Furnace Atmosphere Control: Eurotherm ControlsDocument5 pagesFurnace Atmosphere Control: Eurotherm ControlsefasaravananNo ratings yet

- Irt/C Irt/C Irt/C Irt/C Infrared Infrared Infrared Infrared Temperature Sensor Temperature Sensor Temperature Sensor Temperature SensorDocument7 pagesIrt/C Irt/C Irt/C Irt/C Infrared Infrared Infrared Infrared Temperature Sensor Temperature Sensor Temperature Sensor Temperature SensorefasaravananNo ratings yet

- Heat/Cool With Carbon Potential or Oxygen Level Monitoring Using The Nanodac Recorder/ControllerDocument4 pagesHeat/Cool With Carbon Potential or Oxygen Level Monitoring Using The Nanodac Recorder/ControllerefasaravananNo ratings yet

- Thermocouples Colour Code ChartDocument1 pageThermocouples Colour Code ChartefasaravananNo ratings yet

- Monitoring, Operation and Control of Ion Exchange Plant: Mel HallDocument73 pagesMonitoring, Operation and Control of Ion Exchange Plant: Mel HallefasaravananNo ratings yet

- z204 206Document2 pagesz204 206efasaravananNo ratings yet

- CAL 400 4 CatalogueDocument1 pageCAL 400 4 CatalogueefasaravananNo ratings yet

- CAD of Engine Dynamic Test Bed Based On Hybrid Simulation: Zhang Junzhi Lu QingchunDocument6 pagesCAD of Engine Dynamic Test Bed Based On Hybrid Simulation: Zhang Junzhi Lu QingchunefasaravananNo ratings yet

- Metravi: Digital T-Rms Multimeter With Wireless Usb PC InterfaceDocument2 pagesMetravi: Digital T-Rms Multimeter With Wireless Usb PC InterfaceefasaravananNo ratings yet

- Compiling A ProjectDocument22 pagesCompiling A ProjectefasaravananNo ratings yet

- SE250SM-Ce (1) - User ManualDocument10 pagesSE250SM-Ce (1) - User ManualJoão Francisco MontanhaniNo ratings yet

- Benchmark Report Serbia 2017Document18 pagesBenchmark Report Serbia 2017thabetNo ratings yet

- dct4 Operator CodesDocument14 pagesdct4 Operator Codesapi-26122926No ratings yet

- DemandaDocument1,038 pagesDemandaNARONo ratings yet

- Chapter 2 The Cellular ConceptDocument4 pagesChapter 2 The Cellular ConceptJhon Smith0% (1)

- Abstract of Fiber Optic SensorsDocument6 pagesAbstract of Fiber Optic SensorsKamal UniyalNo ratings yet

- Edc Lab ManualDocument96 pagesEdc Lab ManualUday DesirajNo ratings yet

- ABB Drives: Installation and Start-Up GuideDocument64 pagesABB Drives: Installation and Start-Up Guidedorin serbanNo ratings yet

- 3GBP281240 ADL 3gbp281240 AdlDocument3 pages3GBP281240 ADL 3gbp281240 Adljuan diego jaramilloNo ratings yet

- Analysis and Design of the Class-Φ Inverter: Keisuke Kitazawa, Xiuqin Wei, Akihiko Katsuki, and Masahiko HirokawaDocument6 pagesAnalysis and Design of the Class-Φ Inverter: Keisuke Kitazawa, Xiuqin Wei, Akihiko Katsuki, and Masahiko HirokawaAdam RodriguezNo ratings yet

- Cisco Touch 10 Referencia GuideDocument2 pagesCisco Touch 10 Referencia GuideArturo García MolinaNo ratings yet

- Hubbell - Connector Theory - Failure Modes & Practical ApplicationsDocument30 pagesHubbell - Connector Theory - Failure Modes & Practical Applicationssulemankhalid100% (1)

- (2004) 750-1060 CFM (Form 09-0001)Document2 pages(2004) 750-1060 CFM (Form 09-0001)Israel RuizNo ratings yet

- Bootable Usb Windows 10Document3 pagesBootable Usb Windows 10Rajan BabuNo ratings yet

- (CSM51A / EE16 S10) Solutions For Midterm: Problem Points Score 1 15 2 10 3 20 4 20 5 15 6 20 Total 100Document10 pages(CSM51A / EE16 S10) Solutions For Midterm: Problem Points Score 1 15 2 10 3 20 4 20 5 15 6 20 Total 100krazykrnxboyNo ratings yet

- Discus Launch PackageDocument69 pagesDiscus Launch Packageourstocks2002No ratings yet

- CKP Cranksaft PositionDocument3 pagesCKP Cranksaft PositionĐức HòangNo ratings yet

- Nee Lab ReportDocument21 pagesNee Lab ReportARJAYCHRISTOPHER MORALESNo ratings yet

- Honeywell 4500 User ManualDocument36 pagesHoneywell 4500 User ManualFawadajmalNo ratings yet

- Hyundai X93W X93S X224W W240D DSDocument1 pageHyundai X93W X93S X224W W240D DSGhoual MohamedNo ratings yet

- Aks PHPDocument8 pagesAks PHParyaNo ratings yet

- ACC20 Engine Safety UnitDocument2 pagesACC20 Engine Safety UnitVictor EugenNo ratings yet

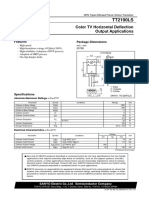

- TT2190LS: Color TV Horizontal Deflection Output ApplicationsDocument4 pagesTT2190LS: Color TV Horizontal Deflection Output ApplicationsFreddyNo ratings yet

- DX DiagDocument13 pagesDX DiagBernardus WasitaNo ratings yet

- Dewanto Arby Hudhaya PDFDocument9 pagesDewanto Arby Hudhaya PDFWiddy TimursariNo ratings yet

- Music With Matlab PDFDocument2 pagesMusic With Matlab PDFali aminNo ratings yet

- C191HM Powermeter and Harmonic Manager CommunicationsDocument30 pagesC191HM Powermeter and Harmonic Manager CommunicationsRoberto GarridoNo ratings yet