Professional Documents

Culture Documents

GUIDELINE FOR COUPLINGS USED FOR UNLOADING OF CHEMICALS Rev 5 - Eng PDF

Uploaded by

dzungOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GUIDELINE FOR COUPLINGS USED FOR UNLOADING OF CHEMICALS Rev 5 - Eng PDF

Uploaded by

dzungCopyright:

Available Formats

BELGIAN ASSOCIATION OF CHEMICAL DISTRIBUTORS

GUIDELINE FOR COUPLINGS USED FOR LOADING/UNLOADING

OF CHEMICALS

August Reyerslaan, 80

B-1030 Brussel

Fifth edition: 04/04/2013

COUPLING GUIDELINE

1. Introduction

Continuous efforts to enhance safety during transport of chemicals and the associated handlings are part of the overall aim to improve the safety

performance of both the chemical industry and the transport industry.

Analysis of accident statistics indicates that a substantial number of transport related incidents happen during loading and unloading operations. It is

therefore essential that proper use is being made of appropriate equipment during these operations.

One of the burdens that the transport companies are confronted with is the wide variety of couplings that are used at (un)loading stations.

This Guidance is of a voluntary nature and individual companies may decide to apply the Guidance in full or partly in accordance with their own judgment

and taking into account the specific circumstances and requirements.

Applicable national and international regulations, in particular chapters 4.2 and 4.3 of ADR should always be complied with as they take precedence over

the recommendations made in the present Guidance.

2. Objective

The objective of the present Guidance is to provide recommendations on the use of couplings at (un)loading stations where commodity products are

(un)loaded.

This Guidance should help in selecting an appropriate coupling for such products taking into account the specific properties of the product(range), the

throughput and other conditions.

The workgroup has made an evaluation based on compatibility of material with the product, safety, easy to use, potential leakages, availability,

3. Scope

The scope of this Guidance is limited to couplings used for the loading and unloading of bulk commodity liquids in tank transport operations.

This Guidance does however not aim dedicated transports or specific products with a limited throughput nor does it provide an exhaustive overview of all

existing couplings (such as dry-break and flange couplings).

It neither focuses on hoses nor gaskets. For these the technical specifications of the different producers should be respected.

Guideline for couplings Rev 5 04/04/2013 page 2

COUPLING GUIDELINE

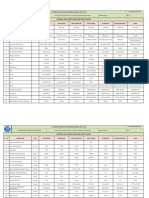

4. Table

Color code used in the table:

- Green : preferred coupling

- Yellow : acceptable coupling

- Orange : acceptable coupling but to be avoided because one (or more) of above mentioned criteria are negative

- Red : non-acceptable coupling

It is obvious that the work group strives towards a situation where only preferred couplings are used.

TW (VK) TW (VK) Guillemin Guillemin KNZ KNZ KNZ KNZ Camlock Guillemin

DN50 DN80 DN50 DN80 M88 M110 M88 M110 PE/PP

SS SS SS SS PE PE PE PE

CCW CCW CW CW

male male male male

Metal depleting acids

Other acids

Alcalis

Solvents

Sodium hypochlorite

5. Definitions

SS : Stainless Steel PE/PP : Polyethylene, polypropylene

TW (VK) : Tank Wagen Male coupling TW (MK) : Tank Wagen Female coupling

CCW : Counterclockwise (left turning) CW : Clockwise (right turning)

Metal depleting acids : Hydrochloric acid, Sulfuric acid (con. < 70%), Other acids : Phosphoric acid, Nitric acid, Sulfuric acid > 70 %

Zinc Chloride, Ferric Chloride,

Polyaluminiumchloride (PAC),

Alcalis : Caustic soda, Potassium hydroxide, Ammonia Solvents : Hydrocarbons

solution

Guideline for couplings Rev 5 04/04/2013 page 3

COUPLING GUIDELINE

6. Type of couplings

TW : TankWagen coupling (German coupling) TW : TankWagen coupling (German coupling) TW coupling

VK : Male

Guillemin : French coupling Guillemin : French coupling Guillemin : French coupling

Guideline for couplings Rev 5 04/04/2013 page 4

COUPLING GUIDELINE

KNZ : AKZO coupling male KNZ : AKZO coupling KNZ : AKZO coupling

Camlock male Camlock Camlock

Guideline for couplings Rev 5 04/04/2013 page 5

You might also like

- The Art of Welding: Practical Information and Useful Exercises for Oxyacetylene and Electric Arc WeldingFrom EverandThe Art of Welding: Practical Information and Useful Exercises for Oxyacetylene and Electric Arc WeldingNo ratings yet

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesFrom EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesNo ratings yet

- Level Swichgage For Engine Liquids: L150 and EL150K1 SeriesDocument2 pagesLevel Swichgage For Engine Liquids: L150 and EL150K1 Seriesruyolmos_zeroNo ratings yet

- Auto CannonsDocument32 pagesAuto Cannonsjitendra25252100% (1)

- Flash Recovery Vessels-Technical InformationDocument2 pagesFlash Recovery Vessels-Technical InformationdzungNo ratings yet

- RAM 5.7 2020 EcmDocument7 pagesRAM 5.7 2020 Ecmjesus mtzNo ratings yet

- Project Standards and Specifications Basic Design Package Rev01.1Document11 pagesProject Standards and Specifications Basic Design Package Rev01.1Popescu Andrei-MihaiNo ratings yet

- Corrosion GuideDocument23 pagesCorrosion Guideachmaddach100% (4)

- STAUFF Catalogue 1 STAUFF Clamps English PDFDocument172 pagesSTAUFF Catalogue 1 STAUFF Clamps English PDFGBHJRNo ratings yet

- DNV-RP-E301 Design and Installation of Fluke Anchor in ClayDocument32 pagesDNV-RP-E301 Design and Installation of Fluke Anchor in Clayluciansargu100% (1)

- Uber Elevate White PaperDocument98 pagesUber Elevate White PaperRoger AllanNo ratings yet

- Service Manual Power Supply Unit Panasonic KX-TDA0104XDocument134 pagesService Manual Power Supply Unit Panasonic KX-TDA0104XRicardo Rodriguez Rodriguez62% (13)

- GC Column Selection GuideDocument28 pagesGC Column Selection Guidetaufikiskandar1705No ratings yet

- Company Profile (ACE VALVE)Document20 pagesCompany Profile (ACE VALVE)DDFSFNo ratings yet

- Aashto CatalogDocument16 pagesAashto CatalogFranklinNo ratings yet

- Naphthenic Acid CorrosionDocument6 pagesNaphthenic Acid CorrosionCristian Otivo100% (1)

- Marine and Offshore Pumping and Piping SystemsFrom EverandMarine and Offshore Pumping and Piping SystemsRating: 4.5 out of 5 stars4.5/5 (2)

- Valvula Salenoide 3 y 4 Vias PDFDocument32 pagesValvula Salenoide 3 y 4 Vias PDFAgustin MirafuentesNo ratings yet

- ALDEC 30 - Parts - 2012Document57 pagesALDEC 30 - Parts - 2012Centrifugal Separator100% (1)

- Marine Chain Cable Pocket GuideDocument51 pagesMarine Chain Cable Pocket GuideTimmyJuri100% (1)

- DnV-RP-E302 - Design and Installation of Plate Anchors in Clay (2000)Document34 pagesDnV-RP-E302 - Design and Installation of Plate Anchors in Clay (2000)adenlanNo ratings yet

- Lis Practice Modul 03 2012Document43 pagesLis Practice Modul 03 2012Alina SocolNo ratings yet

- 04 1 Sec IV STD Specs PipingDocument152 pages04 1 Sec IV STD Specs PipingdzungNo ratings yet

- Butterfly: ValveDocument23 pagesButterfly: Valvehuutan12345No ratings yet

- Traced and Jacketed Piping - PIPING GUIDEDocument14 pagesTraced and Jacketed Piping - PIPING GUIDELeDzungNo ratings yet

- Class 1CB2S01 (Pip PN01CB2S01 - 2005)Document6 pagesClass 1CB2S01 (Pip PN01CB2S01 - 2005)Zvonko BešlićNo ratings yet

- Distillation Matlab CodeDocument8 pagesDistillation Matlab CodeSaurab Devanandan0% (1)

- Flight Operations: Operational Information Supplement For G150 and G200 AirplanesDocument6 pagesFlight Operations: Operational Information Supplement For G150 and G200 AirplanesAlisa KirjanovaNo ratings yet

- Engleza MaritimaDocument37 pagesEngleza MaritimaZamolxes100% (2)

- Honda Xr500 PDFDocument2 pagesHonda Xr500 PDFPieter SteenkampNo ratings yet

- Natural Gas: Operations and Transport: A Handbook for Students of the Natural Gas IndustryFrom EverandNatural Gas: Operations and Transport: A Handbook for Students of the Natural Gas IndustryNo ratings yet

- Screw Conveyor PDFDocument100 pagesScrew Conveyor PDFsamurai7_7792% (13)

- 28 Manual de Servicio ToritoDocument133 pages28 Manual de Servicio ToritoJulian Uribe HerreraNo ratings yet

- Stauffenberg RBW5RUL PDFDocument172 pagesStauffenberg RBW5RUL PDFErikas AbepaNo ratings yet

- Fv-Kupplung: Couplings General Catalogue - 2015Document28 pagesFv-Kupplung: Couplings General Catalogue - 2015Ivano VerbiNo ratings yet

- STAUFF Catalogue 1 STAUFF Clamps EnglishDocument196 pagesSTAUFF Catalogue 1 STAUFF Clamps EnglishÇAĞATAY ÇALIŞKANNo ratings yet

- Seal-Lok O-Ring Face Seal FittingsDocument36 pagesSeal-Lok O-Ring Face Seal FittingsZackyD03No ratings yet

- Seal-Lok O-Ring Face Seal Tube FittingsDocument34 pagesSeal-Lok O-Ring Face Seal Tube Fittingsarmin_kunosic9871No ratings yet

- Thermal Power ApplicationsDocument27 pagesThermal Power ApplicationsKrisNo ratings yet

- STAUFF Catalogue 1 STAUFF Clamps English PDFDocument172 pagesSTAUFF Catalogue 1 STAUFF Clamps English PDFshe02No ratings yet

- 5527 Iom Utd55Document4 pages5527 Iom Utd55abinasnayakNo ratings yet

- Environmental Test Chambers Testing StandardsDocument3 pagesEnvironmental Test Chambers Testing StandardsKishorDeshmukhNo ratings yet

- GC Column Selection Guide SUPELCODocument24 pagesGC Column Selection Guide SUPELCOmagicianchemistNo ratings yet

- Breather & Filler Breather Product Range: Innovative Fluid PowerDocument22 pagesBreather & Filler Breather Product Range: Innovative Fluid PowerSai RamNo ratings yet

- Wo Space Valve CatalogDocument30 pagesWo Space Valve CatalogGilbert MejulioNo ratings yet

- Technical Manual: At-Pac Tube & ClampDocument12 pagesTechnical Manual: At-Pac Tube & ClampKen SuNo ratings yet

- KALPURDocument8 pagesKALPURLuis CanoNo ratings yet

- Junt Sub. GenDocument109 pagesJunt Sub. GenInternational companyNo ratings yet

- Samwha Electric Catalog EngDocument140 pagesSamwha Electric Catalog Englehaphuong03No ratings yet

- STAUFF Catalogue 3 STAUFF Flanges EnglishDocument124 pagesSTAUFF Catalogue 3 STAUFF Flanges Englishomar farukNo ratings yet

- Allied Piping Catalouge 2018Document8 pagesAllied Piping Catalouge 2018ArshadNo ratings yet

- USV-Unit Shut-Down ValveDocument12 pagesUSV-Unit Shut-Down ValveReguloNo ratings yet

- Anode CatalogueDocument161 pagesAnode CataloguePrabuNo ratings yet

- TriMarkCatalog Filler MaterialDocument50 pagesTriMarkCatalog Filler MaterialSuphi YükselNo ratings yet

- Xyzljsdöaklsd Ask 1En/Ld, Kdks 1En/Ld and Kdks 1Pe/LdDocument1 pageXyzljsdöaklsd Ask 1En/Ld, Kdks 1En/Ld and Kdks 1Pe/LdJuan Esteban Benjumea BenjumeaNo ratings yet

- Errata 2016 - RCC CW 2015 - ENDocument113 pagesErrata 2016 - RCC CW 2015 - ENahmedalshawiNo ratings yet

- BURNDY NNTR29A29A SpecsheetDocument2 pagesBURNDY NNTR29A29A SpecsheetJorge Dario Jarrin VivarNo ratings yet

- WPDB Powerdistributionblocks: WPDB 70/35 1-4 WPDB 70/35 1-4 Al WPDB 185 1-1 WPDB 185 1-1 Al WPDB 70 1-1 WPDB 70 1-1 AlDocument1 pageWPDB Powerdistributionblocks: WPDB 70/35 1-4 WPDB 70/35 1-4 Al WPDB 185 1-1 WPDB 185 1-1 Al WPDB 70 1-1 WPDB 70 1-1 AlRavi VarmaNo ratings yet

- BURNDY KS25 SpecsheetDocument2 pagesBURNDY KS25 SpecsheetLesly Meza WillarsNo ratings yet

- RA FittingsDocument16 pagesRA FittingsDejanNo ratings yet

- Scalloped Gun System 4.5 12Spf 135°-45° Spiral Sgs - S45-1201-CDocument2 pagesScalloped Gun System 4.5 12Spf 135°-45° Spiral Sgs - S45-1201-CDenier RubianoNo ratings yet

- PacificValvesCastSteelBoltedBonnetCatalogCV 421 PDFDocument28 pagesPacificValvesCastSteelBoltedBonnetCatalogCV 421 PDFGoutham KSNo ratings yet

- Z3P Full en Us A4Document4 pagesZ3P Full en Us A4Yavuz YURTTAKALNo ratings yet

- Safety Valve ListDocument3 pagesSafety Valve ListYair Alexis Muñoz RojasNo ratings yet

- Welding Filler Metals For Power Generation: Voestalpine Böhler Welding Voestalpine Böhler WeldingDocument27 pagesWelding Filler Metals For Power Generation: Voestalpine Böhler Welding Voestalpine Böhler WeldingKrisNo ratings yet

- Flexible Conduit - Fitting-US - R19Document34 pagesFlexible Conduit - Fitting-US - R19Budhi Prasetya HakimNo ratings yet

- Rust Preventative GuideDocument11 pagesRust Preventative GuideEduardo Fuentes Renner100% (1)

- Ferulok Flareless Bite Type Fittings: Visual IndexDocument14 pagesFerulok Flareless Bite Type Fittings: Visual IndexMauricioNo ratings yet

- For More Information Please Call 1-800-Belden1: SFI LRC Hardline Connectors - LRC W-Series Hardline Three-Piece SpliceDocument2 pagesFor More Information Please Call 1-800-Belden1: SFI LRC Hardline Connectors - LRC W-Series Hardline Three-Piece SpliceLeidy RamirezNo ratings yet

- E-CATALOGUE EngDocument46 pagesE-CATALOGUE EngMeet JaniNo ratings yet

- Pharmacist PedalPCBDocument6 pagesPharmacist PedalPCBnghtlghtNo ratings yet

- For More Information Please Call 1-800-Belden1: 5502FE Multi-Conductor - Commercial ApplicationsDocument3 pagesFor More Information Please Call 1-800-Belden1: 5502FE Multi-Conductor - Commercial ApplicationsLuis ZavalaNo ratings yet

- Nozzle Holders Clemco Industries Corp. Parts List 2005Document1 pageNozzle Holders Clemco Industries Corp. Parts List 2005Fredy SierraNo ratings yet

- Cpe Xomox Jacketed SPV Bu en LT 2018-04-24 WebDocument16 pagesCpe Xomox Jacketed SPV Bu en LT 2018-04-24 WebdzungNo ratings yet

- Juice Concentration - Adifferent Technique For C C PDFDocument2 pagesJuice Concentration - Adifferent Technique For C C PDFozzy75No ratings yet

- Project Standards and Specifications Basic Design Package Rev01.1Document12 pagesProject Standards and Specifications Basic Design Package Rev01.1dzungNo ratings yet

- Introduction To Chemical Engineering For Lecture 5: Flash DistillationDocument10 pagesIntroduction To Chemical Engineering For Lecture 5: Flash DistillationAkmalNo ratings yet

- 2 SteamPipeDocument4 pages2 SteamPipebugerkngNo ratings yet

- Piping Geometry - Grasp Line LayoutDocument7 pagesPiping Geometry - Grasp Line LayoutdzungNo ratings yet

- Flow Fab Jacketed Pipe BrochureDocument1 pageFlow Fab Jacketed Pipe BrochuredzungNo ratings yet

- Introduction To Chemical Engineering For Lecture 5: Flash DistillationDocument10 pagesIntroduction To Chemical Engineering For Lecture 5: Flash DistillationAkmalNo ratings yet

- Engineered Engineered: Thermal Maintenance S Stems For Urea Systems For Urea Applications PPDocument31 pagesEngineered Engineered: Thermal Maintenance S Stems For Urea Systems For Urea Applications PPdzungNo ratings yet

- Viscosity of Saturated Ammonia Liquid and Ammonia Vapor of Various TemperaturesDocument1 pageViscosity of Saturated Ammonia Liquid and Ammonia Vapor of Various TemperaturesdzungNo ratings yet

- AEI Spiral Chute FlyerDocument4 pagesAEI Spiral Chute FlyerdzungNo ratings yet

- Screw Conveyor Corporation: Catalog and Engineering ManualDocument64 pagesScrew Conveyor Corporation: Catalog and Engineering ManualdzungNo ratings yet

- ASA SeriesDocument43 pagesASA SeriesdzungNo ratings yet

- Traced and Jacketed Piping - PIPING GUIDEDocument16 pagesTraced and Jacketed Piping - PIPING GUIDEdzungNo ratings yet

- 2015 Plant Ops Chemical Pump Types and ApplicationsDocument53 pages2015 Plant Ops Chemical Pump Types and ApplicationsdzungNo ratings yet

- Branchenbroschuere Fertilizer 210x297mm en WebDocument24 pagesBranchenbroschuere Fertilizer 210x297mm en WebdzungNo ratings yet

- PRPP 2013 Natural GasDocument21 pagesPRPP 2013 Natural GasdzungNo ratings yet

- Sulphonation Plants & Reactors For Manufacturing LABSA, SLES, AOS and MoreDocument11 pagesSulphonation Plants & Reactors For Manufacturing LABSA, SLES, AOS and Moredzung100% (1)

- Foam Control EPS Industrial Pipe InsulationDocument2 pagesFoam Control EPS Industrial Pipe InsulationdzungNo ratings yet

- NPK Compound Fertilizer Making Producti... Ine Machinery Co., Ltd.Document17 pagesNPK Compound Fertilizer Making Producti... Ine Machinery Co., Ltd.dzungNo ratings yet

- Long Term Experience With Polypropylene Thermal Insulation For Subsea PipelinesDocument22 pagesLong Term Experience With Polypropylene Thermal Insulation For Subsea PipelinesdzungNo ratings yet

- 4 - Pipe Insulation With PU BASF 2012 05 08Document24 pages4 - Pipe Insulation With PU BASF 2012 05 08dzungNo ratings yet

- NH3 Compressor UnitDocument1 pageNH3 Compressor UnitdzungNo ratings yet

- Packed Bed Fluid Dynamics and Ammonia AbsorptionDocument11 pagesPacked Bed Fluid Dynamics and Ammonia AbsorptiondzungNo ratings yet

- Neighbourhood Speed Limit Map Ward3Document1 pageNeighbourhood Speed Limit Map Ward3CTV CalgaryNo ratings yet

- Shipping Container Tracking and Tracing - MSCDocument2 pagesShipping Container Tracking and Tracing - MSCShiv KumarNo ratings yet

- Station: Date: Flights: Evaluated By: Compliance Y N Remarks B. Aircraft Onload/DepartuerDocument2 pagesStation: Date: Flights: Evaluated By: Compliance Y N Remarks B. Aircraft Onload/Departuerrebin azizNo ratings yet

- The All New Arocs 6x4 and 8x4 Tipper RangeDocument5 pagesThe All New Arocs 6x4 and 8x4 Tipper Rangemikelyon06No ratings yet

- FlairAir - RESERVATION #MT37HZ ITINERARYDocument4 pagesFlairAir - RESERVATION #MT37HZ ITINERARYSBNTRADE INTNo ratings yet

- 460 Efi Ac Cobra - Google SearchDocument1 page460 Efi Ac Cobra - Google SearchVishpul JangraNo ratings yet

- VDPPVDSR PDF 1698713106Document18 pagesVDPPVDSR PDF 1698713106David XueNo ratings yet

- 1.5.2 MB Bus OF 917Document2 pages1.5.2 MB Bus OF 917alim potlotNo ratings yet

- Vehicle Registration Plates of Cambodia: TypesDocument1 pageVehicle Registration Plates of Cambodia: Typestann sunlayNo ratings yet

- POSTER TEMPLATE FyPEx 2022Document1 pagePOSTER TEMPLATE FyPEx 2022Muhd Afiq AzmiNo ratings yet

- LC GatesDocument19 pagesLC GatesPAUL DURAINo ratings yet

- IRCTC Sample Train TicketDocument3 pagesIRCTC Sample Train TicketPawan KumarNo ratings yet

- Decose Kenya LimitedDocument3 pagesDecose Kenya LimitedForecourt Mails100% (1)

- How To Deal With Freight ForwardersDocument45 pagesHow To Deal With Freight ForwardersaskarqqqqNo ratings yet

- Motor Sport'S Brand: JsaccessoriesDocument8 pagesMotor Sport'S Brand: JsaccessoriesRandyNo ratings yet

- Irfd ChartsDocument29 pagesIrfd ChartsSebasツ50% (2)

- Eastar ManualDocument280 pagesEastar ManualNuñez JesusNo ratings yet

- ASB - BK117 D2 11 010 Rev0 ENDocument11 pagesASB - BK117 D2 11 010 Rev0 ENDejan ZlatanovicNo ratings yet

- Transport and Communication: Unit IV Unit IV Unit IV Unit IV Unit IVDocument12 pagesTransport and Communication: Unit IV Unit IV Unit IV Unit IV Unit IVrakesh kumarNo ratings yet

- Egllltfm PDF 1651701752Document83 pagesEgllltfm PDF 1651701752Halil OnarNo ratings yet

- 80 US T (72.6 T) Lifting Capacity Rough Terrain Crane Sales Flyer Imperial/MetricDocument2 pages80 US T (72.6 T) Lifting Capacity Rough Terrain Crane Sales Flyer Imperial/MetricReyes VargasNo ratings yet

- GMC Acadia 2007 - 2008 Fuse Box DiagramDocument5 pagesGMC Acadia 2007 - 2008 Fuse Box DiagrampgallegosromanNo ratings yet