Professional Documents

Culture Documents

ITP For ICC Fabrication - Rev-02

Uploaded by

Anwar Mohiuddin0 ratings0% found this document useful (0 votes)

36 views2 pagesITP for ICC Fabrication

Original Title

ITP for ICC Fabrication - Rev-02

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentITP for ICC Fabrication

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

36 views2 pagesITP For ICC Fabrication - Rev-02

Uploaded by

Anwar MohiuddinITP for ICC Fabrication

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

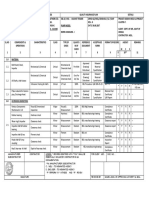

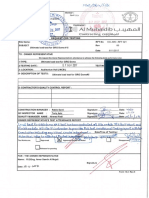

Rev : 02

Date : 15/03/2017

INSPECTION & TEST PALN ( Fabrication works)

Activity No Activity Description Controlling Documents Frequency Acceptance Criteria Verifying Documents Inspection

DOCUMENT SUBMISSION ATTAS ITL TPI AMC DAR

a. Government Certificates H N/A N/A R RA

b. Engineer CV'S H N/A N/A R RA

c.Current & Executed Projects H N/A N/A R RA

1 d.Plant Machineries H N/A N/A R RA

Prior to start work Contractor Approval Submitted Document

e.WPS,PQR & WQT Spec 051200 H N/A R R RA

f.Material Test Certificate H N/A R R RA

g.Coating Specification H N/A R R RA

h.Company Profile H N/A N/A R RA

MILL CERTIFICATE COMPLIANCE CHECK

a. Check mill certificate for the

Material Certificate 100% Compliance with MTO & PO Material Receiveing Record H N/A R R RA

compliance with MTO & PO

2

As per approved material /

b. Check mill certificate for chemical & mechanical Material Product data 100% Material Certificate H N/A R R RA

product data and related code/standard

properties compliance to the required specification

MATERIAL RECEIVING INSPECTION H N/A N/A N/A N/A

a.Structural Steel Spec 051200 AWS D 1.1 2010 H N/A N/A N/A N/A

Material Receiving Record

3 b.Welding Electrode / Coil Spec 051200 AWS D 1.1 2010 H N/A N/A N/A N/A

Each Delivery Inspection Check List

c.Bolts,Conectors and Anchor Spec 051200 AWS D 1.1 2010 H N/A N/A N/A N/A

d.Coating Spec 051200 AWS D 1.1 2010

MATERIAL PREPARATION

4.1 Material Marking

AWS D 1.1 2010/

a.Mark-up identification Approved Shop Drawing Approved Shop Drawing H N/A N/A N/A N/A

100% Compleince with approved Shop Drawing/

b.Layout ID and Mark outCuttingDetails Cutting Plan Inspection Check List H N/A N/A N/A N/A

AISC/ASTM A6

C.Mark Reference line H N/A N/A N/A N/A

4.2 Cutting / Drilling

4 a. Cutting & Shapping AWS D 1.1 2010/ H N/A N/A N/A N/A

Shop Drawing Approved Shop Drawing

b.Joint Configuration to drawing / WPS 100% Compleince with approved Shop Drawing/ H N/A N/A N/A N/A

Cutting Plan Inspection Check List

c.Check joint profile, surface AISC/ASTM A6 H N/A N/A N/A N/A

4.3 ASSEMBLY

a.Fit-up Assembly H N/A N/A N/A N/A

Shop Drawing Complaince with approved shop

b.DressWeld joint to correct weld profile 100% Approved Shop drawings H N/A N/A N/A N/A

drawings

c.Tack weld Joint ( if needed) H N/A N/A N/A N/A

FIT-UP INSPECTION

a.Check fit up weld joint Complaince with approved Shop Drawings H N/A N/A R R

5

b.Check overall Pre-Weld Dimension Shop Drawing 100% AWS D1.1 2010 Approved Shop Drawing/WPS H N/A N/A R R

c. Check weld joint cleanliness H N/A N/A R R

WELDING/ WELDING OPERATOR

a.Date of qualified , Code, range, position

6 H N/A N/A R RA

and process Welder List/ 100% AWS D1.1 Approved WPS/ PQR / WQT

b.Check Welder identification Qualification Record H N/A N/A R RA

WELDING MONITORING

a.Welding Procedure H N/A N/A R R

7

b.Welding Parameters WPS 10% Compliance With WPS Welding monitoring Record H N/A N/A N/A N/A

c.Interpass Temperature H N/A N/A N/A N/A

VISUAL Inspection

a.Check Weld Profile H N/A R R R

8

b.Check fillet weld size to approved drawing WPS 100% Compliance With WPS Visual Inspection Report H N/A R R R

c.Check weld appearance & weld Cleanliness H N/A R R R

NDT Method

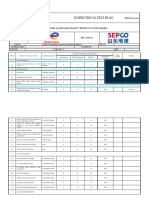

Rev : 02

Date : 15/03/2017

INSPECTION & TEST PALN ( Fabrication works)

Welding inspection (100% UT for but weld joints

100% NDT Report H N/A R R N/A

greater than 8mm

9

Welding inspection (100% DPT for but weld joints As Per Project Specs. AWS D1.1

100% NDT Report H N/A R R N/A

less than 8mm

Welding inspection (10%DPT for all fillet welds) 10% NDT Report H N/A R R N/A

DIMENSION INSPECTION R

a.Check Straightness H N/A R R N/A

10

b.Check Flatness Shop Drawing 100% Compliance with Approvedshop drawing Dimension report H N/A R R N/A

c.Check Width and Height H N/A R R N/A

SHOP PAINTING

10.1 SURFACE PREPATION

a.Check Finishing H N/A R R R

Spec 099600 100% SA2.5 / SSPC.Sp-10 Blasting Inspection report

b.Ckeck surface profile H N/A R R R

11

10.2 APPLICATION R

a.Wet Film Thickness H N/A R R R

b.Dry Film thickness Manufacture'r Instruction AVG 10 Points Minus 15% Plus 50% Painting Inspection Report H N/A R R R

c.General Visual Insprction H N/A R R R

FINAL INSPECTION

a.General Visual inspection Not be mentioned H N/A R R R

12

b.Verify Piece Marks Shop Drawing 100% Compliance Approved With Drawing Final Inspection Report H N/A R R R

c. Check stroage / packing for deliver to site Not be mentioned H N/A R R R

LEGENDS:

ATTAS- Attas Steel ITL: Independent Testing Laboratory W- WITNESS H - HOLD RA - Review and Approval

TPI - Third Party Inspector AMC - AlMuhaidib Co DAR - Dal Al Handasah R-REVIEW N/A - NOT APPLICABLE

You might also like

- ITP For ICC Erection - Rev-02Document1 pageITP For ICC Erection - Rev-02Anwar MohiuddinNo ratings yet

- Ongc B-22 Field Development Project CONTRACT NO. MR/OW/MM/B-22/19/2008 NPCC Project No. 8118Document7 pagesOngc B-22 Field Development Project CONTRACT NO. MR/OW/MM/B-22/19/2008 NPCC Project No. 8118Ankit Kumar100% (1)

- Quality Assurance Plan For Austenitic Stainless Steel Welded Pipe AS PER ASTM A 312, Latest Edtion Vendor: Jindal Quality Tubular LimitedDocument2 pagesQuality Assurance Plan For Austenitic Stainless Steel Welded Pipe AS PER ASTM A 312, Latest Edtion Vendor: Jindal Quality Tubular Limitedamit rajputNo ratings yet

- ITP Structural SteelDocument4 pagesITP Structural SteelfranNo ratings yet

- PROJECT Site Record Acceptance Norms RefDocument6 pagesPROJECT Site Record Acceptance Norms Refvanchai sapaNo ratings yet

- Dept of WR., Govt. of OdhishaDocument3 pagesDept of WR., Govt. of OdhishaNaveen NagisettiNo ratings yet

- Rai Industrial Power PVT - LTD Inspection Test Plan (Check/Hold Points) For Piping WorksDocument4 pagesRai Industrial Power PVT - LTD Inspection Test Plan (Check/Hold Points) For Piping WorksVijaya Barani100% (1)

- Inspection Test Plan Check Hold Points For Piping WorksDocument4 pagesInspection Test Plan Check Hold Points For Piping WorksYoucef Chorfa100% (1)

- WE1884 - ITP For Shop Fab. of Header Coils-120813Document4 pagesWE1884 - ITP For Shop Fab. of Header Coils-120813imran100% (1)

- Inspection and Test Plan Sheet: Pt. Pertamina Geothermal Energy Pt. Bina Rasano EngineeringDocument2 pagesInspection and Test Plan Sheet: Pt. Pertamina Geothermal Energy Pt. Bina Rasano EngineeringHerruSetiawan100% (1)

- Qap - NRLDocument1 pageQap - NRLStructures ProductionNo ratings yet

- ITP For Steel StructureDocument3 pagesITP For Steel Structuretrey100% (4)

- Inspection and Test Plan - Plumbing Works (Qcitp) : Material InspectionsDocument28 pagesInspection and Test Plan - Plumbing Works (Qcitp) : Material InspectionsJay Chris L. BeronNo ratings yet

- ITP For Site Installation of Pipe Rev 1 15.07.10Document4 pagesITP For Site Installation of Pipe Rev 1 15.07.10Rejoy babyNo ratings yet

- Quality Control Plan: ClientDocument7 pagesQuality Control Plan: ClienteliiiiiiNo ratings yet

- Artson ITPDocument8 pagesArtson ITPI Kailash RaoNo ratings yet

- Quality Assurance Plan: NEW AGE FAB Technologies Pvt. LTDDocument6 pagesQuality Assurance Plan: NEW AGE FAB Technologies Pvt. LTDRajnikant PatelNo ratings yet

- Quality Control Plan: ClientDocument7 pagesQuality Control Plan: ClienteliiiiiiNo ratings yet

- Inspection Test Plan PV Nozzle Modification/AlterationDocument4 pagesInspection Test Plan PV Nozzle Modification/AlterationMohd Shafuaaz KassimNo ratings yet

- ITP For PV Mounting Structure and Module Installation-2023!05!19Document3 pagesITP For PV Mounting Structure and Module Installation-2023!05!19Mohammad BayisNo ratings yet

- ItpDocument2 pagesItpVinay YadavNo ratings yet

- QAMTBOI036 Rev-01Document4 pagesQAMTBOI036 Rev-01Suntech Engineering CorporationNo ratings yet

- QAP - ITP - Steel Girder ApproachDocument21 pagesQAP - ITP - Steel Girder ApproachPartha Gangopadhyay100% (1)

- Inspection and Test Plan: Company Name OR Logo CompanyDocument3 pagesInspection and Test Plan: Company Name OR Logo Companyhanif faisalNo ratings yet

- Inspection and Testing Plan For Cable TrayDocument2 pagesInspection and Testing Plan For Cable TrayJohn Rey Perlas100% (2)

- Itp Ash HandlingDocument4 pagesItp Ash HandlingPratama Trendy LeoNo ratings yet

- Inspection and Test Plan For Cpno5 Installation of Conduits and Boxes For All BuildingDocument1 pageInspection and Test Plan For Cpno5 Installation of Conduits and Boxes For All BuildingJoyce GordonioNo ratings yet

- Site Inspection and Test Plan For Architectural Work Rev-1Document23 pagesSite Inspection and Test Plan For Architectural Work Rev-1Mohammed MujahidNo ratings yet

- Ask Team To Add Company Logo Her "Shri Ganesh Engineering"Document4 pagesAsk Team To Add Company Logo Her "Shri Ganesh Engineering"manoj thakkar100% (1)

- Inspection and Test Planrev01Document16 pagesInspection and Test Planrev01Nguyễn MinhNo ratings yet

- Sangeetha Engineering Works (P) LTD.: Ernakulam - 682 305 B-NO:14/107A, Near Agastya Ashram, Kureekkad, ThripunithuraDocument2 pagesSangeetha Engineering Works (P) LTD.: Ernakulam - 682 305 B-NO:14/107A, Near Agastya Ashram, Kureekkad, ThripunithuraSANGEETHANo ratings yet

- BSIBV-ITP-07-2 PP ITP For 3LPP Coating DPE Rev. 0Document10 pagesBSIBV-ITP-07-2 PP ITP For 3LPP Coating DPE Rev. 0AMALENDU PAULNo ratings yet

- Field Inspection &test PlanDocument4 pagesField Inspection &test PlanSofda ImelaNo ratings yet

- 01 - A - I Test PlanDocument1 page01 - A - I Test Planrahmath nawazNo ratings yet

- Bsibv-Itp-07-2 Pe Itp For 3lpe Coating Dpe Rev. 0Document10 pagesBsibv-Itp-07-2 Pe Itp For 3lpe Coating Dpe Rev. 0AMALENDU PAULNo ratings yet

- Rai Industrial Power PVT - LTD Inspection Test Plan (Check/Hold Points) For Piping WorksDocument4 pagesRai Industrial Power PVT - LTD Inspection Test Plan (Check/Hold Points) For Piping Worksmanoj thakkarNo ratings yet

- Appendix C ITP SDrums & Combustion Chamber RevDocument4 pagesAppendix C ITP SDrums & Combustion Chamber RevArif HakimNo ratings yet

- ITP RoadDocument2 pagesITP RoadSyed AliNo ratings yet

- Fitp For Concrete Works & GabionDocument4 pagesFitp For Concrete Works & GabionSofda ImelaNo ratings yet

- Ajts QCP Fab Format Rev 01Document4 pagesAjts QCP Fab Format Rev 01Pradip DabhiNo ratings yet

- 54 ITP-For Piping PDFDocument2 pages54 ITP-For Piping PDFrize1159No ratings yet

- 100 KLPD of 2G Ethanol From Biomass at Iocl PanipatDocument7 pages100 KLPD of 2G Ethanol From Biomass at Iocl PanipatSuraj ShettyNo ratings yet

- Inspection and Test Plan Piping Work ActivitiesDocument2 pagesInspection and Test Plan Piping Work ActivitiesAbram Berkat100% (2)

- ITP - Painting & SandBlasting Rev00Document2 pagesITP - Painting & SandBlasting Rev00Sulist N Wahyudie80% (5)

- ITP COATING (Sign)Document4 pagesITP COATING (Sign)totok.madriantolubisNo ratings yet

- ITP For Fabrication & Installation of Tensile Fabric ShadesDocument1 pageITP For Fabrication & Installation of Tensile Fabric ShadesSun ShadeNo ratings yet

- Khalifa University Extension Phase 2 - External Roads Improvement at Al Saada Street, Abu DhabiDocument1 pageKhalifa University Extension Phase 2 - External Roads Improvement at Al Saada Street, Abu DhabiimranNo ratings yet

- Itp For Ug PipelineDocument3 pagesItp For Ug PipelineJustin Alwar100% (1)

- CW2099436 Q006 0003 - R1Document1 pageCW2099436 Q006 0003 - R1D S Sagar TripuramalluNo ratings yet

- Civil Quality Control Plan EarthworksDocument3 pagesCivil Quality Control Plan Earthworksroekyat hendrawanNo ratings yet

- 34222-4010 Itp Rev 0Document2 pages34222-4010 Itp Rev 0anwar sadatNo ratings yet

- Regulations, Licensing and Enforcement Division: Records Retention and Disposition ScheduleDocument1 pageRegulations, Licensing and Enforcement Division: Records Retention and Disposition ScheduleKarenina VictoriaNo ratings yet

- Qap ReactorDocument6 pagesQap ReactorPARMAR MUKESHNo ratings yet

- Public Health and Municipal Engineering Department - NelloreDocument3 pagesPublic Health and Municipal Engineering Department - Nellorejuliyet strucNo ratings yet

- 01-Ge-Aqa-9600 Itp DMF FRP Water Trough r2Document29 pages01-Ge-Aqa-9600 Itp DMF FRP Water Trough r2Eljo AndsNo ratings yet

- Inspection and Test Plan For Cpno5 Concreting Works For All BuildingDocument17 pagesInspection and Test Plan For Cpno5 Concreting Works For All BuildingMike MagatNo ratings yet

- Burckhardt Compression (India) PVT - LTD.: 1.0 MaterialsDocument2 pagesBurckhardt Compression (India) PVT - LTD.: 1.0 MaterialsYOGESHNo ratings yet

- ITP For Installation of Automatic Sliding DoorDocument1 pageITP For Installation of Automatic Sliding DoorKalid JmalNo ratings yet

- P1066-CTD-QAC-ITP-002-B-Inspe... of Structural Steel WorkDocument4 pagesP1066-CTD-QAC-ITP-002-B-Inspe... of Structural Steel WorkEILA545 QAQCNo ratings yet

- Method Statement For Antibacterial PaintDocument7 pagesMethod Statement For Antibacterial PaintAnwar MohiuddinNo ratings yet

- Welding & Cutting HazardsDocument1 pageWelding & Cutting HazardsAnwar MohiuddinNo ratings yet

- Method Statement For Antibacterial PaintDocument7 pagesMethod Statement For Antibacterial PaintAnwar MohiuddinNo ratings yet

- STAIRCASEDocument10 pagesSTAIRCASEAnwar MohiuddinNo ratings yet

- Under Ground Utilities HazardsDocument1 pageUnder Ground Utilities HazardsAnwar MohiuddinNo ratings yet

- Heavy Equipment Inspection ChecklistDocument1 pageHeavy Equipment Inspection ChecklistMyco Cris RomasantaNo ratings yet

- Static Pressure Cal. (KG-MECH)Document3 pagesStatic Pressure Cal. (KG-MECH)Anwar MohiuddinNo ratings yet

- Investment Contract of AgreementDocument1 pageInvestment Contract of AgreementAnwar MohiuddinNo ratings yet

- Hos-Sqm-Mos-009-01 Method Statement For Earthwork - CRSDocument1 pageHos-Sqm-Mos-009-01 Method Statement For Earthwork - CRSAnwar MohiuddinNo ratings yet

- Method Statement For Bolting SystemDocument6 pagesMethod Statement For Bolting SystemAnwar Mohiuddin100% (1)

- Method Statement For Cmu Block WorkDocument8 pagesMethod Statement For Cmu Block WorkAnwar MohiuddinNo ratings yet

- Risk AssesmentDocument6 pagesRisk AssesmentAnwar Mohiuddin0% (1)

- Hos-Pmt-Pro-001-01 Document and Communication Codification ProcedureDocument7 pagesHos-Pmt-Pro-001-01 Document and Communication Codification ProcedureAnwar MohiuddinNo ratings yet

- Hos-Sqm-Mos-008-00 Method Statement For Cmu Block Work - CRSDocument1 pageHos-Sqm-Mos-008-00 Method Statement For Cmu Block Work - CRSAnwar MohiuddinNo ratings yet

- Saep 13 PDFDocument23 pagesSaep 13 PDFAnwar MohiuddinNo ratings yet

- Air Conditioning System Presentation 160419174932Document28 pagesAir Conditioning System Presentation 160419174932selvaNo ratings yet

- Fire Prevention ChecklistDocument1 pageFire Prevention ChecklistAnwar MohiuddinNo ratings yet

- Non-Conformance Report (NCR) : 100 Bed Isolation Hospital For COVID-19Document1 pageNon-Conformance Report (NCR) : 100 Bed Isolation Hospital For COVID-19Anwar MohiuddinNo ratings yet

- Method Statement For Cmu Block WorkDocument8 pagesMethod Statement For Cmu Block WorkAnwar MohiuddinNo ratings yet

- Ultimate Load Test For GRG DomeDocument11 pagesUltimate Load Test For GRG DomeAnwar MohiuddinNo ratings yet

- PipingDocument1 pagePipingAnwar MohiuddinNo ratings yet

- Sha'ban & Shabe Baraat - UrduDocument6 pagesSha'ban & Shabe Baraat - UrduAnwar MohiuddinNo ratings yet

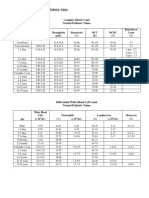

- 30a2131 Complete Blood Count Normal Pediatric Values PDFDocument1 page30a2131 Complete Blood Count Normal Pediatric Values PDFReziel Basilan Manalo100% (2)

- Weld DefectsDocument16 pagesWeld DefectsAnwar MohiuddinNo ratings yet

- Air Handling 02Document20 pagesAir Handling 02Anwar MohiuddinNo ratings yet

- PT 1Document4 pagesPT 1Anwar MohiuddinNo ratings yet

- Extract Pages From Standard ASTM A370Document3 pagesExtract Pages From Standard ASTM A370Anwar MohiuddinNo ratings yet

- Class Flanges Bolt Torque LoadsDocument2 pagesClass Flanges Bolt Torque LoadsAulia RahmanNo ratings yet

- Zinc Spray Bright GradeDocument1 pageZinc Spray Bright GradeAnwar MohiuddinNo ratings yet

- Acce (I) Foundation Day Awards 2021: Association of Consulting Civil Engineers (India)Document3 pagesAcce (I) Foundation Day Awards 2021: Association of Consulting Civil Engineers (India)Bernadette VergaraNo ratings yet

- New Microsoft Word DocumentDocument3 pagesNew Microsoft Word DocumentSannena GovindaNo ratings yet

- Effective Width Flange Provisions For Composite Steel BridgesDocument9 pagesEffective Width Flange Provisions For Composite Steel BridgesJorge PalominoNo ratings yet

- Concrete Forming Accessories HBDocument108 pagesConcrete Forming Accessories HBorlandolanchipaNo ratings yet

- Concrete Frame Design: ACI 318-14 Column Section DesignDocument2 pagesConcrete Frame Design: ACI 318-14 Column Section Designျမတ္ သူ ေအာင္No ratings yet

- Nectra CalydraDocument16 pagesNectra CalydraMike RogueNo ratings yet

- CSIR Sponsored: State-of-the-Art and Future Perspective of Hybrid Supercapacitor For Greener EnvironmentDocument2 pagesCSIR Sponsored: State-of-the-Art and Future Perspective of Hybrid Supercapacitor For Greener Environmentperiasamy_nanoNo ratings yet

- Kanchan ReportxDocument90 pagesKanchan ReportxAnonymous hu42KMNo ratings yet

- Faq Iso 55000Document5 pagesFaq Iso 55000Aleksandar Micasevic100% (1)

- Outcome Based Education: WWW - Cecos.edu - PKDocument94 pagesOutcome Based Education: WWW - Cecos.edu - PKDaanyal Ibn UmarNo ratings yet

- Verilog Vs VHDLDocument15 pagesVerilog Vs VHDLSebastin SureshNo ratings yet

- Bis Code1Document12 pagesBis Code1Starla HillNo ratings yet

- Design and Performance of Automatic Vending Machine Using VHDLDocument9 pagesDesign and Performance of Automatic Vending Machine Using VHDLIJCERT PUBLICATIONSNo ratings yet

- Pile Design Using Euro CodeDocument51 pagesPile Design Using Euro CodeDoreen PohNo ratings yet

- Ktu Soex Ii 4033 2017Document12 pagesKtu Soex Ii 4033 2017Sayooj PilasseriNo ratings yet

- Wre 2Document1 pageWre 2Shahrukh ShahNo ratings yet

- IntlCP StandardConstructionContractsForm PDFDocument18 pagesIntlCP StandardConstructionContractsForm PDFRahul BaliNo ratings yet

- 2012 Dda2132 Introduction To IbsDocument13 pages2012 Dda2132 Introduction To IbsC-one GurlzNo ratings yet

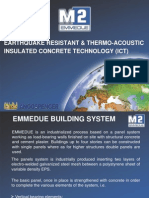

- M2 PresentationDocument34 pagesM2 PresentationHelvecio da CunhaNo ratings yet

- Choice of Process ModelsDocument14 pagesChoice of Process Models20PW02 - AKASH ANo ratings yet

- The Institution of Engineers (India) : 'Innovation, Mechanization and Modern Techniques in Civil Engineering'Document9 pagesThe Institution of Engineers (India) : 'Innovation, Mechanization and Modern Techniques in Civil Engineering'Satyam BhartiNo ratings yet

- Sany MagazineDocument30 pagesSany MagazineJon Carbon100% (1)

- Analysis of Integral Abutment of Non-Skew Bridge Subjected Under Lateral Loading Using Finite Element SoftwareDocument71 pagesAnalysis of Integral Abutment of Non-Skew Bridge Subjected Under Lateral Loading Using Finite Element Softwarerabiatuladda92No ratings yet

- Tank Erection ProcedureDocument29 pagesTank Erection ProcedureVisas Siva100% (3)

- Beau Randall Moreau - ResumeDocument2 pagesBeau Randall Moreau - Resumebeau.moreau100% (1)

- Culvert InspDocument91 pagesCulvert Inspdik_gNo ratings yet

- BSI Group - Smart-cities-report-Mapping-Smart-City-Standards-UK-EN PDFDocument47 pagesBSI Group - Smart-cities-report-Mapping-Smart-City-Standards-UK-EN PDFPepe JeansNo ratings yet

- Doc. Ref. R - N - I D P:::: ISB/MSM/CW/01 0: EV O Ssue ATE AGE OFDocument2 pagesDoc. Ref. R - N - I D P:::: ISB/MSM/CW/01 0: EV O Ssue ATE AGE OFPuzzelsProductionNo ratings yet

- Bs en Iso 1127-1997 不锈钢管.尺寸、公差和单位长度的规范质量Document14 pagesBs en Iso 1127-1997 不锈钢管.尺寸、公差和单位长度的规范质量Jason100% (2)

- Project Flat SlabDocument4 pagesProject Flat SlabRahul Harsha ThatiNo ratings yet