Professional Documents

Culture Documents

Materials Handling

Uploaded by

Jessica SaballeroCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Materials Handling

Uploaded by

Jessica SaballeroCopyright:

Available Formats

MATERIAL HANDLING

MATERIALS HANDLING

I. INTRODUCTION

Material handling is a field involving the transport, storage, and control of goods and

products throughout the processes of manufacturing, distribution, consumption and disposal of

all related materials. The focus of the material handling industry is on the methods, mechanical

equipment, systems and related controls used to achieve necessary functions.

Factors to consider in Selecting the Material Handling Equipment:

Selection of material handling equipment is an important decision as it affects both the cost and

efficiency of handling system. The following factors are to be taken into account while selecting

the material handling equipment.

1. Properties of the Material

Whether the material is solid, liquid or gas, and in what size, shape and weight it is to be moved,

are important decisions and can be lead to a preliminary elimination from the range of available

equipment under review. Similarly, if the material is fragile, corrosive or toxic this will imply that

certain handling method and containers will be preferable to others.

2. Layout and Characteristic of the building

Another restricting factor is availability of space for handling. Low-level ceiling many preclude

the use of hoist or cranes, and the presence of supporting columns in awkward places can limit

the size of material handling equipment. If the building is multi-storeyed, chutes or ramp for

industrial trucks may be used. Layout itself will indicate the type of production operation

(continuous, intermittent, fixed position or group) and indicate some items of equipment that will

be more suitable than others. Floor capacity also helps in selecting the best material handling

equipment.

3. Production Flow

If the flow is fairly constant between two fixed positions that are not likely to be changed, fixed

equipment such as conveyors or chutes can be successfully used. If, on the other hand, the flow

is not constant and the direction changes occasionally from one point to another because

several products are being produced simultaneously, moving equipment such as trucks would

be preferable.

4. Cost Considerations

This is the most important consideration. The above factors can help narrow the range of

suitable equipment, while costing can help in taking the final decision. Several cost elements

need to be taken into consideration when comparisons are made between various items of

equipment that are all capable of handling the same load. Initial investment and operating and

maintenance cost are the major costs to be considered. By calculating and comparing the total

cost of each items of equipment under consideration, a more rational decision can be reached

on the most appropriate choice.

5. Nature of Operations

Selection of equipment also depends on the nature of operations like whether handling is

temporary or permanent, whether the flow is continuous or intermittent and material, flow

pattern-horizontal or vertical.

6. Engineering Factors

Engineering factors such as door, ceiling dimensions, floor space, floor conditions and structural

strengths are also taken in consideration in the selection of equipment.

-ABANADOR ASA PATENIA

NALUZ

1

MATERIAL HANDLING

7. Equipment reliability

Reliability of the equipment and supplier reputation and the after sale services plays an

important role in selecting the equipment.

Goals of Material Handling

1. Maintain product quality, reduce damage and provide protection of materials.

2. Promote safety and improve working conditions.

Improve productivity through:

Materials should move as short distance as possible

Increase the size of materials handled

Mechanize /Automate Material Handling

Maintain/Improve material handling ratios

Increase throughput by using automated material handling equipment

3. Promote increase use of facilities

Increase cubic utilization

Purchase versatile equipment

Standardize material handling equipment

Maintain, and replace as needed, all equipment and develop a preventive maintenance

program

4. Integrate all material handling equipment into a system

5. Reduce tare weight (describe the weight of packaging material).

6. Control inventory.

How Does Materials Handling Works

Material handling is a necessary and significant component of any warehousing and

logistics activity. Material handling means providing the right amount of the right material, in the

right condition, at the right place, at the right time, in the right position and for the right cost, by

using the right method. It applies to the movement of raw materials, work in process, finished

goods, packing materials, and disposal of scraps. In general, hundreds and thousands of tons of

materials are handled daily requiring the use of a large amount of manpower and equipment

while the movement of materials takes place from one processing area to another or from one

department to another department of the plant.

As a process, material handling incorporates a wide range of manual, semi-automated

and automated equipment and systems that support logistics and make the supply chain work.

Their application helps with:

Forecasting

Resource allocation

Production planning

Flow and process management

Inventory management and control

Customer delivery

After-sales support and service

-ABANADOR ASA PATENIA

NALUZ

2

MATERIAL HANDLING

Principles of Material Handling

By analyzing the goals of the material handling process and aligning them to guidelines, such as

the 10 Principles of Material Handling, a properly designed system will improve customer

service, reduce inventory, shorten delivery time, and lower overall handling costs in

manufacturing, distribution and transportation (Mhi.org, 2017). These principles include:

1. Planning: Define the needs, strategic performance objectives and functional

specification of the proposed system and supporting technologies at the outset of the

design. The plan should be developed in a team approach, with input from consultants,

suppliers and end users, as well as from management, engineering, information

systems, finance and operations.

2. Standardization: All material handling methods, equipment, controls and software

should be standardized and able to perform a range of tasks in a variety of operating

conditions.

3. Work: Material handling processes should be simplified by reducing, combining,

shortening or eliminating unnecessary movement that will impede productivity. Examples

include using gravity to assist in material movement, and employing straight-line

movement as much as possible.

4. Ergonomics: Work and working conditions should be adapted to support the abilities of

a worker, reduce repetitive and strenuous manual labor, and emphasize safety.

5. Unit load: Because less effort and work is required to move several individual items

together as a single load (as opposed to moving many items one at a time), unit loads

such as pallets, containers or totes of itemsshould be used.

6. Space utilization: To maximize efficient use of space within a facility, it is important to

keep work areas organized and free of clutter, to maximize density in storage areas

(without compromising accessibility and flexibility), and to utilize overhead space.

7. System: Material movement and storage should be coordinated throughout all

processes, from receiving, inspection, storage, production, assembly, packaging,

unitizing and order selection, to shipping, transportation and the handling of returns.

8. Environment: Energy use and potential environmental impact should be considered

when designing the system, with reusability and recycling processes implemented when

possible, as well as safe practices established for handling hazardous materials.

9. Automation: To improve operational efficiency, responsiveness, consistency and

predictability, automated material handling technologies should be deployed when

possible and where they make sense to do so.

10. Life cycle cost: For all equipment specified for the system, an analysis of life cycle

costs should be conducted. Areas of consideration should include capital investment,

installation, setup, programming, training, system testing, operation, maintenance and

repair, reuse value and ultimate disposal.

II. MATERIAL HANDLING SYSTEM EQUATION

Before planning, one should be very clear about perspective, material handling equation which

emphasizes the necessity of careful analyzing both the material to be handled and the move to

be made before selecting method. Such an equation is also helpful in the planning stage of

selection of materials handling equipment for the proposed project. (Comprehensive production

and operation management (1st ed., p. 304), Arora, K. (2004))

Why What Where + When How + Who

Unnecessar Material Move Method

y

Factors to be considered: Factors to be considered: Factors to be considered:

1. Type 1. Source 1. Unit handled

2. Characteristics destination 2. Equipment

3. Quantity 2. Logistics 3. Manpower

3. Characteristics 4. Physical restrictions

-ABANADOR ASA PATENIA

NALUZ

3

MATERIAL HANDLING

4. Type

Viewing the complex nature of materials handling, one can conclude that it needs

through planning for smooth and economic running of any productive and distributive system. It

further needs a large amount of data necessary for planning, no matter one is using it within an

industry or on a national transportation basis.

III. MATERIAL HANDLING SYSTEMS CLASSIFICATION

Mechanized System

Most mechanized systems combine different handling devices

Moderate fixed and variable cost with good flexibility

Examples

o Forklift

o Rider pallet trucks

o Towlines

o Tractor trailers

o Conveyors

o Carousels

o Paperless picking

labor capability: machine

Control capability: human

Automated System

Automated materials handling (AMH) refers to any automation that reduces or eliminates

the need for humans to check-in, check-out, sort material, or to move totes and bins

containing library material.

Highest fixed cost, lowest variable and labor cost with low flexibility

Potential to automate is the elimination of direct labor by substituting capital equipment

Examples

o Order selection systems

o Automated storage and retrieval system (AS/RS)

The mechanical equipment used in AMH systems includes:

-ABANADOR ASA PATENIA

NALUZ

4

MATERIAL HANDLING

o check-in machines

o sorters

o conveyors

o singulators

o stackers and unstackers

o totes

o bins

o trolleys

o tote carriers.

labor capability: machine

Control capability: machine

Semi-automated System

Most existing material handling equipment is only semi-automated because a human

operator is needed for tasks like loading/unloading and driving that are difficult and/or

too costly to fully automate, although ongoing advances in sensing, machine

intelligence, and robotics have made it possible to fully automate an increasing number

of handling tasks.

High fixed cost, low variable cost with low flexibility

Examples:

o Automated guided vehicles (AGV)

o Sortation systems

o Robotics

Build and breakdown unit loads

o Live racks

Information-directed System

Moderate fixed and variable cost with high flexibility and utilization

Offers selected benefits of automation without substantial capital investment

Main drawback is accountability regarding work assignment

Examples

o RF wireless (Wi-Fi)

-ABANADOR ASA PATENIA

NALUZ

5

MATERIAL HANDLING

Use lift trucks, RFID scanners and data collection terminals

o Pick-to-light carousel system

Characteristics of Materials

size

weight

shape

other (slippery, fragile, sticky, explosive, frozen)

IV. FOUR MAIN CATEGORIES MATERIAL HANDLING EQUIPMENT

1. Storage And Handling Equipment

Storage equipment is usually limited to non-automated examples, which are grouped in with

engineered systems. Storage equipment is used to hold or buffer materials during downtimes,

or times when they are not being transported. These periods could refer to temporary pauses

during long-term transportation or long-term storage designed to allow the buildup of stock. The

majority of storage equipment refers to pallets, shelves or racks onto which materials may be

stacked in an orderly manner to await transportation or consumption. Many companies have

investigated increased efficiency possibilities in storage equipment by designing proprietary

packaging that allows materials or products of a certain type to conserve space while in

inventory.

Examples of storage and handling equipment include:

Racks, such as pallet racks, drive-through or

drive-in racks, push-back racks, and sliding

racks

Source: http://www.ontarioindustrial.com/

-ABANADOR ASA PATENIA

NALUZ

6

MATERIAL HANDLING

Stacking frames

Source: https://www.worksafe.qld.gov.au

Shelves, bins and drawers

Source:

http://www.nationwideindustrialsupply.com

Mezzanines

Source: http://www.aw-systems.com

2. Engineered Systems

An engineered system is one that is typically

automated. Such systems are also usually created from a variety of units. When combined, they

work to enable both storage and transportation.

AUTOMATED STORAGE AND RETRIEVAL SYSTEM

There are several types of automated storage and retrieval systems. Their common feature is

the ability to quickly and directly access each designated storage location. There are also

different levels of automation for these systems, depending on the type of equipment used.

Storage and retrieval systems primarily are used to:

Store raw materials or bulk containers of goods for later use in manufacturing or

distribution operations

Temporarily store or buffer items between various manufacturing processes

Store and stage items for picking and kitting in distribution or assembly operations

Store and sequence finished goods in manufacturing facilities prior to shipping

Some of the most common type of Automated Storage and Retrieval System are as

follows:

-ABANADOR ASA PATENIA

NALUZ

7

MATERIAL HANDLING

Unit Load Automated Storage & Retrieval

Systems (AS/RS)

These systems are designed to handle

common size unit loads such as totes or

pallets of goods. The goods are usually

stored on static racking (or on pitched gravity

conveyors in flow through systems). The

items are stored and retrieved via automated

cranes that move through aisles between the

racks.

Source: http://www.isddd.com

Vertical Lift Module (VLM) Storage

& Retrieval Systems

These systems are primarily intended to store

product for quick access in picking and kitting

operations. Goods are placed on trays that

are stored and retrieved by a shuttle

mechanism within the unit. Some

advantages of this unit are:

Fast, direct, random access to all

stored items

Secure storage of items within the

unit's enclosure

Dense storage of items in a small

footprint

Better utilization of vertical building

space

Automatic presentation of the next

item to pick

Reduction of worker travel distance to

retrieve or store items

Multiple access points on the same or

multiple building floors are possible

Available with refrigerated enclosures

Carousel-type Storage & Retrieval

Systems

Carousels come in vertical and horizontal

models and have the same uses as Vertical

Lift Module-type storage and retrieval units.

Goods are stored on shelves in vertical

carousels and in bins or shelves on horizontal

carousels. The shelves or bins are linked to

each other by a chain. Like the name

implies, the units rotate in a carousel-like

manner to the appropriate item storage

location. Vertical carousels have the same

advantages as VLM-type storage systems

except for the direct, random access and

multiple access points.

CONVEYORS

-ABANADOR ASA PATENIA

NALUZ

8

MATERIAL HANDLING

Flat belt conveyor - Flat belt conveyor is

that in which the belt runs flat on the carrying

side over straight roller type idler or a set of

idlers. Flat belt conveyors are suitable for

lower capacity, low speed requirement and

for handling unit goods or bulk material of

small lump size and higher angle of repose.

Declination is undesirable. Source: http://beltconveyorsystems.in/products/

Belt Conveyor is typically used in package

handling, raw material handling, and small

part handling. It is effectively used for

elevation change or incline/decline

applications. A more common application of

belt conveyor you might not notice is in the

check-out line at your local grocery store.

Source:

http://www.haroldsequipment.com/equipment/belt-

conveyors

Minimum Pressure Conveyor is used in

short sections of accumulation, general

transport of product, and is ideal for medium

to light loads such as package handling

applications.

Source: http://www.automatedconveyors.com/

Drag Chain is typically used for handling

extremely heavy loads, special pallet

configurations, and extremely low- to high-

temperature areas.

Source: http://sites.dksh.com/htm/620/en/Drag-

Chain-Interflex-SLE-Steel-line.htm

Roller Roller pallet conveyor is typically

used for handling extremely heavy loads and

is ideal for accumulation zones in pack out

areas.

Source: http://www.arrcoolingtowers.com/roller-

conveyors.html

Live Roller Conveyor is typically used in

general transport when product accumulation

is not required. It is also used in package

handling applications and is ideal for light- to

medium-product loads.

http://www.lewcoinc.com/conveyors/conveyors

-ABANADOR ASA PATENIA

NALUZ

9

MATERIAL HANDLING

Diverter Source: http://www4.ncsu.edu/

Stationary or movable arms that

deflect, push, or pull a product to

desired destination

Since they do not come in contact

with the conveyor, they can be used

with almost any flat surface conveyor

Usually hydraulically or pneumatically

operated, but also can be motor

driven

Simple and low cost

Pop-Up Device Source:

One or more rows of powered rollers

or wheels or chains that pop up above

surface of conveyor to lift product and

guide it off conveyor at an angle;

wheels are lowered when products

not required to be diverted

Only capable of sorting flat-bottomed http://www4.ncsu.edu/

items

Pop-up rollers are generally faster

than pop-up wheels

Sliding Shoe Sorter Source:

Sliding shoe sorter (a.k.a. moving slat

sorter) uses series of diverter slats

that slide across the horizontal

surface to engage product and guide

http://www4.ncsu.edu/

it off conveyor

Slats move from side to side as

product flows in order to divert the

product to either side

Gentle and gradual handling of products

AUTOMATED GUIDED VEHICLES

- AGVs do not require an operator

- Good for high labor cost, hazardous, or environmentally sensitive conditions (e.g., clean-

room)

- Also termed "automated" guided vehicle

- AGVs good for low-to-medium volume medium-to-long distance random material flow

operations (e.g., transport between work cells in a flexible manufacturing system (FMS)

environment)

Two means of guidance can be used for AGV systems:

i. Fixed path: Physical guidepath (e.g., wire, tape, paint) on the floor used for guidance

ii. Free-ranging: No physical guidepath, thus easier to change vehicle path (in software), but

absolute position estimates (from, e.g., lasers) are needed to correct dead-reckoning error

a. Tow AGV

- Used to pull a train of trailers

- Automated version of a tractor trailer

Trailers usually loaded manually (early type

of AGV, not much used today)

-ABANADOR ASA PATENIA

NALUZ

10

MATERIAL HANDLING

Source: http://www4.ncsu.edu/

b. Unit Load AGV

- Have decks that can be loaded

manually or automatically

- Deck can include conveyor or

lift/lower mechanism for automatic

loading

- Typically 4 by 4 feet and can carry 1

2,000 lb. loads Source: http://www4.ncsu.edu/

- Typically less than 10 vehicles in AGV

system

c. Assembly AGV

- Used as assembly platforms (e.g., car

chassis, engines, appliances)

- Greatest development activity during

the 1980s (alternative to AEMs)

- Typically 50100 vehicles in AGV

system

Source: http://www4.ncsu.edu/

3. Industrial Trucks

This term is another broad definition that can be applied to many different types of equipment.

Such pieces of equipment do have one thing in common, though they all provide

transportation. Trucks have the capability to lift via powered or manual means, and can be

ridden upon in a drivers cab, or simply power-assisted when pushed. Such tucks can also be

steered by human intervention, or can be completely automated, following a pre-defined track

on the production floor, sunken or raised tracks, or colored strips that are laid out and sensed by

optical sensors. Such automated industrial trucks also have anti-collision technology that

senses when an employee or other obstacle is near.

Characteristics of Industrial Trucks:

Pallet/Non-Pallet: Does the truck have forks for handling pallets, or does the truck have

a flat surface on which to place loads. Non-Pallet (usually) other means required to load

truck.

Manual/Powered: Does the truck have manual or powered vertical (lifting) and/or

horizontal (travel) movement capabilities. Manual => walk => operator provides the force

needed for lifting loads and/or pushing the vehicle. Powered => on-board power source

(e.g., batteries) used for lifting and/or travel.

Walk/Ride: For non-automated trucks, can the operator ride on the truck (in either a

standing or sitting position) or is the operator required to walk with the truck during

travel. Walk => manual or powered travel possible => powered travel speed limited to a

normal walking pace. Ride => powered => travel speed can be faster than a walking

pace.

Stack/No Stack: Can the truck be used to lift loads for stacking purposes. Stack => can

also be used as no stack => more expensive to add stacking capability. No Stack may lift

a load a few inches to clear the floor for subsequent travel (e.g., pallet jack), but the

loads cannot be stacked on top of each other or on shelves.

Narrow Aisle: Is the lift truck designed to have a small turning radius or does it not have

to turn at all in an aisle when loading/unloading. Narrow Aisle => greater cost and

(usually) standing operator => less aisle space required. Counterbalance and/or straddle

-ABANADOR ASA PATENIA

NALUZ

11

MATERIAL HANDLING

used for load support. Small turning radius => load support via straddle or reaching

capabilities. No turning required => even narrower aisle => only one-side loading

(sideloaders) or the capability to rotate the load (turret truck).

Automated: Is the truck automated so that it can transport loads without requiring an

operator. Non-Automated => direct labor cost of operator is by far the largest cost to

operate a non-automated truck. Semi-Automated => operator used to control

loading/unloading, but automated transport control (e.g., the S/R machine of a Man-on-

board AS/RS). Automated => Automated Guided Vehicle (AGV) => no direct labor cost,

but higher equipment costs.

Hand Truck

Two-Wheeled Hand Truck - Load tilted

during travel

Source: http://www4.ncsu.edu/

Dolly - Three or more wheeled hand truck

with a flat platform in which, since it has no

handles, the load is used for pushing

Source: http://www4.ncsu.edu/

Floor Hand Truck - Four or more wheeled

hand truck with handles for pushing or

hitches for pulling. Sometimes referred to as

a "cart" or "(manual) platform truck".

Source: http://www4.ncsu.edu/

Pallet Jack - Front wheels are mounted inside the end of the forks and extend to the floor

as the pallet is only lifted enough to clear the floor for subsequent travel

Pallet restrictions: reversible pallets cannot be used, double-faced nonreversible pallets cannot

have deckboards where the front wheels extend to the floor, and enables only two-way entry

into a four-way notched-stringer pallet because the forks cannot be inserted into the notches.

Manual Pallet Jack - Manual lifting and/or

travel

Source: http://www4.ncsu.edu/

-ABANADOR ASA PATENIA

NALUZ

12

MATERIAL HANDLING

Powered Pallet Jack - Powered lifting and/or

travel

Source: http://www4.ncsu.edu/

Walkie Stacker

Manual Walkie Stacker - Manual lifting

and/or travel (and straddle load support)

Source: http://www4.ncsu.edu/

Powered Walkie Stacker - Powered lifting

and/or travel (and either counterbalance or

straddle load support)

Source: http://www4.ncsu.edu/

Pallet Truck - Same pallet restrictions as a pallet jack

- Control handle typically tilts to allow operator to walk during

loading/unloading

- Powered pallet jack is sometimes

referred to as a "(walkie) pallet truck"

Pallet Truck

http://www4.ncsu.edu/

Platform Truck - used to provide support for nonpalletized loads

- Used for skid handling; platform can lift skid several inches to allow it

to clear the floor

- Greater lifting capacity compared to fork trucks because the platform

provides a greater lifting surface to support a load

-ABANADOR ASA PATENIA

NALUZ

13

MATERIAL HANDLING

Walkie Platform Truck -

Operator walks next to truck

Floor hand truck is sometimes

referred to as a "(manual)

platform truck"

Source:

http://www4.ncsu.edu/

Rider Platform Truck - Operator

can ride on truck

Source: http://www4.ncsu.edu/

Counterbalanced (CB) Lift Truck

- Also referred to as fork truck.

- Weight of vehicle (and operator) behind the front wheels of truck counterbalances weight

of the load (and weight of vehicle beyond front wheels); front wheels act as fulcrum or

pivot point.

- Rated capacity reduced for load centers greater than 24 in. and lift heights greater than

13 ft.

Sit-Down Counterbalanced Lift Truck -

Operator sits down; 12-13 ft. minimum aisle

width requirement

Source: http://www4.ncsu.edu/

Stand-Up Counterbalanced Lift Truck -

Operator stands up, giving vehicle narrow-

aisle capability; 9-11 ft. minimum aisle width

requirement;

Source: http://www4.ncsu.edu/

Narrow-Aisle (NA) Straddle Truck

- Similar to stand-up CB lift truck, except outrigger arms straddle a load and are used to

support the load instead of the counterbalance of the truck

- 7-8 ft. minimum aisle width requirement

- Less expensive than stand-up CB lift truck and NA reach truck

- Since the load is straddled during stacking, clearance between loads must be provided

for the outrigger arms

- Arm clearance typically provided through the use of load-on-beam rack storage or

single-wing pallets for load-on-floor storage

-ABANADOR ASA PATENIA

NALUZ

14

MATERIAL HANDLING

Narrow-Aisle (NA) Straddle Truck

http://www4.ncsu.edu/

Narrow-Aisle (NA) Reach Truck

- Similar to both stand-up CB lift truck and NA straddle truck

- 8-10 ft. minimum aisle width requirement

- Load rests on the outrigger arms during transport, but a pantograph (scissors)

mechanism is used for reaching, thereby eliminating the need to straddle the load during

stacking

- Reaching capability enables the use of shorter outrigger arms (arms > 1/2 load depth) as

compared to NA straddle truck (arms = load depth)

- Counterbalance of the truck used to support the load when it extends beyond the

outrigger arms

- Although the NA reach truck requires slightly wider aisles than a NA straddle truck since

its outrigger arms do not enter a rack during storage, it does not require arm clearance

between loads (arm clearance is still required when the truck must enter a storage lane

when block stacking or drive-in or -through racks are used)

- Extended reaching mechanisms are available to enable double-deep storage

Narrow-Aisle (NA) Reach Truck

http://www4.ncsu.edu/

Turret Truck

- Greater stacking height compared to other narrow-aisle trucks (40 ft. vs. 25 ft.), but

greater investment cost

- Forks rotate to allow for side loading and, since truck itself does not rotate during

stacking, the body of the truck can be longer to increase its counterbalance capability

and to allow the operator to sit

- Can function like a sideloader for transporting greater-than-pallet-size load

Operator-Down Turret Truck - Operator not

lifted with the load; 5-6 ft. minimum aisle

width requirement

Source: http://www4.ncsu.edu/

Operator-Up Turret Truck - Operator lifted

with the load to allow precise stacking and

picking; 5-7 ft. minimum aisle width

requirement

Source: http://www4.ncsu.edu/

Order Picker

-ABANADOR ASA PATENIA

NALUZ

15

MATERIAL HANDLING

- Similar to NA straddle truck, except operator lifted with the load to allow for less-than-

unit-load picking

- Typically has forks to allow the truck to be used for pallet

stacking and to support a pallet during less-than-pallet-load

picking

- "Belly switch" used for operator safety during picking

Order Picker

http://www4.ncsu.edu/

Sideloader

- Forks mounted perpendicular to direction of travel to allow for side loading and straddle

load support

- 5-6 ft. minimum aisle width requirement

- Can be used to handle greater-than-pallet-size loads (e.g., bar

stock)

Sideloader

http://www4.ncsu.edu/

Tractor-Trailer

- Non-load-carrying tractor used to pull a train of

trailers (i.e., dollies or floor hand trucks)

- Extends the transporting capacity of floor hand

trucks

- Typically used at airports for baggage handling

Tractor-Trailer

http://www4.ncsu.edu/

Personnel and Burden Carrier

- Non-load-carrying vehicle used to transport personnel within a facility (e.g., golf cart,

bicycle, etc.)

Personnel and Burden Carrier

http://www4.ncsu.edu/

-ABANADOR ASA PATENIA

NALUZ

16

MATERIAL HANDLING

Automatic Guided Vehicle (AGV)

Bulk Handling Material Equipment

Materials Handling Equipment that falls into the bulk material handling category is used to

control loose materials in bulk form such as food or liquid. Equipment such as conveyor belts or

elevators are designed to move large quantities of material in loose form, or in packaged form,

through the use of drums and hoppers.

Some equipment used in Bulk Handling

Stackers - Stackers are bulk stockpiling

machines that are used to stack material in

stockyards in different shapes according to

specific requirements.

Source: http://www.ameco.eu.com/our-

products/stackers/

Reclaimers - These devices work closely

with stackers. Reclaimers are also large

pieces of machinery. They are used to

recover bulk material that has been placed in

a stockpile. Reclaimers often use bucket

wheels to recover the material from

stockpiles and, like stackers, are capable of

moving horizontally, vertically, and

rotationally. The majority of reclaimers used

today are computer automated.

Source: http://www.zyfzg.com/82.html

Bucket elevators - Elevating products to

processing or storage is easy with our

industrial duty bucket elevators

Source:http://www.ashoka.cc/material-handling-

equipment.html

Hoppers - Hoppers are wide, bin-like entries : https://www.rouramh.com/

that help feed bulk materials into other

machines. Generally, a hopper is open at the

top and it tapers at the bottom to assist with

feeding the machine.

REFERENCES

Anon, (2017). Material Handling Systems. [online] Available at:

http://www2.isye.gatech.edu/~mgoetsch/cali/logistics_systems_design/material_handling_systems/materi

al_handling_systems.pdf [Accessed 12 Feb. 2017].

-ABANADOR ASA PATENIA

NALUZ

17

MATERIAL HANDLING

Bayt.com. (2017). What is the Types of Material Handling Equipment?. [online] Available at:

https://www.bayt.com/en/specialties/q/184810/what-is-the-types-of-material-handling-equipment/

[Accessed 12 Feb. 2017].

Galecia.com. (2017). Automated Materials Handling: More Information | The Galecia Group. [online]

Available at: http://galecia.com/content/automated-materials-handling-more-information [Accessed 12

Feb. 2017].

Isddd.com. (2017). Automated Storage and Retrieval Systems | Integrated Systems Design. [online]

Available at: http://www.isddd.com/storage-retrieval-systems [Accessed 12 Feb. 2017].

Kaseconveyors.com. (2017). Belt Conveyors | Screw Conveyors | Bucket Elevators | Bulk Material

Handling Equipment Manufacturer. [online] Available at: http://www.kaseconveyors.com/ [Accessed 12

Feb. 2017].

Lom200704.blogspot.com. (2017). Material Handling Equipment: Goals of Material Handling. [online]

Available at: http://lom200704.blogspot.com/2007/01/goals-of-material-handling.html [Accessed 12 Feb.

2017].

Materials Handling. (2017). 1st ed. [ebook] Available at: http://discovery.bits-

pilani.ac.in/dlpd/courses/coursecontent/courseMaterial/mmzg511/MOML12.pdf [Accessed 12 Feb. 2017].

S.p.A., T. (2017). Bulk material handling - TENOVA. [online] Tenova.com. Available at:

http://www.tenova.com/products-technologies/mining/bulk-material-handling/ [Accessed 12 Feb. 2017].

San Jose, D., Thang, S. and Muhammad, I. (2017). Selection of Material Handling Equipment. [online]

Asilogi.blogspot.com. Available at: http://asilogi.blogspot.com/2008/01/selection-of-material-handling.html

[Accessed 12 Feb. 2017].

Team, (2017). Information-directed Systems | BMS.co.in. [online] BMS.co.in : Bachelor of Management

Studies. Available at: http://www.bms.co.in/information-directed-systems/ [Accessed 12 Feb. 2017].

Thomasnet.com. (2017). About Material Handling Equipment. [online] Available at:

http://www.thomasnet.com/about/material-handling-equipment-50140409.html [Accessed 12 Feb. 2017].

Www4.ncsu.edu. (2017). Industrial Trucks. [online] Available at:

http://www4.ncsu.edu/~kay/mhetax/TransEq/IndusTr/index.htm#Hand truck [Accessed 12 Feb. 2017].

www.alllifting.com.au. (2017). MATERIALS HANDLING EQUIPMENT WHAT ARE THE DIFFERENT

TYPES?. [online] Available at: https://www.alllifting.com.au/materials-handling-equipment [Accessed 12

Feb. 2017].

-ABANADOR ASA PATENIA

NALUZ

18

You might also like

- Material HandlingDocument17 pagesMaterial HandlingJessica SaballeroNo ratings yet

- MM ch6Document7 pagesMM ch6thebestofworld2014No ratings yet

- Introduction of Material HandlingDocument14 pagesIntroduction of Material HandlingsankasturkarNo ratings yet

- UNIT 1 - Introduction To Material Handling EquipmentsDocument20 pagesUNIT 1 - Introduction To Material Handling EquipmentsAdugna GosaNo ratings yet

- MM CH 6Document7 pagesMM CH 6dawitsam7No ratings yet

- Bba PM 4Document10 pagesBba PM 4jyoti.singhNo ratings yet

- Materials HandlingDocument6 pagesMaterials HandlingRose LopezNo ratings yet

- Chapter 3 - MATERIAL HANDLING PDFDocument10 pagesChapter 3 - MATERIAL HANDLING PDFShiverrania 29080% (1)

- Chapter 6 Material HandlingDocument18 pagesChapter 6 Material HandlingRamadan DestaNo ratings yet

- Material Handling Ch-1&2Document98 pagesMaterial Handling Ch-1&2Shuguta LatiNo ratings yet

- Material Handling SystemDocument2 pagesMaterial Handling SystemsureshNo ratings yet

- Material HandlingDocument12 pagesMaterial Handlingseid negashNo ratings yet

- Material HandlingDocument26 pagesMaterial HandlingRohit AroraNo ratings yet

- Chapter 1Document12 pagesChapter 1Priya dharshiniNo ratings yet

- Material HandlingDocument5 pagesMaterial HandlingSIMON JOSIAHNo ratings yet

- Material HANDLING PowerPoint PresentationDocument34 pagesMaterial HANDLING PowerPoint PresentationSamiul AlamNo ratings yet

- Definition of Material HandlingDocument12 pagesDefinition of Material HandlingAnkur MahteNo ratings yet

- Iyyappan Chapter 1 DONEDocument14 pagesIyyappan Chapter 1 DONEPriya dharshiniNo ratings yet

- Tugas Resume Perencanaan FasilitasDocument11 pagesTugas Resume Perencanaan FasilitasFathi RahmanNo ratings yet

- III I Material Handling (OE)Document109 pagesIII I Material Handling (OE)RINKAL LOUNGANINo ratings yet

- WINSEM2021-22 MEE1018 TH VL2021220503069 Reference Material I 11-04-2022 Module6Document57 pagesWINSEM2021-22 MEE1018 TH VL2021220503069 Reference Material I 11-04-2022 Module6Harsh VermaNo ratings yet

- A Scientific Criteria For Determining A Good Plant LayoutDocument36 pagesA Scientific Criteria For Determining A Good Plant LayoutSenthilKumar SubramanianNo ratings yet

- Methods, Processes and Equipment Involved in Handling of SolidsDocument137 pagesMethods, Processes and Equipment Involved in Handling of SolidsRhadel Gantuangco100% (1)

- Chapter 3 Material Handling WordDocument8 pagesChapter 3 Material Handling WordVine Lyka Ordiz PalerNo ratings yet

- Material Handling-POMDocument19 pagesMaterial Handling-POMLavkeshhNo ratings yet

- Food EngineeringDocument14 pagesFood EngineeringDomician BenardNo ratings yet

- Material HandlingDocument10 pagesMaterial Handlingmerlin masterchiefNo ratings yet

- Material Handling SystemsDocument15 pagesMaterial Handling SystemsShreyas JyothishNo ratings yet

- Material Handling Flow PatternDocument20 pagesMaterial Handling Flow PatternAli WarsiNo ratings yet

- Material Handling: Jomon Joseph Roll No: 029Document17 pagesMaterial Handling: Jomon Joseph Roll No: 029Jomon JosephNo ratings yet

- By/ Rawan Ashraf - 14104116 Represented To DR/ Aya El-WardanyDocument9 pagesBy/ Rawan Ashraf - 14104116 Represented To DR/ Aya El-WardanyRawan AshrafNo ratings yet

- Material Handling and Equipments: Chapter-OneDocument35 pagesMaterial Handling and Equipments: Chapter-Oneeba yohannesNo ratings yet

- Materialhandling Principles and EquipDocument15 pagesMaterialhandling Principles and EquipNishkarsh AgarwalNo ratings yet

- Material HandelingDocument14 pagesMaterial HandelingAakanshaNo ratings yet

- Material Handling System Design and DecisionDocument4 pagesMaterial Handling System Design and DecisionAshli RachelNo ratings yet

- Assignment-1: Facility & Layout PlanningDocument26 pagesAssignment-1: Facility & Layout PlanningRamkumarArumugapandiNo ratings yet

- 1 Material Handling and Identification TechnologiesDocument75 pages1 Material Handling and Identification TechnologiesPavan Teja100% (1)

- Material HandlingDocument30 pagesMaterial HandlingGeeta Rani100% (1)

- Unit 5 Design of CranesDocument51 pagesUnit 5 Design of CranesHarshad AherNo ratings yet

- Gec524 - Handling EquipmentDocument10 pagesGec524 - Handling EquipmentElfawizzyNo ratings yet

- Material HandlingDocument41 pagesMaterial HandlingmjbicaldoNo ratings yet

- Materials Handling Chapter 1 and 2Document9 pagesMaterials Handling Chapter 1 and 2Edel Quinn Madali100% (1)

- Material Handling Equipment. HTTPWWW - Ise.ncsu - Edukaymaterial Handling Equipment PDFDocument67 pagesMaterial Handling Equipment. HTTPWWW - Ise.ncsu - Edukaymaterial Handling Equipment PDFAan D'yantoNo ratings yet

- Material Handling Systems: For Exploiting Productivity Potential in LogisticsDocument25 pagesMaterial Handling Systems: For Exploiting Productivity Potential in LogisticsSwapnil MalpathakNo ratings yet

- 7-Principles of Material Handling-170811Document5 pages7-Principles of Material Handling-170811pammy313No ratings yet

- Chp.7 Material HandlingDocument26 pagesChp.7 Material HandlinganfaalNo ratings yet

- Material Handling EquipmentDocument52 pagesMaterial Handling EquipmentmichaelNo ratings yet

- Report: Material Handling SystemDocument3 pagesReport: Material Handling SystemAmad ShaikhNo ratings yet

- Module 2 Material Handling - Part 2 by ADFerrerDocument56 pagesModule 2 Material Handling - Part 2 by ADFerrerCzarina OpagueNo ratings yet

- Material Handling SummaryDocument4 pagesMaterial Handling SummaryBoyd Mearns100% (1)

- Introduction To Materials Handling PDFDocument8 pagesIntroduction To Materials Handling PDFhijzain75% (4)

- 5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityFrom Everand5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityRating: 5 out of 5 stars5/5 (3)

- Procedure and Documentation in Supply Chain Management: Business strategy books, #1From EverandProcedure and Documentation in Supply Chain Management: Business strategy books, #1No ratings yet

- Integrated Design of Multiscale, Multifunctional Materials and ProductsFrom EverandIntegrated Design of Multiscale, Multifunctional Materials and ProductsNo ratings yet

- Approval Sheet: Melongena (Eggplant) Peel and Synthesized TioDocument1 pageApproval Sheet: Melongena (Eggplant) Peel and Synthesized TioJessica SaballeroNo ratings yet

- Chapter I PDFDocument18 pagesChapter I PDFJessica SaballeroNo ratings yet

- Title PageDocument1 pageTitle PageJessica SaballeroNo ratings yet

- CONCEPTSDocument10 pagesCONCEPTSJessica SaballeroNo ratings yet

- DataDocument1 pageDataJessica SaballeroNo ratings yet

- h2s AdditionDocument1 pageh2s AdditionJessica SaballeroNo ratings yet

- Gantt Chart of ActivitiesDocument2 pagesGantt Chart of ActivitiesJessica SaballeroNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Catalysts 03 00189Document30 pagesCatalysts 03 00189Jessica SaballeroNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Storage Tanks and Pressure Vessels Written ReportDocument11 pagesStorage Tanks and Pressure Vessels Written ReportJessica SaballeroNo ratings yet

- The Problem and Its BackgroundDocument10 pagesThe Problem and Its BackgroundJessica SaballeroNo ratings yet

- Assignment 4Document3 pagesAssignment 4Jessica SaballeroNo ratings yet

- PrintDocument2 pagesPrintJessica SaballeroNo ratings yet

- Instruction For Obe Requirement For Computer ApplicationsDocument1 pageInstruction For Obe Requirement For Computer ApplicationsJessica SaballeroNo ratings yet

- Assumptions and HypothesesDocument1 pageAssumptions and HypothesesJessica SaballeroNo ratings yet

- PrintDocument2 pagesPrintJessica SaballeroNo ratings yet

- Concept PaperDocument3 pagesConcept PaperJessica SaballeroNo ratings yet

- NJ Lemon LawDocument2 pagesNJ Lemon Lawscd9750No ratings yet

- CNC Roo:M: I Qumjtr AssuranceDocument2 pagesCNC Roo:M: I Qumjtr AssuranceSalvador TiñoNo ratings yet

- ERP Assignment Group 2Document30 pagesERP Assignment Group 2rajatjbp100% (2)

- Pipe SupportDocument224 pagesPipe SupportViswanath NeswaNo ratings yet

- Access Hardware Architectural CatalogueDocument87 pagesAccess Hardware Architectural CatalogueAccess HardwareNo ratings yet

- RENK Coupling Solutions enDocument182 pagesRENK Coupling Solutions enhumayun121No ratings yet

- Workplace Inspection ChecklistDocument60 pagesWorkplace Inspection ChecklistANILNo ratings yet

- SAP PM TrainingDocument163 pagesSAP PM TrainingVaibhav100% (1)

- HP DeskJet Printer Supply Chain - Group 10 - SecFDocument11 pagesHP DeskJet Printer Supply Chain - Group 10 - SecFshahzad2689No ratings yet

- Control Valve PresentationDocument61 pagesControl Valve PresentationDhanny Miharja100% (1)

- DOT Size CodesDocument104 pagesDOT Size CodesArjunNo ratings yet

- IT7021 Software Testing UGDocument2 pagesIT7021 Software Testing UGSaraswathy KNo ratings yet

- VCTDS-03143-En Sea Water Valve PU 2192Document8 pagesVCTDS-03143-En Sea Water Valve PU 2192TimNo ratings yet

- 05 - FIDIC and NEC3Document55 pages05 - FIDIC and NEC3Ka Yu YeungNo ratings yet

- Kyambogo University: Examination PermitDocument1 pageKyambogo University: Examination PermitAmuronNo ratings yet

- Railway Reservation System DocumentationDocument19 pagesRailway Reservation System DocumentationSaroj Cipher80% (5)

- Ready Mix Concrete and Batching PlantDocument23 pagesReady Mix Concrete and Batching PlantJohnsonDaniel100% (1)

- NSCP 2018Document3 pagesNSCP 2018bhhNo ratings yet

- Project SQLDocument5 pagesProject SQLHazaratAliNo ratings yet

- Manufacturing Processes Ch.6 (20) Sheet Metal WorkingDocument73 pagesManufacturing Processes Ch.6 (20) Sheet Metal Workingashoku24007100% (1)

- 2.what Are Fundamental Stages of Data Warehousing?: WikipediaDocument7 pages2.what Are Fundamental Stages of Data Warehousing?: WikipediaRajan SinghNo ratings yet

- As 2550.6-1995 Cranes - Safe Use Guided Storing and Retrieving AppliancesDocument8 pagesAs 2550.6-1995 Cranes - Safe Use Guided Storing and Retrieving AppliancesSAI Global - APACNo ratings yet

- Caso COLCHERTER LATHE-PROJECT SCAMP FMSDocument11 pagesCaso COLCHERTER LATHE-PROJECT SCAMP FMSTeam Winter FiveNo ratings yet

- Active Tenders - BUIDCODocument1 pageActive Tenders - BUIDCOPrasenjit DeyNo ratings yet

- Thesis Driven InvestingDocument6 pagesThesis Driven Investingambermooreeverett100% (2)

- Preguntas Al Comite API 1104Document12 pagesPreguntas Al Comite API 1104alefeli26No ratings yet

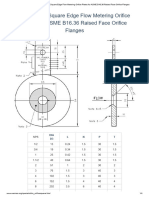

- Wermac - Dimensions of Square Edge Flow Metering Orifice Plates For ASME B16.36 Raised Face Orifice FlangesDocument4 pagesWermac - Dimensions of Square Edge Flow Metering Orifice Plates For ASME B16.36 Raised Face Orifice Flangestechnicalei sulfindoNo ratings yet

- Coursework Structural Integrity 2023-24Document7 pagesCoursework Structural Integrity 2023-24Yacine HalwaneNo ratings yet

- BIMcollab Also Available in French, Spanish and GermanDocument3 pagesBIMcollab Also Available in French, Spanish and GermanPR.comNo ratings yet

- 3 HP CompressorDocument3 pages3 HP Compressorgokul saravananNo ratings yet