Professional Documents

Culture Documents

Assign2 Mix Design To ACI 211.1-91 and BRE

Uploaded by

Mbayo David GodfreyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Assign2 Mix Design To ACI 211.1-91 and BRE

Uploaded by

Mbayo David GodfreyCopyright:

Available Formats

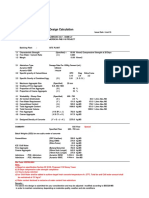

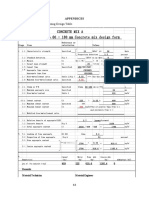

Table 1: CONCRETE MIX DESIGN FORM USING BRE METHOD

Reference or

Stage Item Values

calculation

1 1.1 Characteristic Strength Specified 25 N/mm2 at 28 days

Specified Proportion defective 5 %

1.2 Standard deviation Fig 3 N/mm2 or no data 8 N/mm2

1.3 Margin C1 (k= 1.64 ) 1.64 X 8 .= 13.12 N/mm2

or Specified N/mm2

1.4 Target mean strength C2 25 .+ 13.12 .= 38.12 N/mm2

1.5 Cement type Specified 42.5

1.6 Aggregate type: coarse Uncrushed

Aggregate type: fine Uncrushed

1.7 Free-water/cement ratio Table 2, Fig4 0.53

1.8 Maximum free

water/cement ratio Specified 0.5 Use lower value 0.5

2 2.1 Slump or V-B Specified Slump 30-60mm or Vebe time 3-6 s

2.2 Maximum aggregate size Specified 40 mm

2.3 Free-water content Table 3 160 kg/m3

3 3.1 Cement content C3 160 ./ 0.5 320 kg/m3

3.2 Maximum cement

Specified n/a kg/m3

content

3.2 Minimum cement

Specified 290 kg/m3

content

Use 3.1 if<3.2 320 kg/m3

Use 3.3 if>3.1

4 4.1 Relative density of

aggregate (SSD) 2.5

4.2 Concrete density Fig 5 2335 kg/m3

4.3 Total aggregate content C4 2335 .- 320 .- 160 1855 kg/m3

5.1 Grading of fine

5 %pass

aggregates

600m seive 90 %

5.2 Proportion of fine

Fig 6 21.25 %

aggregate

5.3 Fine aggregate content 1855 .X 0.2125 .= 394.19 kg/m3

C5

5.4 Coarse aggregates 1855 .- 394.19 .= 1460.81 kg/m3

There fore the quantities of the constituent materials per m 3 are:

Quantities Cement (kg) Water (kg/ltrs) Fine aggregates (kg) Coarse aggregates (kg)

Per m3 320 160 394.19 1460.81

Per trial mix of 0.08m3 25.6 12.8 31.535 116.87

Trial mix ratio 1 : 1.23 : 4.6

Fig3: Relationship between standard deviation and characteristic strength

You might also like

- Essential Oil ExtractionDocument159 pagesEssential Oil ExtractionAubrey Hernandez100% (4)

- Rebound Hammer Test Method StatementDocument2 pagesRebound Hammer Test Method StatementBassam AbdulwahabNo ratings yet

- 7 Examples of Mix Design: Reference Stage Item or Calculation Values 1Document1 page7 Examples of Mix Design: Reference Stage Item or Calculation Values 1Thoong Yew ChanNo ratings yet

- C35 A Concrete Mix DesignDocument2 pagesC35 A Concrete Mix Designcecb100% (9)

- 15b - ACI Mix Design (Updated)Document84 pages15b - ACI Mix Design (Updated)TahirNo ratings yet

- 2a-Concrete Mix DesignDocument21 pages2a-Concrete Mix Designpankaj_paul6451No ratings yet

- Concrete Mix Design CalculationDocument10 pagesConcrete Mix Design CalculationHari RNo ratings yet

- Proportioning Concrete MixesDocument54 pagesProportioning Concrete Mixesgman444No ratings yet

- Concrete Mix Design DOE PDFDocument15 pagesConcrete Mix Design DOE PDFkarthiksamp100% (1)

- Site Survey - ReportDocument22 pagesSite Survey - Reportmubashar_6186144No ratings yet

- Concrete Mix DesignDocument13 pagesConcrete Mix DesignJoseph Muturi MuguNo ratings yet

- Concrete Frame Design Manual: CSA A23.3-04Document82 pagesConcrete Frame Design Manual: CSA A23.3-04Mbayo David GodfreyNo ratings yet

- Mix Design As Per BSDocument10 pagesMix Design As Per BSChetan SohalNo ratings yet

- Mix Design ProcedujersDocument19 pagesMix Design ProcedujersAbinet AlemuNo ratings yet

- Optimal Mix Design For Pervious ConcreteDocument9 pagesOptimal Mix Design For Pervious ConcretejanakarajNo ratings yet

- Concrete Mix Design: Stage Item Reference or Values CalculationDocument8 pagesConcrete Mix Design: Stage Item Reference or Values Calculationmanish100% (1)

- Concrete Mix DesignDocument7 pagesConcrete Mix DesignUma MaheshwaraNo ratings yet

- Ordinary Portland CementDocument3 pagesOrdinary Portland CementKimo KenoNo ratings yet

- Steps of Concrete Mix Design BSDocument11 pagesSteps of Concrete Mix Design BSAlhilali Ziyad75% (8)

- Ds - Concrete Mix DesignDocument51 pagesDs - Concrete Mix DesignDarshan ShahNo ratings yet

- CT PhysicsDocument117 pagesCT PhysicsGarima Bharti100% (2)

- Nestle SWOT AnalysisDocument3 pagesNestle SWOT AnalysisMubeen AbdulshakoorNo ratings yet

- Concrete Mix DesignDocument20 pagesConcrete Mix DesignRony BaloyiNo ratings yet

- Bs 1881 - 112 (1983) PDFDocument11 pagesBs 1881 - 112 (1983) PDFAdesina AlabiNo ratings yet

- BS 812-106 Testing Aggregates - Shell Content in Coarse AggrDocument9 pagesBS 812-106 Testing Aggregates - Shell Content in Coarse AggrGasper ShirimaNo ratings yet

- Jadual Mix Design (Example1)Document1 pageJadual Mix Design (Example1)Fareez SedakaNo ratings yet

- THESISDocument44 pagesTHESISRowena Shaira AbellarNo ratings yet

- 3.3 Road Note No. 4-1Document40 pages3.3 Road Note No. 4-1Asad Choudhary100% (1)

- 7 Specification of Concrete PDFDocument64 pages7 Specification of Concrete PDFscegtsNo ratings yet

- Updated Study Guide PDFDocument44 pagesUpdated Study Guide PDFrendaninNo ratings yet

- Concrete Setting TimeDocument2 pagesConcrete Setting TimeLloyd R. PonceNo ratings yet

- Properties of Fresh and Hard ConcreteDocument13 pagesProperties of Fresh and Hard Concretemudasir afzal100% (1)

- Concrete Mix Design Beng 2021Document31 pagesConcrete Mix Design Beng 2021musinguzi robertNo ratings yet

- Mix DesignDocument29 pagesMix Designshahhassa9No ratings yet

- Lab Concrete Mix Design C25aDocument17 pagesLab Concrete Mix Design C25aSoundar PachiappanNo ratings yet

- Mix Design Using Is CodeDocument67 pagesMix Design Using Is CodeNilesh SaksenaNo ratings yet

- Effects of Aggregate Sizes On The Concrete StrengthDocument29 pagesEffects of Aggregate Sizes On The Concrete StrengthAmusa Yakxub100% (1)

- Slab On GradeDocument2 pagesSlab On GradeVistash Buhary100% (1)

- Progress ReportDocument8 pagesProgress ReportMbayo David Godfrey100% (1)

- Hot Weather ConcretingDocument6 pagesHot Weather ConcretingMazharYasinNo ratings yet

- Grade 11 Learning GuideDocument28 pagesGrade 11 Learning GuideMary-Rose Casuyon100% (1)

- BS 1881 - Part 108 - 1983Document5 pagesBS 1881 - Part 108 - 1983RACCH1977No ratings yet

- Self Compacting ConcreteDocument27 pagesSelf Compacting ConcreteJatin MaggoNo ratings yet

- Mix Design To ACI 211.1-91 and BREDocument11 pagesMix Design To ACI 211.1-91 and BREMbayo David Godfrey100% (1)

- Concrete Mixed Design For C30Document2 pagesConcrete Mixed Design For C30raju_420034520No ratings yet

- Economic Design of Working Platforms For Tracked PlantDocument3 pagesEconomic Design of Working Platforms For Tracked PlantSalvatore MirandaNo ratings yet

- (Merdeka PNB 118) C85 Mix DesignDocument1 page(Merdeka PNB 118) C85 Mix DesignUma Selladurai100% (1)

- Repairing Methodology of Honeycombs in Concrete SurfaceDocument4 pagesRepairing Methodology of Honeycombs in Concrete Surfacejohn paul100% (1)

- Concrete Mixed Design MethodDocument11 pagesConcrete Mixed Design Methodabdicasis rashidNo ratings yet

- Concrete Mix Design FormDocument1 pageConcrete Mix Design FormLAYLA SALIKIN CHE ROSMINNo ratings yet

- C-35 Mix Design by Estimate of MassDocument26 pagesC-35 Mix Design by Estimate of MassTewodros TadesseNo ratings yet

- Design MixDocument7 pagesDesign MixMohammad Hafiz MahadzirNo ratings yet

- Concrete Mix DesignDocument21 pagesConcrete Mix DesignIftikhar KamranNo ratings yet

- 45mpa Mix DesignDocument2 pages45mpa Mix DesignSamuel YekoNo ratings yet

- BS-7263-1 Part - 1 Concrete Spesification of Pre-Cast ConcrDocument24 pagesBS-7263-1 Part - 1 Concrete Spesification of Pre-Cast ConcrAshraf TomizehNo ratings yet

- Fresh ConcreteDocument28 pagesFresh ConcreteAmar WadoodNo ratings yet

- Monitoring Methods of Concrete From Early Age Strength Gain of Concrete A ReviewDocument8 pagesMonitoring Methods of Concrete From Early Age Strength Gain of Concrete A ReviewAmit Sharma IPS AcademyNo ratings yet

- 6 Defects in Brickwork Due To Poor WorkmanshipDocument7 pages6 Defects in Brickwork Due To Poor WorkmanshipMichael Matshona100% (1)

- Plate Bearing Load TestDocument1 pagePlate Bearing Load TestTk Kendrick Lau100% (1)

- Concrete Repair Materials and Selection CriteriaDocument33 pagesConcrete Repair Materials and Selection Criteriahusrem2001No ratings yet

- How Aggregate Cement Ratio Affect Workability of ConcreteDocument3 pagesHow Aggregate Cement Ratio Affect Workability of Concretevenkateswara rao pothinaNo ratings yet

- Mix DesignDocument40 pagesMix DesignDawit SolomonNo ratings yet

- Concrete Mixing DesignDocument15 pagesConcrete Mixing DesignChris ArtecoNo ratings yet

- Grade 20 N PDFDocument1 pageGrade 20 N PDFSujithNo ratings yet

- Doe LatestDocument1 pageDoe Latesthajjiyare2016No ratings yet

- A1 (Week 9) PDFDocument8 pagesA1 (Week 9) PDFHazarina AbdullahNo ratings yet

- 2.0 Assignment 1 - ECS246Document8 pages2.0 Assignment 1 - ECS246Muhammad Adli Amin Mohd AmzukiNo ratings yet

- Differences Between ACI and BREDocument2 pagesDifferences Between ACI and BREMbayo David GodfreyNo ratings yet

- A Study of Combined Bending and Axial Load in Reinforced Concrete MembersDocument2 pagesA Study of Combined Bending and Axial Load in Reinforced Concrete MembersMbayo David GodfreyNo ratings yet

- Mix Design To ACI 211.1-91 and BREDocument18 pagesMix Design To ACI 211.1-91 and BREMbayo David GodfreyNo ratings yet

- Nyamango Site Meeting 9 ReportDocument18 pagesNyamango Site Meeting 9 ReportMbayo David GodfreyNo ratings yet

- (E.) Explain The Likely Strategic Planning Traps To Be Encountered When Handling The AssignmentDocument1 page(E.) Explain The Likely Strategic Planning Traps To Be Encountered When Handling The AssignmentMbayo David GodfreyNo ratings yet

- Request For Approval 9Document1 pageRequest For Approval 9Mbayo David GodfreyNo ratings yet

- RCVI 01 Nyamango Technical InstituteDocument2 pagesRCVI 01 Nyamango Technical InstituteMbayo David GodfreyNo ratings yet

- Fortified Rice FssaiDocument8 pagesFortified Rice FssaisaikumarNo ratings yet

- Catalogue Pièces Moteur R984Document150 pagesCatalogue Pièces Moteur R984Eza IR100% (1)

- Curicullum Vitae Hendri Zand Franxiscus LahaguDocument3 pagesCuricullum Vitae Hendri Zand Franxiscus LahaguSepta Yudistira Inggil PambudiNo ratings yet

- MHR PreCal 12 Textbook CH 1 SolutionsDocument57 pagesMHR PreCal 12 Textbook CH 1 SolutionsBryan LowNo ratings yet

- B.ing Wajib - XI IPA1-2Document3 pagesB.ing Wajib - XI IPA1-2iwan fals NurjaniNo ratings yet

- 002-679e-08.19 v1.6.x KLDocument523 pages002-679e-08.19 v1.6.x KLChanon OnramoonNo ratings yet

- User'S Design Requirements For Single Chamber Pressure VesselsDocument8 pagesUser'S Design Requirements For Single Chamber Pressure VesselspjsanchezmNo ratings yet

- Previous Years Questions (2020-1983) Segment-Wise: Ordinary Differential EquationsDocument16 pagesPrevious Years Questions (2020-1983) Segment-Wise: Ordinary Differential EquationsAniket bhaiNo ratings yet

- British Vs American English - CrosswordDocument3 pagesBritish Vs American English - Crosswordlkham enkhsaikhanNo ratings yet

- Balance Diet and NutritionDocument9 pagesBalance Diet and NutritionEuniceNo ratings yet

- List Lagu EnglishDocument7 pagesList Lagu EnglishRyn ZulfanNo ratings yet

- CE-401CE 2.0 Network Diagrams 2015Document83 pagesCE-401CE 2.0 Network Diagrams 2015Shubham BansalNo ratings yet

- Accomplishment Report: Gass/Mfo Success Indicators Actual Accomplishments RemarksDocument1 pageAccomplishment Report: Gass/Mfo Success Indicators Actual Accomplishments RemarksGlenn HernandezNo ratings yet

- 4.5.redistrribution - PBR Quiz AnswersDocument4 pages4.5.redistrribution - PBR Quiz AnswersffbugbuggerNo ratings yet

- Aeration PaperDocument11 pagesAeration PapersehonoNo ratings yet

- Class 12 Psychology PDFDocument209 pagesClass 12 Psychology PDFSoumyashis Bhattacharya0% (1)

- Hemiplegia LectureDocument37 pagesHemiplegia LectureRancesh FamoNo ratings yet

- Formula 1638 Collagen Eye CreamDocument2 pagesFormula 1638 Collagen Eye CreamLinh Sa LaNo ratings yet

- Teiaiel - Visions of The FutureDocument2 pagesTeiaiel - Visions of The FutureMarkosNo ratings yet

- AlasDocument3 pagesAlasdara HinariNo ratings yet

- Gexcon DDT Scotts PresentationDocument33 pagesGexcon DDT Scotts PresentationMochamad SafarudinNo ratings yet

- Automatic Door Opener With PIC12C508 CircuitDocument3 pagesAutomatic Door Opener With PIC12C508 CircuitLingaraj BeharaNo ratings yet

- SWOT Analysis Textile IndustryDocument23 pagesSWOT Analysis Textile Industrydumitrescu viorelNo ratings yet

- By Beholding We Are ChangedDocument2 pagesBy Beholding We Are ChangedAdrian EbensNo ratings yet